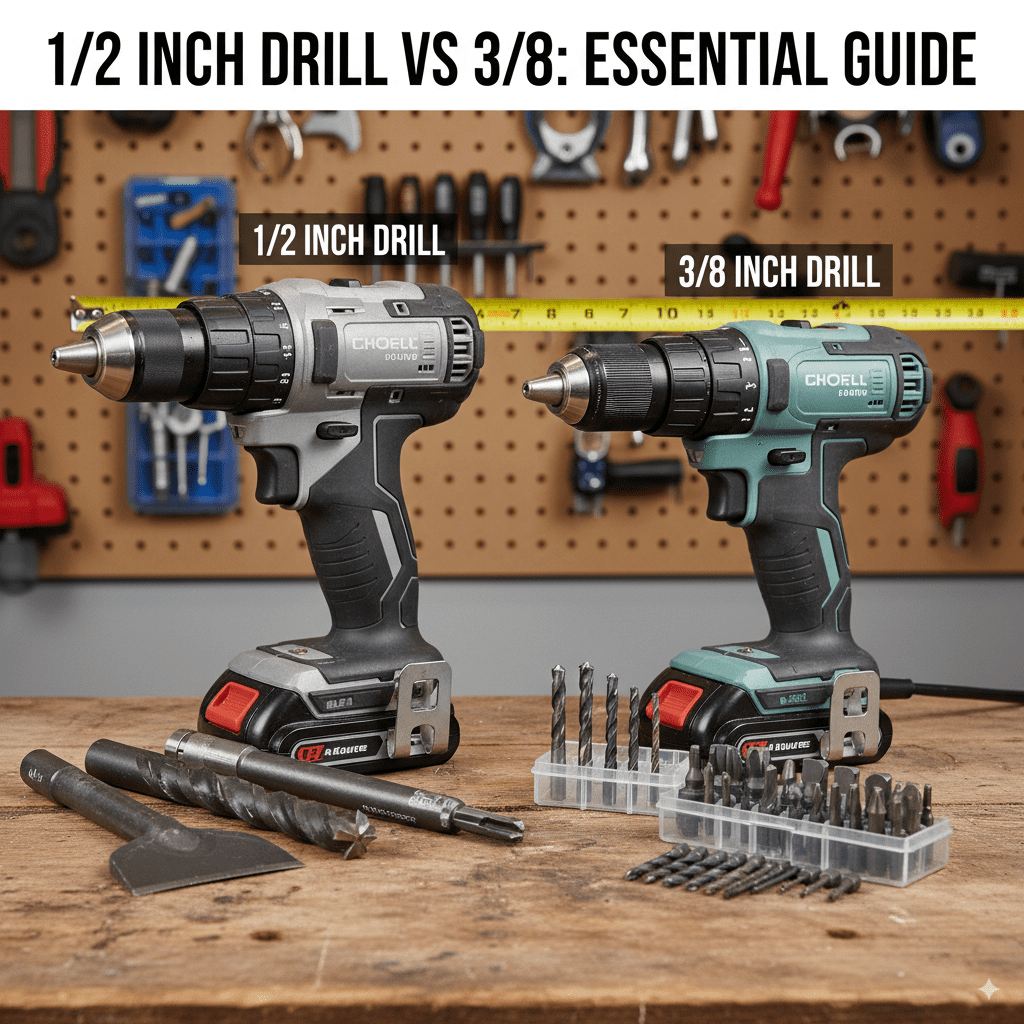

1/2 Inch Drill Vs 3/8: Essential Guide

Choosing between a 1/2 inch drill vs 3/8 inch drill chuck is straightforward for beginners. For general DIY, home repairs, and most smaller projects, a 3/8 inch drill is lighter, more affordable, and perfectly capable. A 1/2 inch drill is overkill for beginners but offers more power and versatility for heavy-duty tasks and larger bits down the road.

Hey there, woodworking pals! Md Meraj here, your go-to guy for making DIY projects a breeze. Ever stand in the tool aisle, scratching your head between a 3/8 inch drill and a 1/2 inch drill? It’s a common question, and honestly, it can feel a bit overwhelming when you’re just starting out. You want to pick the right tool for the job without breaking the bank or buying something you’ll never use. Don’t you worry! We’re going to break down the differences in a way that makes perfect sense, so you can walk away feeling confident about your choice. We’ll explore what each drill is best for, so you can get back to building and creating!

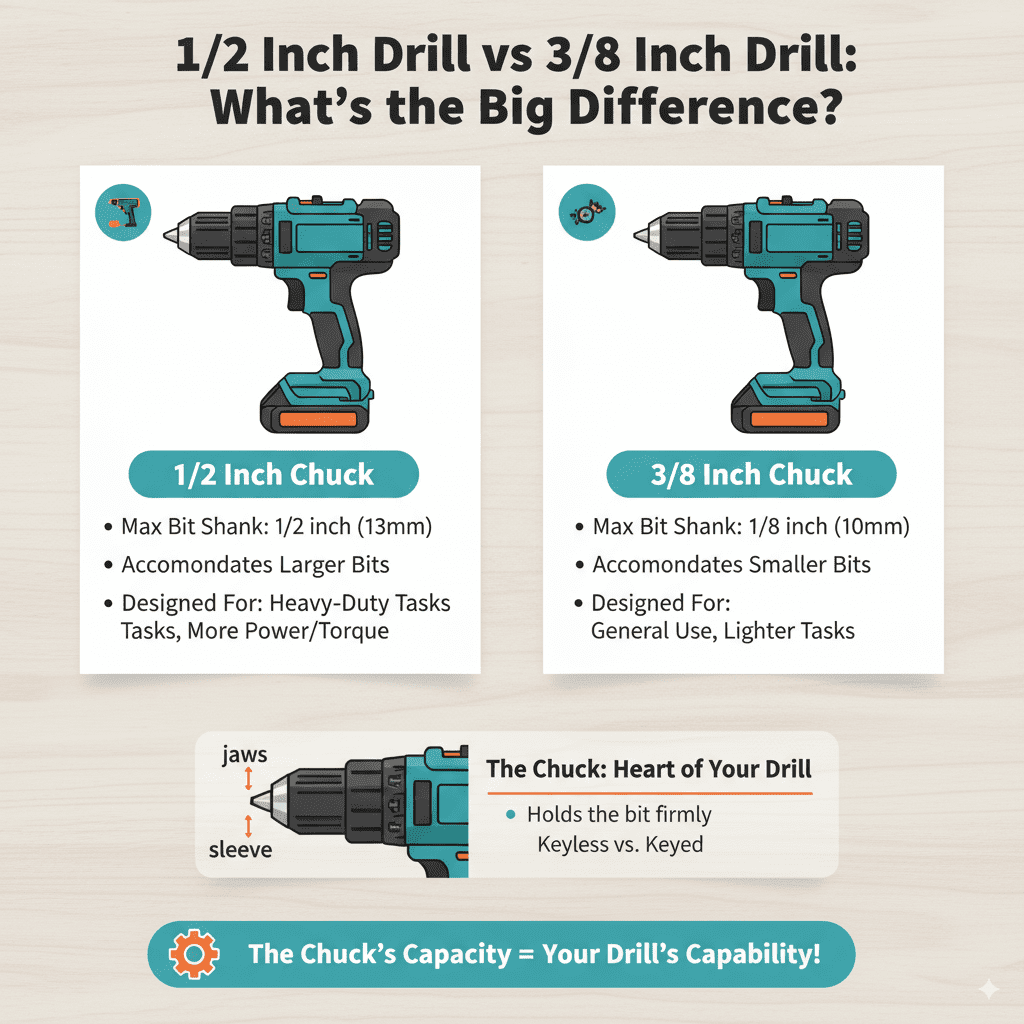

1/2 Inch Drill vs 3/8 Inch Drill: What’s the Big Difference?

At its core, the “1/2 inch” or “3/8 inch” in a drill’s name refers to the maximum diameter of the drill bit shank (the part that inserts into the drill’s chuck) that it can securely hold. Think of the chuck as the drill’s “hand” – it needs to be able to grip the bit firmly.

So, a 3/8 inch drill can hold drill bits with shanks up to 3/8 of an inch in diameter, and a 1/2 inch drill does the same for bits up to 1/2 inch in diameter. This might seem like a small distinction, but it hints at the power and intended use of each drill.

Understanding Drill Chuck Sizes

The chuck is the part of the drill that clamps down on the drill bit. It’s usually adjustable, allowing you to insert different sizes of drill bits.

- 3/8 Inch Chucks: These are the most common size for general-purpose drills. They can accommodate most standard drill bits used for wood, metal, and plastic.

- 1/2 Inch Chucks: These are typically found on more powerful, heavy-duty drills. They can hold larger diameter drill bits, which are often used for more demanding tasks.

The Practical Impact for Beginners

For most DIYers and homeowners tackling projects like hanging shelves, assembling furniture, drilling pilot holes for screws, or even basic woodworking, a 3/8 inch drill is more than sufficient. They are:

- Lighter and More Maneuverable: Easier to handle for extended periods.

- More Affordable: Typically cost less than their 1/2 inch counterparts.

- Adequate for Most Tasks: They handle the vast majority of everyday drilling needs.

A 1/2 inch drill, while capable of handling larger bits, might be heavier and more expensive. For beginners, the extra capacity and power often go unused, making the 3/8 inch drill the smarter, more economical choice.

When is a 3/8 Inch Drill the Right Choice?

Let’s be honest, for the vast majority of your DIY adventures around the house, a 3/8 inch drill will be your trusty sidekick. If your projects typically involve:

- Assembling flat-pack furniture.

- Hanging pictures, mirrors, or shelves.

- Drilling pilot holes for screws in wood.

- Working with materials like drywall, plaster, or softer woods.

- Basic repairs and maintenance around the home.

…then a 3/8 inch drill is likely all you’ll ever need. Think of it as your reliable everyday driver for your toolbox.

Pros of a 3/8 Inch Drill

Here’s why a 3/8 inch drill is a fantastic starting point:

- Cost-Effective: You’ll spend less upfront, leaving more budget for other tools or project materials.

- Lightweight and Ergonomic: Easier to hold and control, especially when working in tight spaces or overhead.

- Wide Availability of Bits: Most common drill bit sizes are designed for 3/8 inch chucks.

- Perfectly Sufficient Power: Delivers enough power for typical household tasks.

Cons of a 3/8 Inch Drill

While great for most, there are a few limitations:

- Cannot accept large-diameter bits: For very large holes (like those needed for running conduit or large-diameter dowels), you might need a larger bit that won’t fit.

- Less power for heavy-duty tasks: If you plan on drilling through thick, dense hardwoods or frequently drilling into masonry, it might struggle.

When is a 1/2 Inch Drill the Right Choice?

A 1/2 inch drill starts to shine when your projects get a bit more demanding or when you anticipate needing to drill larger holes. If you find yourself:

- Frequently drilling through thick pieces of hardwood.

- Using large-diameter drill bits (e.g., spade bits larger than 1 inch, or hole saws for larger openings).

- Working with dense materials like concrete or stone (though a hammer drill is often better for this).

- Undertaking more ambitious woodworking projects or construction tasks.

- Needing the versatility to handle a wider range of bit sizes for future projects.

Then, a 1/2 inch drill might be a worthwhile investment. It’s like upgrading from a sedan to a more powerful SUV – it can handle tougher terrain and bigger loads.

Pros of a 1/2 Inch Drill

Here’s the appeal of stepping up to a 1/2 inch drill:

- Accommodates Larger Bits: The primary advantage is the ability to use large-diameter twist bits, spade bits, and hole saws. This is crucial for tasks like drilling large-diameter holes for plumbing, electrical, or structural purposes.

- More Power and Torque: Generally, 1/2 inch drills have more powerful motors, providing greater torque. This is essential when drilling into dense materials or when the drill bit is under significant load. This extra power helps prevent the drill from bogging down.

- Increased Versatility: You gain the capability to tackle a wider range of projects that simply aren’t feasible with a 3/8 inch drill.

- Often More Durable: Higher-end 1/2 inch drills are typically built with more robust components for heavy-duty use.

Cons of a 1/2 Inch Drill

However, there are trade-offs:

- Heavier and Bulkier: They are typically larger and weigh more, which can lead to fatigue during prolonged use or in awkward positions.

- More Expensive: The initial cost is usually higher than for a comparable 3/8 inch model.

- Overkill for Beginners: For many common tasks, the extra power and chuck size are unnecessary.

- Larger Bits are More Expensive: Drill bits designed for 1/2 inch chucks, especially larger ones, can be considerably more costly.

Key Features to Consider (Beyond Chuck Size)

While chuck size is a big differentiator, it’s not the only thing that matters when choosing a drill. Here are other important features to keep in mind:

Power Source: Corded vs. Cordless

This is a major decision that impacts portability and power.

- Cordless Drills: Offer ultimate freedom and portability. They run on rechargeable batteries, making them perfect for working anywhere, from the backyard shop to a job site. Battery voltage (e.g., 12V, 18V, 20V) is a good indicator of power, with higher voltages generally meaning more strength.

- Corded Drills: Plug into a wall outlet, providing consistent, unlimited power. They are usually lighter than their cordless counterparts and don’t require charging. However, they are tethered by a cord, limiting where you can work. They are excellent for stationary tasks or when you need sustained power without worrying about battery life.

Motor Type: Brushed vs. Brushless

This affects efficiency, lifespan, and performance.

- Brushed Motors: The traditional motor type. They are reliable and less expensive but can generate more heat and are less energy-efficient.

- Brushless Motors: More advanced and efficient. They offer longer runtimes, more power, and a longer lifespan because they have fewer moving parts that wear out. Many modern cordless drills feature brushless technology.

Speed Settings and Torque Control

Most drills offer variable speed settings, allowing you to control how fast the bit spins. Higher speeds are great for drilling clean holes, while lower speeds are better for slowly driving screws. Torque control (often indicated by numbered clutches) lets you set the maximum rotational force, preventing over-tightening screws and stripping them or damaging the material.

Impact Function (for Hammer Drills)

Some drills, particularly 1/2 inch models, have an “impact” or “hammer” function. This adds a percussive action to the rotation, making them very effective for drilling into hard materials like brick, stone, or concrete. If you plan on doing any masonry work regularly, a hammer drill is a must-have, and these are almost always 1/2 inch chuck size.

Ergonomics and Weight

Consider how the drill feels in your hand. A comfortable grip and balanced weight distribution are crucial, especially for longer work sessions or when reaching awkward spots. This is where a lighter 3/8 inch drill often has an advantage for general users.

1/2 Inch Drill vs 3/8 Inch Drill: Feature Comparison Table

To make it even clearer, let’s look at a side-by-side comparison:

| Feature | 3/8 Inch Drill | 1/2 Inch Drill |

|---|---|---|

| Max Drill Bit Shank Diameter | 3/8 inch (9.5 mm) | 1/2 inch (12.7 mm) |

| Typical Use Cases | General DIY, home repairs, furniture assembly, light woodworking, pilot holes. | Heavy-duty tasks, large diameter holes, dense hardwoods, construction, occasional masonry (if hammer drill). |

| Power/Torque | Sufficient for most common tasks. | Generally higher power and torque for tougher jobs. |

| Weight & Size | Lighter, more compact, easier to handle. | Heavier, bulkier, can be more fatiguing. |

| Cost | More affordable. | More expensive. |

| Bit Availability | Excellent for standard bit sizes. | Accommodates a wider range, including very large bits. |

| Impact Function? | Rarely found, usually on specialized models. | Commonly available, especially on heavier-duty models. |

Drill Bit Compatibility: Important Notes

It’s not just about the chuck size; it’s about the specific drill bit you’re using. Modern drill bits come with different shank types:

- Round Shanks: The most common type, found on standard twist bits. These are what the chuck grips directly.

- Hex Shanks: Often found on professional-grade drill bits, especially those designed for impact drivers or for better grip in impact wrenches. They have a hexagonal shape to prevent slipping. All modern drill chucks will grip hex shanks, but using a hex shank bit in a standard drill is fine.

- SDS Shanks: Specifically designed for SDS hammer drills, these have slots that lock into the chuck, allowing for efficient power transfer during hammering. You cannot use SDS bits in a standard 3/8 or 1/2 inch chuck.

Remember, a 1/2 inch drill can hold smaller bits, including those designed for 3/8 inch chucks. The chuck is adjustable to accommodate a range of sizes up to its maximum capacity. It’s the opposite that isn’t true – a 3/8 inch drill simply cannot physically accept a drill bit with a shank diameter larger than 3/8 inch.

For a deeper dive into drill bits themselves, you can find excellent resources on the Occupational Safety and Health Administration (OSHA) website concerning power tool safety and proper usage.

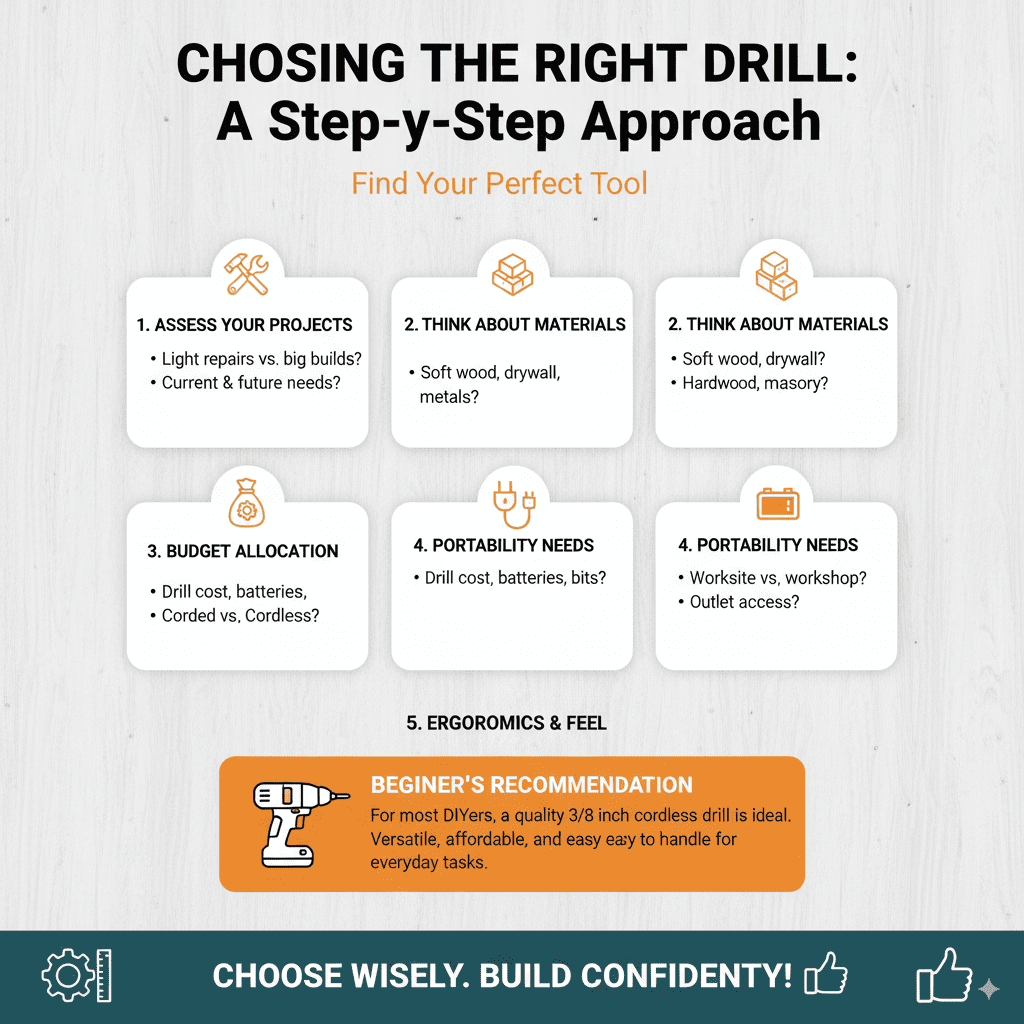

Choosing the Right Drill: A Step-by-Step Approach

Still feeling a little unsure? Let’s walk through the decision process together:

- Assess Your Typical Projects: Be honest with yourself. What do you actually do with a drill most often? Light repairs, assembly, or bigger builds?

- Consider Future Projects: Are you planning on taking on more ambitious woodworking or construction projects in the next year or two? If yes, a 1/2 inch might offer better longevity.

- Think About Materials: Will you be drilling mostly into softwoods, drywall, or thin metal, or do you anticipate working with hardwoods, dense plastics, or even masonry?

- Budget Allocation: How much can you comfortably spend? Remember to factor in the cost of batteries and chargers for cordless models, and potentially more expensive larger drill bits if you go the 1/2 inch route.

- Portability Needs: Do you need to work far from a power outlet, or will you always be near one? This will heavily influence your corded vs. cordless decision.

- Ergonomics: If possible, try holding both types of drills. See which feels more comfortable and balanced for your hands.

Beginner’s Recommendation

For anyone just starting their DIY journey, 9 times out of 10, a good quality 3/8 inch cordless drill is the way to go. It’s versatile, affordable, and easy to handle. Most people find they can accomplish everything they need with a 3/8 inch drill for years.

If you know you’re going to be doing a lot of heavy-duty work, or if you’re the type of person who likes to have the “best tool for the job” even if it’s more than you need right now, then a 1/2 inch drill is a solid choice. It’s an investment that provides flexibility for bigger jobs.

Frequently Asked Questions (FAQ)

Q1: Can a 3/8 inch drill handle all common drill bits?

Yes, a 3/8 inch drill can comfortably hold and use most standard drill bits commonly found in home improvement stores, up to 3/8 inch in shank diameter. This covers the vast majority of tasks for DIYers.

Q2: Is a 1/2 inch drill too powerful for a beginner?

It’s not necessarily “too powerful,” but it might be more than you need and can be heavier to handle. For simple tasks, a 3/8 inch drill is often easier to manage and more cost-effective.

Q3: What is the difference between a drill and a hammer drill?

A hammer drill has two modes: standard drilling and a hammering action that delivers rapid blows along with rotation. This is ideal for drilling into hard materials like concrete or masonry. Standard drills (both 3/8 and 1/2 inch) do not have this hammering function.

Q4: Do I need a 1/2 inch drill if I want to use large hole saws?

If you plan to use hole saws larger than 1-1/4 inches to 1-1/2 inches in diameter, a 1/2 inch drill is highly recommended due to the increased torque and leverage required. Smaller hole saws can often be used with a powerful 3/8 inch drill.

Q5: Are brushless motors better than brushed motors in drills?

Yes, generally. Brushless motors are more efficient, provide longer battery life, generate less heat, and have a longer lifespan compared to brushed motors. They are a key feature in many high-performance cordless tools.

Q6: Can I use a 1/2 inch cordless drill for driving screws?

Yes, you can. Most 1/2 inch drills have variable speed and torque settings, allowing them to be used effectively for driving screws. However, their size and weight can make them less ideal for this task compared to a dedicated impact driver or a lighter drill.