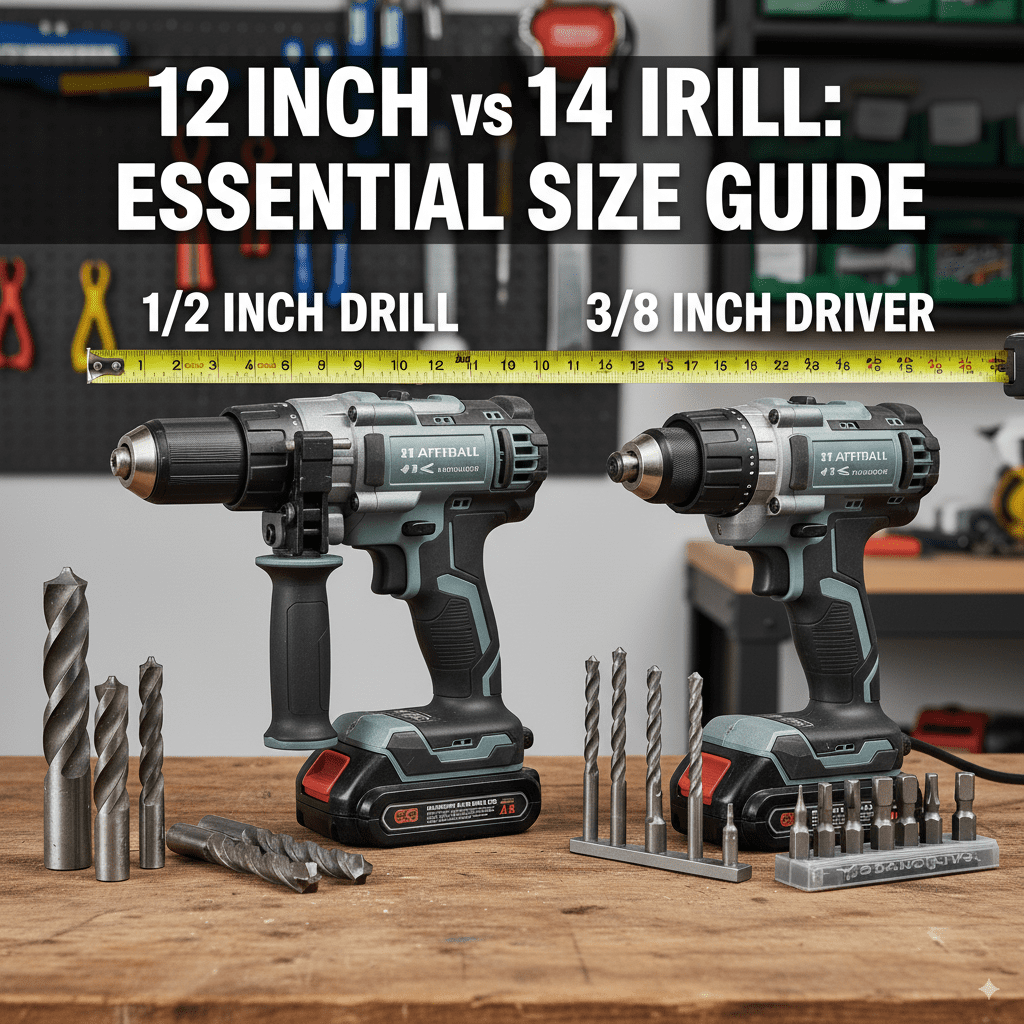

1 2 in vs 1 4 in Drill: Essential Guide

The main difference between a 1/2 inch and 1/4 inch drill lies in their chuck size, impacting the shank diameter of bits they can accept. A 1/2 inch drill is more powerful and versatile, ideal for larger bits and tougher jobs, while a 1/4 inch drill is lighter, simpler, and often geared towards smaller, more precise tasks.

Hello there, fellow makers and DIY lovers! Md Meraj here, ready to demystify another common question that pops up when starting out in woodworking or home improvement: wrestling with drill sizes. You’ve probably seen drills advertised or on job sites with terms like “1/2 inch” or “1/4 inch,” and maybe you’ve wondered what on earth they mean. It can feel a bit confusing when you’re just trying to get a hole drilled! Don’t worry, many beginners get stuck here, but it’s simpler than it sounds. I’m here to break down the difference between a 1/2 inch drill and a 1/4 inch drill in a way that makes perfect sense. We’ll cover what those numbers really mean, how to choose the right one for your projects, and why it matters. Let’s get drilling!

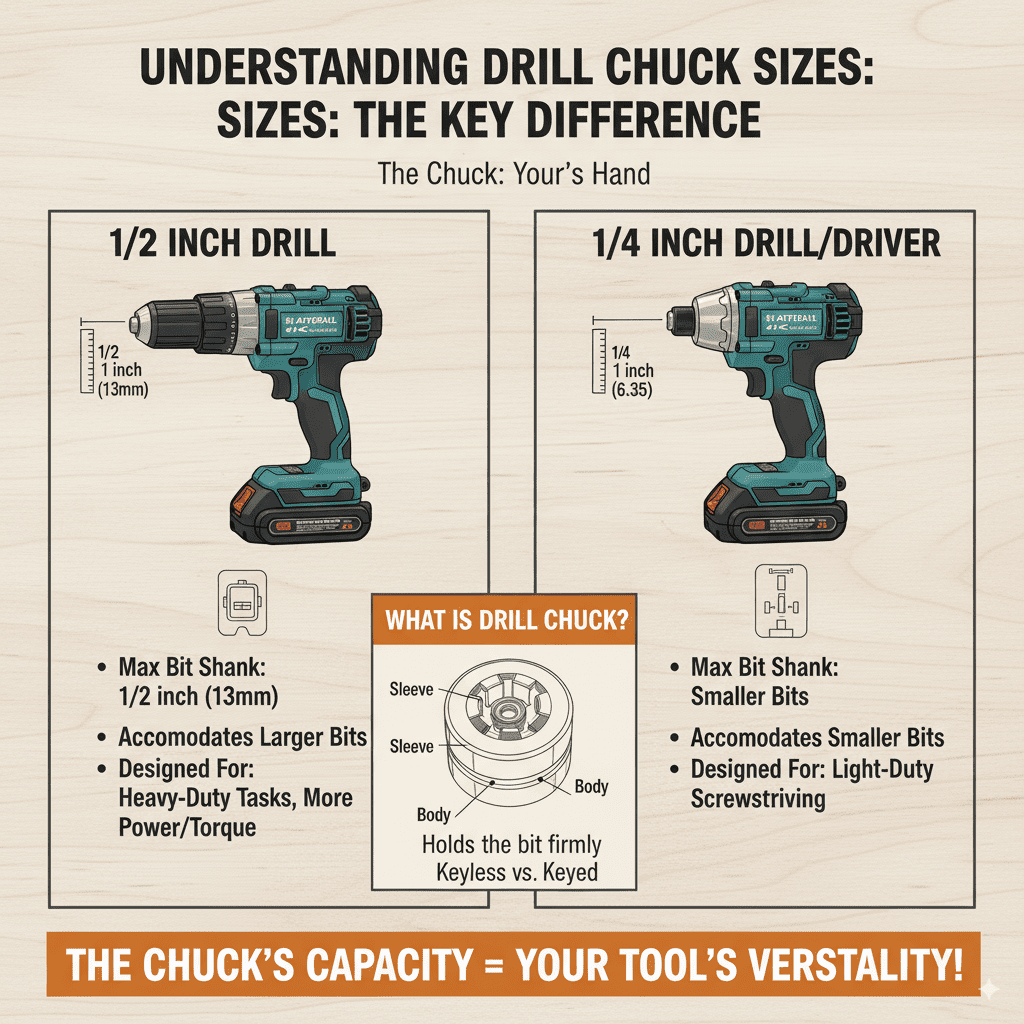

Understanding Drill Chuck Sizes: The Key Difference

When we talk about a “1/2 inch drill” or a “1/4 inch drill,” we’re not talking about the size of the hole it drills, but rather the maximum diameter of the drill bit shank that its chuck can securely hold. Think of the chuck as the drill’s “hand” that grips the drill bit. This is the most fundamental distinction and dictates the range of bits you can use with a particular drill.

What is a Drill Chuck?

The chuck is the part of the drill that tightens around the drill bit. Most modern drills use a keyless chuck, meaning you can tighten or loosen it by hand. Older or more heavy-duty drills might use a keyed chuck, which requires a special chuck key to tighten and loosen. Regardless of the type, the chuck’s capacity is measured by the largest diameter shank it can grip firmly.

1/4 Inch Drills: Compact and Capable

A drill with a 1/4 inch chuck is typically designed for smaller, lighter-duty tasks. These drills often have a smaller motor and are more lightweight, making them easy to handle for extended periods. They are perfect for drilling small pilot holes, driving screws, or using with small drill bits for delicate materials like thin plastic or soft wood. You’ll often find these in cordless versions, offering great portability.

1/2 Inch Drills: Power and Versatility

A drill with a 1/2 inch chuck is generally built for more demanding jobs. The larger chuck capacity means it can accommodate thicker drill bits, which are necessary for drilling larger holes or working with harder materials like dense hardwoods, concrete, or metal. These drills usually pack more power and torque, making them suitable for tasks that require significant force, such as mixing paint or drilling through tough surfaces.

1/2 in vs 1/4 in Drill: Direct Comparison

To make things even clearer, let’s put the two side-by-side. This table highlights the primary differences you’ll notice between a 1/4 inch and a 1/2 inch drill, helping you visualize their roles in your toolkit.

| Feature | 1/4 Inch Drill | 1/2 Inch Drill |

|---|---|---|

| Chuck Size Capacity | Maximum 1/4″ (6.35mm) bit shank diameter | Maximum 1/2″ (12.7mm) bit shank diameter |

| Typical Use Cases | Small pilot holes, screw driving, light-duty drilling in soft materials, intricate work. | Larger holes, drilling in dense hardwoods, metal, concrete (with hammer function), mixing paint/thin-set mortar. |

| Power & Torque | Generally lower power, suitable for less demanding tasks. | Higher power and torque, designed for tougher jobs. |

| Size & Weight | Often smaller, lighter, and more maneuverable. | Typically larger, heavier, and more robust. |

| Drill Bit Compatibility | Limited to bits with shanks up to 1/4 inch. | Can accept a wider range of bits, including those with larger hex or round shanks up to 1/2 inch. |

| Versatility | More specialized for smaller tasks. | More versatile, capable of handling a broader spectrum of DIY and professional applications. |

| Cost | Often more affordable. | Can be more expensive due to higher power and build quality. |

When to Choose a 1/4 Inch Drill

If your DIY projects mostly involve assembling furniture, hanging light decorations, drilling pilot holes for small screws, or working with thin sheet goods, a 1/4 inch drill is likely all you’ll need. Its compact size makes it incredibly user-friendly, especially for beginners who might feel intimidated by larger, heavier tools. Cordless 1/4 inch drills are particularly popular for their convenience and portability around the house and yard.

When to Choose a 1/2 Inch Drill

For the more ambitious DIYer or homeowner who plans to tackle a variety of tasks, a 1/2 inch drill is a worthwhile investment. This is the go-to for drilling larger holes in wood, metal, or masonry (especially if it has a hammer drill function). If you envision yourself building shelves, decks, fences, or even doing minor renovations, the extra power and capability of a 1/2 inch drill will serve you well. It’s the workhorse that can handle just about anything you throw at it.

Drill Bit Shanks: The Connection

Understanding drill bit shanks is crucial when discussing chuck sizes. The shank is the part of the drill bit that fits into the drill chuck. They come in various shapes and sizes, but the most common for general use with 1/4″ and 1/2″ drills are:

- Straight Shanks: These are cylindrical and are the most common type. They can be round or have reduced diameters for better grip. A 1/4 inch drill can usually accept straight shanks up to 1/4 inch. A 1/2 inch drill can accept straight shanks up to 1/2 inch.

- Hex Shanks: These have a hexagonal shape, which provides excellent grip and prevents slippage, especially in impact drivers or high-torque drills. You’ll find 1/4 inch hex shank bits commonly used for driving screws and in smaller drills. 1/2 inch drills can also accept 1/4 inch hex shank bits, but their primary advantage comes with larger bits that might also have hex shanks up to 1/2 inch.

It’s important to match your drill bit shank to your drill’s chuck capacity. Trying to force a bit with a shank larger than your chuck can handle will not work and could damage both the bit and the drill.

Beyond the Chuck: Other Factors to Consider

While chuck size is the primary differentiator between “1/4 inch” and “1/2 inch” drills, other features can influence your choice and the drill’s performance. These are worth considering as you shop for your perfect tool.

Power Source: Corded vs. Cordless

Both 1/4 inch and 1/2 inch drills come in corded and cordless (battery-powered) versions.

- Cordless Drills: Offer unparalleled portability and convenience, ideal for working around the house or in areas without easy access to power outlets. Battery life and charging time are key considerations here. Modern lithium-ion batteries are powerful and long-lasting.

- Corded Drills: Provide consistent, unlimited power and are often more budget-friendly than their cordless counterparts. They are excellent for prolonged use or heavy-duty applications where constant power is essential. However, they restrict your movement due to the power cord.

You’ll find many compact, lightweight 1/4 inch drills as cordless models, while more powerful 1/2 inch drills are available in both corded and cordless options.

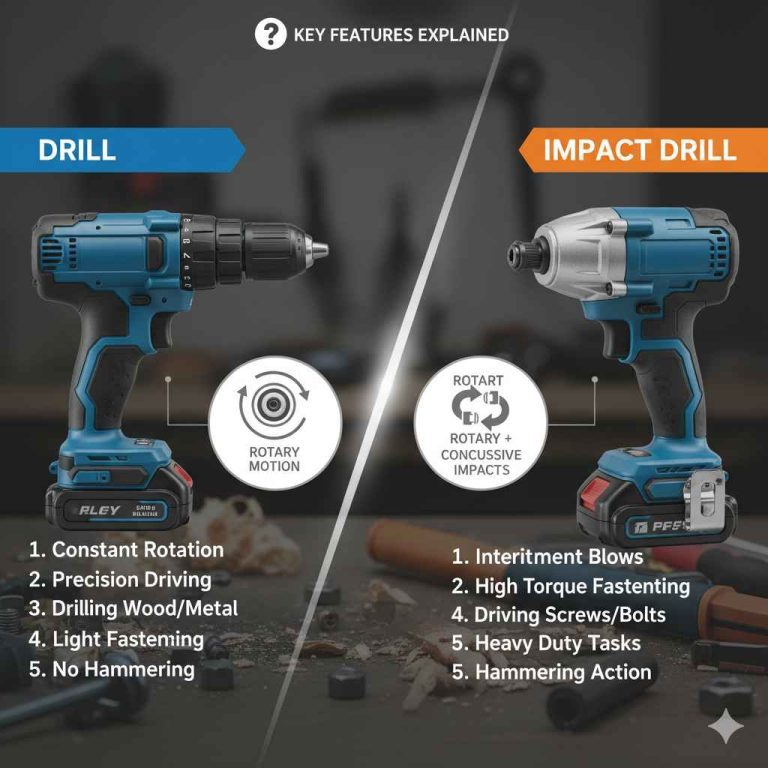

Drill Type: Standard, Hammer, or Impact

The type of drill also plays a role in its application:

- Standard Drill/Driver: The most common type, designed for drilling holes and driving screws.

- Hammer Drill: Combines drilling with a hammering action, making it effective for drilling into concrete, brick, and masonry. A 1/2 inch drill often features a hammer function for this purpose.

- Impact Driver: Primarily designed for driving screws, especially longer or thicker ones, and faster than a standard drill. They deliver rapid rotational and percussive blows. While not strictly related to chuck size, they are often found in similar DIY toolkits.

Motor Brushes: Brushed vs. Brushless

This refers to two different types of electric motors:

- Brushed Motors: The traditional standard for power tools. They are reliable but can wear out over time as the carbon brushes need replacement.

- Brushless Motors: A newer technology offering several advantages, including increased efficiency, longer tool life, more power, and better battery runtimes. Many higher-end cordless drills, including both 1/4″ and 1/2″ models, now feature brushless motors.

For more information on the benefits of brushless motors and other tool technologies, resources like The U.S. Department of Energy’s guide to electric motors offer valuable technical insights, though we’ll keep our discussion here focused on practical application.

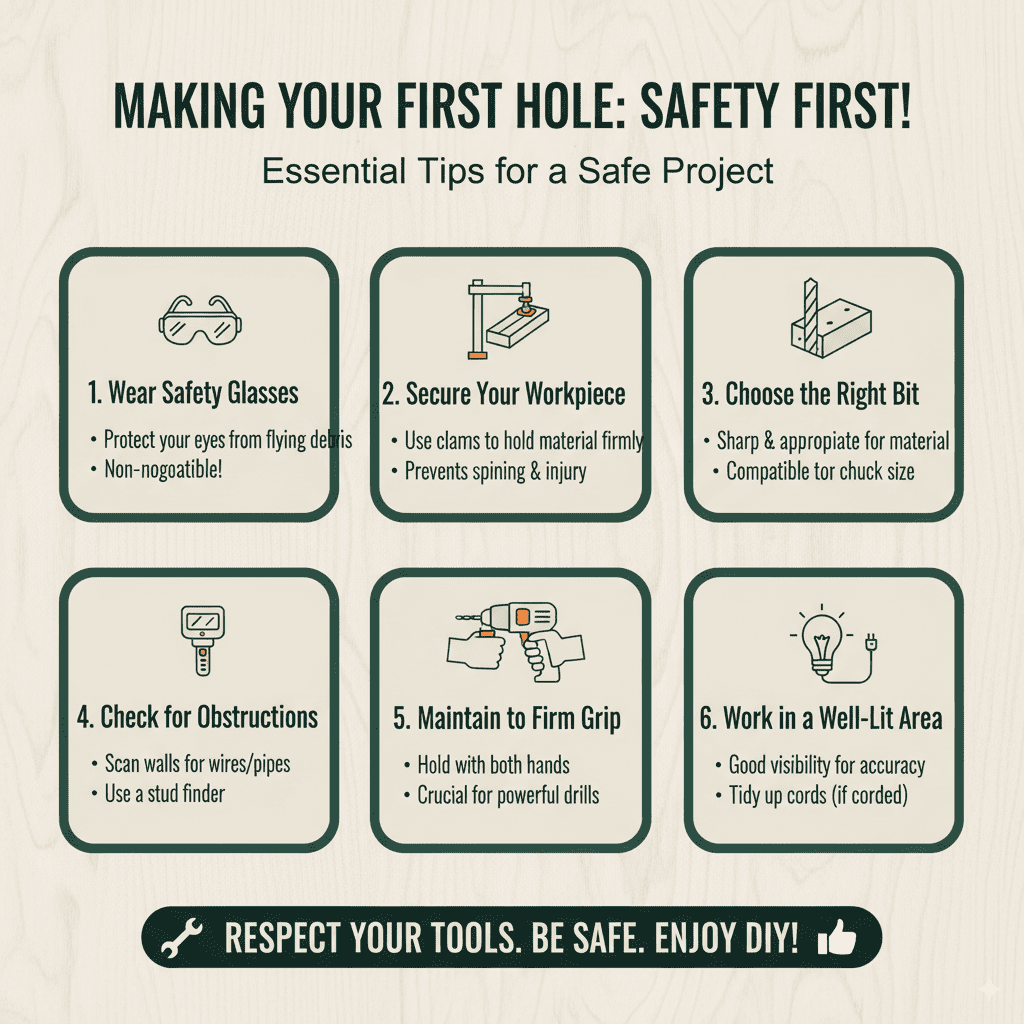

Making Your First Hole: Safety First!

Before you even pick up your drill, safety is paramount. Woodworking and DIY projects should always be fun and rewarding, and that means prioritizing your well-being. Here are some essential safety tips, applicable whether you’re using a 1/4 inch or a 1/2 inch drill:

- Wear Safety Glasses: Always protect your eyes from flying debris, dust, or splinters. This is non-negotiable!

- Secure Your Workpiece: Use clamps to hold your material firmly in place. This prevents the material from spinning with the drill bit and potentially causing injury or a ruined project.

- Choose the Right Drill Bit: Ensure your drill bit is sharp, appropriate for the material you’re drilling, and compatible with your drill’s chuck size.

- Check for Obstructions: Before drilling into walls or existing structures, ensure there are no hidden electrical wires or pipes. A stud finder with a wire/pipe detection feature can be invaluable.

- Maintain a Firm Grip: Hold the drill with both hands, especially when using a more powerful 1/2 inch drill or drilling larger holes.

- Keep Cords Tidy (if corded): Ensure power cords are out of the way to prevent tripping hazards.

- Work in a Well-Lit Area: Good visibility is crucial for accuracy and safety.

FAQ: Your Beginner Drill Questions Answered

Here are some common questions beginner woodworkers and DIYers have about 1/4 inch and 1/2 inch drills:

Q1: Can I use a 1/4 inch drill bit in a 1/2 inch drill?

A: Absolutely! This is one of the great advantages of a 1/2 inch drill. Its larger chuck capacity allows it to securely grip drill bits with shanks up to 1/2 inch, which includes all smaller sizes, like 1/4 inch bits (both straight and hex shank). You’ll have no problem using your smaller bits with a larger drill.

Q2: Will a 1/4 inch drill handle drilling through hardwood?

A: It depends on the hardwood and the size of the hole. For very small pilot holes or shallow holes in moderately hard woods, a 1/4 inch drill might suffice, especially if it has decent power. However, for deeper holes, larger diameters, or very dense hardwoods (like oak or maple), a 1/2 inch drill with more torque will make the job significantly easier and faster, and less likely to overheat the drill.

Q3: What is the difference between a drill itself and the drill chuck?

A: The drill is the entire tool – the motor, the housing, the trigger, the battery (if cordless), and the chuck. The chuck is a specific component of the drill, located at the front end, which is designed to securely hold the drill bit. The chuck’s opening size is what determines its capacity (e.g., 1/4 inch or 1/2 inch).

Q4: Is a 1/2 inch drill always more powerful than a 1/4 inch drill?

A: Generally, yes. The 1/2 inch chuck denotes a tool built for more substantial tasks, which usually requires a more powerful motor. However, there can be exceptions. A high-end cordless 1/4 inch drill with a brushless motor might outperform a very basic, older, corded 1/4 inch drill. But when comparing comparable quality levels, the 1/2 inch drill will typically have more power and torque.

Q5: When should I consider a hammer drill function?

A: A hammer drill function is essential if you plan to drill into hard materials like concrete, brick, or stone. The added hammering action helps to break up the material, making drilling much faster and more efficient. Most 1/2 inch drills that are aimed at general construction or renovation tasks will include this feature. For purely woodworking or light drilling, it’s usually not necessary.

Q6: Can I use a 1/2 inch drill bit in a 1/4 inch drill?

A: No, you cannot. A 1/4 inch drill’s chuck is only designed to grip drill bits with shanks up to 1/4 inch in diameter. A 1/2 inch drill bit simply will not fit securely and safely into a 1/4 inch chuck, and attempting to force it would likely cause damage.

Q7: Which drill size is better for a beginner homeowner?

A: For most homeowners who have basic tasks like hanging shelves, assembling flat-pack furniture, and general light repairs, a good quality 1/4 inch cordless drill is an excellent starting point. It’s easy to handle, lightweight, and very versatile for everyday needs. If you anticipate doing more involved projects like building decks, fences, or doing more significant home renovations, then investing in a 1/2 inch drill from the start would be more beneficial.

Choosing Your First Drill: A Practical Approach

As you can see, the choice between a 1/4 inch and a 1/2 inch drill isn’t about one being “better” than the other; it’s about choosing the right tool for the job and your specific needs. Think about the projects you want to accomplish now and in the near future.

- For the absolute beginner tackling simple tasks: A compact, lightweight 1/4 inch cordless drill is probably your best bet. It’s less intimidating, easy to use, and sufficient for a wide range of household needs.

- For the homeowner or hobbyist looking to grow: A 1/2 inch drill, especially a cordless model with good torque and perhaps a hammer function, offers much greater versatility. It will handle more demanding jobs and grow with your skills.

Don’t feel pressured to buy the biggest or most powerful tool right away. Start with what you need, and you can always expand your toolkit later. Many brands offer great value packs that include batteries and chargers, making it more affordable to get started with a quality tool. Remember to check out reputable tool retailers and read reviews to find a drill that offers a good balance of performance, durability, and price for your budget. For instance, resources from organizations like Popular Mechanics often provide up-to-date reviews and comparisons of various drill models that can help guide your decision.

Conclusion

So, there you have it! The mystery of the 1/2 inch versus 1/4 inch drill is solved. It all boils down to the chuck size, which dictates the diameter of the drill bit shank the tool can accept. The 1/4 inch drill is your handy companion for lighter tasks and precision work, while the 1/2 inch drill is the robust workhorse ready for bigger challenges. By understanding these differences, considering factors like power source and drill type, and always prioritizing safety, you’re well on your way to making informed decisions for your DIY projects. Happy building, and remember, the most important tool you have is your willingness to learn and create!