Is Birch Plywood Good for Speaker Cabinets

Figuring out the best materials for building your own speakers can feel a bit tricky, especially if you’re just starting out. People often wonder, Is Birch Plywood Good for Speaker Cabinets? This question pops up because choosing the right wood affects how your speakers sound. Don’t worry, though!

This guide will make it simple. We’ll walk through everything you need to know so you can build awesome speaker cabinets with confidence. Let’s get started on what makes birch plywood a great choice.

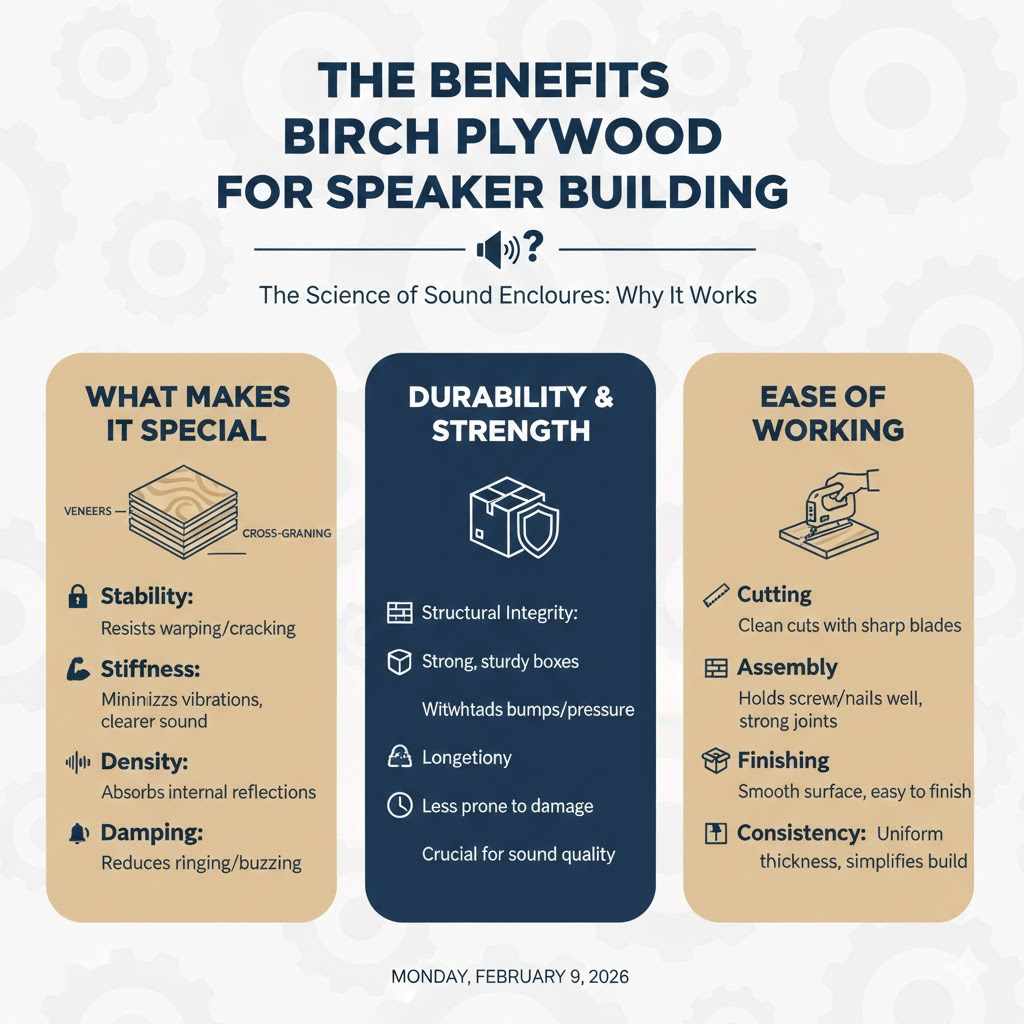

The Benefits of Birch Plywood for Speaker Building

Birch plywood is a popular choice for speaker cabinets because it offers a great balance of strength, stability, and acoustic properties. Its dense nature helps to minimize unwanted vibrations and resonance, which are critical for clear sound reproduction. For beginners, understanding why a material works well can seem complicated, but birch plywood simplifies things by providing predictable results.

We will explore the key reasons why this material is so well-suited for audio enclosures, making your DIY speaker projects more successful.

What Makes Birch Plywood Special for Sound

Birch plywood is made by layering thin sheets of birch wood, called veneers. These veneers are glued together with their grain running in different directions. This criss-cross layering is called cross-graining.

This cross-graining is super important. It makes the plywood very strong and stable. Unlike solid wood, which can warp or crack easily with changes in humidity, birch plywood stays put.

This stability means the cabinet won’t easily change shape or size.

For speakers, this is a big deal. The cabinet needs to be a solid box to work correctly. If the box vibrates too much or flexes, it colors the sound.

It adds its own unwanted noises, making the audio sound muddy or distorted. Birch plywood’s stiffness helps keep the cabinet quiet and rigid, letting the speakers inside do all the work of producing clear sound.

The density of birch also plays a role. It absorbs sound waves slightly better than softer woods. This helps to reduce internal reflections within the cabinet, which can also mess with the sound.

Think of it like a solid wall that doesn’t easily let sound bounce around inside.

One study, “Acoustic Properties of Wood-Based Panels for Loudspeaker Enclosures,” noted that birch plywood exhibits favorable damping characteristics compared to some other common wood materials. This damping means it naturally reduces the ringing or buzzing that can occur in a speaker cabinet. This property is crucial for achieving accurate bass response and clear mid-range frequencies.

Durability and Strength Considerations

When building speaker cabinets, durability is a major factor. These enclosures often need to withstand moving, occasional bumps, and the constant pressure from internal speaker drivers. Birch plywood stands up very well to these demands.

Its layered construction makes it incredibly strong for its weight. Each layer of veneer adds strength, and the glue holding them together creates a solid sheet. This means you can build sturdy boxes that won’t fall apart.

Think about how speakers are used. They might be placed on shelves, moved to different rooms, or even taken to events. A cabinet made from birch plywood is less likely to get damaged compared to softer woods or particleboard.

This robustness ensures your speakers look good and perform well for a long time.

The strength of birch plywood also means you can often use thinner sheets than you might need with less stable materials. This can save on weight and cost without sacrificing structural integrity. For example, a 3/4-inch (18mm) birch plywood cabinet will be much more rigid and resistant to flexing than a solid wood cabinet of the same thickness.

The resistance to warping is another key benefit. Solid wood can twist or cup when moisture levels change. This can lead to cracks or gaps in your cabinet, affecting its airtightness and sound quality.

Birch plywood, due to its cross-grained structure, is much less prone to these issues. This means a more reliable and long-lasting speaker.

Ease of Working with Birch Plywood

For DIY enthusiasts, how easy a material is to work with is just as important as its performance. Birch plywood is generally straightforward to cut, shape, and assemble. This makes it a good choice for beginners who may not have extensive woodworking experience.

You can use standard woodworking tools like saws, drills, and routers to work with birch plywood. Its surface is usually smooth and consistent, which makes it easy to glue and finish. This means you can achieve a professional-looking result without needing specialized equipment or techniques.

When cutting, it’s important to use sharp blades to avoid chipping the veneer. However, compared to some other engineered woods, birch plywood is less prone to splintering. This makes for a cleaner cut and a tidier workspace.

Screws and nails generally hold well in birch plywood. You can easily create strong joints by using wood glue along with fasteners. This reliability in joinery ensures that your speaker cabinets will be robust and airtight, contributing to their acoustic performance.

The consistent thickness of plywood sheets also simplifies construction. You don’t have to worry about variations that can occur with solid lumber, which can make assembling perfectly square boxes more challenging. This predictability helps to reduce errors and frustration during the building process.

Comparing Birch Plywood to Other Materials

When deciding what to build your speaker cabinets from, many options exist. Birch plywood is a top contender, but it’s helpful to know how it stacks up against other common materials. This comparison will highlight why birch plywood often wins out for many speaker builders.

Birch Plywood vs. MDF (Medium-Density Fiberboard)

MDF is another very common material for speaker cabinets. It’s made from wood fibers that are pressed and glued together.

One of the main differences is density and rigidity. Birch plywood is generally considered more rigid and less prone to flexing than MDF. This is due to its layered structure.

Higher rigidity means less internal resonance, which can lead to a cleaner sound.

MDF can sometimes be easier to cut and shape with a router for creating smooth edges or decorative inlays. However, MDF is also much heavier than birch plywood. For portable speakers, weight can be a significant concern.

Dust from MDF can be a health hazard, requiring good ventilation and a mask when working with it. Birch plywood dust is less problematic.

Moisture is also a greater enemy of MDF than birch plywood. If MDF gets wet, it can swell and fall apart. Birch plywood, while not waterproof, handles moisture much better.

Acoustically, MDF has good damping properties. It can absorb internal sound well. However, its lower rigidity can sometimes lead to a slightly less “tight” bass response compared to birch plywood, which offers a more controlled sound.

Here’s a quick comparison:

| Feature | Birch Plywood | MDF |

|---|---|---|

| Rigidity | High | Medium |

| Weight | Medium | High |

| Moisture Resistance | Good | Poor |

| Ease of Cutting | Good | Very Good (for routing) |

| Acoustic Damping | Good | Very Good |

| Cost | Medium to High | Low to Medium |

For many, the superior rigidity and better moisture resistance of birch plywood make it the preferred choice, despite its often higher cost and slightly more challenging cutting if you’re doing heavy routing.

Birch Plywood vs. Solid Wood

Solid wood, like pine, oak, or maple, is what many people think of first when building with wood. It has a natural beauty that’s hard to match. However, when it comes to speaker cabinets, it has some significant drawbacks compared to birch plywood.

The biggest issue with solid wood is its tendency to warp, twist, and crack with changes in temperature and humidity. Wood is a natural material and it moves. This movement can be a disaster for a speaker cabinet.

A warping cabinet means leaks in the seal, which ruins bass performance. It can also introduce unwanted vibrations and rattles.

Birch plywood, with its cross-grained layers, is much more stable. It resists these environmental changes, ensuring the cabinet stays true and airtight. This stability is crucial for predictable and accurate sound.

Solid wood can also be more expensive, especially hardwoods like oak or maple. Plywood is often more cost-effective, particularly when considering the stability you get for the price.

The acoustic properties of solid wood vary greatly by species. Some woods might offer good damping, but they still suffer from the instability problem. You would need to carefully select and dry the wood, and even then, you’re taking a risk.

Working with solid wood can also be more challenging. Finding boards of consistent thickness and flatness can be difficult. Joining solid wood panels securely to create a rigid box requires careful joinery techniques.

For these reasons, while solid wood can be used, birch plywood is often the more practical and reliable choice for most speaker cabinet projects. The stability and predictable acoustic behavior of birch plywood are highly valued by speaker designers and builders.

Birch Plywood vs. Particle Board

Particle board is made from wood particles, such as sawdust and wood chips, bonded together with resin. It’s typically the cheapest option among common panel materials.

However, particle board is generally the least desirable material for speaker cabinets. It is significantly less dense and much weaker than birch plywood or even MDF. This low density means it doesn’t offer much acoustic damping and is prone to vibrating and resonating, which will degrade sound quality.

Particle board is also very susceptible to moisture damage. Even a small spill can cause it to swell and lose its structural integrity. It does not hold screws or fasteners as well as plywood, making it harder to build strong, airtight enclosures.

While it might seem tempting due to its low cost, the compromises in sound quality, durability, and ease of construction make particle board a poor choice for serious speaker building. For anyone asking Is Birch Plywood Good for Speaker Cabinets?, the answer is a resounding yes when compared to particle board.

Understanding Birch Plywood Grades and Types

Not all birch plywood is created equal. It comes in different grades, which refer to the quality of the wood veneers and how they are joined. Understanding these grades is key to selecting the right birch plywood for your speaker cabinets.

The ABC Grading System Explained

Birch plywood is often graded using letters like A, B, C, and D. These letters describe the appearance of the face and back veneers.

- A-Grade: This is the highest quality face veneer. It’s smooth, sanded, and typically free of defects like knots, patches, or large repairs. It’s ideal for visible surfaces where a perfect finish is desired.

- B-Grade: This grade is also good, but it might have some minor defects like small knots, minor color streaks, or small plugs (small circular pieces used to fill knots). It’s still a smooth, sanded surface.

- C-Grade: This grade has more visible defects, such as larger knots, some veneer repairs, and a rougher surface. It’s less about appearance and more about structural integrity.

- D-Grade: This is the lowest grade and is usually rough and full of defects. It’s generally not suitable for visible parts of a speaker cabinet but might be used for internal bracing if strength is the only concern.

When building speaker cabinets, you often see a grading like “AB” or “BB”. The first letter refers to the face veneer and the second to the back veneer.

- AB Grade: This is a very popular choice for speaker cabinets. The face is smooth and attractive (A-grade), while the back might have minor cosmetic imperfections (B-grade). This gives you a great-looking front without paying for a perfect back you’ll never see.

- BB Grade: This means both the face and back veneers are B-grade. It’s still a very strong and stable material, suitable for speaker cabinets, but it will have more visible knots and repairs than AB grade.

- CC Grade: This means both sides are C-grade. It’s very functional and strong but will have significant cosmetic flaws. Best used for internal parts or cabinets where appearance isn’t a top priority.

For most DIY speaker projects where you want a good balance of appearance and cost, AB or BB grade birch plywood is a great choice. The structural integrity is the same across grades; it’s the surface finish that differs.

Baltic Birch Plywood – A Special Kind

You’ll often hear the term “Baltic birch plywood.” This isn’t just a marketing term; it refers to a specific type of birch plywood known for its high quality and unique construction.

Baltic birch plywood is typically made from 100% birch veneers, unlike some other plywoods that might use cheaper woods for the inner layers. It’s also manufactured using exterior-grade glues, making it very water-resistant.

The key characteristic of Baltic birch is its very high number of plies (layers) for a given thickness. For example, a 3/4-inch (18mm) sheet of Baltic birch might have 13 or more plies. This creates an exceptionally strong, rigid, and stable panel.

The edge of Baltic birch plywood is also quite distinctive. Because it has so many thin plies, the edges are clean and attractive. This makes it easy to create exposed-ply edge designs on speaker cabinets, which is a popular modern look.

Because of its superior construction and all-birch composition, Baltic birch plywood is generally more expensive than standard birch plywood. However, for high-end or critical speaker builds where maximum rigidity and a premium finish are desired, it is an excellent choice.

Many professional speaker manufacturers prefer Baltic birch for its consistent quality and acoustic performance. Its density and lack of voids ensure minimal internal resonance, contributing to a clear and accurate sound output from the speakers.

Thickness Matters for Sound and Strength

The thickness of the birch plywood you choose will significantly impact both the strength and the acoustic performance of your speaker cabinet.

Thicker plywood (e.g., 3/4 inch or 18mm) provides greater rigidity and strength. This is especially important for larger speaker cabinets or those housing powerful woofers that can create substantial air pressure and vibrations. A thicker cabinet is less likely to flex or resonate, leading to a cleaner, more controlled bass response and clearer overall sound.

For smaller satellite speakers or bookshelf speakers, thinner plywood might be sufficient, perhaps 1/2 inch (12mm) or even 3/8 inch (9mm). However, even with smaller cabinets, using a thicker material like 3/4 inch for the front baffle (where the drivers are mounted) can help reduce baffle-induced distortions.

A common recommendation for general-purpose bookshelf or floorstanding speaker cabinets is 3/4 inch (18mm) birch plywood. This thickness offers a superb balance of rigidity, acoustic damping, and workability.

It’s worth noting that sometimes, builders will use a thinner material for the cabinet sides and back, but a thicker front baffle. This helps to optimize both cost and performance. The baffle needs to be as stiff as possible to prevent the drivers from exciting the panel.

Here’s a general guide for thickness selection:

- 3/8 inch (9mm): Suitable for very small satellite speakers or internal bracing. Not recommended for main cabinet panels.

- 1/2 inch (12mm): Can be used for smaller bookshelf speakers, but a thicker front baffle is advised.

- 3/4 inch (18mm): The most common and recommended thickness for general-purpose speaker cabinets, offering excellent rigidity and acoustic properties.

- 1 inch (25mm) or thicker: Used for very large subwoofers or high-performance cabinets where maximum resonance control is paramount.

Choosing the right thickness ensures that your cabinet supports the drivers properly and minimizes unwanted acoustic coloration, allowing the true sound of your drivers to shine through.

Building Your Speaker Cabinet with Birch Plywood

Now that we know Is Birch Plywood Good for Speaker Cabinets? (yes, very!), let’s talk about how to actually use it. Building your own speaker cabinets can be a rewarding project, and birch plywood makes it easier.

Design Considerations for Optimal Sound

Before you cut any wood, you need a good design. The cabinet’s shape and volume are critical for how your speakers will sound. The drivers you choose will have specific enclosure requirements.

The volume of the cabinet is often determined by the speaker driver’s specifications. Manufacturers provide parameters like Thiele-Small parameters that help calculate the ideal box size for a given driver. This calculation ensures the best bass response.

The cabinet’s shape also matters. While a simple rectangular box is easiest to build, other shapes can help reduce internal standing waves. Standing waves are sound waves that bounce back and forth inside the cabinet, creating peaks and dips in the frequency response.

Some design features to consider include:

- Internal Bracing: Adding wooden braces or spars across larger panels significantly increases rigidity. This reduces panel vibration and coloration. These braces can be made from scrap birch plywood or solid wood.

- Damping Material: Lining the inside walls of the cabinet with acoustic foam or fiberglass helps absorb internal sound waves. This reduces echoes and standing waves, leading to a cleaner sound.

- Porting: If you are building a bass-reflex (ported) enclosure, the size and length of the port are crucial for tuning the bass response. This is often calculated along with the cabinet volume.

- Driver Placement: The position of the drivers on the baffle can affect sound dispersion and diffraction. While complex, slight offsets can sometimes improve imaging.

Even a basic sealed box design made from sturdy birch plywood will yield much better results than a poorly designed or constructed cabinet made from inferior materials.

Cutting and Assembly Techniques

Once you have your design, it’s time to cut the birch plywood. Precision is key here. Measure twice, cut once!

Use a good quality circular saw or a table saw with a fine-tooth blade to get clean cuts. For the best results, especially with Baltic birch, consider using a track saw or a table saw with a zero-clearance insert to support the wood and prevent tear-out.

When assembling, wood glue and screws are your best friends. Apply a generous amount of wood glue to all mating surfaces before joining. This creates a strong, airtight bond.

Pre-drilling pilot holes for screws is essential. This prevents the plywood from splitting, especially near the edges. Counter-sinking the screw heads allows them to be hidden later if you plan on a smooth finish.

Some common assembly tips:

- Accurate Cuts: Ensure all your cuts are square. This will make assembling a perfectly aligned box much easier.

- Glue and Clamp: Use wood glue on all joints. Clamps are essential to hold the pieces together tightly while the glue dries. If you don’t have enough clamps, use screws and then remove them once the glue is dry, or leave them in for added strength if they will be hidden.

- Air Tightness: Seal all internal joints with a bead of caulk or sealant after assembly. This is critical for sealed enclosures and beneficial for ported ones to ensure the port is the only intended air leak.

- Front Baffle: Consider using a thicker front baffle (e.g., two layers of 3/4-inch plywood glued together) to provide a very rigid mounting surface for your drivers. This minimizes vibration from the drivers affecting the baffle.

A well-built cabinet using birch plywood will not only look good but will also contribute significantly to the overall sonic performance of your speakers.

Finishing Your Speaker Cabinets

The finish you choose for your speaker cabinets is important for both aesthetics and protection. Birch plywood offers a beautiful surface that can be finished in many ways.

Before finishing, ensure all surfaces are smooth. Sand the plywood progressively with finer grits of sandpaper (e.g., 120, 180, 220 grit). Pay attention to edges and any areas where glue might have squeezed out.

For a natural wood look, a clear coat or varnish works well. This highlights the natural grain of the birch. Using a pre-finishing wood conditioner can help the stain or clear coat absorb more evenly, especially if you are using different grades of plywood or if there are variations in the wood.

If you want to paint your cabinets, a good quality primer is recommended. Birch plywood takes paint very well, allowing for a smooth, uniform finish. You can choose any color to match your decor.

Some popular finishing options include:

- Clear Varnish or Polyurethane: Protects the wood while showcasing its natural beauty. Multiple thin coats are better than one thick coat.

- Stain: Allows you to change the color of the wood while still seeing the grain pattern. Follow with a protective clear coat.

- Paint: Offers endless color possibilities. Requires good preparation with primer for a flawless finish.

- Veneer: For a high-end look, you can apply a thin decorative wood veneer over the birch plywood.

- Textured Coatings: Some builders use textured spray paints or truck bed liner for a rugged, durable finish, especially for pro audio or DJ speakers.

Remember to allow adequate drying time between coats and sand lightly between coats for a super smooth finish. A well-finished cabinet not only looks professional but also protects your investment.

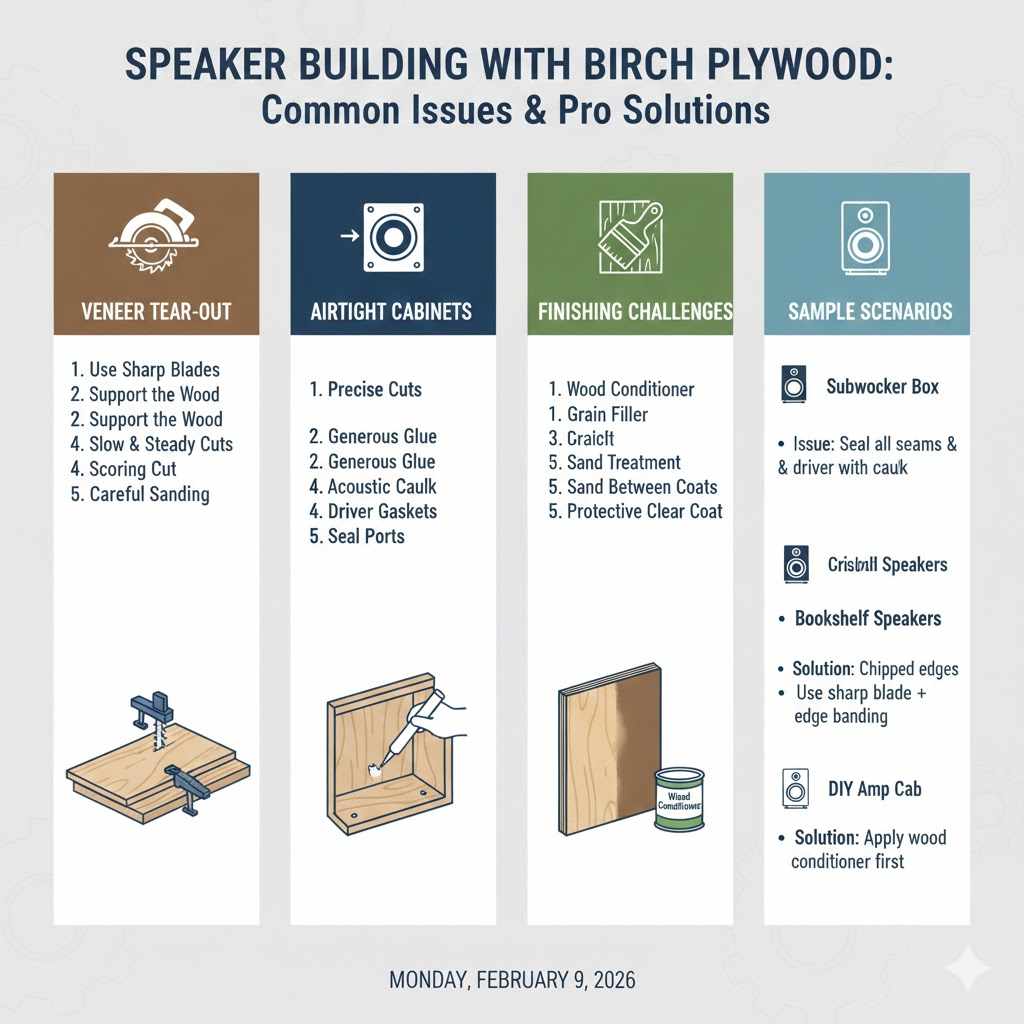

Common Issues and How to Solve Them

Even with a great material like birch plywood, some challenges can arise during the building process. Knowing these common issues and how to fix them will save you time and frustration.

Dealing with Veneer Tear-Out

The thin layers of veneer in plywood can sometimes splinter or tear when cut, especially on the exit side of the blade. This is called tear-out.

To minimize tear-out:

- Use Sharp Blades: A dull blade will always cause more tear-out. Use a high-quality, sharp blade designed for plywood or fine cuts.

- Support the Wood: Ensure the plywood is well-supported on both sides of the cut. Use a backing board clamped to the plywood where the blade will exit.

- Slow and Steady: Don’t try to rush the cut. A consistent, moderate speed often yields cleaner results.

- Scoring: For critical cuts, you can lightly score the cut line with a utility knife before cutting with a saw. This helps to pre-cut the wood fibers.

- Router Tricks: If using a router, climb cutting (cutting against the normal direction of the router bit) can sometimes produce a cleaner edge on plywood, but it can be dangerous and requires caution.

If you do get minor tear-out, it can often be fixed with careful sanding. For deeper damage, you might need to use wood filler or a small plug.

Ensuring Airtight Speaker Cabinets

For most speaker designs, especially sealed enclosures, an airtight cabinet is crucial for proper performance. Leaks can cause significant distortion and poor bass response.

How to ensure airtightness:

- Precise Cuts: The better your cuts fit together, the fewer gaps you’ll have.

- Glue Application: Make sure glue is applied to all edges that will be joined.

- Sealant: After assembling the main box, use a bead of acoustic caulk or silicone sealant along all internal seams. This is a critical step.

- Driver Gaskets: When mounting your speaker drivers, use rubber gaskets or a thin bead of sealant around the mounting flange. This seals the driver to the baffle.

- Port Sealing: Ensure your port is well-sealed into the cabinet if you are using a ported design.

You can test for leaks by sealing the driver/port openings, playing a low-frequency tone through the speaker, and listening for escaping air or feeling drafts around the seams. Alternatively, you can lightly pressurize the cabinet with air and listen for leaks.

Finishing Challenges with Plywood

While birch plywood is excellent, finishing it can sometimes present challenges, especially if you’re aiming for a flawless look.

Common finishing issues and solutions:

- Uneven Stain Absorption: Different parts of the plywood, especially where there are patches or repairs in the veneer, might absorb stain differently, leading to blotchiness. Using a wood conditioner before staining helps promote even absorption.

- Grain Filling: While birch has a nice grain, it’s not as open as some hardwoods like oak. For a truly glass-smooth finish, you might need to use a grain filler.

- Edge Treatment: The layered edges of plywood can look different from the face veneer. For a premium look, you might want to cover the edges with solid wood trim, apply a thick edge banding, or carefully sand and fill them to match the face.

- Dulling the Finish: If you’re using polyurethane, multiple coats and light sanding between coats will give you a smooth, durable finish. A final buffing can achieve a high-gloss look if desired.

Taking the time for proper preparation, using the right products, and following good finishing practices will result in a beautiful and professional-looking speaker cabinet, no matter the chosen finish.

Frequently Asked Questions

Question: Is birch plywood better than MDF for speaker cabinets?

Answer: Birch plywood is generally considered better due to its superior rigidity, strength, and resistance to moisture. While MDF offers good acoustic damping, birch plywood’s stiffness often leads to a cleaner, more accurate sound, especially in the bass frequencies, and it’s less prone to damage from humidity.

Question: What thickness of birch plywood should I use for bookshelf speakers?

Answer: For most bookshelf speaker cabinets, 3/4 inch (18mm) thick birch plywood is recommended. This thickness provides excellent rigidity to minimize cabinet vibrations, which is crucial for clear sound reproduction. For smaller cabinets, 1/2 inch (12mm) might suffice, but 3/4 inch is a safer bet for performance.

Question: Can I use lower grades of birch plywood for speaker cabinets?

Answer: Yes, you can use lower grades like BB or even CC for the main cabinet panels if appearance is not your primary concern. The structural integrity and acoustic performance of plywood are not significantly affected by surface grades as long as there are no large voids or delaminations. Lower grades are often more budget-friendly.

Question: Is Baltic birch plywood worth the extra cost for DIY speakers?

Answer: Baltic birch plywood is often worth the extra cost for high-end or critical speaker builds. Its exceptional rigidity, stability, and high ply count contribute to superior acoustic performance. The attractive edge grain also allows for a modern exposed-ply finish.

For standard projects, regular birch plywood is often perfectly adequate.

Question: How do I seal speaker cabinet joints made from birch plywood?

Answer: After assembling the cabinet with wood glue, you should use a bead of acoustic caulk or silicone sealant along all internal seams. This ensures an airtight enclosure, which is vital for proper bass response in sealed cabinets and generally beneficial for all types of speaker enclosures.

Summary

Birch plywood is an excellent choice for building speaker cabinets due to its strength, stability, and acoustic properties. Its layered construction offers rigidity that minimizes unwanted vibrations and resonance, leading to clearer sound. Grades like AB and BB provide a good balance of appearance and cost, while Baltic birch offers premium performance for demanding builds.

Proper design, careful cutting, assembly with glue and sealant, and thoughtful finishing will result in professional-looking and great-sounding speaker enclosures.