DIY Small Cedar Wood Projects: Essential, Proven Now

Embarking on diy small cedar wood projects is brilliantly simple for beginners. Cedar’s natural resistance to rot and insects makes it highly durable. You maximize reward while minimizing complicated tools for easy, essential, and proven homemade backyard goods destined to last.

Hello there! I’m happy you’re picking up cedar for your first few home builds. Facing a pile of lumber can sometimes feel overwhelming when you new to tools. But don’t worry; there truly is no better starter wood than cedar. It resists bugs and sogginess all on its own, meaning fewer steps spent agonizing over treatments. Cedar cuts nicely, smells great while you work, and gives your finished piece a touch of rustic class.

We are going to walk through proven projects and set you up confidently—from the first cut to that satisfying final placement in your yard or on your porch. Forget expert skills; we focus only on what is truly essential.

Ready to turn those initial plans into something built to last? Let’s explore some fantastic, achievable outcomes perfectly suited for your new workshop adventure!

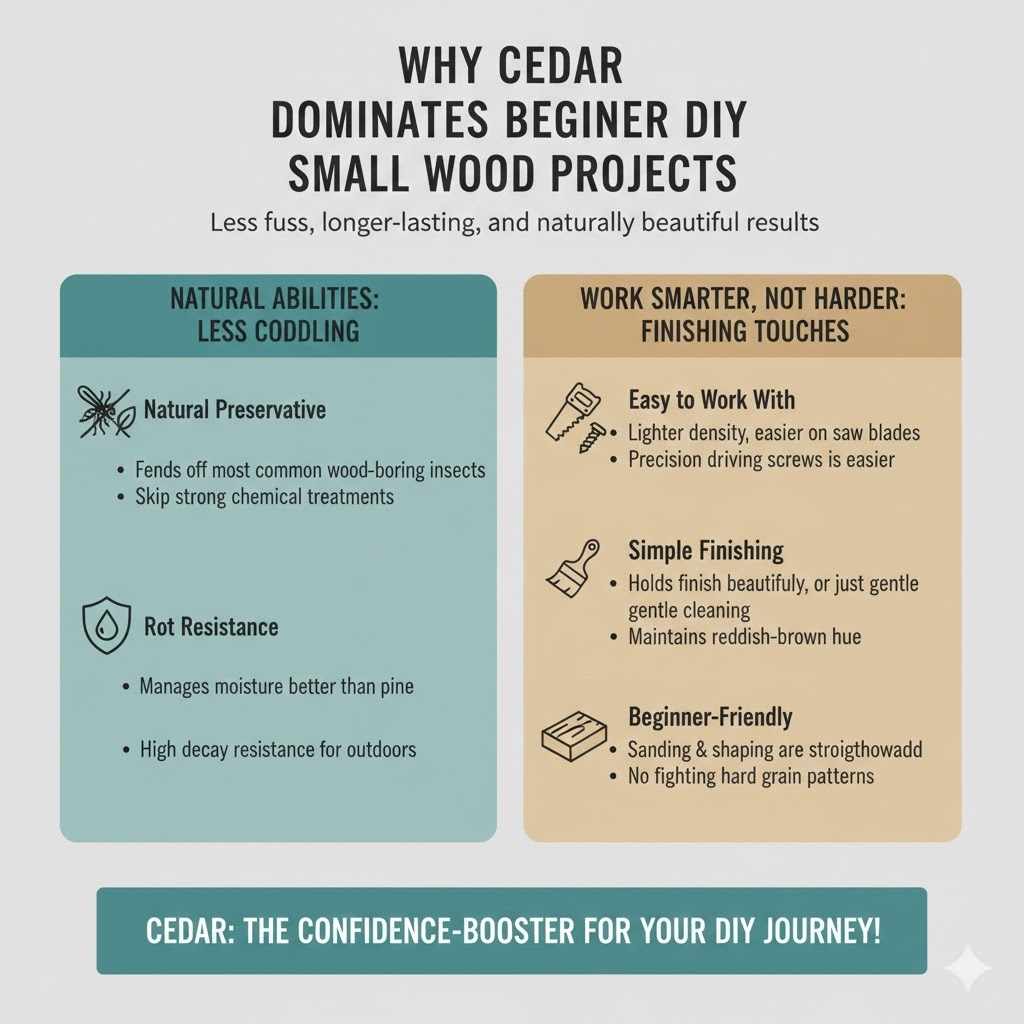

Why Cedar Dominates Beginner DIY Small Wood Projects

When selecting material for outdoor or even indoor decorative items, cedar shines brightly. It’s the gold standard for approachable DIY woodworking. Why should seasoned vets and total newbies alike gravitate toward it? Great cedar quality means results last longer and look naturally better requiring less fuss.

Natural Abilities: Less Coddling the Wood

Cedar wood contains natural oils collectively called cypressene. This oil does two wonderful things for little projects:

- Natural Preservative: It fends off most common wood-boring insects. You skip steps that normally involve strong chemical treatments. This is good for your wallet and your yard!

- Rot Resistance: Cedar manages moisture much better than, say, pine. This high decay resistance means those adorable porch bird feeders or window boxes will survive seasons outdoors without turning mushy. Check authoritative sources like agricultural extensions regarding wood durability class ratings to confirm this feature.

Work Smarter, Not Harder: Finishing Touches

Cedar’s lighter density means it isn’t as tough as oak, which eases the strain on your beginner saw blades. For assembling diy small cedar wood projects, precision driving screws is easier.

- It holds finish beautifully, but you don’t strictly need most finishes! A simple yearly gentle cleaning might be all it needs to maintain its beautiful reddish-brown hue.

- Sanding and shaping are generally straightforward. You won’t fight hard grain patterns that try to splinter tools—a massive confidence boost for newbie builders!

Essential Gear: Keeping Your Toolset Beginner-Friendly

You don’t need a whole cabinet saw setup for effective diy small cedar wood projects. Keeping tools simple dramatically reduces overhead the frustration. You need the right measuring capability, decent cutting power, and sound fastening supplies.

The Tool Trustworthy List (Essential for Starters)

If you invested in one or two reliable items, here is where that first budget should go. Focus quality over specialized quantity for now.

- Measuring: A quality tape measure (must lock tight) and a speed or combination square set. Precision wins ease of final assembly!

- Cutting: A reliable circular saw is transformative simplicity for fence boards or cutting boards to size quickly. If that feels large now, even high-quality hand saws work for tiny first-time pieces pending future budget comfort.

- Fastening: A cordless drill/driver is one indispensable 5-star tool. Lithium-ion batteries last long during these small jobs.

- Safety First: Get snug wraparound safety glasses ($5!) and some reliable ear protection suitable for longer work sessions. Never skip this part; it’s the most essential “tool” for longevity in this hobby.

Fasteners Breakdown

Because cedar expands and contracts softly (less sharply than many hard woods), standard fasteners often rust quickly, leaving nasty green streaks right down your beautiful wood.

| Purpose | Recommended Fastener | Why It Matters |

|---|---|---|

| General Assembly Outdoors | Hot-Dipped Galvanized Screws/Nails OR Stainless Steel | Resists rust which ruins the aesthetics and strength of cedar over time. |

| Small Connects (Decor) | Trim Head Screws (#6 or #8 size) with slightly tapered slot | They hold well but the tiny heads (heads) reduce visual impact dramatically. Ideal for appearance-focused builds. |

Project 1: Cedar Starter Step Block or Small Planting Box

This is the perfect gateway project. A strong, square planter box is instantly useful—decorates the porch or deck, perhaps even holds kitchen herbs near the screen door. It introduces you gently a measuring, cutting a board straight, and secure fastening.

Materials Needed for the Cedar Planter Box (Example Size: roughly 16″ x 8″ x 10″ assembled)

- Dimensional Cedar Lumber (nominal 1×4 or 1×6 are great beginner sizes).

- Outdoor Rated Fasteners (1 1/4″ corrosion resistant screws). Very important!

- Small amount of exterior wood glue allowed for outdoor application (optional—adds joint rigidity).

Step-by-Step Confidence Building Guide

We plan for square joints, meaning every piece relies on precise measuring from the single 4-foot master line on your tape measure. Remember: measure twice, cut perfectly once (my simplified workshop mantra!).

- Plan Measure & Mark: Decide your final four sides (two long, two short legs, one base width). We are making simple butts joints, no messy angles required for confidence building! For simple sizing, a 4-sided, open box.

- Target 2 Outer long sides @ 16 inches length.

- Target 2 Outer short sides @ 8 inches length.

- Crucially, if using the remaining stock space, cut a floor / bottom panel now, sized to sit perfectly inside your finished frame size.

- Cutting Accuracy: Slow down; let the saw do the work. Make straight, crisp cross-cuts at every marked line. Consistency across all five pieces is our single goal. Even slight gaps here encourage wobbling down the road when screws go through.

- Joint Dry Fit: Arrange all four walls flat. Hold them together. Do the two designated long pieces slightly overlap the very ends (widths) of the two short pieces? This ensures your box becomes exactly 16 inches long at the exterior measurement, not 16 inches plus two board thicknesses!

- Assembly – The Corner Secure: Put glue sparingly (just small dots) at one corner junction where a board tip meets a piece face. Drill very narrow pilot holes (even crucial for small boards) slightly smaller than your screw shank diameter to prevent cracking cedar fibers out as the screw bites hard. Drive two screws carefully into that joint point.

- Rinse and Repeat: Work slowly to the corners until the rectangle is rigid. Check aggressively on diagonal measurements for square by checking the dimensions from very opposite corners—if they match, your frame stage assembly is perfect—great success!

- Attach the Floor (If Using Base): Place your box down. Position your base piece (cut shorter earlier) so that it rests flush against the bottoms of the long-term side members right at the ground level. Fasten down through the sides right into the base on steady placements (every 5–6 inches).

A Note on Drainage (Critical for Planters!)

Even naturally resistant cedar slowly degrades if water is continuously trapped beneath the base or the planting floor.

- Drill six well-spaced holes in every square foot of the bottom plane. Think large holes—at least 3/8 inch each—as this dramatically helps move lingering damp away preventing premature decay spots. Utilize resources from cooperative extension university sites about drainage necessity!

Project 2: DIY Cedar Shelf Brackets (Under $5 A Pair)

When aesthetics meet pure function, these little carved out L-brackets look like complex woodworking but use only simple cuts and minimal fasteners. These transform boring drywall! This project solidifies feel and function of power tools without risk.

Skills Highlighted

- Wasteful (but satisfying!) wood removal known as “notching” or “scroll cutting” to create clearance. This teaches blade control beyond simple straight lines.

- Understanding how leverage works through strong joint strength using only geometry.

Cut List Approximation (Use A Thicker Board: True 3/4 inch cedar for rock solid strength)

| Member Role | Approximate Final Size (Target L x H) | Notes |

|---|---|---|

| Wall Anchor Leg | 6 Inches (Height Vertical to receive book shelf above) x 8 Inches (Depth Projecting Out) | This needs strength; cut stock needs excellent grain alignment. |

| Shelf Platform Angle | Shorter Side (Wall attachment side) approx. 2 Inches | This piece supports material at wall, allowing for decorative profile cutoff on front plate. |

Two Key Cuts for Aesthetic Difference and Core Stability

Instead of just driving a screw through two boards mashed 90 degrees (which allows too much wiggle room outdoors or with heavy items), these bracket solutions rely on interlocking cuts before fastening.

- The Slot Cut: On your wider 8-inch piece (the shelf support section), measure two points that fit your shelf width (e.g., if supporting a 3/4 inch piece of matching cedar wall liner lumber resting on it). Carefully cut two square slits (relying absolutely on square blade setting) matching that lumber thickness. This forms a small U-shaped slot allowing the shelf piece to slip half-way into the bracket for support leverage you wouldn’t otherwise get here cheaply.

- Angling the Lower Support Plate: The lower portion that crosses the 2″ mark needs structural integrity relative to holding weight against outward torque. Some classic bracket geometries employ deep diagonal cuts. For beginners, keep this simple: after the shelf slot it cut parallel to top axis on the shelf arm, fasten securely, ensuring your securing screws into the final wall piece cross both members diagonally in a Z geometry. No fancy joining saws yet! We lean hard on excellent fastener alignment here.

- Wall Mounting: Always mount shelf brackets into solid framing members of your wall studs. Fastening only into drywall promises only sad, inevitable collapse over time. Use adequate length of exterior screws to confirm stud penetration past the drywall layer. Make sure studs are plumb using level!

Project 3: The Essential Cedar Monogram Décor Piece

This truly maximizes that wonderful cedar aroma and is fantastic for indoor décor near a fireplace or exterior window, as few tools are required beyond jigsaw, coping saw, or fine hand saw work if an electric jigsaw feels scary.

Focus: The Grain Pattern and Visual Appeal

You are choosing a recognizable letter form. Letters like H, O, A, or simple block text blocks are superior starting models than curves like ‘D’s or the highly complicated’. The density and straight grain of cedar handles these flat-dimension cuts incredibly well.

Design and Cutting for Great First Efforts

- Selection: Select a bold, legible typeface style (thick serifs are easiest!). Print the needed letter very large, often as large as your cedar offcut slab permits after trimming edge imperfections.

- Transferring: Carefully spray adhesive a good, smooth printout to the usable side of your cedar piece. Make sure it lays entirely flat. Do not proceed until it is permanently stuck lightly! Alternatively, thick ink trace works too IF you are going truly manual.

- Saw Work Hierarchy: This is where feeling the saw blade connection shines. For simple internal gaps (like cutting out the center hole of an ‘O’ or the pocket within an ‘A’):

- Identify an anchor point near what you wish needs removing.

- Carefully drill an initial wide entrance pilot hole completely through into background scrap plywood where that material waste will inevitably fall. This is crucial to initiate cutting inside lines.

- Feed the corner of your choice JIGSAW blade through that entrance hole into position. Work slowly. Follow traced lines exactly where the paper meets wood.

- Finishing Soft Touches: Once cut out, peel the white paper off gently. Use 120-grit sandpaper lightly over ALL surviving wood surfaces. A cedar surface looks marvelous in natural state; rough edges look unfinished but new, sharp routes call attention back to your success and take off pencil edge marks cleanly before any finish is even applied (if you apply any finish at all!).

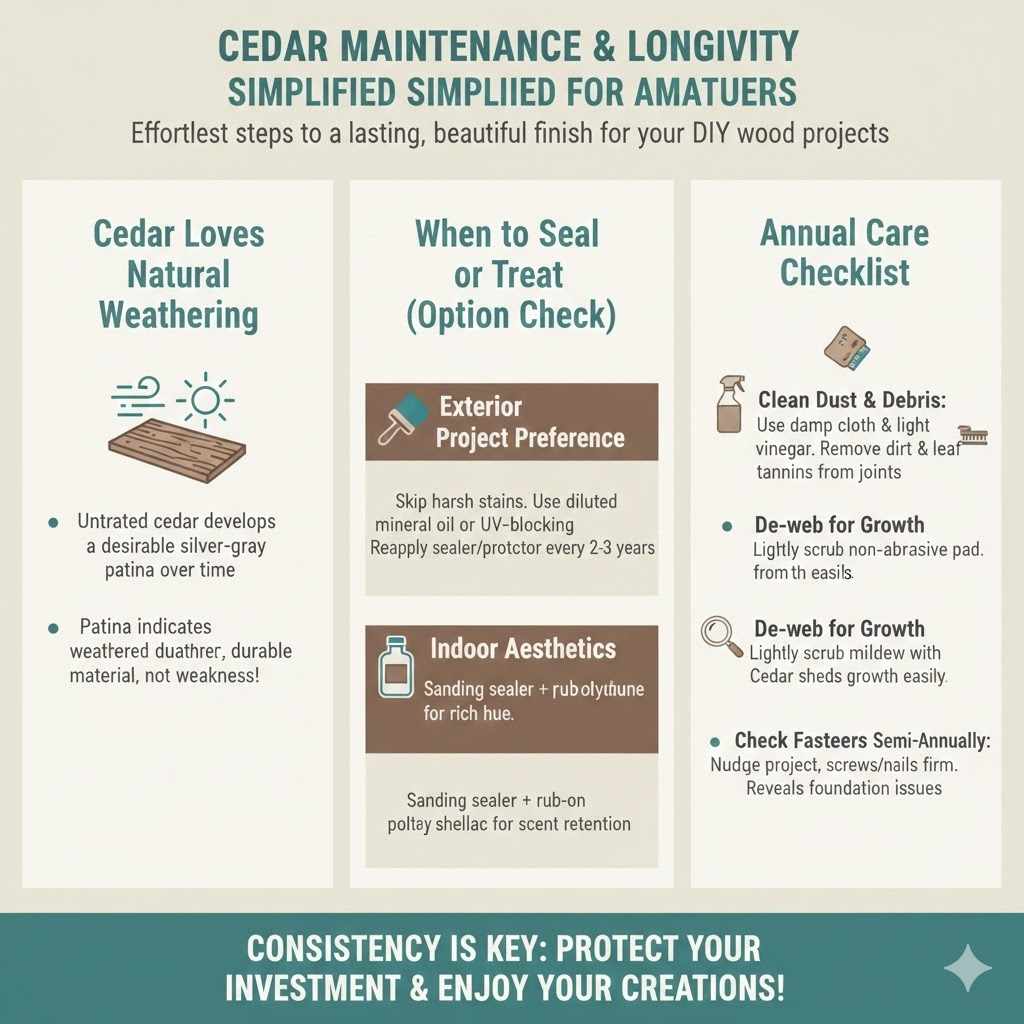

Cedar Maintenance and Longevity Simplified for Amateurs

What secures that rewarding long-lasting glow of your diy small cedar wood projects? Generally, maintenance is less rigorous here than with construction lumber, but consistency helps its outlook and structural commitment.

Cedar Loves Natural Weathering

If you leave cedar untreated outdoors, wind and sun start stripping natural tannins and extracting oils slowly. This results in the highly desire silver-gray patina. This patina appearance does not mean weakness! It usually indicates durable material has weathered, which many see as very attractive.

When to Seal or Treat (Option Check)

For projects where water doesn’t drain easily (like a flat garden bench without drainage spots) or if you live in heavy, damp coastal mist areas, a modest sealer application does protect wood strength.

- Exterior Project Preference: Skip harsh stains initially. Opt for mineral oil diluted heavily, or specific penetrating waterproof protectors that boast UV blocking without heavy surface build-up. Applying sealer/protector every 2–3 years prevents over-commitment.

- Indoor Aesthetics: Light coats of sanding sealer followed by a rub-on polyurethane if you want rich hue maintained years longer. Cedar smell retention improves greatly also with slight treatments of clear shellac base treatments.

Annual Care Checklist

These are super easy steps:

- Clean Dust and Debris: Use only damp (not soaking wet!) cloth and possibly a very light vinegar cleanup solution. Ensure dirt and leaf tannins (which can trap moisture) are purged from joints and corners.

- De-web for Growth: If any mildew appears (often green sludge appearing where water pools around planters), lightly scrub using non-abrasive sanding screen or fine synthetic non-scratch pad. Cedar sheds tough growing things easily—it rarely develops deep spores.

- Check Fasteners Semi-Annually: Just look. Grab your project and nudge it. Screws/nails should feel firm. Given great initial fastener and drilling strategy, movement will reveal foundation issues before structural wood problems occur often!

FAQ: Starting Safely and Smartly With Cedar

Q1: Do I really need to drill pilot holes in every single one of my cedar pieces before screwing them?

Pilot holes are highly recommended, especially nearer the end or edge of any cedar board for two critical reasons: preventing splitting errors and making screw driving far smoother. Because cedar is medium in density, using a pilot just slightly narrower than your screw ensures the fibers separate gently rather than exploding upon high torque load.

Q2: Can cedar trap bugs or pests once installed outdoors, even if it’s naturally resistant?

While superior in general, concentrated moisture or sitting directly on dark soil can invite certain unwanted company. The real threat comes if you paint cedar with an exterior latex paint that cracks or peels, allowing water penetration into heartwood structure. Keep joins clear of sludge, and regular use helps keep insects deterred; infrequent use means damp dark hideaways!

Q3: What is the easiest way to check if my board corner cuts are truly square (90 degrees) during assembly?

The easiest trusted method, besides that speed square or combination square, is the A & B measurement reference trick. Measure diagonally from corner A (top, furthest right) to corner B (bottom, furthest left). Write measurement down. Then measure opposing diagonal corners. If A to B matches B to A exactly (e.g. 15.25 inches both ways), your corners guarantee 90-degree assembly intersections! This builds immense builder confidence when assembling any box shape easily.

Q4: Where is the truly best place to buy cedar lumber appropriate for my small diy small cedar wood projects purchase?

For utility builds like these, dedicated small local lumberyards or reputable big box stores that maintain good stock levels usually work great for standardized cuts (like 1×4 or 1×6). Avoid scraps piles unless you already know precisely what natural defects or splits look like! For specialty trim pieces, finding a dedicated urban or specialty cedar/reclaimed wood shop is worthwhile for excellent grain matching.

Q5: Does unfinished cedar wood bleed sap when I finally place my planter outside immediately after finishing?

Newly cut cedar has more volatile compounds. High-strength outdoor projects require curing time. It is wise practice to let your completed cedar build reside on an old concrete slab or sacrificial staging area outdoors for about one week before you place delicate paved stones or carpeting underneath it. This initial week allows a primary rush of exterior oils or minor surface inconsistencies to stabilize due to normal exterior moisture/sun exposure.

Q6: What wood glue strength is required if I choose to use glue for extra strength in my outdoor cedar joints?

Forget standard PVA glue like yellow wood glue entirely if any exposure to environment occurs! Due to low shear strength when wet, standard white glue fails catastrophically outdoors by softening. Always only select Weather-Resistant-P5, PU (polyurethane), or certified T7 outdoor aliphatic resin formula glues** for exterior connections lasting durability. Most project builders prefer buying specialty T7 type glues marked explicitly OK for outdoor decking assembly safety, as this category offers superb water resistance needed ultimately.

Conclusion: Building Your Foundation, Project by Project

Congratulations on taking the leap! Starting right with cedar ensures that project success feels well-deserved rather than accidental. We mastered measuring straight for durability, using the right tiny fasteners, and securing your corners accurately based on geometry we actually understand; those are three skills professional builders carry every day for high-quality results.

Keep it sturdy over complicated by leaning on cedar’s unique qualities that resist weather naturally. Whether your next beautiful piece becomes serving refreshments from a cedar-made tray indoors or holding soil on your porch within that sturdy box, the confidence you gained today is what guarantees success for your fourth, tenth, and next big cedar effort. Your small projects define your next steps! Pick up your driver, measure twice, and build proof that DIY craftsmanship fits right into everyone’s weekend goals seamlessly right now.