Baltic Birch vs Maple Plywood: Essential Guide

For homeowners and DIY crafters, Baltic Birch plywood usually wins for superior edge aesthetic purity, stability, and lightness, making it ideal for visible joinery projects where Maple shines due to harder wearing surfaces suitable for dining tables or high-contact furniture needing extra scratch resistance.

Welcome to the workshop aisle! Choosing the right piece of dimensional building material, like plywood, can feel confusing when you’re starting out. You see beautiful photos of handmade cabinets and furniture, but that polished final look depends entirely on your foundation material. Faced with shiny stacks of “Baltic Birch” and “Maple Plywood,” it’s easy to feel overwhelmed about which one suits your first project. Don’t worry at all! As a friend in carpentry, I promise to sort out these beautiful wood products for you. We will break down these two excellent choices with simple facts and pictures in your mind’s eye. Let’s step right in and see which perfect sheet belongs in your next creation or remodeling job.

When it comes to plywood, durability, smoothness, and visual appeal matter a lot for any piece that needs to last—from clever shelving in a bathroom or beautiful kitchen drawer interiors. Baltic Birch and pure Maple plywood are often called the gold standards above standard “hardware store” plywood. Both are stunning multi-laminate options, created by gluing many thin, uniform layers—called plies—together. But though they are both cousins in the high-grade wood family, where exactly do they differ, and how should that guide you to grab the right stack of wood from your lumber supplier next time?

What Is Plywood, Really? The Magic of the Core

Before we compare them head-to-head, let’s make sure we speak the plywood language. Plywood isn’t just layered wood; it’s engineering brilliance. It’s several sheets of real wood laid on top of each other, gluing the next sheet so its grain runs perpendicular (at a right angle) to the one below it. This perpendicular layering eliminates almost all warping and twisting when temperatures change. This gives the sheet incredible stability that solid hard wood lumber almost never achieves.

But where these two specific types totally separate themselves is in the choice of wood making up those inner layers or ‘plies’.

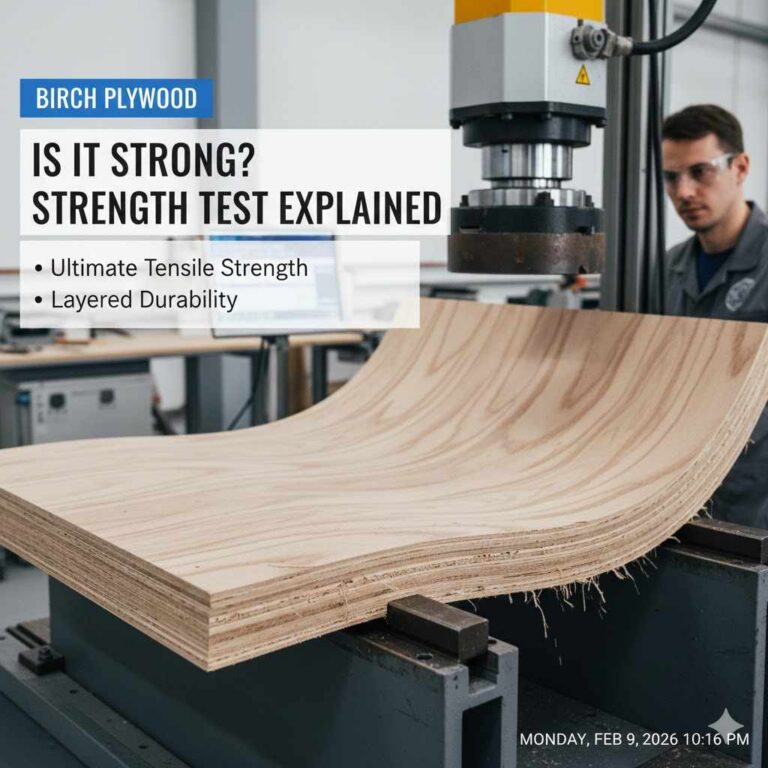

Decoding Baltic Birch Plywood

Baltic Birch, sometimes called Scandinavian Birch, is beloved globally for very good reasons. It comes primarily from the forests surrounding the Baltic Sea (Finland, Russia, and Eastern Europe). Because the local growing season there is cooler and much shorter, trees grow slowly. This tight, dense growth results in very fine growth rings and stronger fiber structure.

The Look and Feel of Baltic Birch

Baltic Birch truly distinguishes itself with its sheer construction. When you slice a piece open and peep the edges, you see beauty that modern materials try to copy. This is where its reputation comes from.

- Excellent Exposed Edges: This is paramount. High-grade Baltic Birch typically features ten or more thin core layers. All these layers should all consist of solid Birch (not mixed veneers). These light, almost seamless edges work wonderfully for open shelving or modern cabinets where you don’t want to use edge banding.

- Color Consistency: The interior veneers have lovely, fairly even light tan appearance, which stains beautifully or paints perfectly.

- Durability and Lighter Weight: Generally, it is lighter weight than domestic Maple, putting less stress on joinery and hardware as we build slightly lighter/healthier furniture right out of hand crafting basics, an element important for things utilizing lighter fixtures like recessed lighting solutions discussed broadly for small space planning in architectural guides at HUD.gov.

Drawbacks of Baltic Birch for Beginners

No material is truly perfect, which means keeping expectations fair from the start helps keep morale high on projects you undertake:

- Price Point: Genuine, A/B or B/B Grade BBB is more expensive than mass-market construction plywood. Factor this into your budget planner sooner rather than just later.

- Scuff Resistance (Surface): Because the facial veneer might be a touch softer for aesthetics than hard Maple, it can dent very slightly more easily with heavy sliding utensils in a kitchen drawer unless strongly sealed or used in lighter traffic areas.

Understanding Pure Maple Plywood (Domestic North American)

North American Maple Plywood is typically made either from hard Maple or soft Maple found widely across the United States and Canada. Hard Maple produces sheets often considered denser and tougher than Birch, especially on the surface veneer.

The Strength and Grain of Maple

When most premium plywood suppliers list “Maple Plywood,” they are usually referring to a product with an entire hardwood core built of dense Maple layers, often top-surface graded like a furniture-grade panel.

- Extreme Hardness: Hard Maple carries very tight rings and a slightly more interlocked wood structure than lesser woods resulting in the best resistance available to scratches, dents, and general wear and tear, excellent for tabletops in a busy household.

- Heavy Duty Performance: Ideal for dining surfaces, floors, industrial workbench tops (if building your very strong shop layout); almost any area where something hard might scrape the surface aggressively. This density adds beneficial weight when the sheet needs to act somewhat like a load-bearing anchor during assembly like certain built-in structures can represent on home remodels.

- Aesthetic Contrast Potential: Maple has a whiter, nearly clear look when raw, taking staining beautifully or providing extremely popular results when clear-coated to maintain that bright foundation tone.

Potential Bumps When Working with Maple

Understandably, dense comes with a few companion hurdles to navigate across for a DIY newcomer:

- Heavier Weight: Maple plywood weighs substantially more box-for-box compared to a Baltic Birch equivalent the exact same thickness. Lifting stacks means working slower or needing a buddy assist, which is important for tool/material staging considerations.

- Edge Visibility Challenge: Due to Maple growth and how the core layers are commonly manufactured (sometimes using mixed core layers in lower ABC grades, sometimes using thinner layers than BBB), you might find rougher, slightly more noticeable seams (voids visible by edge) unless you invest heavily/pay much more for superior A1/B grade faces or guarantee a very smooth visible edge. Where you absolutely must cover edges, Maple handles binding beautifully.

Direct Visual Head-to-Head Comparison Table

Reading descriptions fades quickly compared to a rapid comparison. Here is an easy-to-scan chart to summarize the practical decisions you must make before purchasing those very necessary stacks of flat stock.

| Feature | Premium Baltic Birch (BBB) | North American Maple Plywood ($rightarrow$ Hard) |

|---|---|---|

| Surface Hardness (Scratch Resistance) | Very Good (Slightly Softer) | Excellent (Often Harder/Denser Core & Face) |

| Glue Line/Core Aesthetics (Visible Edges) | Outstanding; Virtually Void-Free Layers | Good to Very Good (Depending on Specific Grade/Price) |

| Weight for same size (Density approx.) | Significantly Lighter | Heavier / Denser Material |

| Core Veneer Uniformity | Extremely Uniform (Baltic Sourcing Influence). | Usually All Maple Core, uniform layers. |

| Typical Cost Benchmarks | High/Mid-to-High | Mid-to-High (Competitive) |

Which Plywood is Best: Matching Wood to Project Needs

So, which material do you choose for your next Saturday job? The decision usually boils down this way. Are you showcasing pretty edges, or are sheer dent resistance and overall weight of hardware coming into play?

- Choose BEST Aesthetic Visibility – Use Baltic Birch:

- If you intend to float bookshelves against white walls, where you want crisp color definition right up to painted or stained surface edges, select BBB.

- For internal construction pieces that add fine detail, like inner drawer boxes where a craftsman may choose not to obscure all good woodworking.

- When you are achieving very modern, light assemblies where adding unnecessary ounces matters for installation convenience.

- For projects requiring complex bend radii where material handling of lighter components offers safety comfort points inside tight construction work zones.

As your mentor figure in woodworking, I lean extremely hard toward Baltic Birch for the majority of cabinetry and furniture facing that uses exposed framing techniques (like Shaker construction visible seams facing front), mainly utilizing its layer control and edge smoothness.

When to lean into that dense ???? power of Maple:

- Choose BEST Wear Protection – Use Maple:

- When making large tabletop working surfaces, outdoor furniture (always seal well with marine spar varnish if outdoors), or commercial-use items destined for heavy friction situations requiring excellent performance longevity according to established wood product testing standards utilized industry-wide.

- If painting high durability components like bathroom vanity doors where constant splashing or hand contact presents abrasion risks. Maple stands taller against moisture impact penetration better on the surface layers too!

- When you want superb structural support while minimizing the thickness of the ply being attached, because, pound-for-pound for absolute stiffness, dense Maple dominates very slightly.

This is where knowing material specifications assists greatly: Hard Maple ranks higher on the Janka Hardness Scale compared to standard Birch, which is a known indicator of its amazing toughness compared to many other standard construction woods you run into. (If you want to read a slightly more technical background reading this hardness information can sometimes become overwhelming, seek out material comparison charts at reliable educational resource repositories from forestry extension offices).

Cutting & Finishing Both Linoleum, Oops, I Mean ‘Material’ Sides

You might be concerned about sawing through these premium sheets. Do they demand specialty tools and complicated routines?

The Cutting Experience

Fear not! If you can rip and cross-cut standard dimensional lumber, these will feel excellent, provided your blades are sharp.

- The Blade Tip: Always utilize a High Alternate Top Bevel (Hi-ATB) blade designed specifically for cutting plywood and panel products. Plywood requires a high tooth count blade (usually 60-80 teeth for a 10″ blade) with a fine, almost razor sharpness to shear through the opposite grain/glue line neatly the second a layer exits for smooth faces adjacent to cuts.

- Support Passes: For extra smooth edge cuts (especially on delicate Baltic cores during tear-out prevention), place painter?s tape over the cut-line, or score it first lightly with a sharp utility knife prior to starting the saw line. This trick really boosts beginner results when using materials famed for their clean faces, like Grade-A Baltic Birch.

Sikinsin? Staining and Sealing Tips

This is a crucial place where they differ!

Finishing Baltic Birch

Baltic Birch takes stains well, BUT it is famed for its tendency here called “blotching or flashing” due to its dense, fine grain soaking finish in irregular patterns if not stabilized first.

- Always Use De-Waxed Shellac or a Stabilizing Gel Stain: Before applying a conventional walnut oil stain, first apply a dedicated sealing step usually one coat of Zinsser brand dewaxed dewaxed shellac sealer. This raises way high up an even saturation leveling platform across both the tight grains and those slight internal odd areas, stabilizing your color profile!

- Top Coat Power: Seal it with polycrylic when painting or painting white, or any durable final protective coat (water-based urethanes cure fastest), often making it surprisingly sturdy in practice despite appearing gentler than raw Maple!

Finishing Maple

Maple’s density offers two primary challenges:

- Extremely Low Absorption: Maple is very tight-grained and naturally prefers to resist deep darkening when staining. Applying a standard wiping stain usually yields a pale result.

- The Solution: Precondition or Dye: You absolutely MUST use a proper Plywood Pre-Stain Conditioner OR (my much preferred method if going very dark) use actual professional wateralcohol-based dyes before any pigment change occurs from pigmented staining products. These penetrating catalysts push color uniformly past the glue seams and face veneer right up near that hardness factor we benefit from!

Final Weight Watch: When Weight Matters

As a wood hobbyist working solo often in smaller workshop spaces, tool organization, shop safety, and material handling become your allies outside of how great the shelf looks aesthetically.

Consider this practical scenario: Modifying interior shelving behind a fixed refrigerator unit in somebody’s small galley kitchen where mobility across lifting/twisting is tight, this requires manageable pieces.

When handling 3/4 inch stock size:

The Maple equivalent pane sheet size listed routinely weighs about NO%-20% more pound-for-pound depending on the sheer density core configuration from the vendor’s supply chain logistics. That feels small on one panel, perhaps less safe when trying high lift installs against standards described for construction components published by organizations focused specifically on lowering installer strain, yet it accumulates significantly over making dozens of cabinet body shelves.

Baltic Birch wins easy favors here as you seek to make shop operations much gentler, safer to maneuver, helping you complete finishing sequences faster as lifting one over is simply simpler from safety training fundamentals.

Can I Just Use Any Birch Instead of Baltic Birch? Safety Heads Up!

This is the crucial pitfall that stops many great aspiring wood workers, so pay very close attention to branding here!

No. You absolutely cannot, period, assume a local supplier’s standard domestic “Birch Plywood” is interchangeable with advertised premium “Baltic Birch Plywood.”

Danger/Quality Divergence Points Between Generics and BBB:

- Core Quality: Standard Birch Plywood, found commonly priced cheaper, is typically constructed using many mixed wood cores (Void Core Sandwich). It might even skip the Birch entire in intermediate plies if the B grade fails to hit quality standard (like many types of structural plywood sheeting). BBB uses ALL Birch plus stringent inner layup quality where very little gap is found.

- Formaldehyde & Adhesives: While modern big box suppliers generally aim low VOC (Volatile Organic Compounds) compliant products now due to increasing building codes, extremely cheap imported or contractor birch ply that just generically says Birch veneer may sometimes use weaker or lesser quality binding agents compared to panels verified compliant under extremely strict (and generally slightly more expensive) Baltic sourcing mandates focused purely on interior architecture grade materials. If using any wood indoors that will provide strong long lasting results you must consult the Certificate Of Compliance for urea-isocyanate limits compared against modern US or EURO regulations. Make sure its EPA TSCA Title VI exempt, or meets those low emission levels for your best wood results going further.

- Visual Deception: Generic local plywood puts a single, thin sheet of pretty yellow Birch face over a mushier poplar or lauan core, destroying dimensional stability that is crucial if you plan revealing edges later. Baltic wins clean structural performance hands down across the entire sandwich.

Frequently Asked Questions (FAQ) for Beginner Builders

Q1: Which one is significantly more affordable to start woodworking with?

Generally, if local availability is good, standard North American hardwood plywood options (like lower-grade domestic Maple/Oak blends) will have a slightly lower material square-foot cost than verified, highest-grade A/B or B/B Euro-Import Baltic Birch. But cheap generic ply using Alder or Poplar core for the inside still beats both on cheapest first cost.

Q2: Can I cover any defects visible on the expensive edges of basic Baltic stacks without messy sanding?

Using solid veneer tape might be difficult if the core gaps (say you bought only B&C grades) show large dark specks. Strong advice: If you cannot find clear, high layer count BBB, you must employ quality edge banding in the form of plastic peel-and-stick trims, or solid wood battens glued hard edge, rather than attempting to fill voids deeply on these visible edges and then trying to match natural stain color across seams – sealing beautifully instead often skips some hassle.

Q3: Does color matching Baltic sides to stain require more color conditioners than plain Maple panels?

Yes, most beginners learn fast that while true Maple takes stain pale compared to raw timber species varieties, almost all Birch cores absorb liquid unevenly—making stabilization (preconditioning) mandatory for a deep, predictable color transfer!

Q4: Which material is slightly easier for a router cutter during edge routing small moldings?

Baltic Birch is actually a little more forgiving here. Because Maple is extremely hard when dense, routers must work harder with superb bearing flatness against that extreme surface density, whereas BBB, owing to its very even density gradient layer systems and thinner layers overall, offers smoother, slightly less resistant feedback on precision, fine English profile templates usually performed at router station installations.

Q5: Is thickness uniformity the same when purchased at 3/4″ from both supply chains?

In theory, 3/4 inch is 19 milimeters. In practical workshops reality? No single source guarantees millimeter perfection across massive batches. Maple MDF-grade piles often swing a little more (perhaps spanning 0.7” to maybe 0.78”), but premium Baltic Birch usually shines slightly past peers tracking much closer than 0.735” by way of quality machine inspection inherent to export sizing targets, resulting in much fewer issues during detailed jig manufacturing set ups like dovetail jigs.

Summary Section: Making That Final Confident Decision

You now hold the knowledge needed to confidently select the base material for your fantastic new woodworking pursuit! It’s not about which wood species is objectively ‘better,’ but determining which characteristic—exposed stability and lighter feel (Baltic Birch) pitted against raw industrial density (Maple)—perfectly fits the stresses your particular project will endure.

When the edges have to shine like jewelry on the exterior frame—pull the beautiful Baltic Birch from the rack every time. When you create custom workbench mats, or heavily tasked high-traffic cabinetry centers in a busy garage or kitchen—let the density power of the superior Maple sheet shoulder the load year after heavy year under abrasion stress AND harsh friction/cleaning scenarios.

Always measure twice (even an excellent plywood panel can slip calibration during final purchase receipt verification checks!), choose your blade system based on the material characteristics you calculated must be retained (smooth cuts critical = high Hi-ATB blades), and most importantly, have fun turning a rough stack of beautiful wood sheets into lasting furniture capable of standing proud in your carefully constructed home environment.