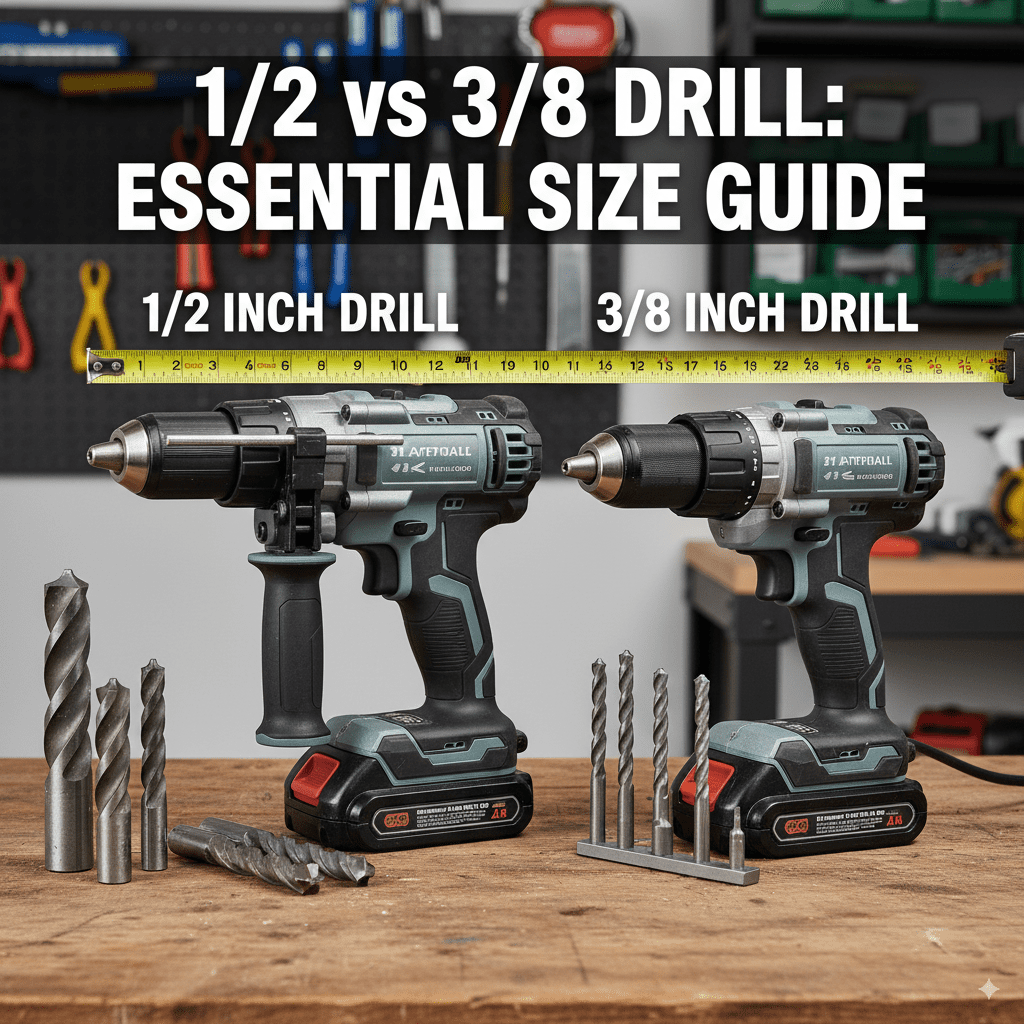

1/2 vs 3/8 Drill: Essential Size Guide

Choosing between a 1/2-inch and a 3/8-inch drill is about matching the right tool size to your project needs. The 3/8-inch drill is lighter and more versatile for general DIY tasks, while the 1/2-inch drill offers more power and torque for demanding jobs. Understanding their differences ensures you pick the best drill for better results and easier work.

Welcome to the workshop! Ever stood in front of a drill aisle, or even just looked at your current drill, and wondered about these numbers like “1/2” and “3/8”? It’s a common question for anyone starting out in woodworking or tackling home improvement projects. You want the right tool for the job, but these measurements can seem a little confusing. Don’t worry, it’s simpler than you think! This guide will break down what these drill sizes mean, how they differ, and most importantly, help you decide which one is perfect for your projects. We’ll make sure you feel confident choosing the right drill for a smooth and successful DIY experience.

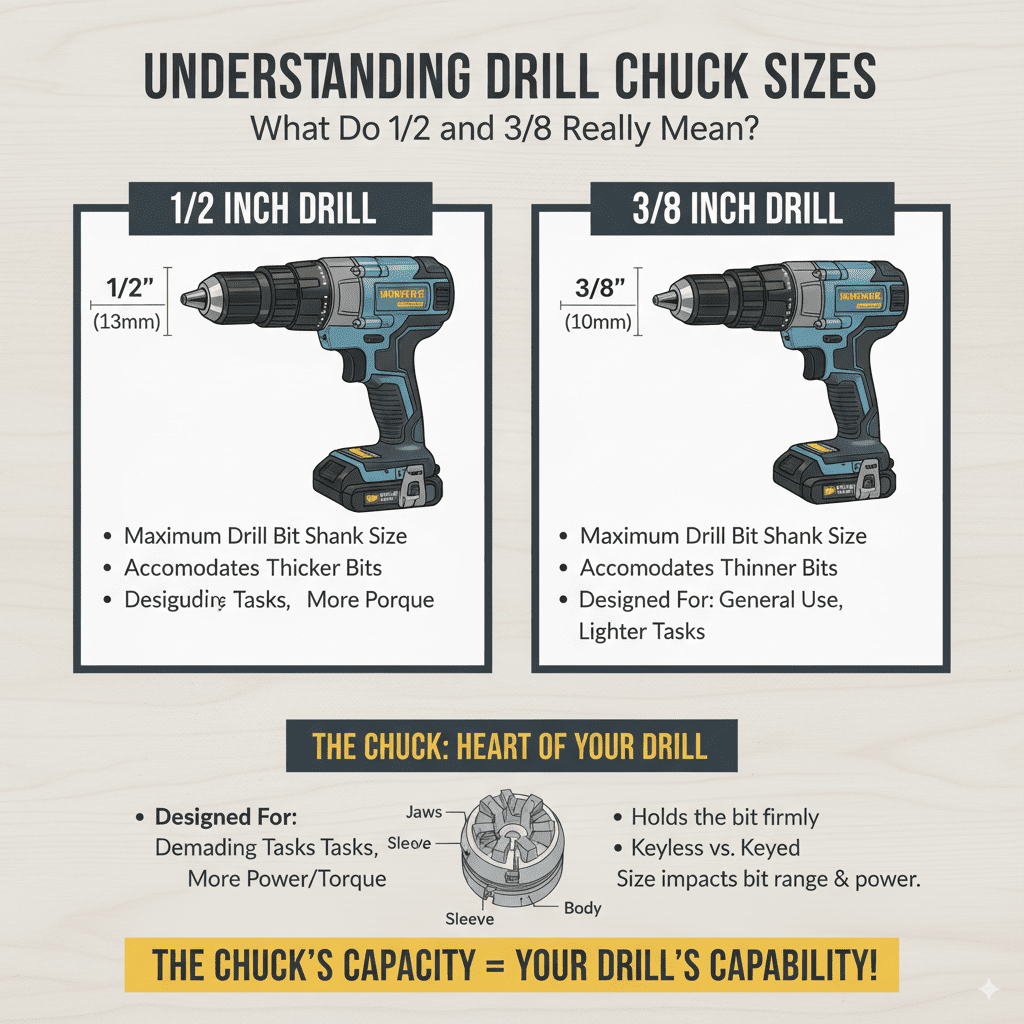

Understanding Drill Chuck Sizes: What Do 1/2 and 3/8 Really Mean?

When we talk about a “1/2 drill” or a “3/8 drill,” we’re actually referring to the maximum size of the drill bit shank that the drill’s chuck can securely hold. The chuck is that part at the front of the drill that tightens around the drill bit. So, a 3/8-inch drill has a chuck that can grip drill bit shanks up to 3/8 of an inch in diameter. Similarly, a 1/2-inch drill can accommodate shanks up to 1/2 inch in diameter.

Think of it like this: the chuck is the drill’s hand. A 3/8-inch hand can grip anything up to 3/8 of an inch wide. A 1/2-inch hand can grip anything up to 1/2 inch wide. This difference might seem small, but it has a big impact on the drill’s capabilities.

The Chuck: The Heart of Your Drill

The chuck is a crucial component. Its primary job is to hold the drill bit firmly in place so it can spin and bore holes or drive screws effectively. Most modern drills use a keyless chuck, which you can tighten and loosen by hand, making bit changes quick and easy. Older or more heavy-duty drills might use a chuck key, a small metal wrench that tightens the chuck’s jaws.

The size of the chuck directly influences the range of drill bits you can use. A larger chuck generally means the drill is designed to handle larger, thicker drill bits, which in turn usually means it’s built for more demanding tasks needing more power and torque.

The 3/8-Inch Drill: The Versatile Workhorse

The 3/8-inch drill is arguably the most common type of drill for homeowners and DIY enthusiasts. It strikes a fantastic balance between size, weight, power, and affordability, making it an excellent choice for a wide array of common tasks around the house.

Key Characteristics of a 3/8-Inch Drill:

- Compact and Lightweight: Generally smaller and lighter than their 1/2-inch counterparts. This makes them easier to handle for extended periods and in tight spaces.

- Versatility: Ideal for drilling holes in wood, plastic, and light metals. They are also perfect for driving screws for furniture assembly, hanging shelves, or minor repairs.

- Ease of Use: Their lighter weight and often less aggressive power profiles make them very forgiving for beginners.

- Battery Life (for cordless models): Often offer better battery life per charge because they consume less power than more powerful drills.

- Cost-Effective: Typically less expensive to purchase than 1/2-inch models.

When is a 3/8-Inch Drill the Best Choice?

If your DIY projects mostly involve:

- Assembling flat-pack furniture

- Hanging pictures and shelves

- Drilling pilot holes for smaller screws

- Making small holes in drywall or plaster

- Light-duty woodworking tasks

- Working in confined areas where space is limited

Then a 3/8-inch drill will likely serve you very well. It’s the go-to for most day-to-day household repairs and simple crafting projects.

The 1/2-Inch Drill: The Powerhouse for Tougher Jobs

The 1/2-inch drill, on the other hand, is built for more demanding applications. Its larger chuck size signals a drill that’s typically more robust, with a stronger motor and higher torque capabilities. This makes it the preferred choice when you need to power through denser materials or drill larger holes.

Key Characteristics of a 1/2-Inch Drill:

- More Power and Torque: The larger motor and gearbox assembly provide significantly more rotational force (torque). This is essential for drilling larger diameter holes or driving large fasteners into dense materials.

- Durable Construction: Often built with heavier-duty components to withstand tougher use.

- Accommodates Larger Bits: Can accept a wider range of drill bit sizes, including larger auger bits, spade bits, and hole saws, which are necessary for larger diameter holes.

- Ideal for Heavy-Duty Tasks: Excellent for drilling through thick hardwoods, mixing paint or thinset with a paddle attachment, or driving long screws into difficult materials.

- Heavier and Larger: These drills are generally bulkier and heavier, which can be fatiguing for prolonged use and trickier in very tight spots.

When is a 1/2-Inch Drill the Best Choice?

Consider a 1/2-inch drill if your projects frequently involve:

- Drilling large diameter holes (e.g., 1 inch or more) in wood for projects like pergolas, decks, or structural supports.

- Using large hole saws for creating openings in cabinets, countertops, or walls.

- Driving long and thick screws into hardwood or pressure-treated lumber.

- Jobs requiring extended periods of high torque, like continuous drilling in construction settings.

- Mixing small batches of material like paint, grout, or mortar with an appropriate attachment.

If you’re into serious woodworking or construction, the 1/2-inch drill is often an indispensable tool.

1/2 vs 3/8 Drill: A Comparative Look

To make the decision even clearer, let’s break down the key differences in a direct comparison. Understanding these distinctions will help you visualize which drill best fits your typical project needs.

| Feature | 3/8-Inch Drill | 1/2-Inch Drill |

|---|---|---|

| Max Bit Shank Size | 3/8 inch (9.5 mm) | 1/2 inch (12.7 mm) |

| Typical Use | General DIY, light woodworking, screw driving, small holes | Heavy-duty tasks, large holes, structural work, mixing |

| Power & Torque | Moderate | High |

| Weight & Size | Lighter and more compact | Heavier and larger |

| Versatility for Small Jobs | Excellent | Can be overkill, less maneuverable |

| Capability for Large Holes/Tough Materials | Limited | Excellent |

| Price Point | Generally lower | Generally higher |

| Beginner Friendliness | High | Moderate (requires more control) |

Drill Bit Compatibility Chart

The chuck size directly dictates the maximum diameter of a drill bit shank you can use. Here’s a quick reference for common drill bit types and how they relate to your drill’s chuck size.

| Drill Bit Type | Typical Shank Size Range | Best Suited For | Compatibility with 3/8″ Chuck | Compatibility with 1/2″ Chuck |

|---|---|---|---|---|

| Twist Bits (Standard) | Up to 3/8″ (metal/wood) | General purpose drilling | Full range | Full range |

| Spade Bits / Paddle Bits | 1/4″ to 1 1/2″ (wood) | Larger holes in wood | Most sizes (up to 3/8″ shank) | All sizes |

| Auger Bits | 1/4″ to 1″ (wood) | Deep, clean holes in thick wood | Up to ~1/2″ diameter (check shank) | All sizes |

| Hole Saws | Various (screw mount or arbor) | Large diameter holes (1″+) in wood, metal, plastic | Only with specific small arbor adapters that grip to < 3/8″ | Standard arbors |

| Masonry Bits | 1/8″ to 1/2″ (concrete, brick) | Drilling into harder materials | Most sizes | All sizes |

As you can see, while a 3/8-inch drill can handle many common bits, larger specialist bits like big spade bits or standard hole saw arbors often require the clamping capacity of a 1/2-inch chuck.

Beyond Chuck Size: Other Factors to Consider

While the chuck size is a primary differentiator, it’s not the only thing to think about when picking out a drill. Here are a few other important features:

- Corded vs. Cordless: Cordless drills offer freedom of movement, while corded drills provide consistent, unlimited power. For most DIYers today, a good cordless drill is very convenient.

- Engine Types:

- Brushed Motors: The traditional and more affordable option.

- Brushless Motors: Offer longer runtime, more power, and longer tool life, but are typically more expensive.

- Battery Voltage (for cordless): Higher voltage (e.g., 18V or 20V MAX) generally means more power and longer runtimes than lower voltage (e.g., 12V).

- Features: Look for variable speed triggers for better control, LED lights to illuminate your work area, and ergonomic designs for comfort. Some drills also have a hammer drill function, which adds a pounding action for drilling into masonry.

For beginners, a 12V or 18V/20V cordless drill with a 3/8-inch chuck and a brushless motor is often an excellent starting point. It provides a great balance of power, portability, and ease of use.

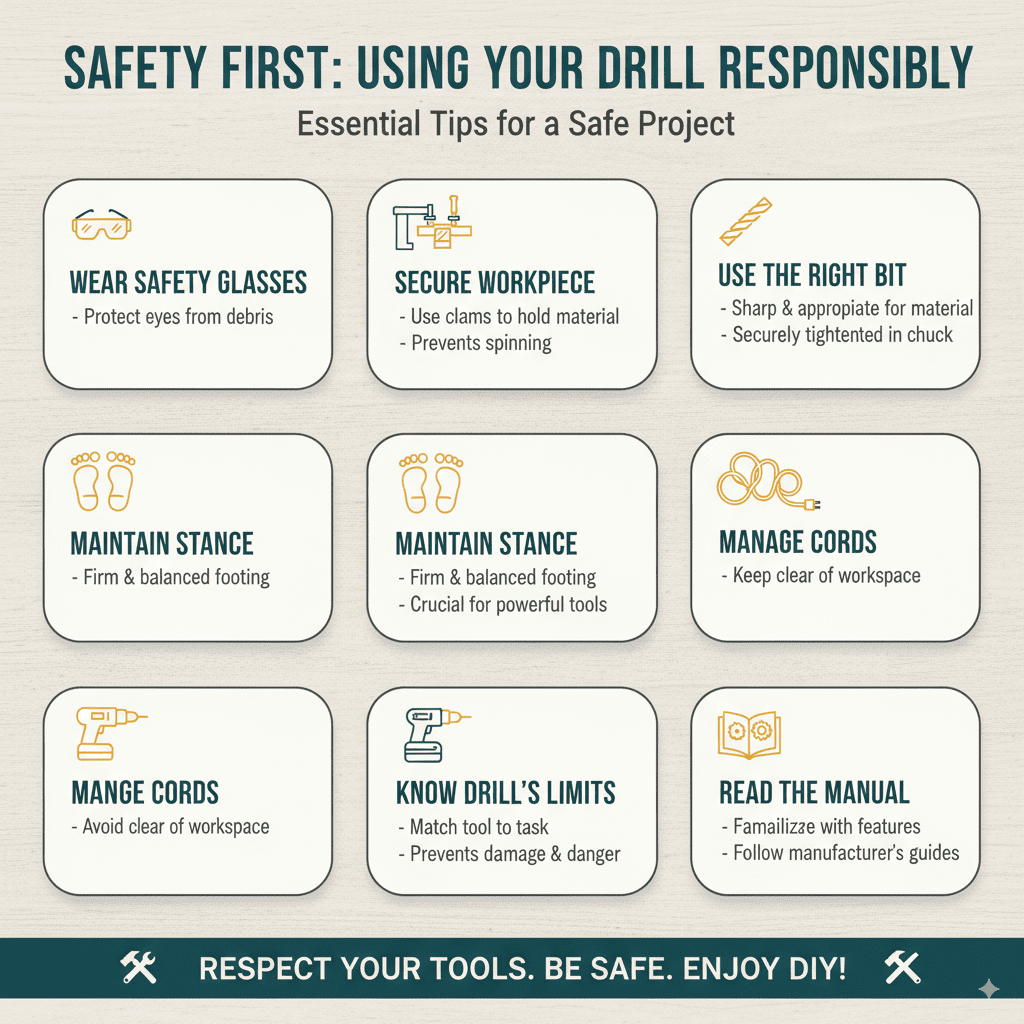

Safety First: Using Your Drill Responsibly

No matter which drill size you choose, safety should always be your top priority. Woodworking and DIY can be very rewarding, but it’s important to respect the tools and potential hazards involved. Here are some essential safety tips:

- Wear Safety Glasses: Always protect your eyes from flying debris.

- Secure Your Workpiece: Use clamps to hold your material in place. This frees up your hands and prevents the material from spinning.

- Use the Right Drill Bit: Ensure your bit is sharp, appropriate for the material, and securely tightened in the chuck.

- Maintain a Stable Stance: Keep your footing firm and balanced when operating the drill, especially when using more powerful tools.

- Keep Cords Tucked Away: If using a corded drill, be mindful of the power cord to avoid tripping or snagging.

- Know Your Drill’s Limits: Don’t force a smaller drill to do the work of a larger one. This can damage the tool and be dangerous.

- Read the Manual: Always familiarize yourself with your specific drill model’s features and safety guidelines. You can often find comprehensive guides from manufacturers or resources like the Occupational Safety and Health Administration (OSHA) on tool safety.

Taking these precautions will help ensure your DIY projects are not only successful but also safe.

FAQ: Your Drill Size Questions Answered

Q1: Can I use a 1/2-inch drill for small DIY jobs?

Yes, you can. A 1/2-inch drill can certainly perform tasks that a 3/8-inch drill can, but it might feel heavier and more cumbersome for very light jobs. If you only do small tasks, a 3/8-inch might be more comfortable.

Q2: Will a 3/8-inch drill be powerful enough for driving screws?

For most common screws used in home projects, yes. However, if you’re driving very long or large screws into hardwoods, a 1/2-inch drill with higher torque might be more suitable to avoid bogging down the motor.

Q3: How do I know what size drill bit my drill can take?

Look at the chuck! It will usually have markings indicating the minimum and maximum shank diameter it can clamp. For example, a 3/8-inch drill’s chuck will be marked with “3/8” or “9.5mm”.

Q4: Is a hammer drill function necessary?

A hammer drill function is specifically for drilling into concrete, brick, or stone. If you won’t be working with these materials, a standard drill (either 3/8″ or 1/2″) without the hammer function will suffice. For occasional masonry, a drill with a hammer function can be useful, but dedicated hammer drills offer more power for this task.

Q5: Should I buy a corded or cordless drill?

Cordless drills offer portability and convenience, making them ideal for most home users and DIYers. Corded drills provide consistent power and never run out of battery, making them great for extended, demanding jobs where a power outlet is readily available.

Q6: Which drill size is better for woodworking, 1/2 or 3/8 inch?

For general woodworking, a 3/8-inch drill is often sufficient for drilling pilot holes and smaller holes. However, for tasks requiring larger bits (like spade bits or hole saws over 1 inch), or for drilling into dense hardwoods, a 1/2-inch drill provides the necessary power and capacity.

Q7: Do I need both a 3/8-inch and a 1/2-inch drill?

Most beginner DIYers start perfectly well with a good quality 3/8-inch cordless drill. If your projects evolve to require more power or larger bit capacity, then adding a 1/2-inch drill to your collection makes sense. For many, one or the other will cover 90% of their needs.

Conclusion: Making Your Choice with Confidence

So, there you have it! Choosing between a 1/2-inch drill and a 3/8-inch drill comes down to understanding the demands of your projects. The 3/8-inch drill is your reliable, everyday companion for the bulk of your DIY tasks – it’s lightweight, versatile, and incredibly user-friendly for beginners. It’s the workhorse that will help you assemble furniture, hang decor, and tackle countless household fixes with ease.

On the other hand, the 1/2-inch drill is your powerhouse. When you encounter tougher materials, need to bore larger holes, or require significant torque, this drill steps up. It’s built for the more demanding challenges that come with larger woodworking projects or certain construction tasks. While it’s a bit heavier, its robustness is invaluable when you need that extra grunt.

For most new DIYers and homeowners, starting with a good quality 3/8-inch cordless drill is an excellent decision. It offers a fantastic blend of capability and ease of use, ensuring your projects are enjoyable and achievable. Listen to your needs, consider the types of materials you’ll be working with and the size of the holes you’ll be drilling, and you’ll confidently select the drill that’s right there with you, ready to help you build, repair, and create. Happy drilling!