Can You Polish Engineered Hardwood Floors Explained

Figuring out Can You Polish Engineered Hardwood Floors? is a common question, especially for those new to home improvement. It can seem tricky because engineered hardwood is built differently than solid wood. But don’t worry! This guide will break down the process in easy steps. We’ll explore the materials, tools, and techniques you need to make your floors shine. Let’s get started and learn how to revive your engineered hardwood!

What Is Engineered Hardwood Exactly?

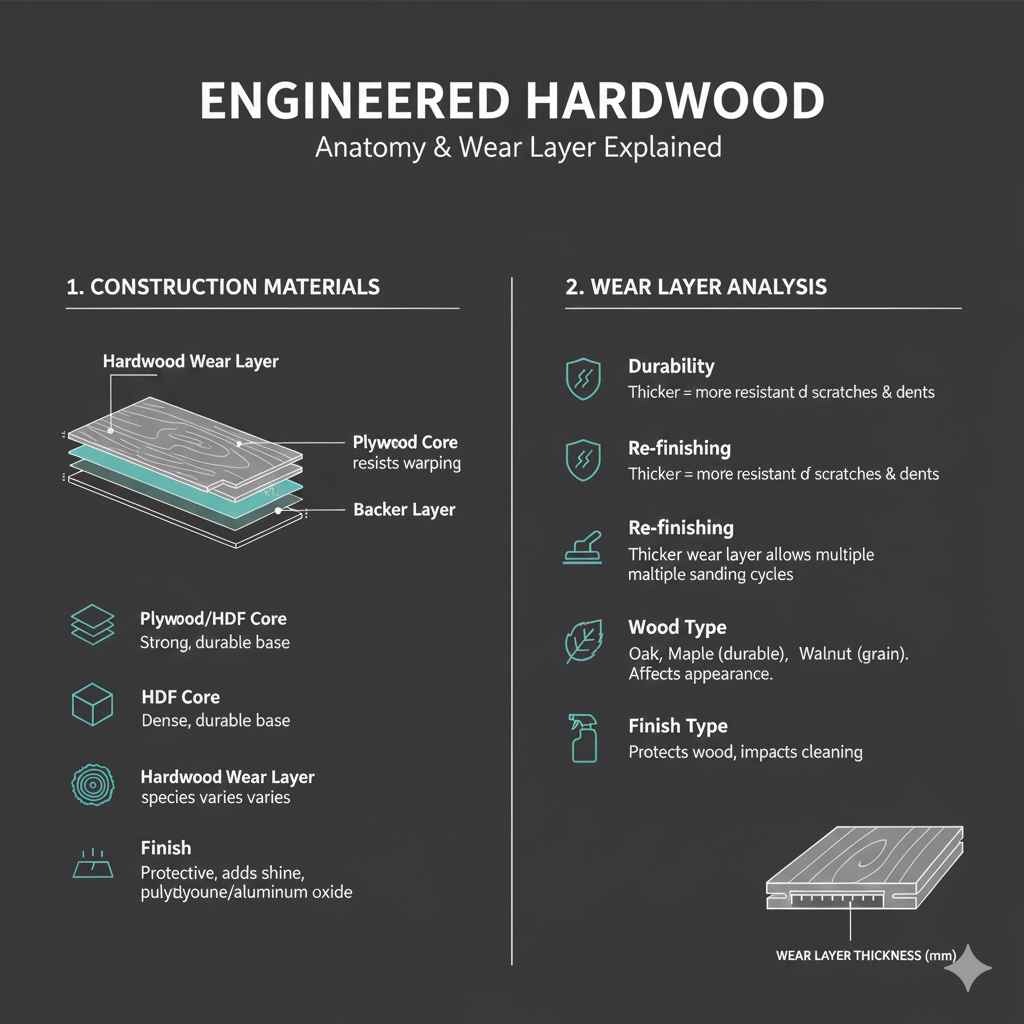

Engineered hardwood floors are a popular alternative to solid hardwood. They’re made with a core of plywood or high-density fiberboard (HDF) and a thin layer of real hardwood on top. This construction makes them more stable and less prone to warping due to changes in humidity and temperature. Because of this unique build, some techniques for solid hardwood aren’t suitable. The top layer, called the wear layer, is crucial because it’s the part you see and walk on. This wear layer’s thickness influences whether you can polish or sand the floor. Also, its finish will impact which products will work.

Wear Layer Analysis

The wear layer is the top layer of engineered hardwood, made of a thin slice of real wood. This layer is crucial because it dictates how well the floor handles wear and tear. Its thickness is measured in millimeters, and it varies depending on the product. Floors with thicker wear layers can often be sanded and refinished multiple times. This allows you to remove scratches or refresh the finish. On the other hand, floors with thinner wear layers might not be suitable for sanding. The wear layer’s type of wood will change the appearance and durability. Knowing your wear layer’s details is the first step in deciding how to treat it.

- Durability: The wear layer’s durability determines how long your floor will last. A thicker wear layer is more resistant to scratches and dents. This means it can withstand more foot traffic and last longer.

- Re-finishing: A thicker wear layer allows for multiple refinishing cycles. Each time, you can sand the wear layer to remove scratches and apply a new finish. This can make your floors look new again.

- Wood Type: The species of wood in the wear layer influences the floor’s appearance. Hardwoods like oak and maple are very common because they are durable and have attractive grain patterns. Softer woods might scratch more easily.

- Finish Type: The finish on the wear layer protects the wood from damage. Common finishes include polyurethane and aluminum oxide. The finish will influence your cleaning and maintenance procedures.

Construction Materials Used

Engineered hardwood uses different materials in its construction. The core is typically made of plywood or HDF. These materials offer stability and resist warping. The wear layer, the top layer, is made from solid hardwood and provides the look and feel of real wood. The core helps give the floor strength and stability. The wear layer provides the aesthetic appeal and protection from wear. Knowing these materials helps you understand how the floor responds to cleaning and polishing.

- Plywood Core: Plywood is made of thin layers of wood glued together, making it strong and stable. It helps resist changes in humidity. This also helps minimize warping.

- HDF Core: High-density fiberboard (HDF) is made from wood fibers that are compressed. It provides a dense and durable base. HDF is a good option for floors where stability is very important.

- Hardwood Wear Layer: The top layer, the wear layer, is made of real hardwood. This provides the appearance and feel of solid wood. Common species include oak, maple, and walnut.

- Finish: The finish protects the wood and adds shine. Finishes can be polyurethane or aluminum oxide, which are durable and provide protection from scratches.

Cleaning vs. Polishing Engineered Hardwood

Cleaning and polishing are different steps in floor maintenance. Cleaning removes dirt and debris, while polishing restores shine and protects the finish. Regular cleaning prevents scratches and keeps your floors looking their best. Polishing can help revitalize worn floors. Cleaning is a daily task, while polishing is less frequent. Understanding the difference is key to good floor care.

The Cleaning Basics

Cleaning is the first step in maintaining your engineered hardwood. Start by sweeping or vacuuming regularly to remove loose dirt and debris. Use a soft broom or a vacuum cleaner with a hardwood floor attachment to prevent scratches. Then, you’ll need to use a cleaner made specifically for hardwood floors. Avoid harsh chemicals and abrasive cleaners that can damage the finish. It’s also important to mop your floors using a slightly damp mop, not soaking wet, to prevent water damage.

- Frequency: Sweep or vacuum daily or as needed. Mop weekly or bi-weekly depending on the level of foot traffic.

- Tools: Use a soft broom, a vacuum cleaner with a hardwood floor attachment, and a microfiber mop. Microfiber mops are gentle and very effective at removing dirt.

- Products: Choose pH-neutral cleaners specifically designed for hardwood floors. Avoid harsh chemicals, ammonia, or abrasive cleaners. These can damage the finish.

- Technique: Sweep or vacuum the floor thoroughly. Mop with a slightly damp microfiber mop, wiping in the direction of the wood grain.

The Polishing Process

Polishing engineered hardwood floors is a key step to restore their shine and protect the finish. Before polishing, thoroughly clean your floors. This removes any dirt or debris that could scratch the surface. Then, apply a polish designed for your floor type. Follow the manufacturer’s instructions for the best results. Use a microfiber applicator to spread the polish evenly. Let the polish dry completely. Be careful not to walk on the floor until it’s fully dry. This ensures a smooth, even finish. Polishing should be done less often than cleaning.

- Preparation: Sweep or vacuum the floor thoroughly to remove any dirt or debris. Clean the floor with a hardwood floor cleaner.

- Product: Choose a polish specifically designed for engineered hardwood. Water-based polishes are easy to apply and environmentally friendly.

- Application: Apply the polish with a microfiber applicator. Spread the polish evenly, following the manufacturer’s instructions.

- Drying: Allow the polish to dry completely. Avoid walking on the floor until it’s fully dry.

Sanding and Polishing: An In-Depth Look

Sanding is a process that removes the existing finish and a thin layer of wood to eliminate scratches. However, it’s not always possible or recommended. The thickness of the wear layer determines if sanding is an option. If the wear layer is too thin, sanding can damage the floor. Polishing is used to restore shine and provide a protective layer without removing any wood. Understanding these options helps you choose the correct method for your floor’s needs.

Is Sanding Suitable?

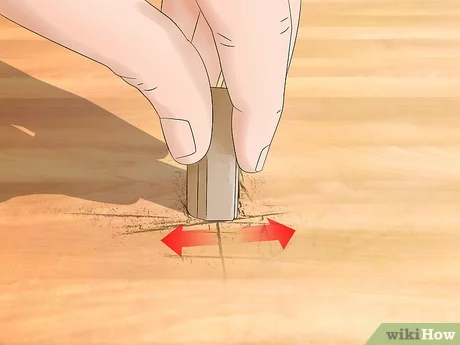

Whether you can sand your engineered hardwood depends on the wear layer. If the wear layer is thick enough, you might be able to sand it to remove scratches and refinish the floor. You might need to contact a professional for advice. If the wear layer is thin, sanding isn’t a good option. Sanding can remove too much of the protective layer. The wear layer will become damaged too easily. Be careful, since improper sanding could lead to floor damage.

- Check the Wear Layer: Find out the thickness of the wear layer. You might find this information from the manufacturer. It’s often included in the product specifications.

- Consider the Depth of Damage: Evaluate the scratches and damage on your floor. If the damage is superficial, polishing might be sufficient. Deep scratches might require sanding.

- Consult a Professional: When unsure, get advice from a flooring expert. They can assess your floor and recommend the best course of action.

- Do a Test Area: If possible, test sand a small, hidden area of the floor. This lets you assess the result before sanding the entire floor.

Choosing a Polish

Choosing the right polish is key to a successful finish. Different polishes are available, each with unique properties and benefits. Water-based polishes are very popular because they dry quickly, have low odor, and are easy to apply. Oil-based polishes offer more durability, providing a richer, more durable finish. Consider the finish on your floor to ensure compatibility. Look at the specific type of finish your floor has. Always follow the manufacturer’s guidelines for the best results. Test the polish on a small, hidden area of the floor before applying it everywhere.

- Water-Based Polishes: These are easy to apply, dry quickly, and have very little odor. They are environmentally friendly and are a great option for many homes.

- Oil-Based Polishes: Oil-based polishes provide more durability and a richer finish. They can take longer to dry and might have a stronger smell.

- Polyurethane Polish: Polyurethane is a very durable finish. It’s resistant to scratches and offers excellent protection. It is a good choice for high-traffic areas.

- Acrylic Polish: Acrylic polishes offer good protection and are often easier to apply than polyurethane. They are very often a good choice for engineered hardwood.

Step-by-Step Polishing Guide

Following a step-by-step guide ensures a good result. Before starting, prepare your floors by cleaning them. This gets rid of any dirt or debris that might interfere with the polish. Start by gathering all the materials you need. Next, apply the polish evenly using a microfiber applicator. Let the polish dry completely. The final outcome is a gleaming floor that’s protected. Taking it one step at a time can help ensure success.

Getting Your Supplies

Gathering the right supplies makes the polishing process easier and more effective. You’ll need a hardwood floor cleaner, a microfiber mop or cloth, and the right polish. A microfiber applicator will help you apply the polish evenly. Also, make sure you have protective gear, like gloves and a mask, to protect yourself. Make sure you have enough polish to cover your entire floor area. This can avoid breaks in the application. Having everything ready saves time and ensures a smooth procedure.

- Hardwood Floor Cleaner: Choose a cleaner designed for hardwood floors. This will remove dirt without damaging the finish.

- Microfiber Mop or Cloth: Microfiber mops and cloths are gentle and effective. They remove dirt and dust. Make sure your mop is clean.

- Hardwood Floor Polish: Select the right polish for your floor type. Follow the manufacturer’s directions.

- Microfiber Applicator: A microfiber applicator will help you apply the polish evenly. This ensures a consistent shine.

- Gloves and Mask: Wear gloves and a mask for protection. Gloves protect your hands, and a mask protects your lungs.

The Application Process

Applying the polish correctly is key for a great finish. After cleaning, apply the polish in thin, even coats. Work in the direction of the wood grain to ensure a uniform appearance. Overlap each pass slightly to avoid streaks. Avoid applying too much polish. This can lead to a sticky finish and take longer to dry. Wait for the polish to fully dry before walking on the floor. Proper application ensures a long-lasting shine and protection.

- Prepare the Floor: Clean the floor thoroughly. Remove any dirt, dust, or debris. Let the floor dry completely.

- Pour the Polish: Pour a small amount of polish onto the floor. Start in a small section and work your way across the floor.

- Apply Evenly: Use a microfiber applicator to spread the polish in thin, even coats. Work in the direction of the wood grain.

- Overlap Sections: Overlap each pass slightly to ensure complete coverage. This avoids streaks. Make sure you don’t miss any spots.

- Allow to Dry: Let the polish dry completely according to the manufacturer’s instructions. Avoid walking on the floor until dry.

Maintenance and Long-Term Care

Regular maintenance is essential for keeping your engineered hardwood floors looking their best. Cleaning frequently and polishing when needed helps maintain their shine and protection. You should avoid harsh chemicals and abrasive cleaners. Protect your floors from scratches by placing mats in high-traffic areas and using felt pads on furniture. These simple steps extend the life of your floors.

Daily and Weekly Maintenance

Daily and weekly maintenance helps keep your floors clean and protected. Sweep or vacuum your floors frequently to remove dirt and debris. This prevents scratches and keeps your floors looking their best. Mop your floors with a hardwood floor cleaner weekly or bi-weekly. This removes any lingering dirt and maintains the shine. Be mindful of spills. Clean them up promptly to prevent stains. These simple steps make a big difference.

- Sweep or Vacuum: Sweep or vacuum your floors daily or as needed. Remove loose dirt and debris.

- Mop Regularly: Mop your floors weekly or bi-weekly with a hardwood floor cleaner. Use a slightly damp mop.

- Clean Spills Promptly: Wipe up spills immediately to prevent stains and water damage. Don’t let liquids sit on the floor.

- Use Doormats: Place doormats at entryways to trap dirt. This stops it from being tracked onto your floors.

- Avoid Harsh Chemicals: Do not use harsh chemicals or abrasive cleaners. Use pH-neutral cleaners designed for hardwood floors.

Protecting Your Floors

Protecting your floors will keep them looking new for longer. Place mats in high-traffic areas to reduce wear and tear. Put felt pads under furniture legs to avoid scratches. Trim your pets’ nails to prevent scratches from their claws. Avoid dragging heavy objects across your floors. Taking these steps helps protect your floors from damage and helps keep them in good condition.

- Use Entryway Mats: Place doormats at all entryways. This helps trap dirt and debris before it gets to the floor.

- Use Felt Pads: Put felt pads under the legs of furniture. These pads prevent scratches when moving furniture.

- Trim Pet Nails: Keep your pets’ nails trimmed. This reduces the risk of scratches.

- Avoid Dragging Objects: Lift furniture and heavy objects instead of dragging them. This will prevent scratches.

- Control Humidity: Maintain a stable humidity level. Extreme changes can damage your floors.

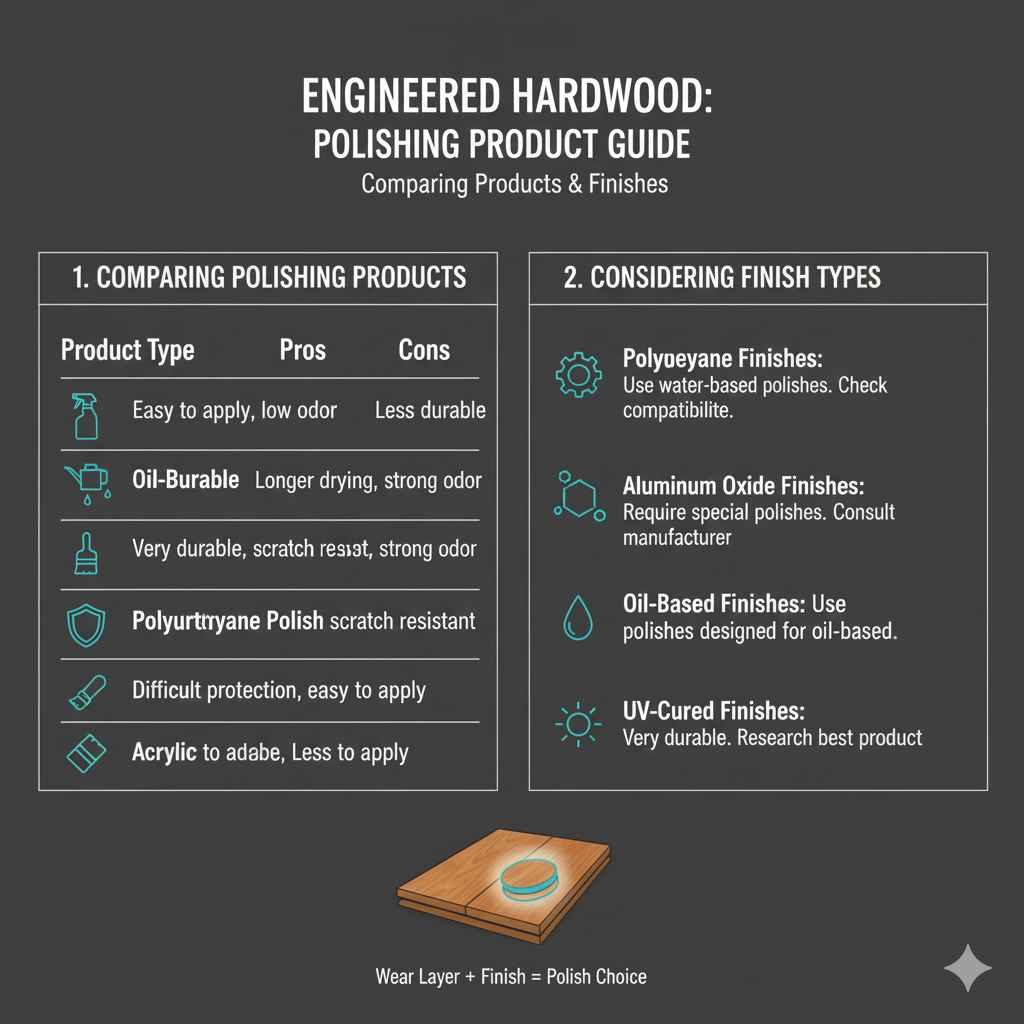

Comparing Polishing Products

Comparing different polishing products is useful to make the right choice for your floors. Consider the type of finish, the level of protection, and ease of application. Water-based polishes are easy to use and environmentally friendly. Oil-based polishes offer more durability. Each product has its benefits and drawbacks. Knowing the differences helps you select the best polish for your specific needs.

| Product Type | Pros | Cons |

|---|---|---|

| Water-Based Polish | Easy to apply, low odor, dries quickly, environmentally friendly | May not be as durable as oil-based polishes |

| Oil-Based Polish | Provides a rich, durable finish, offers good scratch resistance | Longer drying time, can have a strong odor, may yellow over time |

| Polyurethane Polish | Very durable, excellent scratch resistance, long-lasting protection | Can be difficult to apply, can have a strong odor |

| Acrylic Polish | Good protection, easier to apply than polyurethane, fast drying | May not be as durable as polyurethane |

Considering Finish Types

The type of finish on your engineered hardwood is a key factor when choosing a polish. Some polishes work better with specific finishes. For example, water-based polishes usually work well with polyurethane finishes. Oil-based polishes may be better suited for oil-based finishes. Always check the manufacturer’s recommendations. Applying the correct polish can ensure the best results. Incorrect choices could impact the appearance.

- Polyurethane Finishes: Water-based polishes are a common choice because they are compatible and easy to apply. Check for compatibility.

- Aluminum Oxide Finishes: These very durable finishes often require special polishes. Consult the manufacturer’s instructions for the best results.

- Oil-Based Finishes: Look for polishes designed for oil-based finishes. These will help enhance the shine.

- UV-Cured Finishes: These very durable finishes can be more resistant to polishing. Research the best product.

Frequently Asked Questions

Question: Can I sand and refinish my engineered hardwood floors?

Answer: It depends on the wear layer’s thickness. If it’s thick enough, you might be able to. Check with the manufacturer or a flooring expert to confirm.

Question: What’s the best way to clean my engineered hardwood floors?

Answer: Sweep or vacuum regularly, and mop with a pH-neutral cleaner designed for hardwood floors. Use a slightly damp mop.

Question: How often should I polish my engineered hardwood floors?

Answer: Polishing is generally done less frequently than cleaning. The frequency depends on the floor’s wear and the product’s recommendations.

Question: What should I use to apply the polish?

Answer: Use a microfiber applicator. This helps ensure even distribution and prevents streaks.

Question: Are there any polishes I should avoid?

Answer: Avoid polishes with harsh chemicals or abrasive cleaners. Always use products specifically designed for hardwood floors.

Final Thoughts

So, Can You Polish Engineered Hardwood Floors? The answer is often yes, but it’s important to understand the process. We’ve explored the makeup of engineered hardwood, the difference between cleaning and polishing, and the factors to consider before starting. You’ve now seen how to choose the right products and the importance of a good maintenance routine. Remember to check your floor’s wear layer, follow the directions on the polish, and take good care of your floors.

With these steps, you can help keep your floors looking beautiful and protected for a long time. Get ready to enjoy your shining floors!