Are Engineered Hardwood Floors Sealed: Brilliant Protection

Yes, engineered hardwood floors are typically sealed, and this protective layer is what makes them a durable and beautiful choice for your home. Understanding this sealing process helps you care for your floors and appreciate their lasting appeal.

Hey there, DIYers and home enthusiasts! Md Meraj here, your woodworking buddy. Ever looked at a gorgeous engineered hardwood floor and wondered how it stays so stunning, even with daily life happening? You’re not alone! A common question bouncing around is, “Are engineered hardwood floors sealed?” The simple answer is yes, and understanding this is key to keeping your floors looking their best. It’s not as complicated as it sounds, and with a little knowledge, you’ll be a pro at appreciating and caring for this fantastic flooring option. Ready to uncover the secrets behind that brilliant protection? Let’s dive in and make your floors shine!

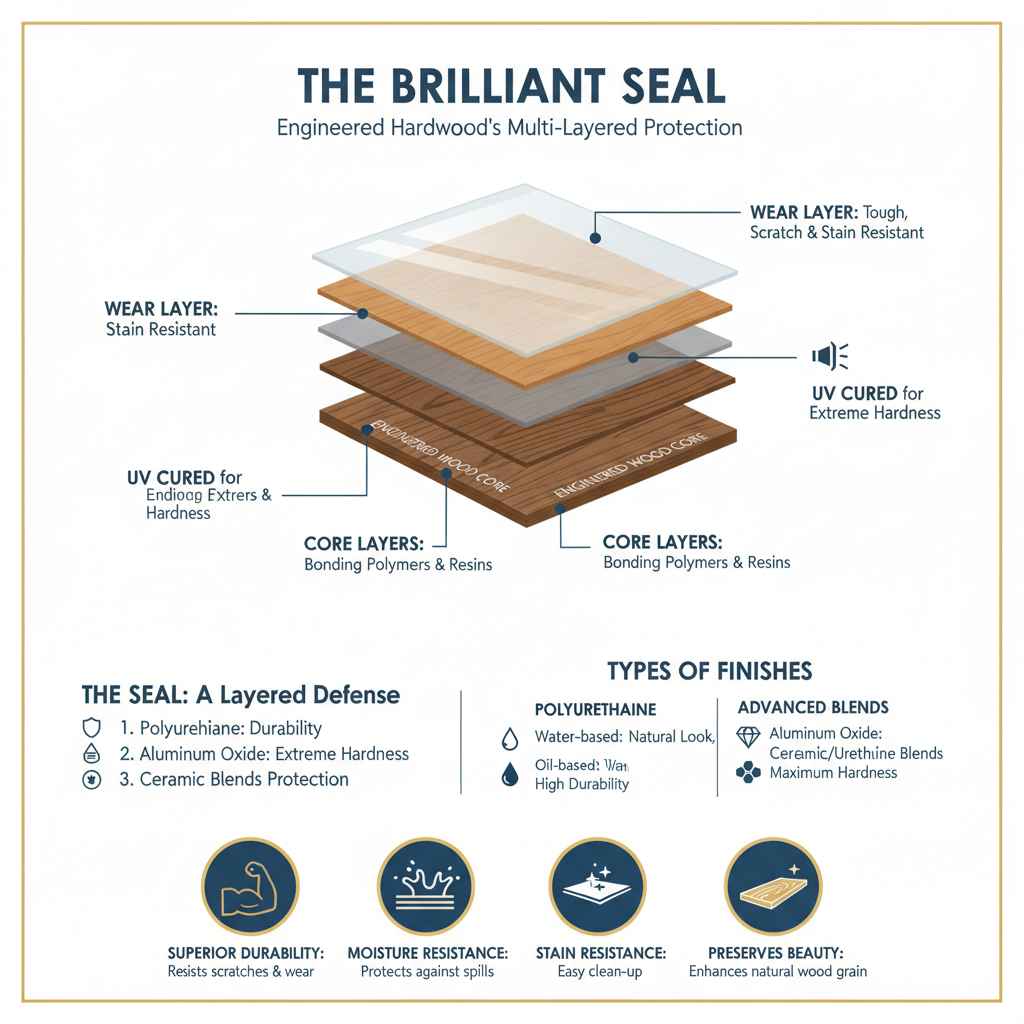

The Brilliant Seal: How Engineered Hardwood Gets Its Protection

When we talk about engineered hardwood floors, the “seal” is a crucial part of their construction and longevity. It’s not just a surface polish; it’s a multi-layered defense system that protects the wood’s natural beauty from everyday wear and tear. Think of it like a knight’s armor for your floors – strong, resilient, and designed to keep the precious wood underneath safe. This sealing process is what differentiates a floor that stays beautiful for years from one that quickly shows its age. We’ll explore what this seal is made of, how it’s applied, and why it’s so important for durability and maintenance.

What Exactly is the “Seal” on Engineered Hardwood?

The “seal” isn’t a single coat of varnish. Instead, it refers to the finish applied to the top layer of engineered hardwood flooring. This finish is typically made up of several layers of tough, durable materials. These are often polyurethane-based, but can also include aluminum oxide or ceramic particles for extreme hardness. The primary goal of these layers is to create a protective barrier against moisture, scratches, stains, and general wear. It’s the resilient shield that allows engineered hardwood to be a practical choice for busy households.

The Layered Defense System

Imagine building a strong wall. You wouldn’t use just one material, right? The same applies to a high-quality floor finish. Engineered hardwood floors benefit from a layered application:

- The Wear Layer: This is the topmost layer, the one that takes the brunt of the action. It’s formulated to be incredibly wear-resistant. High-quality finishes will have a thicker wear layer, offering better protection.

- The Core Layers: Underneath the wear layer are multiple coats of protective finishes. These are often different types of polymers and resins that bond together to create a seamless, protective shell. They add depth and enhance the durability of the entire system.

- UV Curing: Many manufacturers use UV (ultraviolet) light to cure these layers. This process hardens the finish instantly, making it exceptionally tough and ready for foot traffic much sooner than traditional finishes. This is a modern manufacturing technique that contributes significantly to the floor’s resilience.

Understanding the Types of Finishes

While most engineered hardwood floors come pre-finished from the factory with a robust seal, the specific type of finish can vary. Knowing these differences helps you understand your floor’s capabilities:

Polyurethane Finishes

This is the most common type of finish for engineered hardwood. Polyurethane is known for its durability and resistance to moisture and wear. There are two main types:

- Water-based Polyurethane: Lighter in color, dries faster, and has lower VOCs (Volatile Organic Compounds). It’s often preferred for its more natural look and quicker installation. It’s highly durable but might require more coats for optimal protection.

- Oil-based Polyurethane: Tends to create a warmer, amber tone. It’s very durable and offers excellent protection against moisture. However, it takes longer to dry, has stronger fumes, and can yellow over time.

Aluminum Oxide Finishes

This is where we get into the truly tough stuff. Aluminum oxide particles are embedded in the top layers of the finish. This makes the floor incredibly resistant to scratches and abrasion. Many engineered hardwood floors designed for high-traffic areas or commercial use will feature an aluminum oxide finish, often combined with polyurethane. It offers a superior level of protection compared to standard polyurethane alone, often lasting for decades without needing refinishing. For more on wear layers and finishes, you can check out resources from organizations like the National Association of Home Builders (NAHB), which often discuss flooring standards and durability.

Ceramic or Urethane-Aluminum Oxide Blends

Some premium options might incorporate ceramic beads or other advanced materials into the urethane-aluminum oxide blend for even greater hardness and scratch resistance. These are often seen in the highest-end engineered wood products.

How the Sealing Process Benefits Your Floors

The factory-applied seal on engineered hardwood isn’t just for show; it’s the primary reason these floors are so popular and practical for homeowners. Let’s break down the key benefits:

1. Superior Durability and Wear Resistance

The sealed surface is designed to withstand the rigors of daily life. This means it can handle foot traffic, moving furniture (when done carefully!), and the occasional dropped item without immediately showing damage. The protective layers prevent minor scratches and scuffs from penetrating the wood itself, keeping the surface looking fresh for longer. This is particularly important for families with pets or young children.

2. Enhanced Moisture Resistance

While no wood floor is truly waterproof, the sealed finish provides a significant barrier against spills and splashes. This protection is one of the key advantages of engineered hardwood over solid hardwood, especially in areas prone to humidity or where spills are common, like kitchens or dining rooms. The seal helps prevent moisture from seeping into the wood core, reducing the risk of swelling or warping. For more practical advice on protecting wood floors from moisture, consider consulting resources from university extension programs that often provide home maintenance tips.

3. Stain Resistance

The smooth, impermeable surface of a sealed floor makes cleaning up spills a breeze. Many common household stains—like coffee, wine, or pet accidents—will bead up on the surface, allowing you to wipe them away quickly before they have a chance to penetrate and discolor the wood. This stain resistance is a huge plus for maintaining a pristine look with minimal effort.

4. Ease of Maintenance and Cleaning

This is perhaps the most significant benefit for busy homeowners. Because the surface is sealed and non-porous, cleaning is straightforward. Regular sweeping or vacuuming, coupled with occasional damp mopping with a pH-neutral cleaner specifically designed for wood floors, is usually all that’s needed. You don’t need to worry about harsh chemicals or extensive waxing routines that solid hardwood might require.

5. Preserves Natural Beauty

The seal acts as a protective topcoat that enhances and preserves the natural color and grain of the wood. It gives the floor a consistent sheen, whether it’s a matte, satin, or glossy finish. This preserves the aesthetic appeal, ensuring your floors contribute to your home’s overall beauty without fading or dulling prematurely.

Are There Different Levels of Sealing?

Yes, the effectiveness and longevity of the “seal” can vary significantly between different brands and product lines of engineered hardwood flooring. It’s not a one-size-fits-all situation. The quality of the seal is directly related to:

- The number of protective coats applied during manufacturing.

- The type and quality of the finishing materials used (e.g., standard polyurethane vs. urethane-aluminum oxide).

- The thickness of the wear layer.

Manufacturers will often specify the type of finish and the number of coats on their product specifications. More coats and harder-wearing additives generally mean a more resilient and longer-lasting seal.

How to Identify and Care for Your Sealed Engineered Hardwood Floor

Knowing that your engineered hardwood floor is sealed is one thing; knowing how to properly care for it is another. The good news is that this type of flooring is generally very forgiving. Proper care ensures that you maximize the benefits of that brilliant protective seal for years to come.

Step-by-Step Guide to Identifying Your Floor’s Finish

Sometimes, you just need to know what you’re working with. Here’s how to get a good idea of your floor’s finish:

- Check Manufacturer Documentation: This is the easiest and most reliable method. If you know the brand and model of your flooring, look up the product details online or check any installation guides or warranty information you might have. The manufacturer will usually detail the type and number of protective coats.

- Observe the Sheen: While not definitive, the sheen can give clues. A very high gloss might indicate multiple layers of a standard finish. A subtle, low-sheen appearance could be a matte polyurethane or a more modern UV-cured finish.

- Look for Scratch Resistance: Try a very discreet test in an inconspicuous area (like inside a closet). Gently try to scratch the surface with a fingernail or a coin. If it resists easily, it likely has a robust, modern finish, possibly with aluminum oxide. If it’s easy to scratch, it might be an older or less durable type of finish. Please be extremely careful doing this!

- Smell Test (with caution): When new, many finishes have a distinct smell. Modern, low-VOC finishes have less odor. If you notice strong chemical odors that linger, it might indicate an older oil-based polyurethane or a finish with higher VOCs.

- Water Test: Drip a tiny bit of water onto the surface in an out-of-the-way spot. If it beads up immediately and stays that way for several minutes, your seal is performing well against moisture. If it soaks in quickly, the seal might be worn or compromised in that spot.

Daily Cleaning: The First Line of Defense

Consistent daily cleaning is your best friend for maintaining the integrity of the seal. It removes grit and debris that can act like sandpaper underfoot, dulling and eventually scratching the finish.

- Sweep or Dust Mop Daily: Use a soft-bristle broom or a microfiber dusting mop. This effectively picks up dust, dirt, pet hair, and other loose debris without scratching the floor.

- Vacuum Regularly: Use a vacuum cleaner with a soft brush attachment specifically designed for hard floors. Ensure the beater bar is turned OFF or retracted. A vacuum with strong suction but no abrasive brushes is ideal.

Weekly or Bi-Weekly Cleaning: Keeping it Fresh

For a deeper clean and to remove any lingering dirt or grime that sweeping misses:

- Damp Mopping: This is key. Never flood your engineered hardwood floors with water. Use a damp mop, not a wet one. The mop should be wrung out thoroughly so that it’s just slightly moist.

- Use the Right Cleaner: Opt for a pH-neutral cleaner specifically formulated for wood or engineered wood floors. Avoid all-purpose cleaners, ammonia-based products, or abrasive cleaners, as they can damage the finish over time. You can find excellent wood floor cleaning solutions from reputable brands. For a DIY option, a very diluted solution of white vinegar and water (about 1/4 cup vinegar to a gallon of water) can be used sparingly, but always test a small, inconspicuous area first.

- Mop in the Direction of the Grain: This helps prevent streaking and ensures a more even clean. Work in manageable sections, a few feet at a time, and allow the floor to dry before walking on it.

Protecting the Seal from Damage

Beyond cleaning, proactive protection is essential:

- Use Furniture Pads: Place felt or rubber pads under the legs of all furniture—chairs, tables, sofas, etc. This significantly reduces scratches and indentations when furniture is moved. Regularly check and replace worn pads.

- Use Area Rugs and Mats: Place rugs in high-traffic areas like hallways, entryways, and in front of sofas or sinks. Use doormats at all exterior entrances to trap dirt and moisture before it enters your home. Ensure rug backings are wood-floor-safe, as some rubber or latex backings can discolor certain finishes over time.

- Clean Spills Immediately: Don’t let spills sit. Wipe them up promptly with a soft cloth. For sticky residues, use your recommended wood floor cleaner.

- Avoid Harsh Chemicals: Never use waxes, oils, abrasive cleaners, steams mops, or ammonia-based products on your sealed engineered hardwood floors. Steam can force moisture into the wood and seams, causing damage, and waxes can create a slippery buildup that dulls the finish.

- Manage Sunlight: Prolonged, direct sunlight can cause the wood to fade over time. Use curtains, blinds, or UV-filtering window films to protect your floors, especially during peak sun hours.

When to Consider Refinishing (Spoiler: It’s Rare for Engineered!)

One of the key differences between solid hardwood and engineered hardwood lies in refinishing. Solid hardwood, being thick and all wood, can be sanded down many times to remove scratches and wear, revealing fresh wood. Engineered hardwood, however, has a thin top layer of real wood (the veneer) over a core of plywood or HDF.

Refinishing Engineered Hardwood:

- Depends on Wear Layer Thickness: Whether an engineered hardwood floor can be refinished depends entirely on the thickness of its top hardwood veneer. Thicker veneers (3mm or more) might tolerate one or possibly two light sandings and refinishing sessions. Thinner veneers (often 1-2mm) are generally not designed to be refinished.

- Focus on Maintenance: For floors with thin veneers, the best approach is excellent maintenance and protection. The goal is to prevent damage that would necessitate refinishing.

- Recoating vs. Refinishing: Sometimes, a floor might lose its luster but not be deeply scratched. In such cases, a process called “recoating” might be possible. This involves cleaning the floor thoroughly and applying a new coat of the same type of finish over the existing one to restore shine and protection. This is not sanding; it’s a surface treatment that can often be done by professionals and is less invasive than full refinishing.

For most homeowners with modern engineered hardwood, the factory seal is designed to last the lifetime of the product under normal residential use, provided proper care is taken. Referencing guides from organizations like the Environmental Protection Agency (EPA) on indoor air quality and household products can also indirectly inform choices about cleaning products used near wood floors.

Table: Engineered Hardwood Finish Comparison

To help you visualize the differences, here’s a comparison of common finishes:

| Finish Type | Common Wear Layer Thickness | Durability Against Scratches | Moisture Resistance | Maintenance Effort | Typical Appearance | Refinishing Potential |

|---|---|---|---|---|---|---|

| Water-Based Polyurethane | 1mm – 3mm+ | Good | Good | Low | Clear, natural | Rarely (depends on veneer) |

| Oil-Based Polyurethane | 1mm – 3mm+ | Good | Very Good | Low | Warmer, amber tone | Rarely (depends on veneer) |

| Aluminum Oxide | 2mm – 4mm+ | Excellent | Very Good | Very Low | Clear, can be matte to glossy | Rarely (depends on veneer) |

| Urethane-Ceramic Blend | 3mm – 6mm+ | Exceptional | Excellent | Very Low | Clear, can be matte to glossy | Rarely (depends on veneer) |

Frequently Asked Questions (FAQs)

Q1: Can I use a steam mop on my sealed engineered hardwood floors?

A1: No, it’s strongly advised not* to use a steam mop on engineered hardwood. The heat and moisture from steam can seep into the seams and core layers, causing the wood to swell, warp, or delaminate over time. Stick to a well-wrung-out damp mop.

Q2: My dog scratched my engineered hardwood floor. Is the seal ruined?

A2: A minor scratch on the surface might indicate the finish has been compromised in that spot, but it doesn’t automatically mean the entire seal is ruined. The extent of the damage depends on how deep the scratch is. If it only went through the top wear layer, the overall protection of the floor might still be intact. For deeper scratches, you might need professional repair or consider a touch-up kit designed for your floor’s color and finish.