What Kind of Plywood for Workbench Top: Best Choices

For a workbench top, use high-quality plywood, ideally ¾-inch thick. Birch or Baltic birch plywood offers excellent durability and strength.

A sturdy workbench is essential for any DIY enthusiast or professional woodworker. Choosing the right material for the workbench top can significantly impact your projects. Plywood stands out as a popular choice due to its strength, versatility, and cost-effectiveness. It provides a smooth surface for various tasks, from woodworking to crafting.

The right type of plywood can withstand heavy use and resist warping over time. Understanding the different plywood options available will help you make an informed decision. This guide will explore the best plywood types for workbench tops, ensuring your workspace is both functional and durable.

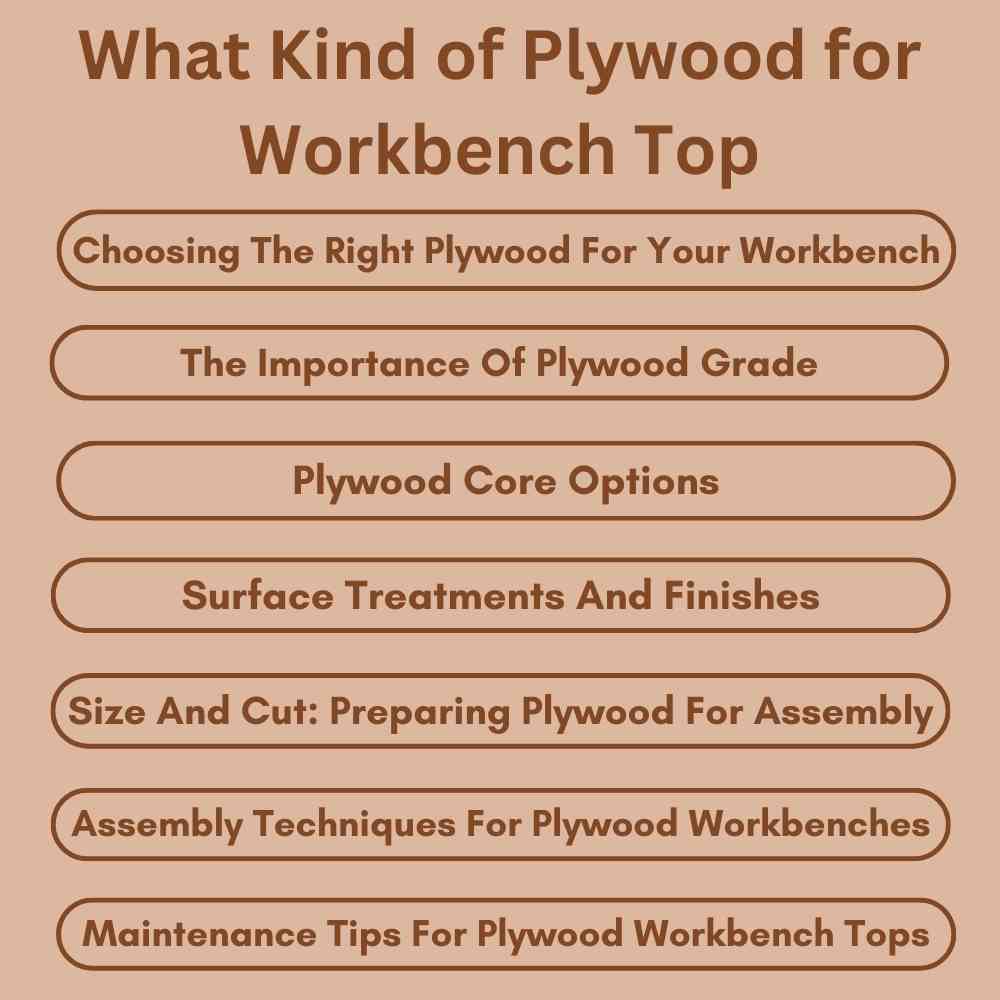

Choosing The Right Plywood For Your Workbench

Choosing the right plywood for your workbench is essential for durability. High-quality plywood resists warping and cracking. Look for hardwood plywood like birch or maple for strength.

Thickness is very important for stability. At least ¾ inch thickness provides a solid surface. Thicker plywood can handle heavy loads without bending.

Consider a veneered plywood for a smooth finish. It helps in easy cleaning and maintenance. Use a laminated plywood for extra durability against wear and tear.

Types Of Plywood Suitable For Workbench Tops

Hardwood plywood is often the best choice for workbench tops. It is strong and durable. This type has a smooth surface, perfect for various projects. It resists scratches and dents well. The layers in hardwood plywood provide stability and strength.

Softwood plywood can also be a good fit for workbenches. It is lighter and easier to handle. This option is typically cheaper than hardwood. Softwood plywood works well for light-duty tasks. It may not last as long as hardwood but offers decent performance.

The Importance Of Plywood Grade

Choosing the right plywood grade is essential for a strong workbench top. Different grades indicate quality and durability. Higher grades have fewer defects and are more stable. For workbench projects, consider using Grade A or Grade B plywood. These grades provide a smooth surface and strong support.

Deciphering plywood grading can be simple. Grades range from AA to D. Grade A has the fewest defects, while Grade D has more visible flaws. It’s crucial to select a grade that meets your project needs.

| Grade | Characteristics |

|---|---|

| Grade A | Smooth, few defects, ideal for visible surfaces. |

| Grade B | Some defects, still good for sturdy projects. |

| Grade C | More visible flaws, suitable for utility use. |

| Grade D | Many defects, best for hidden areas. |

Plywood Core Options

Plywood core options play a key role in choosing a workbench top. Two popular types are veneer core and MDF core. Veneer core plywood has a strong structure. It consists of thin layers of wood glued together. This type is often lighter and less expensive.

MDF core plywood offers a smooth surface. It provides excellent stability and durability. This type is great for heavy use. It resists warping and is easy to work with.

The benefits of a combined core can be significant. A combined core uses both MDF and veneer layers. This results in a balanced mix of strength and smoothness. Such cores often yield better performance in various conditions.

Surface Treatments And Finishes

Sealing plywood is essential for durability. It protects the wood from moisture and stains. Choose a high-quality sealant for the best results. A good sealant can extend the life of your workbench top.

Applying protective coatings is also important. These coatings add a layer of protection against scratches and dents. Use a polyurethane finish for a strong barrier. This finish dries clear and enhances the wood’s natural beauty.

Always follow the manufacturer’s instructions for application. Apply multiple thin coats for the best protection. Allow each coat to dry completely before adding the next.

Size And Cut: Preparing Plywood For Assembly

For a perfect workbench top, size and cut are very important. Start with measuring the area where the workbench will sit. Use a straight edge and a sharp blade for clean cuts. This helps avoid splinters.

Here are some precision cutting tips:

- Always use a saw suitable for plywood.

- Keep the blade sharp for cleaner edges.

- Support the plywood on both sides while cutting.

Edge treatments add both aesthetics and function. Consider using banding to cover raw edges. This makes the plywood look neat. It also protects against moisture and wear.

Assembly Techniques For Plywood Workbenches

For a strong workbench top, use proper gluing and clamping methods. Apply a generous amount of wood glue between the plywood layers. Make sure to clamp the pieces tightly together. This helps create a solid bond.

After gluing, reinforce the top with hardware. Use corner brackets for added strength. These brackets help prevent warping and increase stability. Screws can also be used to secure the plywood layers. They provide extra support and durability.

Always check for any gaps after clamping. Fill them with glue or wood filler for a smooth finish. A well-assembled workbench will last longer and perform better in your projects.

Maintenance Tips For Plywood Workbench Tops

Choosing the right plywood for workbench tops ensures durability and functionality. Opt for a high-grade, thick plywood like birch or maple for better resistance to wear and tear. Regular maintenance, such as sealing and cleaning, can significantly extend the lifespan of your workbench surface.

Routine Cleaning Practices

Regularly clean your plywood workbench top. Use a damp cloth to remove dust. Avoid using harsh chemicals. They can damage the wood surface. For spills, wipe them up immediately. This helps prevent stains and warping.

Dealing With Wear And Tear

Check for scratches or dents often. Lightly sand these areas to smooth them out. Apply a wood conditioner to protect the surface. Refinish the top once a year to maintain its look.

Keep the workbench dry to prevent mold. Store tools properly to avoid scratches. A little care goes a long way in keeping your workbench top in great shape.

Cost Considerations

Choosing the right plywood for your workbench top affects costs. Balancing quality and budget is crucial. Premium plywood often costs more but offers better durability. It can last for many years without damage.

Lower-quality plywood may save money upfront. Yet, it might need replacement sooner. This leads to higher costs in the long run. Investing in premium plywood could save money over time.

| Type of Plywood | Initial Cost | Longevity |

|---|---|---|

| Premium Plywood | Higher | Long-lasting |

| Standard Plywood | Lower | Shorter lifespan |

Real-life Examples

Many woodworkers share their experiences with different types of plywood. Birch plywood stands out for its strength and smooth surface. It’s perfect for a workbench top. Maple plywood is another favorite. It offers great durability and a beautiful finish. Softwood plywood is often used too, as it is lightweight and easy to handle.

Community reviews highlight cost-effectiveness and availability as key factors. Many recommend using 3/4″ thickness for stability. Some users prefer laminated plywood for added durability. Baltic birch is praised for its uniformity and strength. It can withstand heavy tools and impacts.

| Plywood Type | Strength | Cost |

|---|---|---|

| Birch | High | Moderate |

| Maple | High | High |

| Softwood | Moderate | Low |

Frequently Asked Questions

What Type Of Plywood Is Best For A Workbench?

The best plywood for a workbench is typically birch or maple. These hardwood options offer durability and strength. They resist warping and scratching, making them ideal for heavy-duty tasks. Choose at least 3/4-inch thickness for added stability. Quality plywood ensures your workbench can withstand years of use.

Can I Use Mdf For A Workbench Top?

MDF can be used for a workbench top, but it has limitations. While it’s smooth and affordable, MDF is less durable than plywood. It can sag under heavy loads and absorbs moisture, leading to damage. If you choose MDF, consider adding a protective layer to enhance its lifespan.

How Thick Should Plywood Be For A Workbench?

Plywood thickness should ideally be at least 3/4 inch for a workbench. This thickness provides the necessary support for heavy tools and materials. Thicker plywood increases overall stability and reduces the risk of sagging. Always choose high-quality plywood to ensure maximum strength and longevity.

Is Plywood Waterproof For Outdoor Workbenches?

Standard plywood is not waterproof and can warp outdoors. However, you can use marine-grade plywood, designed for wet conditions. This type is treated to resist moisture and is more durable. Always apply a protective sealant to enhance its water resistance further, ensuring your workbench lasts longer outside.

Conclusion

Choosing the right plywood for your workbench top is crucial for durability and performance. Consider factors like thickness, type, and finish to meet your specific needs. A well-selected plywood can enhance your workspace significantly. Invest time in your choice, and enjoy a functional and reliable workbench for years to come.

![How to Adjust Laser on Chicago Electric Miter Saw? [A Step-By-Step Guide]](https://cdn.woodworkingadvisor.com/2023/01/How-to-Adjust-Laser-on-Chicago-Electric-Miter-Saw-_A-Step-By-Step-Guide_-768x384.webp)