Drill vs Impact Driver: A Genius, Essential Guide

A drill is for precision and versatility, best for creating clean holes and driving screws with controlled torque. An impact driver is a specialist for power, using rotational impacts to drive long screws and large fasteners into tough materials quickly and with less effort, preventing stripped screw heads.

Hello, friend! Welcome to the workshop. If you’ve ever stood in the tool aisle, staring at a cordless drill and an impact driver, wondering what on earth the difference is, you are not alone. They look similar, they both spin, and they both seem to do the same thing. But trust me, this is one of the most common points of confusion for new DIYers, and getting it right will make your projects so much easier.

It’s frustrating when a tool fights you—stripping a screw head or getting bogged down in tough wood. The good news is, it’s not you, it’s the tool! Choosing the right one for the job is a game-changer.

In this guide, I’m going to break down the drill vs impact driver puzzle in the simplest terms possible. We’ll explore what each tool does best, when to use it, and how to choose the perfect one for your needs. Let’s build your confidence, one tool at a time.

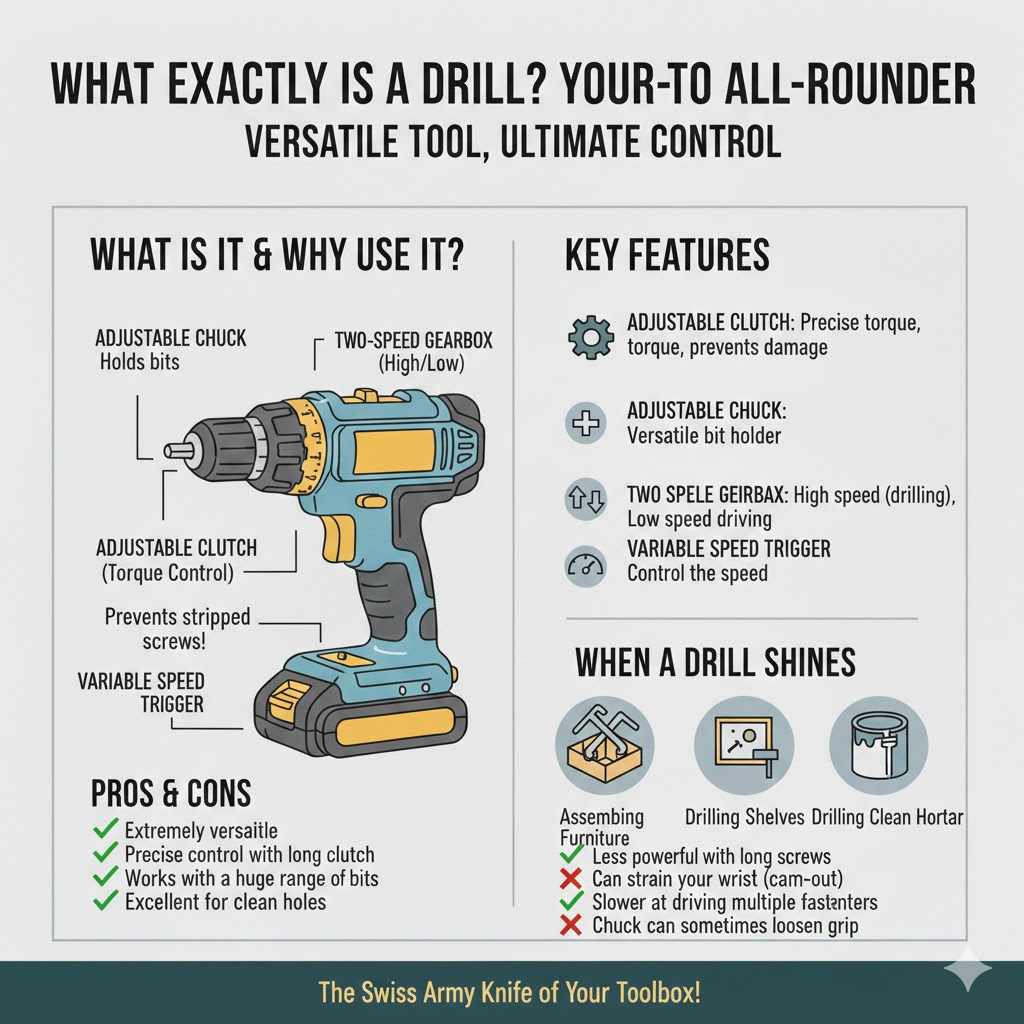

What Exactly is a Drill? Your Go-To All-Rounder

Think of a drill (or more accurately, a drill/driver) as the reliable multi-tool in your power tool collection. Its main job, as the name suggests, is to drill holes. But its gentle, consistent power also makes it a capable screwdriver. It’s the first power tool most people buy, and for good reason—it’s incredibly versatile.

The magic of a drill lies in its two key features: the adjustable chuck and the clutch.

Key Features of a Drill

- Adjustable Chuck: This is the part at the front that you twist to open and close. It’s designed to grip a wide variety of round-shank and hex-shank bits, from tiny drill bits for pilot holes to large hole saws for cutting big circles. This versatility is its superpower.

- Variable Speed Trigger: Just like the gas pedal in a car, the harder you squeeze, the faster it spins. This gives you delicate control for starting a screw or full power for drilling through a thick board.

- Adjustable Clutch: This is perhaps the most important feature for driving screws. The clutch is the ring of numbers right behind the chuck. It controls the amount of torque, or rotational force. When the drill reaches a set torque, the clutch will disengage the motor and make a “clicking” sound. This stops the bit from spinning, preventing you from driving a screw too deep or stripping the screw head.

When a Drill Shines

A drill delivers smooth, continuous rotational force. This is perfect for tasks that require precision and a clean finish.

- Drilling clean, precise holes in wood, metal, plastic, and drywall.

- Using specialty bits like spade bits, Forstner bits, or hole saws.

- Driving screws into softer materials where you need to avoid over-tightening.

- Assembling delicate furniture (like that flat-pack bookcase) where too much power could split the wood.

- Mixing paint or mortar with a paddle attachment.

Pros and Cons of a Drill

| Pros | Cons |

|---|---|

| ✅ Extremely versatile | ❌ Less powerful for long screws |

| ✅ Precise control with the clutch | ❌ Can strain your wrist (cam-out) |

| ✅ Works with a huge range of bits | ❌ Slower at driving multiple fasteners |

| ✅ Excellent for drilling clean holes | ❌ Chuck can sometimes loosen its grip |

What Exactly is an Impact Driver? The Power Specialist

Now, let’s meet the drill’s loud, powerful cousin: the impact driver. If a drill is a versatile family car, the impact driver is a drag racer. It is built for one primary purpose: driving fasteners, and it does it with incredible speed and force. It’s not designed for precision drilling; it’s designed for pure, unadulterated driving power.

The secret to its strength is a special internal mechanism. It spins a bit like a drill, but when it feels resistance, it engages a hammer and anvil. This delivers thousands of powerful rotational “impacts” per minute, in addition to the standard rotation. It’s like a tiny hammer hitting the side of the bit, forcing it to turn.

Key Features of an Impact Driver

- Hex Collet: Unlike a drill’s adjustable chuck, an impact driver has a quick-change 1/4-inch hex collet. You simply pull the collar forward, pop in a hex-shank bit, and release. It only accepts this specific type of bit, making it less versatile but much faster for swapping out driver bits.

- Incredible Torque: An impact driver delivers significantly more torque than a standard drill. This allows it to drive very long screws or large lag bolts into dense wood without bogging down.

- Concussive Action: Those rapid rotational impacts do two amazing things. First, they generate immense turning force. Second, they transfer most of that force directly into the fastener, not your wrist. This means less fatigue and almost no chance of the bit slipping out of the screw head (an event called “cam-out”).

When an Impact Driver Shines

Use an impact driver when you need to drive lots of screws, long screws, or fasteners into tough material. Speed and power are its game.

- Building a deck and driving hundreds of 3-inch deck screws.

- Driving long lag bolts to attach a ledger board to a house.

- Assembling woodworking projects with pocket holes or large screws.

- Working with dense hardwoods that would bog down a regular drill.

- Removing stubborn, over-tightened, or slightly rusted screws and bolts.

Pros and Cons of an Impact Driver

| Pros | Cons |

|---|---|

| ✅ Extremely high torque | ❌ Very loud in operation |

| ✅ Drives fasteners incredibly fast | ❌ Lacks a clutch; can easily overdrive screws |

| ✅ Almost zero wrist strain (no cam-out) | ❌ Not precise enough for fine drilling |

| ✅ Compact and lightweight | ❌ Only accepts 1/4-inch hex-shank bits |

Head-to-Head: A Detailed Drill vs Impact Driver Comparison

Seeing them side-by-side helps clarify everything. Let’s put these two tools in the ring and compare their key attributes directly. This will help you see exactly where each one fits into your workflow.

Core Mechanism and Power Delivery

The fundamental difference is how they work. A drill provides smooth, consistent rotation. Imagine steadily pushing a merry-go-round. An impact driver provides standard rotation combined with rapid, concussive blows. Imagine pushing the merry-go-round and also hitting it with a mallet in the direction of spin every half-second.

This difference in mechanism is why an impact driver can produce 2-3 times more torque than a standard drill. It’s not just spinning; it’s punching and spinning at the same time.

A Clear Comparison Table

| Feature | Drill / Driver | Impact Driver |

|---|---|---|

| Primary Use | Drilling holes, light-duty screw driving | Driving long or numerous fasteners |

| Torque | Lower (e.g., 400-800 in-lbs) | Very High (e.g., 1,500-2,000+ in-lbs) |

| Mechanism | Consistent, smooth rotation | Rotation + tangential impacts |

| Bit Holder | Adjustable 3-jaw chuck | Quick-release 1/4″ hex collet |

| Control | High control via adjustable clutch | Less control, relies on trigger finesse |

| Noise Level | Relatively quiet | Extremely loud when impacting |

| User Experience | Can twist your wrist (cam-out) | Minimal wrist strain |

So, Can One Tool Do It All?

This is the million-dollar question for anyone on a budget or with limited storage space. The answer is… sort of, but not very well.

- Using a Drill as an Impact Driver: You can absolutely drive screws with a drill. For most small jobs around the house, it works perfectly fine. But if you try to drive a 4-inch screw into a pressure-treated 4×4 post, the drill will struggle. You’ll have to push hard to keep the bit in the screw head, your wrist will feel the strain, and you might drain the battery quickly.

- Using an Impact Driver as a Drill: You can buy hex-shank drill bits and use them in an impact driver. It will make a hole. However, it’s not a great experience. The concussive impacts can create a messy, jagged entry hole. It’s difficult to get a perfectly straight and clean hole, and you risk damaging delicate materials. For a quick, rough hole where precision doesn’t matter, it’s fine. For anything else, it’s the wrong tool.

The bottom line: While they have some overlap, they are designed as a team. For any serious DIYer or woodworker, owning both is the ideal scenario. It allows you to use one for pre-drilling holes (the drill) and the other for immediately driving the screw (the impact driver), which vastly speeds up your workflow on big projects like building a deck or a raised garden bed.

Safety is Your Best Friend: A Quick Guide for Both Tools

No matter which tool you grab, safety always comes first in my workshop. Both of these are powerful tools and deserve respect. Always remember to follow the basic safety protocols provided by resources like the Occupational Safety and Health Administration (OSHA).

Essential Safety Tips

- Eye and Ear Protection: Always wear safety glasses! An impact driver, in particular, is extremely loud and requires hearing protection for any extended use. Sawdust and metal shavings can fly anywhere.

- Secure Your Workpiece: Use clamps to hold down what you’re working on. A powerful tool can easily spin a loose piece of wood, which is a serious hazard.

- Use the Right Bit: Use high-quality bits designed for the tool. Impact-rated bits (usually black oxide or a similar dark coating) are tougher and designed to withstand the forces of an impact driver.

- Two-Handed Grip: When drilling large holes or driving large fasteners, use a firm, two-handed grip on the tool to maintain control.

- Know Your Material: Understand what you are drilling into. Avoid drilling into walls where electrical wires or plumbing might be hidden.

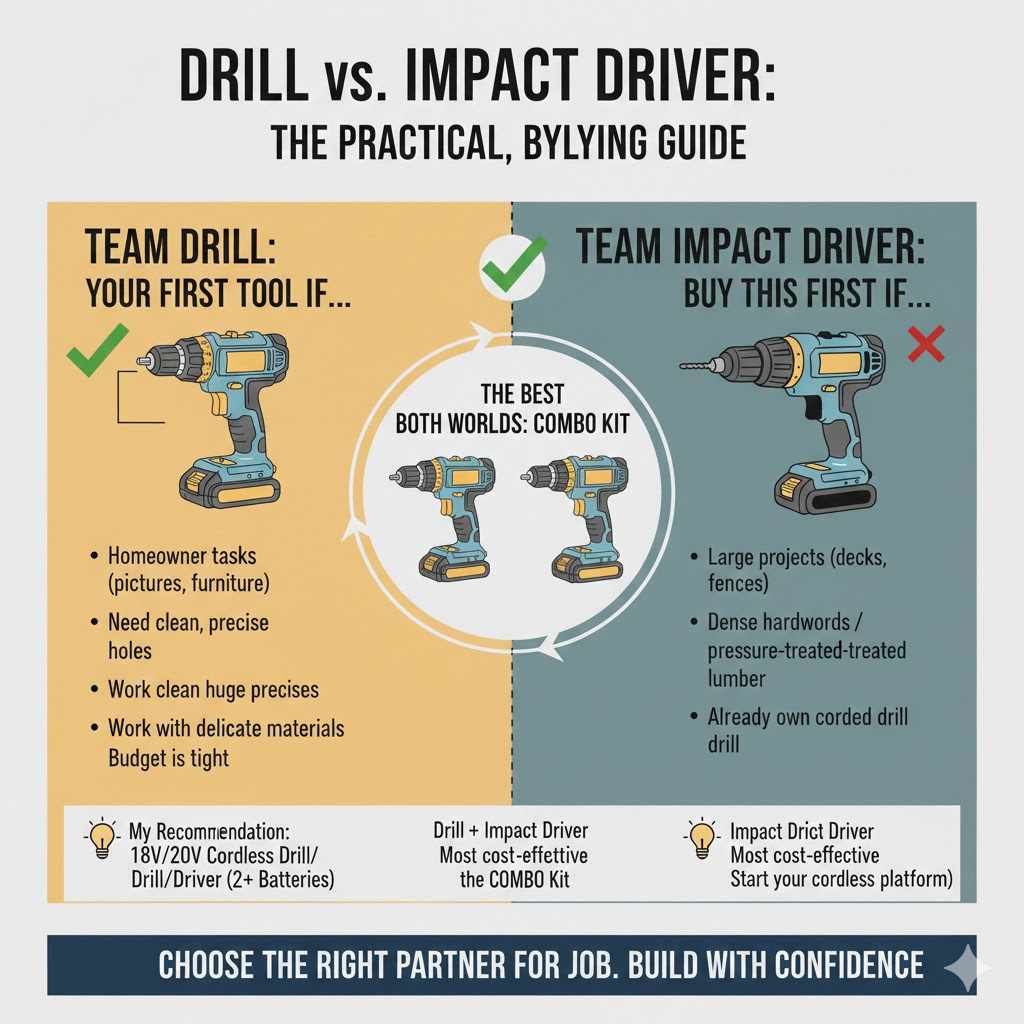

Which One Should You Buy First? A Practical Decision Guide

If you’re just starting and can only afford one tool right now, your choice depends entirely on the types of projects you plan to do.

Team Drill: Buy a Drill First If…

- You are a homeowner who mostly needs a tool for hanging pictures, installing curtain rods, and assembling flat-pack furniture.

- Your projects require drilling clean, precise holes of various sizes.

- You work with delicate materials where precise torque control is essential to prevent damage.

- Your budget is very tight, as a good entry-level drill is often cheaper than an impact driver.

My recommendation: Get a good quality 18V or 20V cordless drill/driver with at least two batteries. It will handle 90% of the small jobs around the house.

Team Impact Driver: Buy an Impact Driver First If…

- You plan to build larger projects like decks, fences, shelving units, or outdoor furniture.

- You will be driving a lot of long screws (over 1.5 inches) on a regular basis.

- You often work with dense hardwoods or pressure-treated lumber.

- You already have a corded drill for your occasional hole-drilling needs.

My recommendation: If you fit this profile, the speed and power of an impact driver will save you an incredible amount of time and effort.

The Best of Both Worlds: The Combo Kit

For anyone who knows they are going to get serious about DIY, the answer is a combo kit. Tool manufacturers almost always sell a drill and impact driver together with a charger and two batteries. This is almost always the most cost-effective way to get both tools and start your cordless tool platform. It’s an investment that will pay for itself with the very first big project you tackle.

Frequently Asked Questions (FAQ)

1. What is the single biggest difference between a drill and an impact driver?

The single biggest difference is the mechanism. A drill uses smooth, continuous rotation, which is great for drilling clean holes. An impact driver uses rotation plus thousands of tiny, hammer-like blows per minute, giving it massive torque for driving screws.

2. Can I use my regular drill bits in an impact driver?

No. An impact driver requires bits with a 1/4-inch hex-shaped shank to fit in its collet. While you can find drill bits with a hex shank, you should not use your standard round-shank drill bits. More importantly, always use bits that are “impact-rated” as they are made from more durable steel that can withstand the tool’s intense force.

3. Why is my impact driver so incredibly loud?

The loud noise is the sound of the internal hammer and anvil mechanism striking together thousands of times per minute. This is what generates the immense torque. The louder it is, the harder it’s working. This is normal, but it’s also why wearing hearing protection is non-negotiable.

4. Is an impact driver powerful enough to remove lug nuts from a car?

Sometimes, but it’s not the right tool for the job. While a powerful impact driver might be able to break a lug nut loose, the tool you’re looking for is an impact wrench. An impact wrench looks similar but is much more powerful and is specifically designed for high-torque automotive work.

5. Is an impact driver better for woodworking than a drill?

It depends on the task. For assembling cabinet carcasses or joining boards with pocket screws, an impact driver is faster and easier. For drilling precise holes for dowels, hardware, or shelf pins, a drill is far superior due to its control and clean finish.

6. Which is better for a beginner, a drill or an impact driver?

For a true beginner doing a variety of small tasks around the home, a cordless drill is the better first choice. Its versatility for both drilling holes and driving screws, combined with the safety net of its adjustable clutch, makes it more user-friendly and adaptable for someone just starting out.

Conclusion: The Right Tool Makes All the Difference

So, there you have it. The drill is your precise, versatile artist, perfect for creating clean holes and handling delicate tasks. The impact driver is your powerhouse laborer, built to drive fasteners with brute force and speed, saving your time and your wrists.

They aren’t competitors fighting for the same spot in your toolbox; they are partners that work best as a team. Understanding their unique strengths is the key to working smarter, not harder. You can now walk into that tool aisle with confidence, knowing exactly which tool you need to bring your next project to life.

Don’t be afraid to invest in good tools. They are the foundation of good work. Now, grab the right tool for your next task and get building. You’ve got this!