Ash Boards For Sale: Essential & Affordable Options

Looking for “ash boards for sale” that are both essential for your projects and kind to your wallet? You can find durable, versatile ash lumber affordably by exploring local sawmills, online marketplaces, and lumber yards. This guide simplifies how to choose the best ash boards for your DIY needs.

Ever found yourself staring at a woodworking project idea, only to be stumped by the material choices? Choosing the right wood can feel tricky, especially when you’re just starting out. Many beginners worry about spending too much on lumber or picking wood that’s too hard to work with. But what if I told you there’s a fantastic wood out there that’s both strong and surprisingly affordable? That’s where ash boards come in! They are a go-to for many DIYers and professionals for good reason. Don’t worry, I’m here to guide you through finding the perfect ash boards for your next creation, making sure you get great value and a wood that’s a joy to work with.

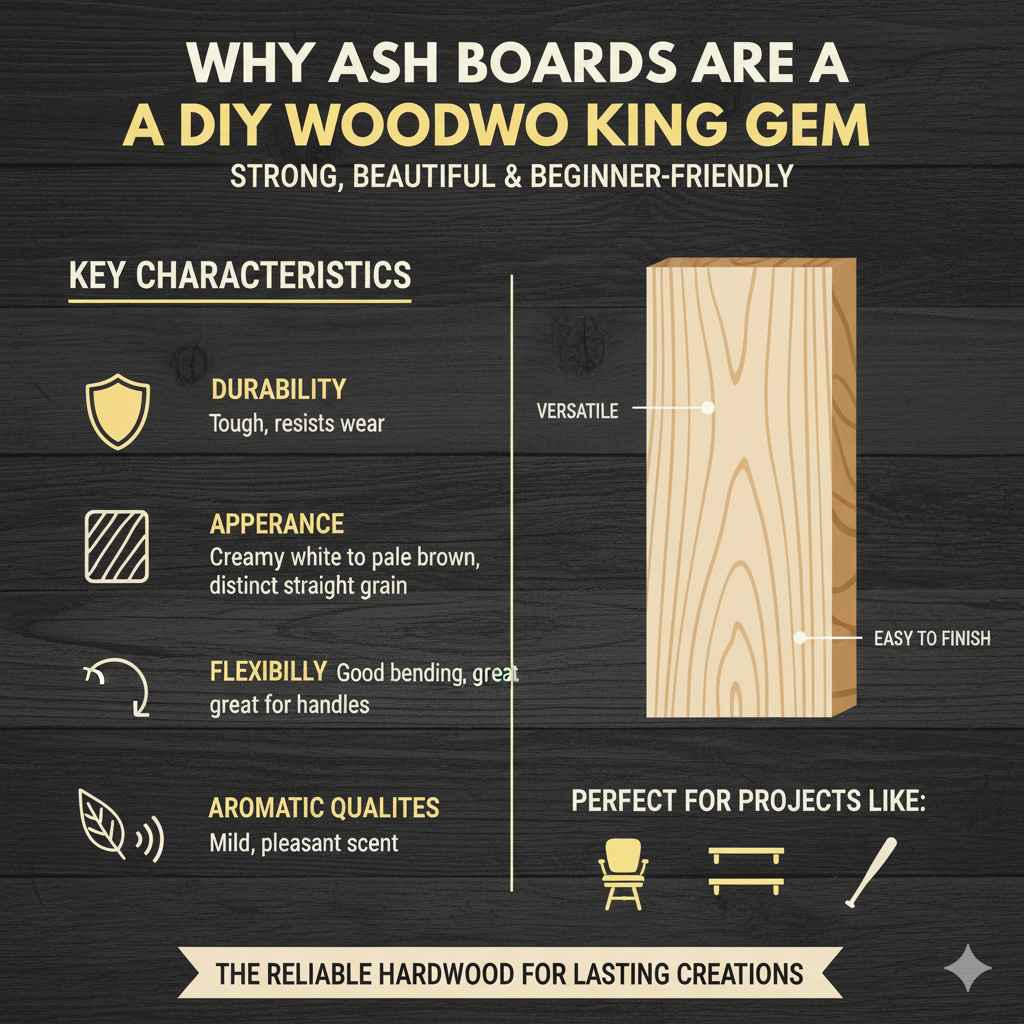

Why Ash Boards Are a DIY Woodworking Gem

Ash (Fraxinus genus) is a popular hardwood known for its strength, flexibility, and attractive grain pattern. For beginners, it strikes a wonderful balance between being durable enough for functional items and workable enough for easy crafting. Think of it as the reliable friend in your lumberyard – it’s there to support your ideas and help them take shape without a fuss.

When you’re building anything from a simple shelf to a robust workbench or even a sturdy chair, ash offers excellent performance. Its shock resistance makes it perfect for tool handles and sports equipment, but it’s also beautiful enough for fine furniture. Plus, its relatively coarse, straight grain is easy to sand and finish, which is a huge plus when you’re learning the ropes.

Key Characteristics of Ash Lumber:

- Durability: Ash is tough. It withstands wear and tear well, making it ideal for projects that need to last.

- Workability: Despite its strength, ash machines, sands, and finishes smoothly. It takes screws and glues well.

- Appearance: Ash typically has a light, creamy white to pale brown color with a distinct, often straight, grain pattern. It can have a subtle wavy or irregular grain that adds character.

- Flexibility: It has good bending properties, which is why it’s historically used for things like baseball bats and bows.

- Aromatic Qualities: Some varieties of ash can have a mild, pleasant scent when worked.

Where to Find Ash Boards For Sale: Your Essential Shopping Guide

Finding good quality ash boards for sale doesn’t have to be complicated or expensive. The key is knowing where to look and what to look for. As a mentor, I always encourage my students to explore local options first, as they often provide the best value and support.

1. Local Sawmills and Lumber Yards

This is hands-down my favorite place to source lumber, especially for project wood. Local sawmills cut lumber directly from logs, often meaning lower prices because you’re cutting out the middleman. Many also offer a wider variety of cuts and dimensions than you’d find at a big box store.

- Pros: Often the best prices, direct from the source, support local businesses, wide selection, knowledgeable staff.

- Cons: Might require more effort to find, selection can vary, may need to arrange transport for larger quantities.

Pro Tip: Call ahead to check their inventory. Ask if they have any “utility grade” or “economy” ash available, which is perfect for practice projects or pieces where appearance isn’t critical. You can learn more about lumber grading from resources like the Forest Products Laboratory (FPL).

2. Online Lumber Retailers

The internet opens up a world of possibilities. Numerous online stores specialize in hardwoods and can ship directly to your door. This is a great option if you live far from good local sources.

- Pros: Huge selection, convenient home delivery, easy price comparison.

- Cons: Shipping costs can be high, you can’t inspect the wood before buying, potential for damage during shipping.

When ordering online, look for reputable dealers who clearly describe their wood grades and offer good return policies. Reading customer reviews is also crucial.

3. Woodworking Stores and Big Box Retailers

While not always the most affordable or diverse, some larger home improvement stores and dedicated woodworking shops carry ash boards. This is convenient for small projects or if you need materials quickly.

- Pros: Easy to access, convenient for small purchases, often have pre-cut project wood.

- Cons: Higher prices, limited selection, wood quality can be inconsistent.

Check the lumber sections of stores like Home Depot or Lowe’s, but be prepared to sift through for the best pieces. Specialty woodworking stores might have better quality but at a higher cost.

4. Reclaimed and Salvaged Wood Sources

This is an eco-friendly and often very affordable option! Look for local architectural salvage yards, deconstruction companies, or even online marketplaces for old furniture, pallets (though often not ash), or building materials that might contain ash wood. You’ll need to be prepared to de-nail, clean, and mill the wood yourself, which can be a rewarding part of the process.

- Pros: Very affordable or free, environmentally friendly, unique character, satisfying to salvage.

- Cons: Labor-intensive preparation, inconsistent sizes and quality, potential for hidden nails or damage, may not always guarantee ash.

Always wear safety glasses and gloves when dealing with salvaged wood, and invest in a good metal detector to find hidden fasteners.

What to Look For When Buying Ash Boards: A Beginner’s Checklist

Selecting the right ash boards means understanding a few key things about wood and its defects. Don’t be intimidated; think of it like picking out produce at the market – you’re looking for quality and value.

Understanding Wood Grades

Lumber is graded based on the number and size of defects it contains. While hardwood grading can be complex, for beginners, understanding a few common grades will help you make informed choices. It’s important to remember that grades often refer to the clearer, more premium portions of the wood.

Here’s a simplified look at common grades you might encounter:

| Grade | Description | Best For |

|---|---|---|

| FAS (Firsts & Seconds) | Highest grade, very few defects, large clear pieces. Primarily used for high-end furniture and cabinetry. | Fine furniture making, show pieces. |

| Select & Better | A mix of FAS and Select grades, offering good quality with some minor limitations. Often found in flooring and millwork. | Quality furniture, cabinetry, flooring. |

| Common Grades (e.g., #1 Common, #2 Common) | Allow for more defects like knots, short boards, and sapwood. More affordable and still excellent for many projects. #2 Common is often called “paint-grade” or “utility-grade.” | Rough construction, shop furniture, practice projects, painted projects, items where clear wood isn’t essential. |

| Shop Grade / Utility Grade | Even more defects allowed, great for small projects or when you plan to cut around imperfections. Very cost-effective. | Small projects, jigs, shop use, practice. |

As a beginner, don’t feel you need FAS grade. Often, #1 or #2 Common grades offer fantastic value and are perfectly suitable for most DIY projects. Sometimes, wood labeled “shop grade” or “utility grade” is the most budget-friendly and still works wonders.

What to Inspect on the Boards:

- Moisture Content: Wood should be properly dried (kiln-dried or well-air-dried) to prevent warping and splitting later. Seek wood with a moisture content around 6-10% for indoor projects. If you’re unsure, ask the seller.

- Warping and Twisting: Lay a board flat on a level surface. Does it rock or have a noticeable bow or twist? Minor bows might be manageable with clamping and techniques, but severe warps are best avoided.

- Cracks and Splits: Check the ends of the boards especially. Small surface checks might be acceptable if you plan to cut them off, but deep cracks can compromise structural integrity.

- Knots: Knots are natural features. Small, tight knots are usually fine and add character. Large, loose, or “wormy” knots can be weak points and might fall out.

- Insect Damage: Look for small holes (pinholes are common in some species but should be minimal) or signs of active infestation. Most kiln-dried wood kills insects, but it’s good to be aware.

- Grain Straightness: For many projects, a straight grain is easier to work with and results in a more predictable outcome. However, some projects benefit from figured or wavy grain.

- Overall Condition: Does the board look like it’s been stored well? Avoid boards that look moldy, stained, or excessively rough from poor handling.

Remember, taking the time to inspect each board can save you a lot of frustration down the line. It’s better to spend a little extra time picking through them than to end up with unusable material.

Affordable Ash Board Projects for Beginners

Thinking about what to make with your ash boards? Here are a few ideas that are perfect for honing your skills and creating something useful and beautiful without breaking the bank.

Project Ideas:

- Simple Shelving Units: Ash is strong, so it makes for excellent, sturdy shelves. You can build a basic floating shelf or a small bookshelf. The straight grain looks great, even with a clear finish.

- Cutting Boards: With proper finishing and care, ash can make a durable and attractive cutting board. Its hardness resists knife marks better than many softer woods.

- Tool Handles or Mallet Heads: The shock resistance and toughness of ash make it an ideal material for upgrading or crafting your own tool handles, or for making a sturdy mallet head for joinery.

- Picture Frames: The attractive grain of ash is perfect for simple picture frames. You can miter the corners for a professional look.

- Coasters or Trivets: Small, simple projects like coasters or trivets are great for using up smaller offcuts and practicing joinery or finishing techniques.

For any project, even simple ones, always use safety gear. This includes safety glasses, hearing protection, and a dust mask when cutting or sanding. If you’re unsure about a tool, take a moment to read the manual or watch a beginner tutorial. The Occupational Safety and Health Administration (OSHA) offers valuable safety guidelines for woodworking.

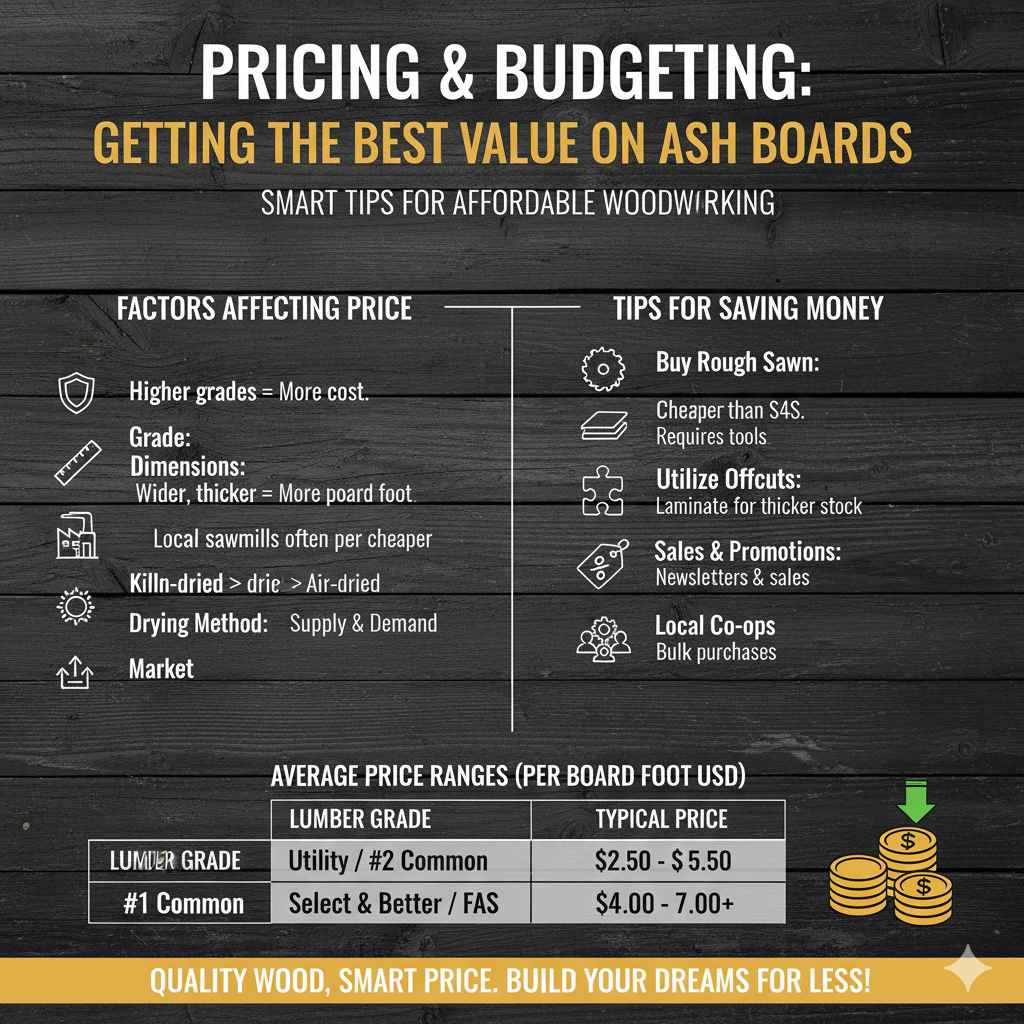

Pricing and Budgeting: Getting the Best Value on Ash Boards

Affordability is a big part of making woodworking accessible. Ash boards generally fall into a very reasonable price range for a hardwood, making them a smart choice for budget-conscious crafters.

Factors Affecting Price:

- Grade: As mentioned, higher grades like FAS will be more expensive than common or utility grades.

- Dimensions: Wider, thicker boards usually cost more per board foot.

- Source: Local sawmills often offer better prices than large online retailers or specialized hardwood dealers.

- Drying Method: Kiln-dried lumber is generally more expensive than air-dried lumber, but it’s more stable for indoor projects.

- Market Demand: Like any commodity, lumber prices fluctuate based on availability and demand.

Average Price Ranges (Approximate):

Prices can vary significantly by region and supplier, but here’s a general idea of what you might expect to pay per board foot (a board foot is 1 foot long, 1 foot wide, and 1 inch thick).

| Lumber Grade | Typical Price Per Board Foot (USD) | Notes |

|---|---|---|

| Utility / #2 Common | $2.50 – $4.50 | Great for projects where perfect appearance isn’t key. |

| #1 Common | $3.00 – $5.50 | A good balance of quality and cost. |

| Select & Better / FAS | $4.00 – $7.00+ | Premium quality for fine furniture and visible surfaces. |

Important Note: These are rough estimates. Always get current pricing from your preferred suppliers. Some sellers might offer discounts for bulk purchases. Don’t be afraid to haggle respectfully at local sawmills, especially if you’re buying a larger quantity.

Tips for Saving Money on Ash Boards:

- Buy Rough Sawn: Rough-milled lumber is usually cheaper than surfaced (S4S – surfaced four sides) lumber. You’ll need a jointer and planer to flatten and dimension it, but the savings can be significant.

- Buy Thinner Boards: Thinner boards (e.g., 4/4, which is about 1 inch thick before planing) are often less expensive than thicker ones. You can laminate thinner boards together to create thicker stock if needed.

- Utilize Offcuts: Plan your cuts carefully to minimize waste. Smaller projects can often be made from the scraps of a larger project.

- Look for Sales and Promotions: Sign up for newsletters from lumber yards or online retailers to be notified of sales.

- Consider Local Co-ops or Woodworking Guilds: Sometimes these groups organize bulk lumber purchases, which can lead to lower prices for members.

Working With Ash: Tips for Success

Ash is a joy to work with once you understand its characteristics. Here are some tips to help you get the best results from your ash boards.

Cutting and Shaping:

- Ash cuts well with both hand tools and power tools. A sharp blade is key to preventing tear-out, especially in figured grain.

- When using a table saw or miter saw, ensure your blade is set correctly for a clean cut. Consider using a zero-clearance insert on your table saw for easier cuts and better support.

- For curves or intricate shapes, a bandsaw or jigsaw works well.

Joining Ash:

- Ash takes glue very well. Ensure your surfaces are clean and properly jointed for strong wood glue bonds.

- It also holds screws and nails reliably. Pre-drilling pilot holes is recommended, especially near the ends of the boards, to prevent splitting.

Sanding and Finishing:

- Ash has an open grain structure. For a perfectly smooth finish, you might need to fill the pores. This can be done with a grain filler, or by using a sanding sealer.

- Start with a coarser grit sandpaper (like 80 or 100) and gradually move to finer grits (150, 220). Always sand in the direction of the grain.

- Ash finishes beautifully. It accepts stains evenly, but its natural color is also very appealing. A clear coat of polyurethane, varnish, or lacquer will protect the wood and highlight its natural grain.

- For a more professional-looking finish, consider using a water-based polyurethane, which doesn’t yellow over time like some oil-based finishes.

Safety First!

Always prioritize safety in your workshop. Wear appropriate personal protective equipment (PPE) for every task. Familiarize yourself with your tools and their safety features. If you’re ever unsure about how to operate a tool or perform a task safely, seek out reliable instructional resources or ask experienced woodworkers for guidance. Organizations like the Woodworkers Guild of America offer excellent safety advice.

Frequently Asked Questions About Ash Boards

Q1: Is ash a good wood for beginners to use?

Absolutely! Ash is considered an excellent hardwood for beginners. It’s strong and durable yet relatively easy to cut, shape, and finish compared to some other hardwoods. Its forgiving nature makes it ideal for learning and practicing woodworking techniques.

Q2: What’s the difference between white ash and red ash?

White ash (Fraxinus americana) is the more common and preferred species for furniture and woodworking. It has a lighter color with a more open grain pattern and is known for its strength and shock resistance. Red ash (Fraxinus pennsylvanica) tends to be a bit coarser, darker, and can sometimes be less stable.