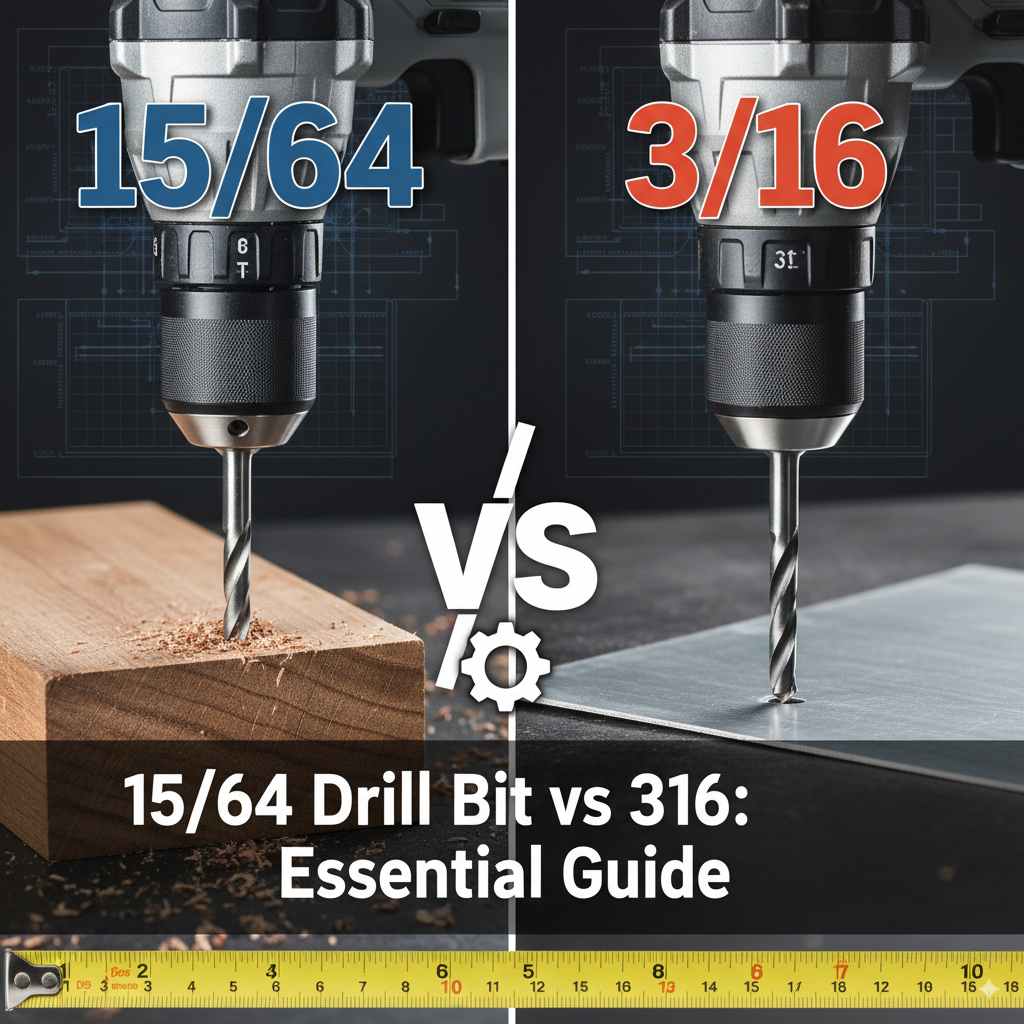

15 64 Drill Bit vs 3 16: Essential Guide

15/64 vs. 3/16 drill bits: They’re almost the same size, but which one is right for your project? This guide breaks down the subtle differences in millimeters and inches, shows you when to use each, and helps you choose the perfect bit for drilling accuracy and success.

Hey there, fellow DIYers and woodworkers! Ever found yourself staring at a project, drill in hand, and wondering if you’ve grabbed the right drill bit? It’s a common sticky point, especially when sizes seem so close. Today, we’re tackling two drill bits that often cause a little confusion: the 15/64-inch and the 3/16-inch. They look alike, but knowing their subtle differences can make a big impact on your work. Don’t worry, we’ll make this super simple, just like checking twice before you cut once! By the end of this, you’ll be a pro at choosing between these two common sizes.

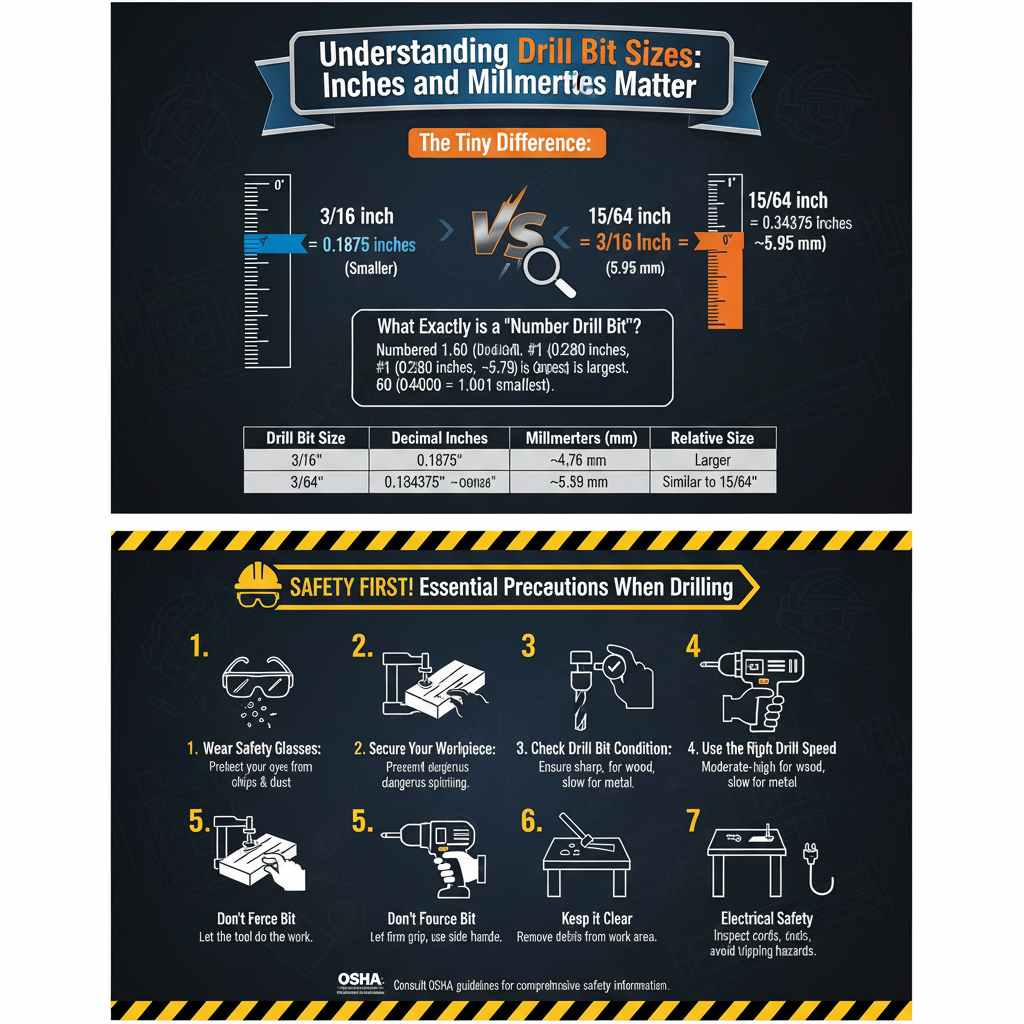

Understanding Drill Bit Sizes: Inches and Millimeters Matter

Drill bits are the workhorses of any project, and understanding their sizes is key to getting a clean, accurate hole. Most drill bits used in North America use the Imperial system (inches), but you’ll also see metrics (millimeters). It’s helpful to know how these relate, especially when you’re in a pinch or buying bits online from different sources.

The Tiny Difference: 15/64 Inch vs. 3/16 Inch

The main reason for confusion between the 15/64 and 3/16 drill bits is their very small size difference. Let’s break it down:

3/16 inch: This is a standard fractional inch measurement. To make it easier to compare, let’s convert it to a decimal: 0.1875 inches.

15/64 inch: This is also a fractional measurement. Converting it to a decimal gives us 0.234375 inches.

Wait a minute, Md Meraj! Did you just say 15/64 is bigger? Yes, you read that right! It’s a common misconception that 15/64 is smaller because of the ’15’ being a larger number than ‘3’. However, when you compare the fractions or their decimal equivalents, you’ll see that 15/64 is actually larger than 3/16.

Let’s look at that again, with millimeters for clarity.

3/16 inch: Approximately 4.76 mm.

15/64 inch: Approximately 5.95 mm.

So, the 15/64 drill bit is actually noticeably larger than the 3/16 drill bit. Surprised? Many are! This difference, while small, is crucial for certain applications.

What Exactly is a “Number Drill Bit”?

Beyond fractions and decimals, you might encounter drill bits labeled with numbers. This is where things can get even more confusing if you’re not familiar with them. The number drill bit set is a collection of bits numbered from 1 to 60.

Number 1 drill bit is the largest, at 0.2280 inches.

Number 60 drill bit is the smallest, at 0.0400 inches.

These number sizes are common in precise machining and electronics, where exact hole sizes are critical. You might see them referred to as “Jobber length” bits for all-around use.

Comparing the Sizes in a Table

To visualize this difference clearly, let’s put it all into a table.

| Drill Bit Size | Decimal Inches | Millimeters (mm) | Relative Size |

|---|---|---|---|

| 3/16″ | 0.1875″ | ~4.76 mm | Smaller |

| 15/64″ | 0.234375″ | ~5.95 mm | Larger |

| #1 drill bit (for context) | 0.2280″ | ~5.79 mm | Similar to 15/64″, but slightly smaller |

As you can see, the #1 drill bit is actually very close in size to the 15/64 drill bit, and both are significantly larger than the 3/16 inch drill bit. This handy chart should clear up any confusion about which is which!

When to Use the 3/16″ Drill Bit

The 3/16-inch drill bit is a true workhorse in many home workshops. It’s a go-to size for a variety of common tasks. Because it’s on the smaller side compared to the 15/64, it’s ideal for applications where you want a tighter fit or less material removal.

Common Applications for 3/16″ Drill Bits:

Pilot Holes for Screws: This is probably its most frequent job. A 3/16-inch bit is perfect for creating pilot holes for wood screws, especially those in the middle to larger sizes (like #8 or #10 screws). A pilot hole prevents the wood from splitting and makes driving the screw much easier.

Hinges and Hardware: When installing standard door hinges, cabinet hinges, or other basic hardware, the 3/16-inch bit is often the specified size for the screw holes.

Light Duty Fasteners: For general construction and assembly tasks where you’re using smaller bolts or fasteners, a 3/16-inch hole is a common choice.

Small Dowels: While not for heavy-duty doweling, it can be used for smaller dowel pins or for starting dowel holes for less critical connections.

General Purpose Drilling: For creating small-to-medium sized holes in thin materials like sheet metal or plastic where a precise, smaller diameter is needed.

Why Choose 3/16″ for These Tasks?

The 3/16″ bit provides a good balance. It’s large enough to create a pilot hole that guides many common screws without being so large that it weakens the material significantly. It’s also a very common size found in standard drill bit sets, making it readily available.

When to Use the 15/64″ Drill Bit

The 15/64-inch drill bit is a bit more specialized but equally important. Since it’s larger than 3/16-inch, its applications often involve creating holes that accommodate slightly larger fasteners, allow for more clearance, or are part of a more precise setup, like those found in engineering or specific woodworking joinery.

Common Applications for 15/64″ Drill Bits:

Specific Screw Sizes: Some screw manufacturers recommend a 15/64-inch pilot hole for certain types or sizes of screws, especially larger wood screws or lag screws where a bit more “bite” is needed for the threads.

Clearance Holes: If you need a hole that a bolt or screw head can pass through easily, leaving the threads to engage in another piece of material, the 15/64-inch can be the perfect clearance hole diameter for certain bolt sizes. This is common in metalworking, but it applies to woodworking too.

Dowel Pins: For slightly larger dowel pins (though typically 1/4″ or 5/16″ are more common for structural doweling), the 15/64″ bit can be used to create a snug fit.

Precision Machining and Craftsmanship: In applications where very specific hole diameters are required, like creating holes for certain types of hardware, jigs, or custom fixtures, this size comes into play. You might find this size specified in plans for certain types of cabinets or furniture.

Electronics and Model Making: For very detailed work, especially when working with metals or plastics, specific fractional sizes like 15/64″ are often called out.

Why the 15/64″ Might Be Your Best Bet

The 15/64-inch drill bit is often chosen when you need a hole that is slightly larger than 3/16″ but not quite 1/4″. This slight increase in diameter can be critical for:

Ensuring a faster engages cleanly: For some screws, especially those with aggressive threads or when driving into hardwoods, a slightly larger pilot hole can prevent the screw from binding or splitting the wood.

Allowing for slight imperfections: The extra tolerance can be helpful if your drilling isn’t perfectly on center or if material dimensions vary slightly.

Specific fitting requirements: When a part needs to slide through a hole with minimal resistance, this size can be ideal.

How to Choose the Right Drill Bit: Tips for Beginners

Choosing between the 15/64″ and 3/16″ drill bit boils down to a few simple questions. Most of the time, your project plans or the hardware you’re using will tell you exactly what size you need.

Always Check Your Plans and Hardware:

Read the instructions: If you’re following a woodworking plan, cabinet mounting instructions, or any hardware packaging, it will usually specify the exact drill bit size. This is your first and best source of information.

Measure your fasteners: If plans aren’t available, take your screw or bolt and see which drill bit size creates the best pilot hole or clearance hole.

For pilot holes: Select a bit that is noticeably smaller than the screw shank (the solid part of the screw shaft without threads). The threads should still be able to grip the wood firmly.

For clearance holes: The hole should be just slightly larger than the diameter of the screw or bolt shank so it passes through freely.

When in Doubt, Test!

Scrap wood is your friend: If you’re unsure, grab a piece of scrap wood that’s similar to your project material.

Drill a test hole with each bit: See how a screw or bolt fits into each hole. Which one feels right? Which one allows the fastener to drive smoothly without splitting the wood?

Look at the difference: You’ll be able to see and feel the difference in hole size. This hands-on test is invaluable.

Consider the Material:

Hardwoods (Oak, Maple, Cherry): These woods are dense and prone to splitting. You might need a slightly larger pilot hole (leaning towards 15/64” or even slightly larger) than you would for softer woods to prevent splitting.

Softwoods (Pine, Fir, Cedar): These are more forgiving. A 3/16″ pilot hole is usually sufficient for most common screws in softwoods.

Plywood and MDF: These engineered woods can also split, especially near edges. Start with a smaller pilot hole and test if needed.

When a Tiny Difference Matters

Remember, the 15/64″ is about 1.2 mm larger than the 3/16″. This 1.2 mm difference is significant enough to affect how a fastener fits or how a dowel seats.

Tight fit needed? If you need a very snug fit for a dowel or a screw thread to grip hard, you might lean towards the smaller 3/16.

Slightly looser fit or clearance? If you need a bit more wiggle room for a bolt to pass through, or you’re worried about splitting, the 15/64″ will be better.

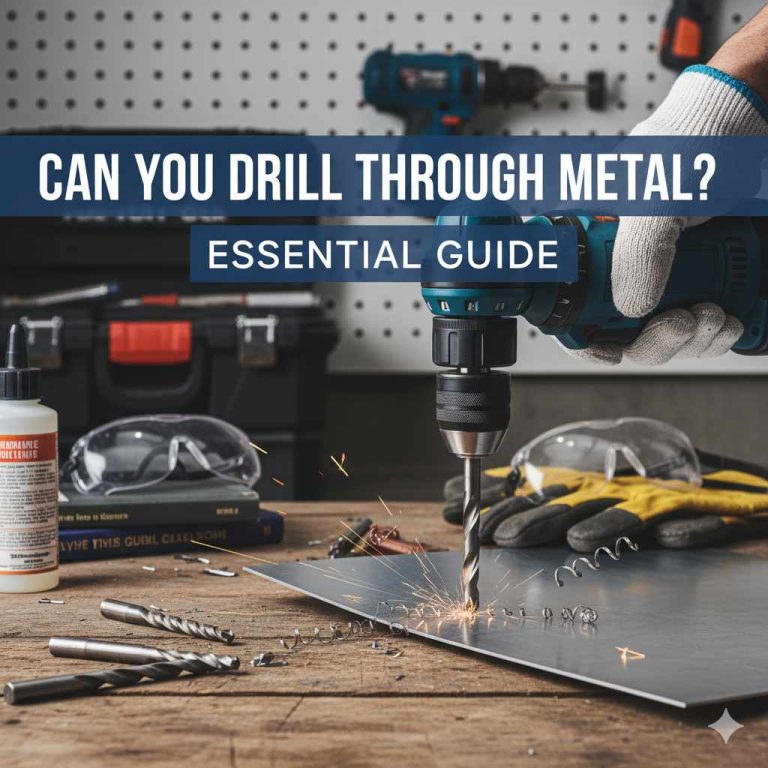

Drill Bit Material and Types: Beyond Size

While size is critical, the material and type of drill bit also play a role in performance and longevity. For most DIY tasks, you’ll be using twist drill bits.

Common Drill Bit Materials:

High-Speed Steel (HSS): This is the most common material for drill bits. HSS is durable and can withstand the heat generated by drilling into wood, metal, and plastic. They are a great all-around choice.

Cobalt: These are HSS bits with cobalt alloyed in. Cobalt adds hardness and heat resistance, making them excellent for drilling into harder metals like stainless steel. They are more brittle and expensive than standard HSS bits.

Carbide Tipped: These bits have carbide tips brazed onto a steel body. They are very hard and durable, ideal for drilling into masonry (concrete, brick) but also perform well in wood.

For your 15/64″ and 3/16″ bits, you’ll most likely find them made of High-Speed Steel, which is perfectly suited for woodworking and general DIY.

Types of Drill Bits:

Twist Drill Bits: The most common type. They have spiral flutes that help remove chips from the hole. Available in various lengths and materials.

Spade Bits (Paddle Bits): Flat, spade-shaped bits used for drilling larger holes (typically 1/4″ and up) relatively quickly in wood.

Forstner Bits: Used for drilling clean, flat-bottomed holes in wood, often for mortises or when you don’t want the bit to go all the way through.

Auger Bits: Designed for drilling deep, clean holes in wood, especially for larger diameters. They have a screw tip to help pull the bit into the material.

For the sizes we’re discussing (15/64″ and 3/16″), you’ll almost exclusively be using standard twist drill bits.

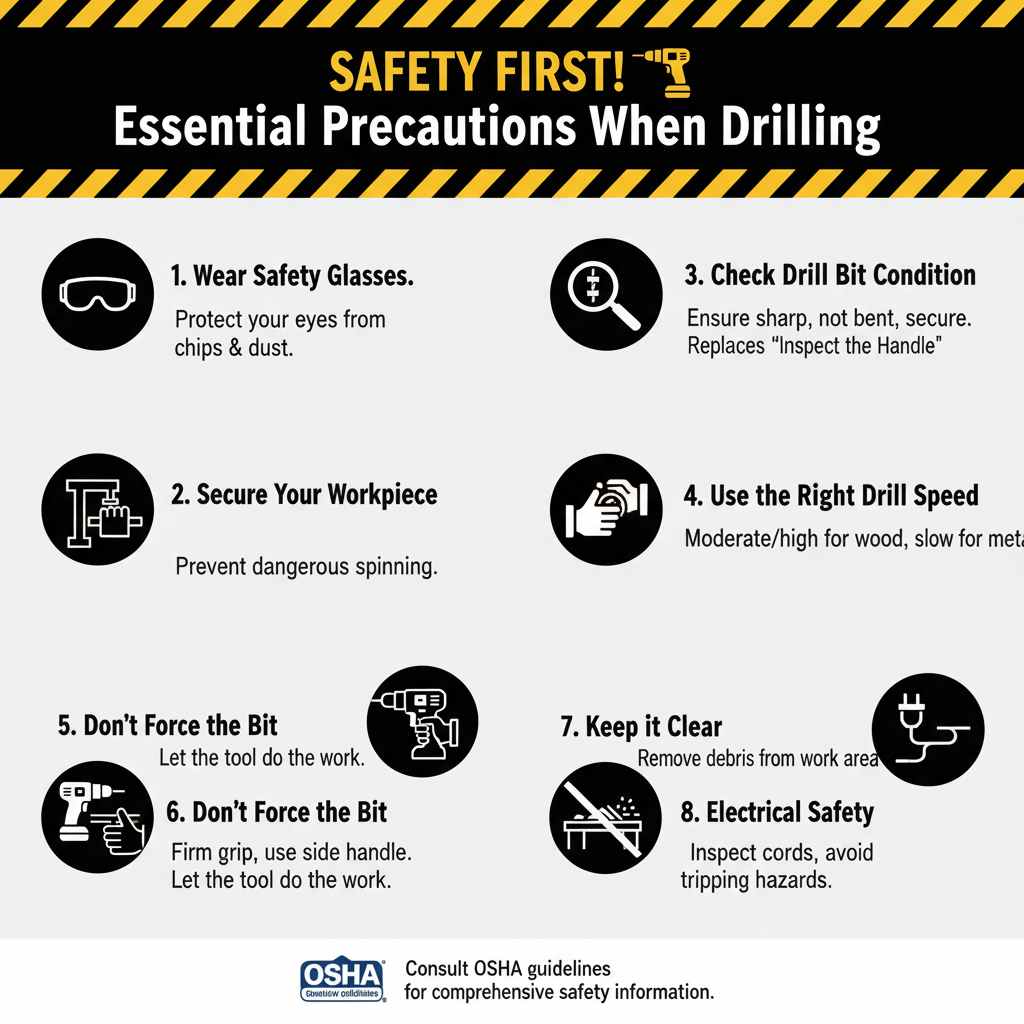

Safety First! Essential Precautions When Drilling

Drilling is a fundamental skill, but like any power tool operation, safety should always be your top priority. Even with small bits like 15/64″ and 3/16″, taking a few simple precautions can prevent injuries and protect your project.

Key Safety Tips:

1. Wear Safety Glasses: This is non-negotiable. Wood chips, dust, and even small pieces of the drill bit can fly at high speeds. Protect your eyes!

2. Secure Your Workpiece: Always clamp your material firmly to a workbench or sturdy surface. A spinning workpiece is incredibly dangerous and can cause serious injury.

3. Check Drill Bit Condition: Ensure your bit is sharp, not bent, and securely tightened in the drill chuck. A dull or wobbly bit makes drilling harder, less accurate, and can increase the risk of kickback.

4. Use the Right Drill Speed: For wood, start with a moderate to high speed. For metal or harder materials, use a slower speed to prevent overheating. Many modern drills have variable speed settings.

5. Don’t Force the Bit: Let the drill bit do the work. Applying too much pressure can dull the bit, break it, or cause the drill to bind, leading to kickback.

6. Brace Yourself: Keep a firm grip on the drill and be prepared for the drill to twist if the bit catches. Using a side handle, if your drill has one, can provide extra control.

7. Keep it Clear: Ensure the area around your drilling site is clear of debris.

8. Electrical Safety: If using a corded drill, be mindful of the cord’s position to avoid tripping or cutting it. Ensure power outlets and extension cords are in good condition.

For more detailed safety guidelines on power tools, the Occupational Safety and Health Administration (OSHA) provides excellent resources and standards. Consult their guidelines on machine guarding and personal protective equipment for comprehensive information.

Frequently Asked Questions (FAQs)

Q1: Is 15/64 the same as 5.95mm?

A1: Yes, 15/64 of an inch is approximately 5.95 millimeters. It’s always good to know both metric and imperial measurements, as tools and projects sometimes use either.

Q2: Can I use a 3/16″ drill bit instead of 15/64″ if my project calls for it?

A2: In some situations, yes, but be aware that the 3/16″ bit is smaller. If you need a tight fit or are drilling a pilot hole for a screw, a 3/16″ hole might be too small, making it harder to drive the screw or increasing the risk of the wood splitting. Always check your project requirements.

Q3: I need to drill a hole for a 1/4″ bolt. Which bit should I use—15/64″ or 3/16″?

A3: For a 1/4″ bolt to pass through freely (a clearance hole), you’ll need a bit slightly larger than 1/4″. Neither 15/64″ (which is smaller than 1/4″) nor 3/16″ (even smaller) would be ideal for a clearance hole for a 1/4″ bolt or screw. You would typically use a 9/32″ or 5/16″ bit for a 1/4″ clearance hole, depending on the desired tolerance.

Q4: Which drill bit is better for preventing wood splitting: 15/64″ or 3/16″?

A4: Generally, when drilling a pilot hole to prevent splitting, a slightly larger pilot hole can help. The 15/64″ bit, being larger than the 3/16″, would provide a slightly larger pilot hole, potentially reducing the risk of splitting, especially in hardwoods or near the edge of a board.