Can You Epoxy Over Wood? Proper Prep Guide: A Simple How-To

Figuring out Can You Epoxy Over Wood? Proper Prep Guide can seem tricky at first. Many people find working with epoxy intimidating, especially when it comes to wood. Don’t worry, it’s totally achievable, even if you’re a beginner! We’ll explore everything from sanding to sealing, making sure your wood surface is perfect for a fantastic epoxy finish. Get ready for a straightforward, step-by-step approach to help you succeed, and let’s get started.

Choosing the Right Epoxy and Wood

The first step in your epoxy project involves picking the right supplies. Using the appropriate materials sets the stage for success. You will explore different types of epoxy suitable for wood, considering factors like cure time, clarity, and resistance to yellowing. Alongside this, you will need to determine which kind of wood you are working with. Different wood types interact with epoxy in distinct ways. Some wood types are porous, others are dense. It’s important to select an epoxy that works well with your chosen wood.

Selecting the Perfect Epoxy

Epoxy resins come in numerous formulations, each with its unique characteristics. Some are ideal for clear coatings, others for casting, and still others are designed to withstand heavy use. Consider the project’s purpose and choose an epoxy accordingly. Look for options with UV resistance, especially if the finished piece will be exposed to sunlight. Choose one with a slow curing time if you’re new to the process, as this gives you more time to work with the material. Also, you will explore the difference between two-part epoxies and one-part epoxies and how they are used.

- Two-Part Epoxy: This is the most common type. It involves mixing a resin and a hardener. The ratio of resin to hardener is essential, and following the manufacturer’s instructions is a must. These epoxies offer great durability and are generally easy to work with.

- Fast-Curing Epoxy: These epoxies set quickly, which can be useful when you need to speed up a project. However, they can also be challenging for beginners, as you have less time to adjust the epoxy before it hardens.

- UV-Resistant Epoxy: If your project will be outside or in direct sunlight, choose an epoxy with UV resistance to prevent yellowing or degradation over time.

- Low-Viscosity Epoxy: Low-viscosity epoxies are thinner, which makes them great for penetrating porous wood and reducing air bubbles.

Consider the color and clarity of the epoxy, too. Some epoxies are naturally clear, while others have a slight tint. You might want a clear epoxy to show off the wood grain, or you might prefer to add color. Some are also designed to be mixed with pigments or dyes, which can be a fun way to customize your project.

Understanding Different Wood Types

The type of wood you choose greatly impacts the outcome of your epoxy project. Different wood species have different properties. Porous woods, like pine or cedar, absorb epoxy more easily than denser woods, such as maple or walnut. This absorption can lead to air bubbles or uneven results if the wood isn’t prepared properly. Also, some woods have natural oils that can interfere with epoxy adhesion. A good way to prevent problems is to always test the epoxy on a small, hidden area of the wood before applying it to the entire surface.

- Porous Woods: Pine, fir, and cedar are porous woods that absorb epoxy. You may need to apply multiple coats or use a sealer before the epoxy to prevent air bubbles.

- Dense Woods: Maple, walnut, and oak are dense woods. They absorb less epoxy, but you’ll still need to prepare the surface with sanding and cleaning.

- Oily Woods: Teak and rosewood contain natural oils that can interfere with epoxy adhesion. It’s often necessary to clean these woods with a solvent before applying epoxy.

- Exotic Woods: These can present unique challenges. Always research the specific wood type and its interaction with epoxy.

It’s important to consider wood movement. Wood expands and contracts with changes in temperature and humidity, which can sometimes cause epoxy to crack or separate if not properly prepared. The selection of epoxy also matters. Some epoxies are more flexible than others, which can help accommodate wood movement.

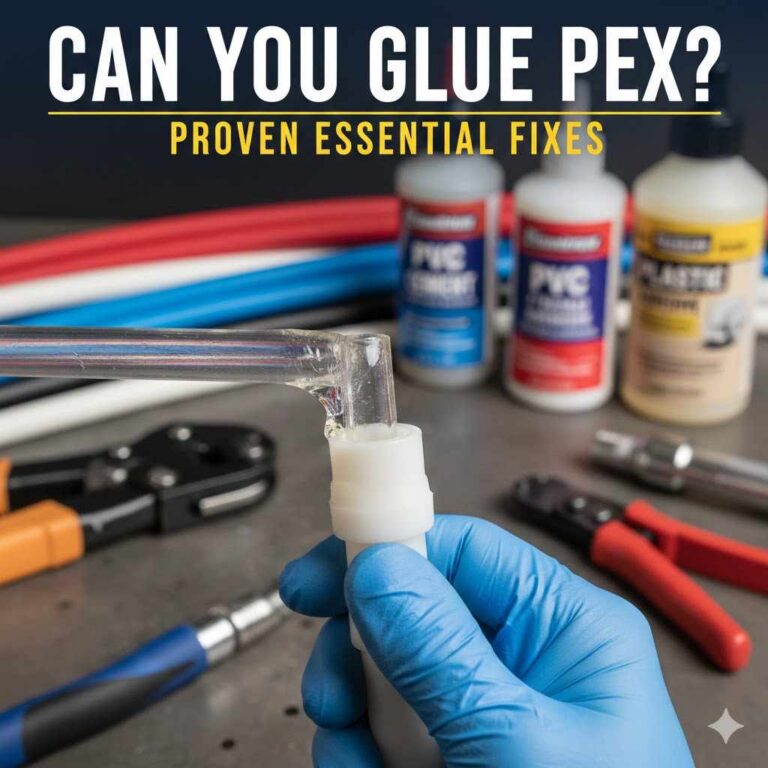

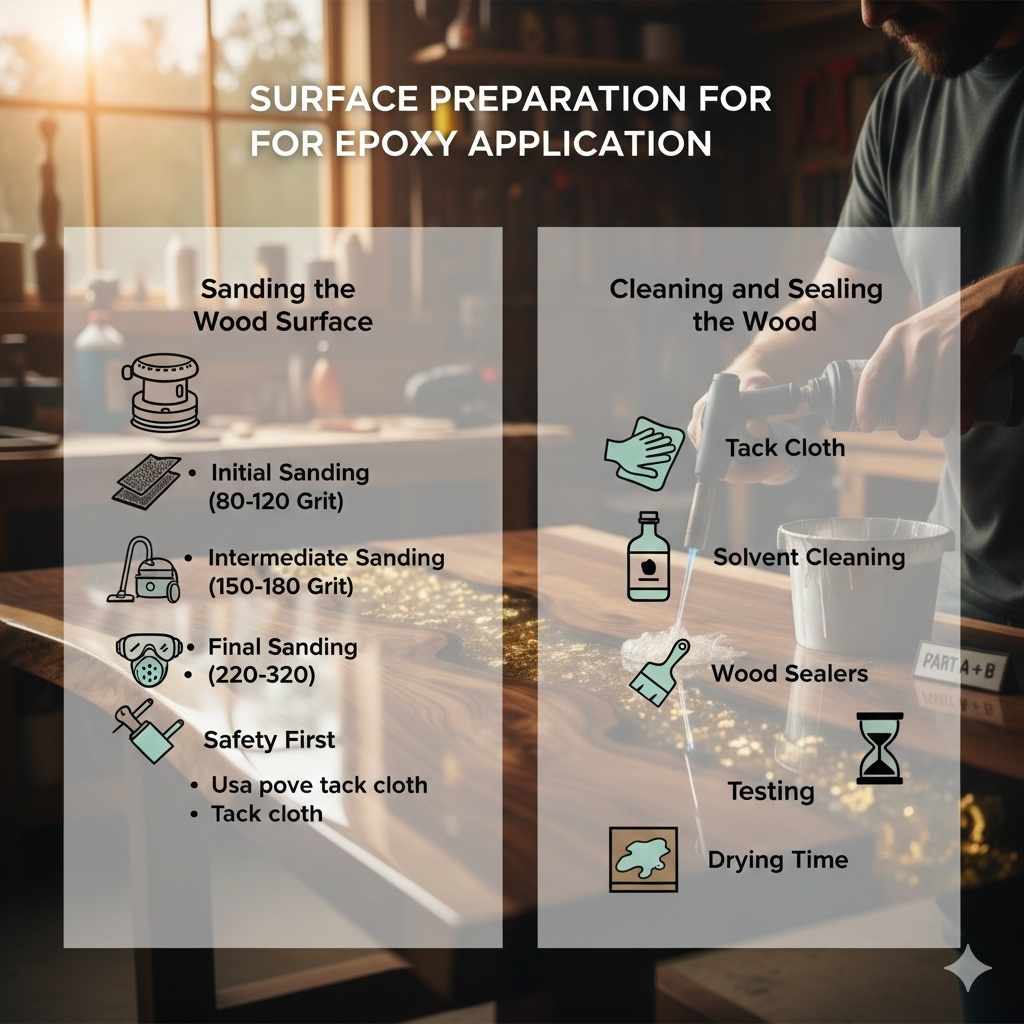

Surface Preparation for Epoxy Application

Surface preparation is absolutely key to a successful epoxy project. Think of it as building a strong foundation. Even if you have the best epoxy and gorgeous wood, if you skip this step, the epoxy might not bond correctly. You will be looking at sanding, cleaning, and sealing the wood, which ensures the epoxy adheres properly, and creates a smooth, bubble-free finish. You will also learn about the importance of a clean work environment, and how to protect the surrounding area.

Sanding the Wood Surface

Sanding is a crucial step in preparing wood for epoxy. It creates a rough surface, which allows the epoxy to bond effectively. The right grit sandpaper to use depends on the wood type and the desired finish. Start with a coarser grit to remove any imperfections, then progressively move to finer grits for a smoother finish. Sanding not only prepares the wood for adhesion, but it also helps remove any loose wood fibers, old finishes, or contaminants. Make sure to sand in the direction of the wood grain for the best results.

- Initial Sanding: Begin with a grit between 80-120 to remove any existing finish and level the surface. This removes any bumps or imperfections that could ruin your final finish.

- Intermediate Sanding: Use a grit between 150-180 to smooth out any scratches from the initial sanding.

- Final Sanding: Finish with a grit between 220-320 to create a smooth surface for the epoxy. This creates the best surface for the epoxy to adhere to.

- Sanding Tools: A random orbital sander is ideal for large surfaces. For smaller or more intricate areas, use a sanding block or hand sand.

- Safety First: Always wear a dust mask and eye protection when sanding.

Keep the sanding area clean. You don’t want any dust or debris getting trapped under the epoxy. Wipe the wood with a tack cloth or a vacuum cleaner after sanding. This will remove any fine particles and ensure a clean surface for epoxy application.

Cleaning and Sealing the Wood

After sanding, it is important to clean the wood to remove dust, oil, and any other contaminants. This step is essential for ensuring good epoxy adhesion. Use a tack cloth to remove any fine dust particles from the surface. Then, clean the wood with a solvent, like denatured alcohol, to remove any oils or residues. If the wood is very porous, sealing it with a wood sealer is a good idea before applying epoxy. This helps prevent the wood from absorbing the epoxy and causing air bubbles. Remember that sealing is necessary to create a barrier and prevent issues down the line.

- Tack Cloth: This removes dust and small particles. Always use a clean tack cloth.

- Solvent Cleaning: Use a solvent like denatured alcohol to remove oils and residues.

- Wood Sealers: Seal porous woods to prevent air bubbles and promote better epoxy adhesion. Make sure the sealer is compatible with epoxy.

- Testing: Test the sealer and epoxy on a hidden area of the wood before applying it to the entire surface.

- Drying Time: Allow the wood to dry completely after cleaning and sealing before applying epoxy.

When selecting a sealer, look for a product that is compatible with epoxy. Some sealers can interfere with epoxy adhesion. A simple test on a small section of the wood can confirm compatibility before you start on your whole project.

Applying the Epoxy Resin

The application of epoxy is the fun part, where your project begins to take shape. This section covers mixing the epoxy, applying it to the wood surface, and handling any air bubbles that may appear. The key to a good epoxy application is to mix it properly, pour it carefully, and handle any imperfections immediately. You will also look at how to properly level the epoxy and achieve a smooth, professional finish. Remember that patience is important for getting the best results.

Mixing and Pouring the Epoxy

Mixing epoxy is crucial for ensuring it cures correctly. Always follow the manufacturer’s instructions for the correct mixing ratio of resin and hardener. Use a clean container, and mix the epoxy thoroughly. Stir slowly to avoid creating air bubbles. Pouring the epoxy should be done with care. Pour slowly and evenly over the wood surface. The thickness of your pour depends on your project’s specifications.

- Mixing Ratio: Always follow the manufacturer’s instructions for the correct ratio of resin to hardener.

- Mixing Process: Mix slowly and thoroughly to avoid air bubbles. Scrape the sides and bottom of the container to ensure everything is mixed.

- Pouring Technique: Pour the epoxy slowly and evenly over the wood surface.

- Thickness: The thickness of your pour will depend on the project requirements. Thicker pours may require multiple layers.

- Working Time: Be aware of the epoxy’s working time. Once mixed, you’ll have a limited time to work with it before it starts to harden.

It’s important to pour the epoxy slowly and steadily to minimize air bubbles. If air bubbles do appear, remove them immediately with a heat gun or a toothpick. Overmixing can also introduce air bubbles. Use a flat-edged stirring stick to scrape the sides and bottom of the container.

Dealing with Air Bubbles and Imperfections

Dealing with air bubbles and imperfections is a standard part of epoxy work. Even with careful mixing and pouring, bubbles can still appear. These can be removed with a heat gun or a toothpick. The goal is to remove the bubbles before the epoxy hardens. Other imperfections might include dust particles or uneven surfaces. You may need to sand and reapply epoxy to correct imperfections. The goal is to achieve a flawless, smooth finish.

- Heat Gun: Use a heat gun to pop air bubbles. Hold it a few inches from the surface and move it slowly across the epoxy.

- Toothpick: Use a toothpick to gently pop any bubbles that remain.

- Dust Removal: Avoid dust. If dust does get into the epoxy, it can be removed by careful sanding or re-pouring a thin layer of epoxy.

- Surface Leveling: Ensure the surface is level to prevent the epoxy from pooling unevenly.

- Multiple Coats: If you are dealing with imperfections, several coats of epoxy may be needed.

If you see bubbles, don’t panic. A heat gun is an effective tool to eliminate most of them. Move the heat gun in a sweeping motion, keeping it a few inches away from the surface. For smaller bubbles, a toothpick can be used to pop them gently.

Curing and Finishing the Epoxy

After applying the epoxy, the next step is curing, which is the process of the epoxy hardening. This is followed by finishing, where you refine the surface to achieve the desired look. Curing time varies depending on the epoxy type and the surrounding environment, like humidity. Finishing involves sanding, polishing, and applying a final protective layer to ensure durability. Achieving a professional finish requires patience and a good eye for detail. This section will guide you through the process of curing, sanding, polishing, and protecting your epoxy-coated wood.

The Curing Process and Environment

Curing is the chemical process by which epoxy hardens. The time required for curing depends on the specific epoxy formula and the environmental conditions. It is important to create a suitable environment for curing. Curing is affected by temperature and humidity. Always refer to the manufacturer’s instructions for specific curing times and conditions. This usually involves keeping the project in a temperature-controlled environment, away from dust, and ensuring the surface is level.

- Temperature: The curing temperature affects the speed of the curing process. Warmer temperatures generally speed up curing, while cooler temperatures slow it down.

- Humidity: High humidity can affect the curing process. Aim for a dry environment to ensure proper curing.

- Dust Control: Cover the project or work in a dust-free area.

- Level Surface: Ensure the surface is level during curing to prevent uneven epoxy distribution.

- Curing Time: Always follow the manufacturer’s suggested curing time. Do not disturb the project while curing.

Controlling the environment can help ensure the best results. Temperature and humidity will both play a role in the process. Warmer temperatures can speed up the curing process. Always follow the manufacturer’s instructions for the specific epoxy you’re using. Ensure that the project is kept away from dust.

Sanding and Polishing the Epoxy Finish

Sanding and polishing are important steps for a flawless epoxy finish. Begin with sanding to level any imperfections and prepare the surface for polishing. Use progressively finer grits of sandpaper to achieve a smooth surface. This creates a surface that’s ready for polishing. The polishing process removes minor scratches and enhances the shine. Polishing gives you a professional, glossy finish. Proper sanding and polishing will create a smooth, clear surface.

- Sanding Steps: Start with a coarser grit (e.g., 220 grit) and gradually work up to a finer grit (e.g., 3000 grit) to remove imperfections.

- Sanding Tools: Use a random orbital sander or hand-sand, depending on the size of the project.

- Polishing Compounds: Use polishing compounds to enhance the shine.

- Polishing Tools: A buffing pad or polishing wheel can be used to apply the polishing compound.

- Surface Preparation: Ensure the surface is clean and free of dust before polishing.

Start with a coarser grit sandpaper to remove any high spots or imperfections, then move to finer grits. The key is to start rough and then progressively smooth until you get a surface ready for polishing. Clean the surface frequently during sanding to remove any sanding residue.

Protecting and Maintaining Epoxy Surfaces

After all the effort you put into your epoxy project, protecting your surface and maintaining it will ensure its longevity. This involves understanding the factors that can impact the epoxy and using techniques for cleaning, protecting, and repairing it. You’ll learn about UV protection, the importance of cleaning products, and how to fix minor scratches. This will help you keep your epoxy surface in good condition for years to come.

UV Protection and Preventative Measures

UV protection is essential for epoxy surfaces that are exposed to sunlight. Direct sunlight can cause epoxy to yellow and degrade over time. You will explore ways to protect your epoxy from UV damage. UV-resistant epoxies are available and are a good first step. Additionally, applying a UV-protective topcoat can significantly extend the lifespan of your project. This topcoat creates a barrier against harmful UV rays and helps to maintain the color and clarity of the epoxy.

- UV-Resistant Epoxy: Choose epoxies that are specifically formulated to resist UV damage.

- UV-Protective Topcoats: These are transparent coatings that can be applied over epoxy to provide an additional layer of UV protection.

- Indoor Storage: If possible, store epoxy projects indoors or away from direct sunlight.

- Window Film: Use window film to reduce UV exposure for items placed near windows.

- Regular Inspection: Inspect epoxy surfaces regularly for signs of yellowing or damage.

Implementing preventative measures helps protect your project from damage. Use a UV-resistant epoxy to begin with, or think about using a protective topcoat. Consider where you place your epoxy projects. Regular checks for any sign of damage are also useful.

Cleaning and Repairing Epoxy Surfaces

Cleaning and repairing epoxy surfaces will ensure they look their best for years. Regular cleaning will remove dust, dirt, and spills that can damage the surface. You will find out the best cleaning methods and products to maintain the shine. Small scratches and imperfections can happen over time. However, many of them can be fixed with simple techniques. Understanding how to handle these minor issues will keep your epoxy surfaces in great condition.

- Cleaning Methods: Clean epoxy surfaces with mild soap and water. Avoid harsh chemicals or abrasive cleaners.

- Spill Cleanup: Wipe up spills immediately to prevent staining.

- Scratch Repair: Minor scratches can be buffed out using polishing compounds.

- Deep Scratch Repair: For deeper scratches, you may need to sand and reapply epoxy.

- Protective Coatings: Consider applying a protective coating to reduce the risk of scratches and damage.

Use mild soap and water for regular cleaning. For spills, wipe them up quickly to avoid staining. Remember that for any deep scratches, you might need to sand and reapply epoxy. Regular care and maintenance will ensure that your epoxy surface maintains its beauty.

Frequently Asked Questions

Question: Can I use any type of wood for epoxy?

Answer: Not all types of wood are ideal. Porous woods like pine require sealing to prevent air bubbles, while oily woods like teak may need special treatment for epoxy to bond properly. Dense woods like maple generally work well.

Question: How do I remove air bubbles from the epoxy?

Answer: You can use a heat gun or a toothpick. The heat gun can be used to pop bubbles. You can also use a toothpick to manually pop any bubbles before the epoxy hardens.

Question: Can I add color to the epoxy?

Answer: Yes, you can add colorants such as pigments or dyes. Always check for compatibility with the epoxy resin.

Question: What’s the best way to sand epoxy?

Answer: Start with a coarser grit sandpaper (e.g., 220 grit) to level imperfections. Gradually work your way up to finer grits (e.g., 3000 grit) to achieve a smooth surface. This creates the best surface for polishing.

Question: How do I protect my epoxy from UV damage?

Answer: Use UV-resistant epoxy. Applying a UV-protective topcoat will also help. Also, store your epoxy project away from direct sunlight.

Final Thoughts

Mastering the process of Can You Epoxy Over Wood? Proper Prep Guide doesn’t have to be hard. From selecting the appropriate epoxy and wood, to meticulously preparing the wood surface through sanding and sealing, each stage contributes to the ultimate finish. The mixing, application, and curing of epoxy are key steps, with techniques like heat guns or toothpicks used to remove air bubbles. Once the epoxy has cured, the final touch includes the refining process of sanding and polishing. Finally, protecting the surface through UV protection, cleaning, and repairing ensures the longevity of your work. Get ready, follow these instructions carefully, and create some beautiful projects.