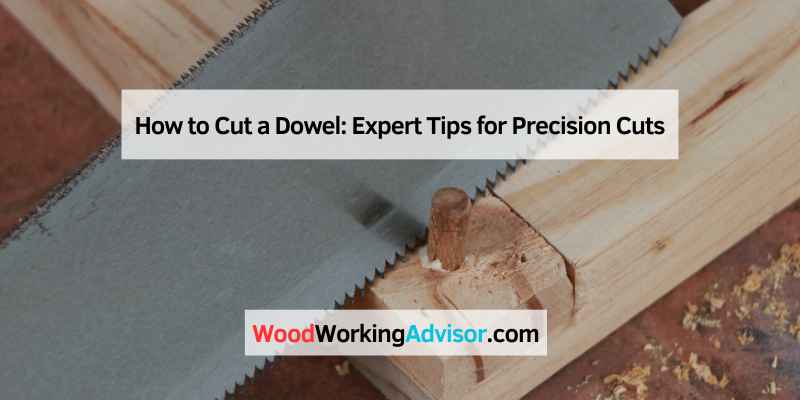

How to Cut a Dowel: Expert Tips for Precision Cuts

To cut a dowel, use a miter saw for precise cuts. Alternatively, a hand saw and a dowel cutting jig can also work well.

Cutting a dowel may seem straightforward, but precision is key for successful projects. Dowels serve various purposes in woodworking, from joining pieces to adding structural support. Using the right tools ensures clean edges and accurate lengths, enhancing the overall appearance of your work.

Different methods exist, each suited to various skill levels and project requirements. Whether you’re a beginner or a seasoned woodworker, knowing how to cut dowels efficiently will improve your craftsmanship. This guide will provide essential tips and techniques for cutting dowels, helping you achieve professional results every time. Let’s explore the best approaches to master this skill.

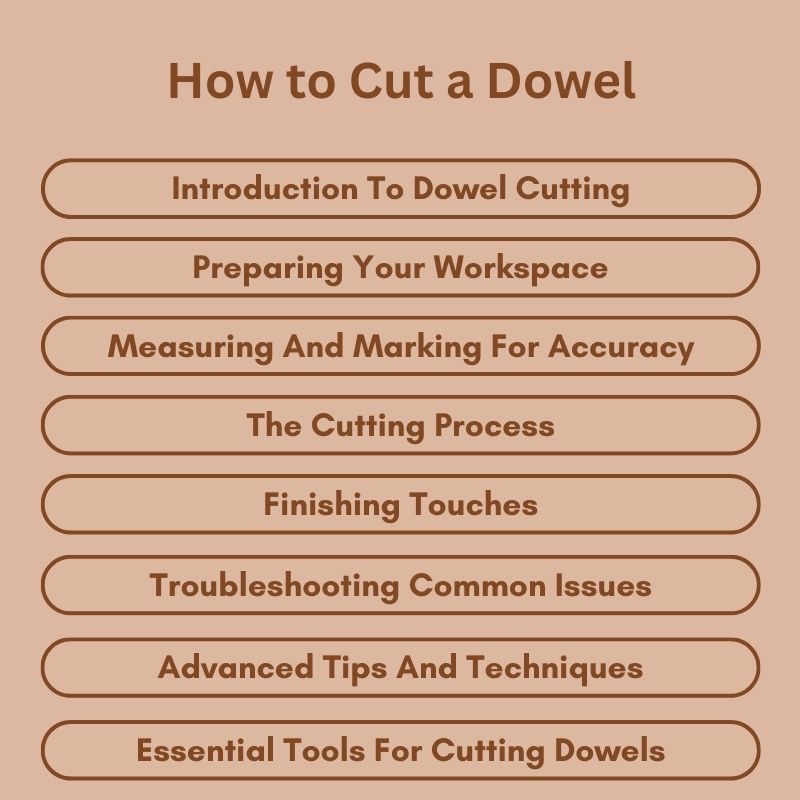

Introduction To Dowel Cutting

Cutting dowels is a simple but essential skill in woodworking. Accurate cuts ensure the best fit for joints. This technique enhances the strength and stability of your projects. Learning how to cut dowels correctly saves time and materials.

The Importance Of Precise Cuts

Precision in dowel cutting is crucial for several reasons:

- Strong Joints: Accurate cuts create tight-fitting joints.

- Reduced Gaps: Less chance of gaps in the assembly.

- Better Aesthetics: Neat cuts improve the overall appearance.

- Time Efficiency: Proper cuts reduce the need for adjustments.

Using the right tools and techniques ensures you achieve these benefits.

Types Of Dowels And Their Applications

Dowels come in various types, each suited for specific tasks. Here’s a quick look:

| Dowel Type | Material | Common Uses |

|---|---|---|

| Wood Dowel | Wood | Furniture, cabinetry, toys |

| Metal Dowel | Steel, Aluminum | Heavy-duty applications, machinery |

| Plastic Dowel | Polymer | Lightweight projects, crafts |

Understanding these types helps choose the right dowel for your project.

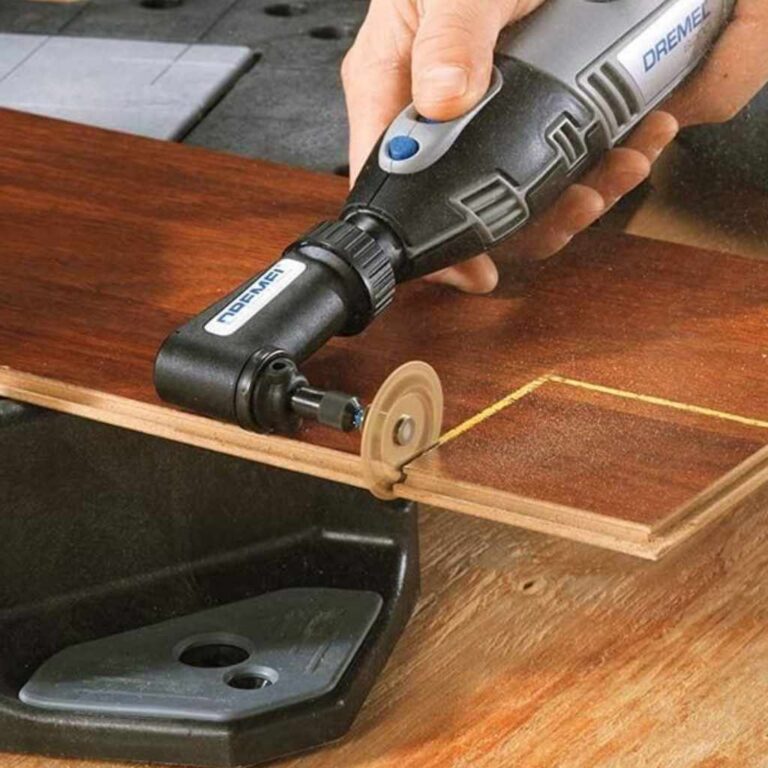

Essential Tools For Cutting Dowels

Cutting dowels requires specific tools for precision and safety. The right tools can make the process easier and more effective. Here are the essential tools to consider.

Choosing The Right Saw

Different saws serve various purposes. Here are some popular options:

- Coping Saw: Ideal for intricate cuts.

- Hand Saw: Great for straight cuts.

- Band Saw: Best for larger projects.

- Table Saw: Perfect for bulk cutting.

Each saw provides unique advantages. Choose one based on your project needs.

Measuring And Marking Tools

Accurate measurements are crucial. Use the following tools:

| Tool | Purpose |

|---|---|

| Measuring Tape | For precise length measurements. |

| Square | Ensures straight cuts and angles. |

| Pencil | Marks the cutting lines clearly. |

Use these tools to ensure accuracy. They help you cut dowels correctly.

Safety Gear And Equipment

Safety should always come first. Equip yourself with the following:

- Safety Glasses: Protect your eyes from debris.

- Dust Mask: Prevent inhaling sawdust.

- Hearing Protection: Safeguard your ears from noise.

- Gloves: Protect your hands while handling tools.

Wearing the right gear keeps you safe. Always prioritize your well-being while working.

Preparing Your Workspace

Creating a tidy workspace enhances focus and efficiency. Organize tools and materials before cutting a dowel to ensure a smooth process. A well-prepared environment minimizes distractions and promotes precision in your woodworking projects.

Setting Up A Stable Workbench

setting up a sturdy workbench.

Ensure the workbench is stable and secured firmly in place.

Organizing Tools For Easy Access

organized and within easy reach.

Arrange the tools neatly to maximize efficiency during the cutting process.

Measuring And Marking For Accuracy

Measuring and marking are crucial steps in cutting a dowel. Accurate measurements ensure a clean, precise cut. This section covers effective techniques and tips for achieving accuracy.

Techniques For Precise Measurements

- Use a Measuring Tape: It provides accurate length measurements.

- Calipers: Ideal for measuring the dowel’s diameter.

- Square Tool: Ensures straight cuts at right angles.

- Marking Gauge: Helps set consistent distances.

Follow these steps for accurate measurements:

- Identify the desired length of the dowel.

- Align the measuring tape with the dowel.

- Take note of the measurement.

Tips For Clear And Accurate Marking

Clear markings prevent mistakes during cutting. Use these tips for better results:

- Sharp Pencil: Always use a sharp pencil for clear lines.

- Mark on the Side: Avoid marking on the end to prevent errors.

- Double-Check Measurements: Verify measurements before marking.

Consider using this simple table for marking guidelines:

| Tool | Purpose |

|---|---|

| Pencil | For making clear markings. |

| Ruler | For straight lines and lengths. |

| Chalk | For marking on rough surfaces. |

Marking accurately leads to better cuts. Follow these tips for best results.

The Cutting Process

Cutting a dowel might seem challenging, but it’s simple. With the right tools and steps, you can achieve clean cuts. Follow this guide to make the process easy and effective.

Step-by-step Guide To Cutting

- Gather your tools:

- Dowel

- Measuring tape

- Pencil

- Cutting tool (saw or dowel cutter)

- Clamps (optional)

- Measure the dowel:

Use a measuring tape to find the length you need. Mark it with a pencil.

- Secure the dowel:

Clamp the dowel to a stable surface. This keeps it in place while you cut.

- Make the cut:

Use a saw or dowel cutter. Cut along your pencil mark slowly and steadily.

- Check the cut:

Inspect the end of the dowel. It should be smooth and even.

Adjusting Your Technique For Different Dowel Sizes

| Dowel Size | Recommended Tool | Cutting Technique |

|---|---|---|

| 1/4 inch | Hand saw | Use gentle pressure to avoid splintering. |

| 1/2 inch | Band saw | Cut slowly for a clean finish. |

| 1 inch | Dowel cutter | Follow the guide for accuracy. |

Adjust your cutting technique based on the dowel size. Smaller dowels need careful handling. Larger dowels may need more pressure but should be cut slowly.

Finishing Touches

After cutting your dowel, finishing touches are essential. These steps ensure a smooth and professional look.

Sanding The Edges

Sanding helps remove rough spots on the dowel. Use fine-grit sandpaper for the best results. Follow these steps:

- Wrap sandpaper around the dowel.

- Apply gentle pressure.

- Sand in a circular motion.

Continue sanding until the edges feel smooth. Check for any remaining rough areas. A smooth dowel looks better and is safer to handle.

Checking For Uniformity

Uniformity is important for both appearance and function. Use these tips to ensure consistency:

- Measure the dowel with a ruler.

- Check the diameter at different points.

- Look for any irregular shapes.

A uniform dowel enhances the quality of your project. Make adjustments if you find any discrepancies.

Troubleshooting Common Issues

Cutting dowels can present challenges. Knowing how to fix these issues helps you achieve clean cuts. Here are common problems and their solutions.

Dealing With Splintering

Splintering can ruin the look of your dowel. It occurs when the wood fibers break unevenly. Follow these steps to avoid splintering:

- Use a sharp saw blade.

- Apply masking tape where you plan to cut.

- Make slow, steady cuts.

- Cut from the top down.

These methods help keep the wood smooth. If splintering occurs, try sanding the edges. Use fine-grit sandpaper for best results.

Fixing Uneven Cuts

Uneven cuts can lead to fitting problems. Here are tips to ensure straight cuts:

- Measure carefully before cutting.

- Use a square to mark your line.

- Clamp the dowel securely.

- Check your saw angle.

In case of an uneven cut, you can fix it:

| Issue | Solution |

|---|---|

| Cut is too short | Join with wood glue and clamp. |

| Cut is too long | Sand down to fit properly. |

By following these tips, you can improve your dowel cutting skills.

Advanced Tips And Techniques

Cutting dowels accurately can elevate your woodworking projects. Mastering advanced techniques enhances precision and efficiency. Here are some expert tips to help you.

Making Angled Cuts

Angled cuts require careful planning. Follow these steps for success:

- Use a miter saw for clean angles.

- Set the angle on the saw. Common angles are 30°, 45°, and 60°.

- Clamp the dowel securely to avoid movement.

- Make sure to measure twice before cutting.

Check the angle after cutting. Use a protractor for accuracy. Mistakes can ruin your project.

Working With Hardwood Dowels

Hardwood dowels require different techniques than softwood. Keep these tips in mind:

- Use a sharp saw blade. Dull blades cause splintering.

- Pre-drill holes for better results. This prevents splitting.

- Sand the edges after cutting. Smooth edges fit better.

Hardwood may require additional pressure. Use a sturdy workbench for stability. Always wear safety goggles while cutting.

| Wood Type | Preferred Tool | Cutting Tips |

|---|---|---|

| Softwood | Hand saw | Light pressure, steady hands |

| Hardwood | Miter saw | Sharp blade, pre-drill holes |

Practice these techniques to improve your skills. Each cut will become easier with experience.

Frequently Asked Questions

How Do You Measure A Dowel For Cutting?

To measure a dowel for cutting, use a measuring tape or ruler. Determine the desired length you need for your project. Mark the dowel with a pencil at the measurement point. Ensure the mark is clear for accurate cutting, which helps achieve precise results.

What Tools Are Needed To Cut A Dowel?

You can use various tools to cut a dowel. A hand saw, miter saw, or a doweling jigs are great options. Each tool offers different precision levels. Choose the one that best suits your project needs and skill level for optimal results.

Can You Cut A Dowel With A Hacksaw?

Yes, a hacksaw is an effective tool for cutting dowels. Its fine teeth provide a clean and precise cut. Ensure you secure the dowel firmly to avoid slipping. Cut slowly and steadily for the best results without damaging the dowel.

What Is The Best Method To Cut A Dowel?

The best method to cut a dowel depends on your tools. For accuracy, use a miter saw or a doweling jig. Hand saws work well for simpler cuts. Always measure twice before cutting to ensure you achieve the desired length.

Conclusion

Cutting a dowel accurately can elevate your woodworking projects. With the right tools and techniques, precision becomes achievable. Remember to measure twice and cut once for the best results. Practice makes perfect, so don’t hesitate to refine your skills. Happy woodworking, and may your projects be sturdy and successful!