How to Strengthen MDF Boards: Ultimate Guide

To strengthen MDF boards, apply wood hardener and use screws with pilot holes. Reinforce edges with solid wood trim.

MDF boards, or medium-density fiberboards, are popular in furniture and cabinetry due to their smooth surface and affordability. They are, however, less durable and prone to damage compared to solid wood. Strengthening MDF boards can enhance their longevity and functionality.

Applying a wood hardener can fortify the material, making it more resistant to wear and tear. Using screws with pilot holes prevents splitting, while adding solid wood trim to edges provides extra support. These methods ensure MDF boards remain sturdy and reliable for various applications, making them a more practical choice in the long run.

Introduction To MDF Boards

MDF stands for Medium Density Fiberboard. It is made from wood fibers mixed with resin. These boards are then compressed and heated to form a solid piece. MDF is popular because it is smooth and easy to work with. It is also cheaper than solid wood.

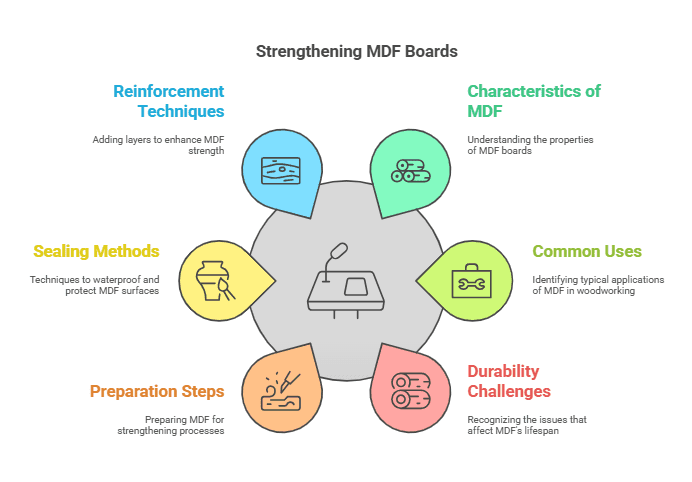

Characteristics Of MDF

MDF has several unique characteristics. It is uniform in texture and has no knots or rings. This makes it ideal for painting and veneering. MDF is also dense and heavy, which adds strength. It can be cut and shaped easily without chipping. However, MDF is susceptible to water damage and can swell if wet.

Common Uses In Woodworking

MDF is used in many woodworking projects. It is common in furniture making, such as cabinets and shelves. MDF is also used for molding and trim work. It is popular for speaker boxes due to its density. MDF can be found in interior doors and paneling as well. Its smooth surface is perfect for painting and laminating.

Challenges With MDF Durability

MDF boards are very sensitive to moisture. Water can make MDF swell and warp. This can damage the board. Always keep MDF dry. Use water-resistant sealants. This can help protect it. Place MDF in dry areas. Avoid bathrooms and kitchens. Water can easily damage it in these places.

MDF can get scratched and dented easily. Be careful with heavy objects. Always use coasters and mats. They can protect the surface. Use furniture pads on legs. This can prevent dents. A protective layer of paint or varnish can help. It makes the MDF surface stronger.

Preparation For Strengthening MDF

Gather all the needed materials first. You will need wood glue, clamps, and sandpaper. Have a clean cloth ready for cleaning. Safety glasses and gloves are also important. These items will help you work safely.

Clean the MDF surface well. Remove all dust and dirt with a clean, dry cloth. This makes the surface ready for sanding. Use sandpaper to gently sand the surface. Sanding makes the surface smooth. It also helps glue stick better. Wipe the surface again after sanding. Make sure no dust is left.

Sealing MDF Surfaces

Sealant is very important for MDF boards. Polyurethane is a strong choice. Shellac works great for many projects. Lacquer is also very effective. Each one has its own benefits. Sealant helps protect the MDF from moisture. Waterproofing is very important. Sealant also makes the surface smooth. This makes painting easier later on.

Brushes and rollers are common tools. Spray guns can work for larger surfaces. Make sure the surface is clean before starting. Apply a thin, even coat. Wait for it to dry completely. Sand lightly between coats. This helps the next layer stick better.

Reinforcing With Laminates And Veneers

Laminates add strength to MDF boards. Choose a high-quality laminate for the best results. Look for moisture-resistant laminates. These are especially good for kitchen and bathroom areas. Thicker laminates provide more durability. They protect the MDF from dents and scratches. Color and pattern options are also available. This can make your project look more attractive.

Use the right adhesive to attach laminates. Contact cement is a popular choice. It bonds quickly and strongly. PVA glue is also effective for laminates. Apply a thin layer of adhesive on both surfaces. Press them together firmly to ensure a good bond. Use a roller to remove air bubbles. Allow it to dry completely before using the MDF board.

Edge Banding For Enhanced Durability

Edge banding significantly boosts MDF boards’ durability by sealing edges and preventing moisture damage. This protective layer enhances the board’s longevity and strength.

Types Of Edge Bands

Edge bands come in various types to suit different needs. Plastic edge bands are common and offer good protection. Wood veneer edge bands are great for a natural look. Melamine edge bands are durable and come in many colors. PVC edge bands are flexible and easy to apply. Using the right type of edge band can make the MDF board last longer.

Attachment Process

First, cut the edge band to the right size. Make sure it matches the edge length. Next, use an iron to heat the glue on the edge band. Press the band firmly against the MDF edge. Let it cool for a few minutes. Trim any extra band with a sharp knife. Finally, sand the edges to make them smooth. This makes the board strong and durable.

Using Support Structures

Frame supports are essential for strengthening MDF boards. A well-designed frame can prevent bending and warping. Use strong materials like metal or hardwood for the frame. Make sure the frame fits snugly around the MDF board. This gives the board better support and increases its durability.

Adding crossbars to the frame can provide extra strength. Place these crossbars at regular intervals. This helps to evenly distribute weight. A strong frame can make your MDF board last longer.

Brackets and gussets are tools to make MDF boards stronger. Install metal brackets at the corners of the board. This helps to keep the corners from breaking. Use gussets to reinforce joints and connections. These tools help to spread out the stress on the board.

Make sure to use screws that are the right size. The screws should fit tightly. This stops the brackets and gussets from moving. With the right tools, your MDF board can be much stronger.

Maintenance Tips For Longevity

Dust your MDF boards often. Use a soft cloth to avoid scratches. Clean spills immediately to prevent damage. Avoid using too much water. Damp cloth is better than a wet one. Use mild soap for tough stains. Dry the board completely after cleaning. Avoid harsh chemicals as they can damage the surface.

Fix small dents with wood filler. Sand the area smooth after it dries. For larger damages, replace the affected section. Use wood glue for small cracks. Clamp the area until the glue dries. Paint or seal the board after repairs to protect it. Regular maintenance helps in the long run.

Advanced Techniques

Epoxy can fill gaps in MDF boards very well. Start by cleaning the gaps. Mix the epoxy as directed. Apply it into the gaps with a small tool. Let it cure for 24 hours. Sand the surface smooth after it dries. This makes the board stronger and smoother.

Layering materials can create stronger MDF boards. Use thin sheets of plywood. Glue them to the MDF board. Press the layers firmly together. Let them dry for 24 hours. This method increases the strength and durability of MDF.

Frequently Asked Questions

How To Make MDF Board Stiffer?

To make MDF board stiffer, apply wood glue and attach a plywood sheet. Reinforce with additional support beams.

How Do You Reinforce MDF?

Reinforce MDF by adding wood glue and screws. Use corner braces for additional support. Apply wood filler to gaps.

How To Make MDF Furniture Stronger?

To make MDF furniture stronger, use wood glue and screws for assembly. Add corner brackets for extra support. Seal edges to prevent moisture damage. Apply a durable finish to protect the surface. Consider reinforcing shelves with additional supports.

Conclusion

Strengthening MDF boards is straightforward with the right methods. Use proper sealing, reinforcement, and care techniques. This ensures durability and longevity. By following these steps, you can enhance the performance of your MDF projects. Invest time and effort for optimal results and a sturdy finish.

Your MDF boards will thank you!