Riving Knife Vs Splitter: Choose The Right Tool for Safe Cuts

A riving knife and a splitter are both safety devices used on a table saw that help to prevent kickback. A riving knife is a preferable option because it does not need to be removed from the saw while cross-cutting or doing a blind cut, and the operator cannot forget to put it back on, unlike the splitter.

Table saws are an essential tool for many woodworkers and contractors. They are primarily used to make precise cuts, but improper use can lead to kickback, exposing the operator to serious injuries. Table saw kickback is a terrifying and dangerous occurrence that can happen when the saw blade binds or stalls, causing the wood piece to be thrown back violently.

To prevent this, a splitter or riving knife is installed on the saw behind the blade. These devices help prevent the blade from binding and reduce the chances of kickback. We will discuss the differences between a riving knife and a splitter and why a riving knife is preferred over a splitter.

Riving Knife Vs Splitter

A riving knife and a splitter are both table saw safety devices that help prevent kickback and injuries. A riving knife is preferable to a splitter because it doesn’t need to be removed when making certain cuts and reduces the risk of forgetting to put it back on.

If you are a woodworker, you know that working with a table saw is an essential part of the process. Table saws are very useful for cutting wood with precision and accuracy. However, when it comes to using a table saw, safety is of utmost importance. There are many safety measures you can employ during table saw use, and one of them is using a riving knife or splitter. In this blog post, we’ll focus on Riving Knife Vs Splitter. We’ll explore the difference between them, why they are essential, and which one you should choose for your woodworking needs.

Difference Between A Splitter And A Riving Knife

A splitter and riving knife are two safety devices found on a table saw. They are both designed to prevent kickback, which is a dangerous situation that occurs when the wood being cut gets pinched between the saw blade and rip fence, causing the wood to get thrown back at the operator. The main difference between a splitter and a riving knife is that a splitter is a stationary plate that keeps the wood from getting pinched. In contrast, a riving knife moves up and down with the saw blade, keeping the kerf (the gap made by the saw blade) open and preventing the wood from binding.

Why Are Riving Knives And Splitters Important?

Riving knives and splitters are essential safety devices that prevent kickback and keep the operator safe. Kickback is a dangerous situation that occurs when the wood being cut gets pinched and is thrown back at the operator. It can cause serious injury or even death. Riving knives and splitters prevent kickback by keeping the kerf open, and preventing the wood from binding. This helps to keep the wood moving forward, preventing it from springing back towards the operator.

Riving Knife Versus Splitter

Riving knives and splitters both serve the same purpose, which is to prevent kickback and keep the operator safe. However, there are a few differences between the two. One of the advantages of a riving knife is that it moves up and down with the saw blade, which means it does not need to be removed when cross-cutting or doing a blind cut. In contrast, a splitter is a stationary plate that needs to be removed when cross-cutting or doing a blind cut. When using a splitter, it’s important to remember to put it back on after making a through cut.

Why Is A Riving Knife Preferable To A Splitter?

When it comes to Riving Knife Vs Splitter, a riving knife is generally preferable to a splitter. One of the main advantages of a riving knife is that it moves up and down with the saw blade, which means it does not need to be removed when cross-cutting or doing a blind cut. In contrast, a splitter is a stationary plate that needs to be removed when cross-cutting or doing a blind cut. When using a splitter, it’s important to remember to put it back on after making a through cut. Riving knives are also more effective at preventing kickback than splitters because they keep the kerf open, preventing the wood from binding.

Should I Use A Riving Knife?

Yes, you should use a riving knife when using a table saw. Riving knives are an essential safety device that prevents kickback and keeps the operator safe. They keep the kerf open, preventing the wood from binding and springing back towards the operator. If you don’t have a riving knife, consider getting one for your table saw.

Is It Safe To Use The Rip Fence On A Table Saw Without An Auxiliary Guard?

No, it’s not safe to use the rip fence on a table saw without an auxiliary guard. An auxiliary guard is a device that attaches to the rip fence and prevents the wood from getting thrown back at the operator. Without an auxiliary guard, the wood can get pinched between the saw blade and rip fence, causing kickback and a potentially dangerous situation.

Should Riving Knife Be Thinner Than Blade?

No, a riving knife should not be thinner than the blade. The riving knife needs to be thicker than the kerf made by the blade. This ensures that the riving knife keeps the kerf open, preventing the wood from binding and springing back towards the operator. If the riving knife is thinner than the blade, it may not be effective at preventing kickback and keeping the operator safe.

In conclusion, when it comes to Riving Knife Vs Splitter, riving knives are generally preferable to splitters. Riving knives are more effective at preventing kickback, and they do not need to be removed when cross-cutting or doing a blind cut. If you don’t have a riving knife or splitter, consider getting one for your table saw. Remember to always use an auxiliary guard when using the rip fence on a table saw, and ensure your riving knife is thicker than the blade. Stay safe while woodworking!

Understanding Saw Blades

A riving knife and splitter are both used for safety in woodworking with table saws, but a riving knife is preferable because it doesn’t have to be removed for cross-cutting, blind cuts, or grooves, eliminating the risk of forgetting to put it back on.

It is a standard piece of safety equipment that can prevent kickback of active hardwoods and has no drawbacks.

When it comes to working with a table saw, safety should always be your top priority. Riving knives and splitters are two critical safety features that can prevent kickback and keep you safe from harm. Understanding saw blades is an essential part of knowing how these safety devices work. In this section, we will explore the different elements of saw blades and how they impact the use of riving knives and splitters.

What is curve thickness?

The curve thickness of a saw blade refers to the width of the blade body. A thinner blade will have a smaller curve thickness than a thicker blade. The curve thickness impacts the type of riving knife or splitter you should use. It determines the gap between the blade and the splitter, which should be close enough to prevent kickback but wide enough to avoid binding.

What is the difference between thin kerf and full kerf blades?

Thin kerf blades have a narrower width than full kerf blades, resulting in thinner cuts. They require a thinner splitter or riving knife to keep the saw blade from binding against the safety device. Full kerf blades, on the other hand, require a wider splitter or riving knife to keep the blade from binding.

Purpose of a splitter or riving knife

Splitters and riving knives serve the same purpose – to prevent kickback and keep you safe. They help keep the stock against the fence as you cut it, preventing it from twisting and binding against the blade.

Why are riving knives and splitters important?

Riving knives and splitters are essential safety devices for table saws. They help keep the stock from twisting and binding against the blade, preventing kickback and keeping you safe.

What if the splitter is narrower than the kerf?

If the splitter is narrower than the kerf, it will not provide enough support for the stock. This can cause the stock to twist and bind against the blade, resulting in a kickback. It is important to use the correct size splitter or riving knife for your blade.

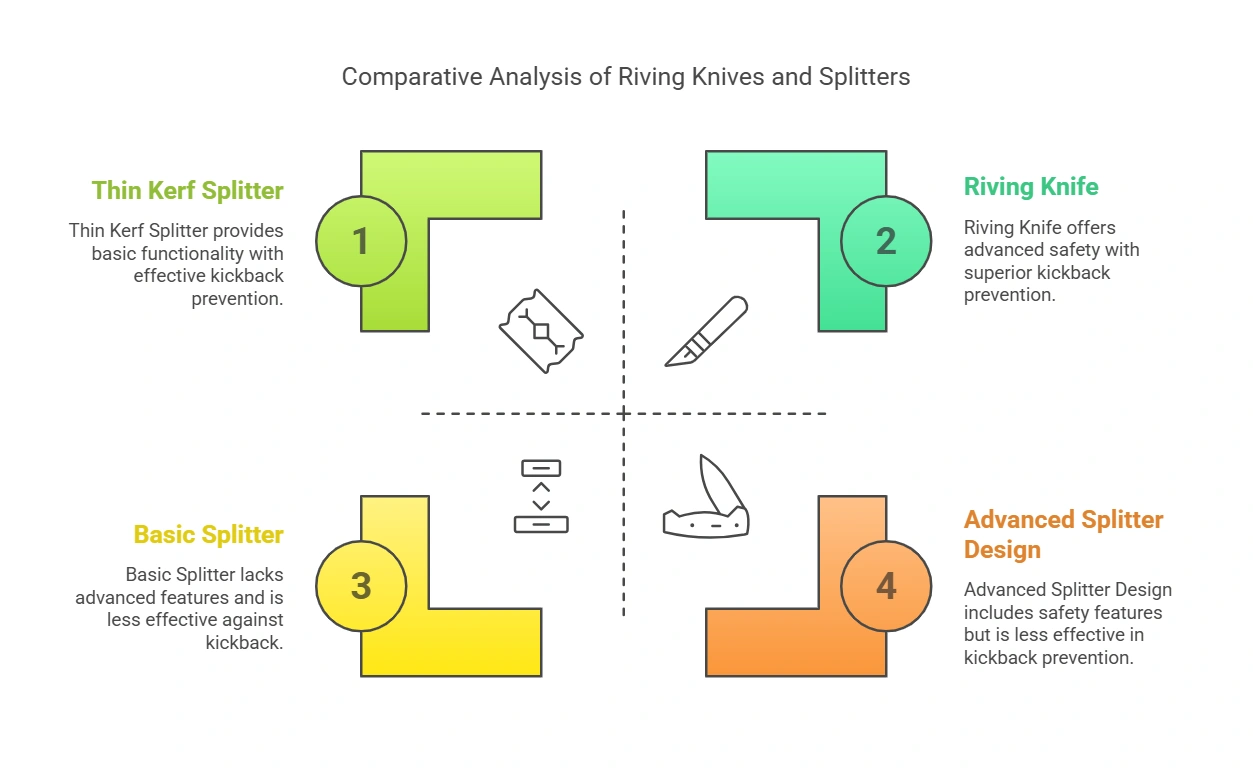

How does a thin kerf splitter prevent kickback?

A thin kerf splitter is designed to prevent the kerf from closing on the back of the blade. This prevents the stock from twisting and binding against the blade, reducing the risk of kickback. The splitter should be positioned close enough to the blade to provide proper support but not so close that it causes binding.

How does kickback work?

Kickback occurs when the wood being cut binds against the saw blade, causing it to kick back towards the operator. Kickback can occur when the stock is not supported properly or when the blade is dull or improperly aligned.

How thick should a splitter be?

The thickness of the splitter should be matched to the thickness of the blade. A thicker blade requires a thicker splitter to prevent binding, while a thinner blade requires a thinner splitter. When in doubt, refer to the manufacturer’s recommendations for proper splitter thickness.

Conclusion:

Understanding saw blades is an essential part of knowing how riving knives and splitters work. By choosing the correct size and type of splitter or riving knife for your blade, you can help prevent kickback and keep yourself safe while working with a table saw. Remember to always follow safety guidelines and use proper safety equipment when working with power tools.

Importance Of Riving Knives And Splitters

Riving knives and splitters are important safety features for table saws. A riving knife is a flat metal plate that sits behind the blade, preventing wood from pinching the blade and causing kickback. A splitter is a similar device, but it is a separate piece that is removable.

It’s recommended that table saw users always use one of these devices to prevent injury.

A riving knife or a splitter is an essential part of a saw to keep the operator safe during cutting. They are important safety devices designed to reduce the risk of kickback, which can cause serious injury to the operator. In this post, we will discuss the importance of riving knives and splitters and why you should consider them when purchasing a saw.

Purpose of a splitter or riving knife

A splitter or a riving knife is an essential component of a saw blade designed to reduce the risk of kickback caused by the saw blade binding. When the saw blade pitch or width does not match the width of the cut, the saw blade can catch material and cause kickback. The splitter or the riving knife helps prevent this by keeping the material from being forced into the saw blade and closing the kerf, which can cause the saw blade to bind.

Dangers of splitters

Splitters have some associated dangers that make them a less favorable option compared to riving knives. A splitter can sometimes bind the material if it is not set correctly. Also, splitters must be removed when cross-cutting or doing a blind cut, and may forget to be put back on resulting in an unsafe cutting situation. Therefore, it is important to opt for riving knives as a safer and more reliable option.

Why are riving knives and splitters important?

Riving knives and splitters are important safety devices that help reduce the risk of kickback injury while using a saw. A riving knife is a better option compared to a splitter since they remove the chances of forgetting to attach the safety feature. They stop the material from being forced into the saw blade and closing of the kerf, which can cause kickback. Their importance in reducing the risk of injury should encourage every saw operator to consider having one.

Conclusion

In conclusion, riving knives and splitters are essential safety devices that should be considered when purchasing a saw. They help reduce the risk of injury and keep the operator safe while cutting. The prevention of kickback is an important aspect that should not be overlooked. Therefore, it is recommended to opt for the safer and more reliable option, the riving knife.

How Splitters Prevent Kickback

A splitter and a riving knife both prevent kickback, but a riving knife has some advantages over a splitter. A riving knife doesn’t need to be removed from the saw when doing certain cuts, so the operator doesn’t forget to put it back on, and it extends closer to the blade, providing more protection.

When it comes to table saw safety, one of the biggest concerns is kickback. This occurs when the wood being cut gets pinched between the blade and the fence, causing it to be shot back towards the operator at high speed. A riving knife or splitter is an important device that helps prevent kickback, but how do they work?

How Does Kickback Work?

During every cut, the blade of the saw creates a kerf (a slot in which the saw blade travels). As the wood moves through the kerf, the sides of the kerf come under pressure and can push the two halves of the board apart. If this pressure causes the wood to pinch the back of the saw blade, it can cause kickback.

What Happens During Every Cut?

During every cut, the splitter or riving knife sits behind the blade and keeps the kerf from closing behind the blade. This prevents the wood from getting pinched and causing kickback.

A riving knife is a thin piece of metal that rises and falls with the blade, keeping the kerf open in front of the blade at all times. This means that it works well for a wide range of cuts, including non-through cuts where the blade does not pass all the way through the wood.

A splitter, on the other hand, is a fixed piece of metal that sits behind the blade and prevents the kerf from closing. It needs to be removed for non-through cuts, leading to the possibility that it could be forgotten and not replaced for through cuts (reducing safety).

In Conclusion

When choosing between a riving knife or splitter, it is important to consider the type of cuts you will be making. A riving knife is more versatile, but a splitter is a simpler device that can still do an excellent job of preventing kickback. Either way, including one of these devices with your table saw setup is an essential safety step for any woodworker.

Choosing The Right Riving Knife Or Splitter

Choosing the right riving knife or splitter for your table saw is crucial to ensure your safety while working. While both options help prevent kickback and other hazards, a riving knife is preferable as it does not need to be removed for blind cuts and reduces the risk of operator error.

been designed to protect woodworkers from potentially dangerous situations while making the cuts. When it comes to choosing the right riving knife or splitter, the decision needs to be made based on the type of table saw you own, the type of cut you need to make, and your budget. So in this section, we will discuss some key factors that need to be considered before making a decision on the right riving knife or splitter for your table saw.

Table Saw Splitter Options

Table saw splitters are available in different sizes and shapes, but the most common types are the blade guard mounted splitters and the anti-kickback pawls. Blade guard mounted splitters are attached to a removable blade guard, while the anti-kickback pawls are attached to a bracket at the rear of the saw blade. These splitters are inexpensive and easy to install, but they have some limitations. For example, they are not effective for narrow cuts, thick materials, and non-through, or blind cuts.

Riving Knife For Old Craftsman Table Saw

If you own an old Craftsman table saw, it might not be compatible with a standard riving knife. In this case, you might need to find a riving knife that is specifically designed for your saw model. Many aftermarket companies produce riving knives for older saw models, but you need to make sure that you get the right size and shape to ensure a proper fit and maximum safety.

Microjig Mj Splitter Steelpro

The Microjig MJ Splitter Steelpro is a popular splitter option that is made of high-quality steel and is suitable for use with narrow kerf blades. It is easy to install and remove and does not require any modifications to the existing saw guard. The Steelpro offers good protection against kickback, but it is limited in terms of the thickness of materials it can handle.

Laguna Fusion Thin Kerf Riving

Laguna Fusion Thin Kerf Riving knife is an excellent option for woodworkers looking for maximum safety and precision. The riving knife is made of high-quality materials and comes with a quick-release mechanism that makes it easy to install and remove. It is compatible with most saw models and is designed to work with thin kerf blades. It provides excellent protection against kickback and ensures accurate cuts, especially when working with narrow materials.

Why Are Bandsaw Blades So Inexpensive?

Bandsaw blades are relatively inexpensive because they are made of cheaper materials compared to other saw blades. Most bandsaw blades are made of carbon steel or flexible steel, which is less expensive than high-speed steel or carbide tipped blades used for other saws such as miter saws or table saws. Carbon steel and flexible steel blades are perfect for cutting curves and contours and are less prone to breakage when subjected to flexing and bending during the cutting process.

In conclusion, choosing the right riving knife or splitter for your table saw is an important decision that should not be taken lightly. It is essential to consider factors like compatibility, safety, precision, and budget before making a decision. The Microjig MJ Splitter Steelpro and the Laguna Fusion Thin Kerf Riving knife are excellent options that offer the right balance of safety, precision, and affordability. Regardless of your choice, ensure that you follow all safety protocols and use the appropriate protective gear while operating any saw.

Frequently Asked Questions On Riving Knife Vs Splitter

Why Is A Riving Knife Preferable To A Splitter?

A riving knife is better than a splitter because it does not need to be removed when cross-cutting or doing a blind cut as it does not extend above the top of the saw blade. This means that the operator cannot forget to put it back on, reducing the risk of kickback and injury.

It is a basic piece of safety equipment with zero drawbacks.

Should I Use A Riving Knife?

Yes, it is recommended to use a riving knife as it is a basic safety equipment that can prevent kickback and minimize the risk of injury. A riving knife has advantages over a splitter, such as not needing to be removed from the saw and cannot be forgotten to put back on.

Is It Ok To Remove Riving Knife Table Saw?

It is not recommended to remove the riving knife from a table saw as it increases the risk of kickback and injury. A riving knife prevents the workpiece from binding against the saw blade and helps in safe cutting. It also does not need to be removed while cross-cutting or doing a blind cut.

So, using a riving knife during operation is safer and better.

Should Riving Knife Be Thinner Than Blade?

A riving knife or splitter should be slightly thinner than the thickness of the blade kerf for safety. This helps prevent kickback and allows for easier cross-cutting without removal. It is recommended to use a riving knife or splitter as a basic piece of safety equipment when operating a table saw.

Conclusion

Choosing between a riving knife and a splitter is a crucial decision that affects your safety and that of those around you. As we have seen, both pieces of equipment perform similar functions, but a riving knife has several advantages over a splitter.

It eliminates the need to be removed when you cross-cut or make blind cuts, minimizing the chances of forgetting to put it back on. Also, it has an added advantage by reducing the risk of kickback, ensuring smooth and safe woodworking operations.

Therefore, invest wisely and choose a riving knife that best suits your needs.