Brushed vs Brushless Drill: Exploring Their Core Differences

Choosing the right drill can feel tricky! If you’re just starting, figuring out the difference between a Brushed vs Brushless Drill: What’s the Real Difference? can be tough. Many people get confused by the tech jargon and what really matters for their projects. But don’t worry, it doesn’t have to be complicated! We’ll explore these drills step-by-step so you can make a smart choice for your next project. We will unpack all of the differences in this guide.

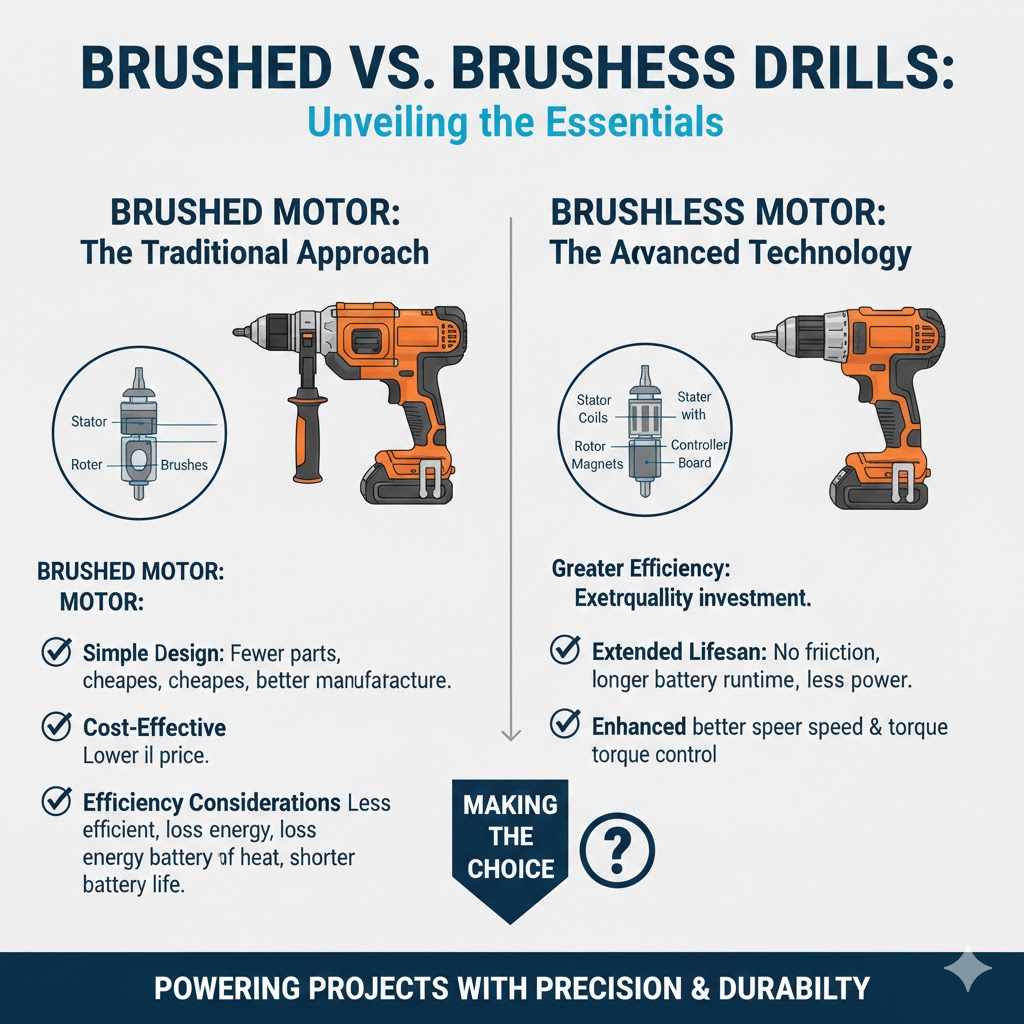

Unveiling the Essentials: Drills and Their Motors

At the core of any power drill is its motor, the engine that provides the force to turn the drill bit. There are two primary motor designs in use today: brushed and brushless. Each design uses a different approach to convert electrical energy into the mechanical force that drives the drill. This affects the drill’s performance, durability, and even its cost. Understanding the basic mechanics of these two motor types is the first move in deciding which drill is right for you. They both do the same job – turning a drill bit to make holes – but they accomplish this goal in very different ways.

Brushed Motor: The Traditional Approach

Brushed motors are the older, more traditional design. They use brushes to transfer electrical current to the rotor, which is the spinning part of the motor. These brushes are made of carbon and wear down over time due to friction. This wear and tear is a key factor in the lifespan of a brushed drill. They also tend to be less efficient than brushless motors, wasting some energy as heat. However, brushed drills are often more affordable and may suit the needs of occasional users.

- Simple Design: Brushed motors have fewer parts, which initially makes them cheaper to manufacture. The basic structure includes a stator (stationary part), a rotor (spinning part), brushes, and a commutator. This simplicity reduces the initial price tag but does not guarantee lasting value.

- Cost-Effective: Because of their straightforward design and widespread availability, brushed drills are usually less expensive to purchase. This makes them a popular choice for DIY enthusiasts and homeowners with infrequent needs. Consider the price and frequency of use when comparing options.

- Efficiency Considerations: Brushed motors tend to be less efficient. A significant portion of the energy is lost as heat. This can lead to a shorter battery life in cordless models and increased power consumption in corded drills.

Brushless Motor: The Advanced Technology

Brushless motors represent a newer technology. They utilize magnets and electronics to control the motor’s operation. This design eliminates the need for brushes, thus reducing friction and wear. Brushless drills are more efficient, delivering better battery life, more power, and lasting longer than brushed motors. Though the initial investment is higher, their improved performance and longevity often make them the better value for frequent users. These types of drills also have more features like speed control.

- Greater Efficiency: Brushless motors are far more efficient. They lose less energy to friction, translating to longer battery runtimes and less wasted power. This makes them especially attractive for cordless tools.

- Extended Lifespan: Without the wear and tear of brushes, brushless motors tend to last much longer. The absence of brushes minimizes the need for maintenance and replacement of parts. This is a big plus for frequent users.

- Enhanced Performance: Brushless motors deliver more power, enabling them to tackle tougher tasks. They can also offer more control over speed and torque. This gives users greater flexibility across different projects.

Key Differences: Performance and Durability

When considering which type of drill to get, the two most important factors are performance and durability. Brushless drills shine when it comes to power and how long they can work before needing maintenance. Brushed drills can still handle many jobs, but they do not always match the output of their brushless counterparts. Understanding these differences can ensure your drill will be up for the tasks you need it to perform.

Power Output and Torque

Brushless motors usually provide more power, particularly under heavy loads. This is because their design allows them to deliver more torque (turning force) to the drill bit. This is noticeable when drilling through tough materials like hardwood or metal. For projects where you are frequently working with difficult materials, a brushless drill’s enhanced power can reduce strain and improve efficiency. This added power translates to more productivity.

- Higher Torque: Brushless motors excel at delivering higher torque, especially at lower speeds. This is very helpful when starting screws or drilling through difficult materials. The added torque makes it easier to complete challenging tasks.

- Consistent Performance: These motors maintain more consistent power output, even when the battery is low. Brushed motors may start to lose power as the battery drains. This means more reliable drilling, even in the final moments of a charge.

- Speed Control: Many brushless drills come with speed control settings. This allows users to adjust the drill’s speed to match the task. This is particularly useful for delicate tasks, where precision is needed.

Lifespan and Maintenance

The lifespan of a drill is a key consideration, especially if you plan to use it often. Because of their design, brushless drills typically last longer. The absence of brushes reduces wear and tear, and also reduces the need for frequent replacements. While brushed drills will get the job done, they often wear out faster. Considering maintenance and cost over time can make the brushless drill a better choice.

- Reduced Wear: Brushless motors have fewer components that wear out. This means less internal friction, which reduces the chance of breakdowns. This leads to a longer lifespan than brushed motors.

- Lower Maintenance: With no brushes to replace, brushless drills require less maintenance. This saves both time and money over the life of the tool. This is a very welcome feature for busy users.

- Durability: Brushless drills are usually designed with more robust components, enhancing their overall durability. They withstand more use than brushed models, particularly under harsh conditions.

Battery Efficiency and Runtime: Which Drill Is Best?

Battery performance is an important aspect to think about, particularly for cordless drills. Brushless motors are more efficient. They draw less power to generate the same level of performance, which results in more runtime per charge. This efficiency can make a big difference, especially for large projects that require extensive drilling or driving. Considering the battery type and power needs is key to making the best choice.

Battery Efficiency Explained

The efficiency of a drill motor directly impacts its battery runtime. Brushed motors tend to waste a portion of the battery’s energy as heat. Brushless motors, with their advanced design, are much more efficient. They convert more of the battery’s power into usable torque, which lets them work longer on a single charge. This can save you time and decrease the number of battery swaps needed.

- Less Energy Waste: Brushless motors minimize energy loss as heat. This results in the battery lasting longer. Users can work for longer periods without interruption.

- Extended Runtime: Brushless drills provide more runtime per charge. This is beneficial for users needing to complete long or complex projects. Reduced downtime means greater productivity.

- Battery Technology: While the motor type matters, the battery technology also has a big impact on overall efficiency. Lithium-ion batteries are common in both types of drills and offer good performance. Consider the battery’s capacity when evaluating runtime.

Real-World Usage Scenarios

To better understand the practical implications of battery performance, here are some typical scenarios. These examples highlight the different performance levels of both types of drills. This can help users better predict which drill type is suitable for their own needs. Remember that these are just examples. Actual results can depend on the brand, materials, and usage patterns.

- Scenario 1: Installing a Deck: A homeowner is building a new deck. They must drive hundreds of screws into treated lumber. A brushless drill’s increased runtime ensures that they do not need to constantly swap batteries. They also benefit from the additional power when driving long screws.

- Scenario 2: Assembling Furniture: An apartment dweller is putting together several pieces of flat-pack furniture. The lighter weight of a brushed drill can be useful. The work is not as intensive, so the lower cost is a bonus.

- Scenario 3: Working on a Car: A car hobbyist is removing bolts and drilling holes for modifications. The extra torque provided by a brushless drill, combined with its sustained power, means the drill is useful for various tasks. The reduced need for battery swaps saves time.

The Cost Factor: Investment and Value

Cost is a huge factor when deciding between a brushed and a brushless drill. While brushed drills are generally less expensive to purchase, brushless drills can offer better long-term value due to their improved durability and lower operating costs. Looking at the long-term price of ownership is key. Both the initial purchase price and ongoing maintenance costs contribute to the total cost. Let’s look at the financial aspects.

Initial Purchase Price

Brushed drills usually have a lower initial price. This is due to their simpler manufacturing process and fewer components. This can make them an easy choice for people with a limited budget or those who only need a drill for occasional use. This lower cost makes it easier to acquire a drill, particularly for novice users or those with less demanding needs. The price difference can be significant.

- Accessibility: The lower cost of brushed drills makes them available to a wider audience. They are usually found in many home improvement stores.

- Budget-Friendly: Brushless drills are more expensive, so brushed drills are better if you have a lower budget. They give homeowners a low-cost option.

- Entry Point: Brushed drills offer a lower-risk entry point for DIY projects. They let users try their hand at different projects without a huge upfront investment.

Long-Term Value and Total Cost of Ownership

While the initial cost of a brushed drill is lower, the total cost of ownership needs consideration. Brushless drills, despite their higher price tag, can offer better value over time. Their increased lifespan, reduced maintenance, and improved battery efficiency can offset the higher initial investment. Looking at the long-term running costs is key. The true cost includes not just the purchase price, but also the costs related to operation, maintenance, and replacement.

- Durability and Lifespan: Brushless drills’ greater durability reduces the need for replacements. This can save money in the long run.

- Maintenance Costs: The lack of brushes in brushless motors cuts maintenance needs. Brush replacement, which is necessary for brushed drills, is costly.

- Efficiency Savings: The greater efficiency of brushless motors means you will spend less on batteries and charging. This can be a savings over time.

Comparing Costs

| Feature | Brushed Drill | Brushless Drill |

|---|---|---|

| Initial Cost | Lower | Higher |

| Lifespan | Shorter | Longer |

| Maintenance | Higher (Brush replacement) | Lower (No brushes) |

| Battery Efficiency | Lower | Higher |

This table summarizes some of the key cost considerations to help you make an informed decision.

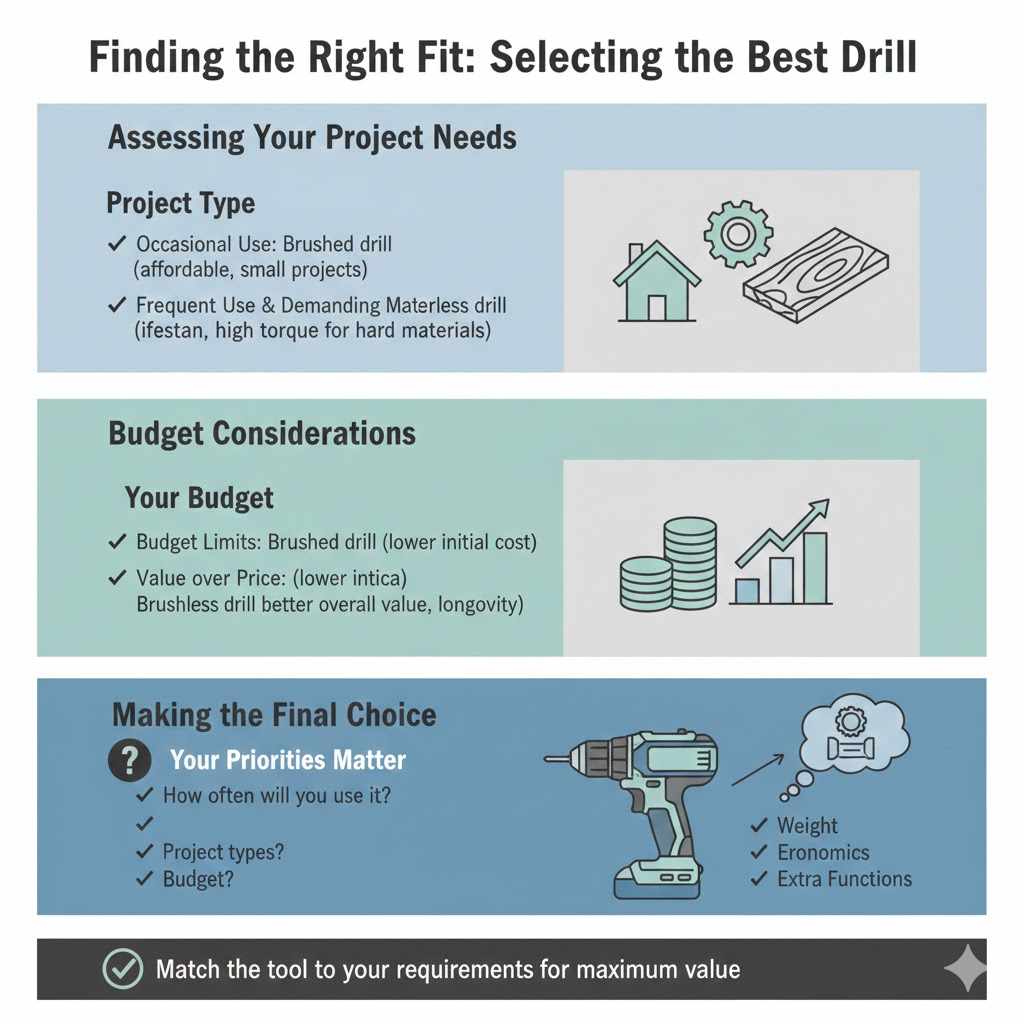

Finding the Right Fit: Selecting the Best Drill

Choosing the best drill is all about matching the tool to your particular requirements and the type of tasks you will undertake. Consider the projects you plan to do, your budget, and how often you will be using the drill. Assess your needs, and you can make the best decision. This can help you get the most out of your tool and increase the value of your purchase.

Assessing Your Project Needs

The type of projects you will be undertaking is the most important thing to consider. For simple home repairs and occasional use, a brushed drill might be sufficient. These drills are affordable and can tackle many basic tasks. However, for more difficult projects or frequent use, a brushless drill is a better choice. Assess the materials you will be working with and the level of performance you require. This includes considering the type of work and the tools you may need.

- Occasional Use: If you only need a drill for basic tasks, a brushed model is a cost-effective option. These drills are great for small projects.

- Frequent Use: If you work on projects regularly, a brushless drill is usually the better choice. The extra power and extended lifespan will provide real benefits.

- Demanding Materials: If you are often working with hard materials (hardwoods or metals), a brushless drill’s higher torque is essential. It will allow you to work faster and more effectively.

Budget Considerations

Your budget plays a vital role. If you are looking for a cheaper option, a brushed drill may be the best fit. Brushless drills are more expensive but can offer better value over time due to their higher performance and extended lifespan. Assess your budget constraints, considering both the initial cost and possible long-term expenses. Think about how important factors like performance and longevity are.

- Budget Limits: If you need to keep costs low, the lower initial price of a brushed drill can be appealing. This may be your primary concern.

- Value over Price: If you are able to spend more upfront, a brushless drill can give you a better overall value. The increased performance and longevity may pay off over time.

- Long-Term Investment: If you are likely to need a drill for many years, investing in a brushless model may be beneficial. The reduced maintenance costs and longer lifespan can make it a smart choice.

Making the Final Choice

Think through your main needs and priorities. Ask yourself how often you will use the drill, what types of projects you will be completing, and what your budget is. This will help you make a smart choice. Take into consideration any additional features that may enhance your work. Think about the drill’s weight, ergonomics, and any extra functions. By making a good decision, you can ensure that you have the right tool to meet your needs and enjoy the process.

Frequently Asked Questions

Question: What is the main difference between brushed and brushless drills?

Answer: The major difference is in the motor technology. Brushed drills use brushes to transfer power to the rotor, while brushless drills use electronic controls and magnets. This affects performance, efficiency, and durability.

Question: Are brushless drills better than brushed drills?

Answer: Brushless drills are usually better for most users. They provide more power, have a longer lifespan, and are more energy-efficient. They are often a better value for the money.

Question: What are the advantages of using a brushed drill?

Answer: Brushed drills are usually less expensive to purchase. This makes them a great option for occasional users or those on a budget.

Question: Do brushless drills last longer than brushed drills?

Answer: Yes, brushless drills typically last longer because they have fewer wearing parts. The absence of brushes reduces friction and the likelihood of breakdowns.

Question: Is it worth upgrading from a brushed drill to a brushless one?

Answer: It depends on your needs. If you often use a drill, you may find that the extra power, efficiency, and longevity of a brushless drill are worth the upgrade. It will likely save you money over time.

Final Thoughts

Deciding between a Brushed vs Brushless Drill: What’s the Real Difference? is not a simple choice, but with the information we’ve explored, you’re well-equipped to make a decision. Remember that brushed drills are usually cheaper, making them good for quick tasks and occasional use. Brushless drills, however, provide more power, extend battery life, and often last longer.

They are better suited for tougher jobs and frequent use. Consider how often you will use the drill and the projects you have in mind. If you value power, long-term durability, and greater efficiency, a brushless drill is the superior choice. Assess your needs, and you’ll find the drill that is right for you. Get ready to start your next project with confidence!