How to Make Wooden C Clamps: DIY Expert Guide

To make wooden C clamps, cut two pieces of wood into a C shape and drill holes for a screw mechanism. Assemble the pieces using a sturdy screw and ensure they move smoothly.

Wooden C clamps are essential tools for woodworking and crafting. They provide strong, reliable pressure to hold materials together while working. Creating your own clamps can be a rewarding project, allowing for customization in size and design. Using wood gives a traditional touch, and it can be more sustainable than metal options.

This guide will walk you through the materials and steps needed to craft wooden C clamps effectively. With a few tools and some patience, you’ll have functional clamps ready for your next project. Embrace your creativity and enhance your woodworking skills with this simple DIY project.

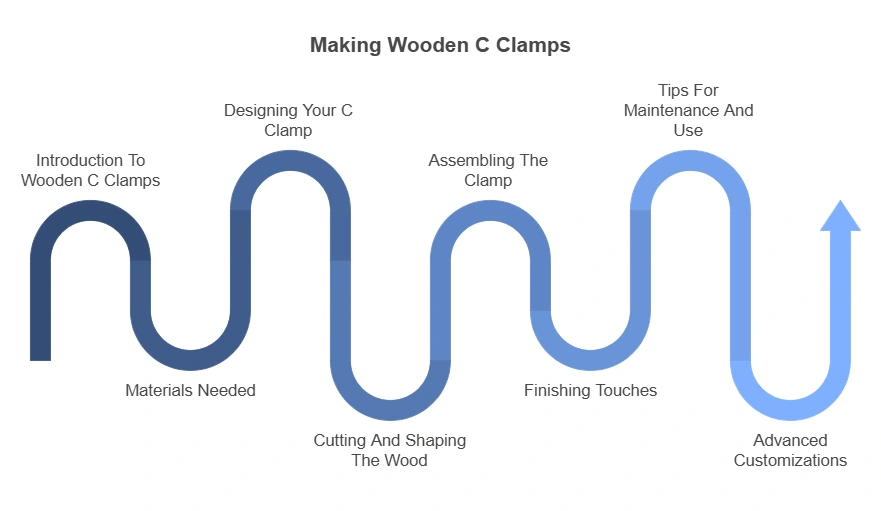

Introduction To Wooden C Clamps

Wooden C clamps are popular for many reasons. They are easy to make and customizable. Crafting your own tools can be very satisfying. It also allows you to create clamps that fit your specific needs.

Using wooden C clamps has many benefits. They are lightweight, making them easy to handle. Wooden clamps also protect surfaces from scratches. They can hold materials firmly without damaging them. Lastly, they are eco-friendly since wood is a natural material.

Materials Needed

For making wooden C clamps, you need specific materials. Choose the right type of wood for strength and durability. Common choices include hardwood, pine, and birch. These woods provide excellent support.

Next, gather the hardware components. You will need screws, bolts, and washers. These items help hold the clamp together securely. Ensure all components are of good quality.

Lastly, the right tools and equipment are crucial. A saw will help cut the wood to size. Use a drill for making holes. A sander smooths the edges. These tools make the work easier.

Designing Your C Clamp

Choosing the right size for your C clamp is important. Measure the maximum thickness of materials you will use. This helps in determining the ideal size for your clamp. A common size for hobbyists is 4 to 6 inches.

Sketching the design allows you to visualize the final product. Start with a simple drawing. Include the base, jaws, and screw mechanism. Make sure the dimensions are clear and accurate. This will guide you during the building process.

Using a template can simplify the process. Print your sketch and cut it out. Trace this template onto your wood. This step ensures symmetry and precision.

Cutting And Shaping The Wood

Safety is very important. Always wear protective gear like goggles and gloves. Keep your workspace clean to avoid accidents.

For cutting, start with a measuring tape. Measure the wood accurately before cutting. Use a saw to make straight cuts. Follow the lines carefully to avoid mistakes.

After cutting, it’s time for shaping. Use a sander to smooth the edges. This helps prevent splinters. Sand until the surface feels soft to the touch.

Finishing touches make a big difference. Apply a wood finish to protect the wood. Choose a color that looks nice. Allow it to dry completely before using the clamps.

Assembling The Clamp

Start by gathering all necessary hardware. This includes screws, bolts, and washers. Use strong materials for durability.

Attach the hardware to the wooden parts of the clamp. Ensure that all screws are tight and secure. Check for any loose fittings that might weaken the clamp.

Use a level to ensure proper alignment. This step is important for functionality and strength. Test the clamp after assembly to confirm it holds well.

| Step | Description |

|---|---|

| Gather Materials | Collect screws, bolts, and wood pieces. |

| Attach Hardware | Securely fasten screws and bolts. |

| Check Alignment | Use a level for proper setup. |

| Test Strength | Ensure the clamp holds firmly. |

Finishing Touches

Start by sanding the wooden clamps. Use fine-grit sandpaper for a smooth finish. Move in the direction of the grain to avoid scratches. Pay extra attention to the edges and corners.

After sanding, clean off the dust with a cloth. This prepares the surface for the finish. Choose a good wood finish for protection. Options include varnish, oil, or polyurethane.

Apply the finish using a clean brush. Make sure to cover all areas evenly. Let it dry completely before handling. Reapply if needed for extra durability.

Tips For Maintenance And Use

Store your C clamps in a dry place. Avoid damp areas to prevent rust. Hang them on a pegboard or place them in a toolbox. This keeps them organized and easy to find.

Regularly check your C clamps for damage. Look for cracks or bends in the metal. Clean them with a cloth to remove dust and dirt. Lubricate the screw with oil to ensure smooth operation.

Use your C clamp correctly for the best results. Always tighten it slowly and evenly. Avoid over-tightening, which can damage your workpiece. Use the right size clamp for your project to achieve the best grip.

Advanced Customizations

To add a swivel pad, cut a small piece of rubber or soft wood. Attach this piece to the clamp’s end. This pad helps protect your workpiece from damage.

Creating different sizes of clamps is easy. Measure the width and height you need. Cut the wood pieces accordingly. Assemble them with screws or glue.

Personalizing your clamp can be fun. Use paint or wood stain for a unique look. You can also engrave your name or a design on it. This makes your clamp special and one-of-a-kind.

Frequently Asked Questions

How Do I Choose Wood For C Clamps?

Selecting the right wood is crucial. Hardwoods like maple or oak are ideal for durability. They provide strength and resistance to wear. Avoid softwoods, as they can bend or break easily. Always ensure the wood is free of knots and defects for the best results.

What Tools Do I Need To Make Wooden C Clamps?

To make wooden C clamps, you’ll need basic tools. Essential items include a saw, drill, and clamps for assembly. A sander will help smooth edges, while measuring tools ensure accuracy. Having wood glue on hand can also enhance the durability of your clamps.

Can I Customize My Wooden C Clamps?

Absolutely! Customizing wooden C clamps is easy and fun. You can adjust their size, shape, or finish to suit your needs. Personalization can enhance both functionality and aesthetics. Experiment with different wood stains or paints to match your workshop decor.

How Long Does It Take To Make C Clamps?

The time required varies based on your skill level. Generally, it takes about 1-3 hours to complete a set. This includes measuring, cutting, and assembling the clamps. Allow additional time for finishing touches like sanding and staining. Patience results in better quality clamps.

Conclusion

Making wooden C clamps is a rewarding DIY project. It combines craftsmanship with practicality, allowing you to create tools tailored to your needs. With the right materials and techniques, anyone can achieve great results. Embrace your creativity and enjoy the satisfaction of using your handmade clamps in future projects.

Happy woodworking!