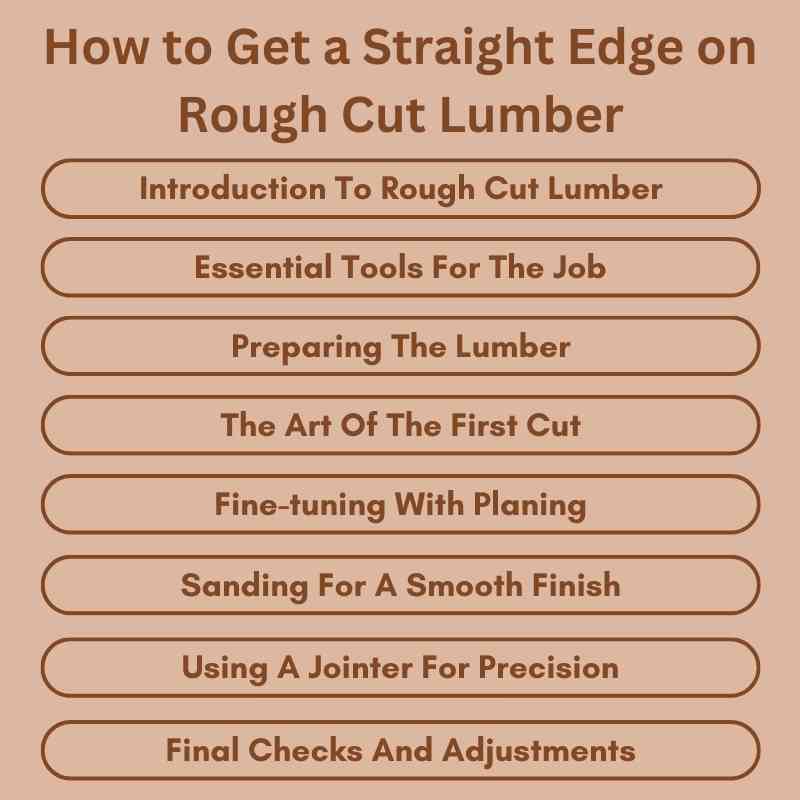

How to Get a Straight Edge on Rough Cut Lumber: Pro Tips

To achieve a straight edge on rough cut lumber, use a straightedge or a level to guide your cuts. A circular saw or hand plane will help refine the edge.

Rough cut lumber often presents challenges for DIY projects and woodworking. Achieving a straight edge is essential for ensuring that your boards fit together seamlessly. A straight edge allows for accurate measurements and cleaner joints, improving the overall quality of your work.

Whether you’re building furniture or crafting shelves, starting with properly edged lumber can save you time and frustration. This guide will provide practical methods to straighten those rough edges, ensuring your projects turn out as envisioned. Learn effective techniques that enhance your woodworking skills and help you achieve professional results at home.

Introduction To Rough Cut Lumber

Rough cut lumber is wood that hasn’t been finished. It is milled directly from the log. This type of lumber retains its natural look and feel. Many woodworkers and builders prefer rough cut lumber for various projects. It offers a unique character that finished wood often lacks.

Using rough cut lumber can save money. It also allows for greater creativity in design. However, working with rough cut lumber has its challenges. Achieving a straight edge is one of them. Understanding the benefits and challenges can help in your woodworking journey.

Benefits Of Using Rough Cut Lumber

- Cost-Effective: Rough cut lumber is often cheaper than finished lumber.

- Unique Aesthetics: Each piece has its own character and charm.

- Eco-Friendly: It reduces waste and utilizes local resources.

- Customization: You can create unique sizes and shapes easily.

Challenges In Achieving Straight Edges

Working with rough cut lumber can be tough. The surfaces are often uneven and rough. Here are some common challenges:

- Inconsistent thickness makes cuts difficult.

- Natural warping can lead to crooked edges.

- Knots and defects complicate the cutting process.

Despite these challenges, skilled techniques can help achieve straight edges. Patience and practice are essential.

Essential Tools For The Job

Getting a straight edge on rough cut lumber requires specific tools. Using the right tools makes the job easier and more accurate. Here’s a breakdown of essential tools you need.

Choosing The Right Saw

Picking the correct saw is crucial. Here are some options:

- Table Saw: Ideal for straight cuts. Provides stability and precision.

- Circular Saw: Portable and versatile. Great for quick cuts.

- Jigsaw: Best for curves but can also make straight cuts.

Ensure the saw has a sharp blade. Dull blades create rough edges. Always use a guide for straight cuts.

Measuring And Marking Tools

Accurate measurements and markings are key to success. Here are tools to consider:

| Tool | Purpose |

|---|---|

| Measuring Tape | For accurate length measurements. |

| Square | Ensures right angles and straight edges. |

| Chalk Line | Creates long, straight lines on lumber. |

| Pencil | For marking cut lines on wood. |

Using these tools together helps create precise cuts. Take your time to measure twice before cutting.

Preparing The Lumber

Getting a straight edge on rough cut lumber starts with proper preparation. This ensures clean cuts and better results. Follow these steps to prepare your lumber effectively.

Inspecting For Defects

Before making any cuts, check the lumber for defects. Common issues include:

- Knots: These can weaken the wood.

- Cracks: Look for any visible cracks.

- Warp: Check if the board is twisted or bowed.

- Sap pockets: These can affect the finish.

Use a straightedge to identify any warping. Lay the straightedge along the board. Look for gaps between the straightedge and the lumber. Mark any areas needing attention.

Marking Your Cut Lines

Accurate markings help achieve straight cuts. Follow these steps:

- Use a tape measure to find your desired length.

- Mark the cut line with a pencil.

- Draw a straight line using a square.

- Double-check your measurements before cutting.

Consider using a chalk line for longer boards. It helps create a straight reference line. This ensures better alignment during cutting.

The Art Of The First Cut

The first cut on rough cut lumber sets the stage for your project. A precise cut makes the rest easier. It ensures a straight edge, which is crucial for good alignment. Mastering this skill can enhance your woodworking quality.

Setting Up Your Saw

Getting your saw ready is vital. Here are steps to set it up correctly:

- Choose the Right Saw: Use a table saw or circular saw for best results.

- Check the Blade: Ensure it is sharp and suitable for wood.

- Adjust the Height: Set the blade height to just above the lumber.

- Square the Blade: Use a square to align the blade with the fence.

- Secure the Lumber: Clamp it down to prevent movement.

Techniques For A Clean Cut

Achieving a clean cut requires technique. Follow these tips:

- Use a Fence: Align the lumber against a straight fence.

- Make a Test Cut: Cut a scrap piece first to check accuracy.

- Steady Pressure: Apply even pressure while pushing the lumber through.

- Follow the Line: Keep the saw blade aligned with your cut line.

Consider using a push stick for safety. It keeps fingers away from the blade.

| Tip | Benefit |

|---|---|

| Use a Fence | Ensures straight cuts. |

| Test Cut | Verifies blade alignment. |

| Steady Pressure | Prevents binding and kickback. |

| Push Stick | Keeps hands safe. |

With these steps, you will master the art of the first cut. A straight edge on rough cut lumber opens doors to creativity.

Fine-tuning With Planing

Planing is essential for achieving a smooth edge on rough cut lumber. This process removes imperfections. It creates a straight and flat surface. You can use hand tools or power tools. Both methods have their unique advantages. Let’s explore how to effectively use them.

Hand Planing Basics

Hand planing is a traditional skill. It requires practice and patience. Here are some basics:

- Select the Right Plane: Choose a bench plane or block plane.

- Adjust the Blade: Set the blade depth for thin shavings.

- Work with the Grain: Always plane in the direction of the wood grain.

Follow these steps for effective hand planing:

- Place the lumber securely on a flat surface.

- Hold the plane at a slight angle.

- Apply even pressure as you push forward.

- Check your progress frequently.

Hand planing can be slow but rewarding. It helps refine your technique.

Using A Power Planer

A power planer speeds up the process. It is perfect for larger projects. Here’s how to use it:

- Choose the Right Tool: Select an electric or battery-operated planer.

- Adjust Depth: Set the cutting depth for optimal results.

- Use Safety Gear: Always wear goggles and ear protection.

Follow these steps for a power planer:

- Secure the lumber firmly to avoid movement.

- Start the planer and let it reach full speed.

- Run the planer along the edge of the lumber.

- Check for smoothness and adjust as needed.

Power planers make the job faster. They are perfect for beginners and pros.

Sanding For A Smooth Finish

Sanding is essential for achieving a smooth finish on rough cut lumber. It removes imperfections and prepares the surface for staining or sealing. Proper sanding techniques enhance the wood’s natural beauty.

Choosing The Right Grit

Selecting the correct sandpaper grit is crucial. Different grits serve different purposes:

| Grit Size | Purpose |

|---|---|

| Coarse (40-60) | Removes material quickly. Good for heavy sanding. |

| Medium (80-120) | Levels the surface. Prepares for finer sanding. |

| Fine (150-220) | Creates a smooth finish. Ideal for final sanding. |

Start with a coarse grit. Gradually move to finer grits for the best results.

Sanding Techniques

Use effective sanding techniques for a smooth finish:

- Sand with the Grain: Always sand in the direction of the wood grain.

- Apply Even Pressure: Use consistent pressure to avoid uneven spots.

- Keep it Clean: Clear dust regularly for better results.

- Use a Block Sander: A block sander helps maintain flat surfaces.

- Finish with a Hand Sander: Use a hand sander for tight corners.

These techniques ensure an even and smooth surface. Take your time for the best finish.

Using A Jointer For Precision

A jointer is an essential tool for achieving a straight edge on rough cut lumber. It removes imperfections and ensures a smooth, flat surface. This tool is perfect for preparing wood for projects. Follow these steps to use a jointer correctly and safely.

Setting Up Your Jointer

Setting up your jointer is crucial for precision. Follow these steps:

- Place the jointer on a stable surface.

- Check the blades for sharpness and alignment.

- Set the infeed table slightly lower than the outfeed table.

- Adjust the depth of cut to about 1/16 inch.

- Ensure the fence is square to the table.

Proper setup helps achieve a straight edge. Always verify settings before starting.

Jointer Safety Tips

Safety is paramount when using a jointer. Follow these tips:

- Wear safety glasses to protect your eyes.

- Use ear protection to guard against noise.

- Keep hands away from the blades.

- Use push blocks for added safety.

- Never remove guards while operating the machine.

Stay focused and alert during operation. Always follow the manufacturer’s guidelines.

| Safety Tip | Description |

|---|---|

| Wear Safety Glasses | Protect your eyes from flying debris. |

| Use Ear Protection | Reduce exposure to loud noise. |

| Keep Hands Clear | Avoid reaching near the blades. |

| Use Push Blocks | Maintain a safe distance from blades. |

| Follow Guidelines | Read and understand the manual. |

Following these safety tips ensures a safe woodworking experience. Always prioritize your safety and the safety of others.

Final Checks And Adjustments

After cutting your rough lumber, it’s crucial to ensure everything is straight. This step guarantees that your wood pieces fit together well. Follow these checks to achieve the best results.

Verifying Straightness

To confirm your lumber is straight, use a few simple methods:

- Visual Inspection: Lay the lumber on a flat surface. Look down its length.

- Straight Edge Tool: Use a long straight edge. Place it against the lumber.

- String Method: Stretch a string along the lumber. Check for gaps.

These methods help you identify any bends or warps. Use your best judgment to decide if adjustments are needed.

Making Minor Corrections

If your lumber isn’t quite straight, don’t worry. Here are ways to fix minor issues:

- Planing: Use a hand planer or electric planer. Remove material from high spots.

- Jointing: Run the lumber through a jointer. This creates a flat edge.

- Sanding: Use sandpaper for small adjustments. Focus on uneven areas.

These methods can help you achieve a straight edge. Always check your progress regularly. Small adjustments can make a big difference.

Frequently Asked Questions

How Do I Straighten Rough Cut Lumber?

To straighten rough cut lumber, use a jointer or a hand plane. Start by flattening one face of the board. Then, run the opposite edge through a table saw for a straight cut. This method ensures a smooth, level surface for your woodworking projects.

What Tools Do I Need For Straightening Lumber?

Essential tools for straightening lumber include a jointer, hand plane, and table saw. A straight edge or level can help you assess flatness. A circular saw or track saw is also useful for making precise cuts. These tools will help you achieve a straight edge effectively.

Can I Use A Hand Planer Instead?

Yes, a hand planer is an excellent option for straightening rough lumber. It allows for fine adjustments and control. Start with the rough side, taking thin passes to avoid removing too much material. This method is effective but requires patience and practice for the best results.

How Long Does It Take To Straighten Lumber?

The time to straighten lumber varies based on the board’s size and condition. Typically, it can take anywhere from 30 minutes to a few hours. Factors include the tools used and your skill level. Patience is key for achieving the best outcome in straightening lumber.

Conclusion

Achieving a straight edge on rough cut lumber enhances the quality of your woodworking projects. By using techniques like hand planing or a table saw, you can ensure precise cuts. These methods not only save time but also improve your craftsmanship.

With practice, you’ll master the skill and elevate your projects significantly.