Driver Drill Vs Impact Driver: A Definitive Winner

The best tool depends on your project. A driver drill is the versatile, all-around choice for drilling holes and driving screws with precise control, making it perfect for beginners. An impact driver is a specialized powerhouse that excels at driving long screws and bolts into tough materials with incredible speed and force, ideal for heavy-duty jobs.

Hello, fellow makers! I’m Md Meraj, and if you’ve ever stood in a tool aisle, staring at a wall of power tools that all look strangely similar, you’re not alone. One of the most common points of confusion I see is the classic showdown: driver drill vs. impact driver. They both spin, they both drive screws, so what’s the big deal?

It’s a frustrating puzzle for many new DIYers. You might feel like you’re overspending on the wrong tool or, worse, that you’ll end up damaging your project. Don’t worry! Today, we’re going to clear up the confusion once and for all. I’ll break down what each tool does best, where it struggles, and help you decide which one truly deserves a spot in your workshop. Let’s find the right tool for you.

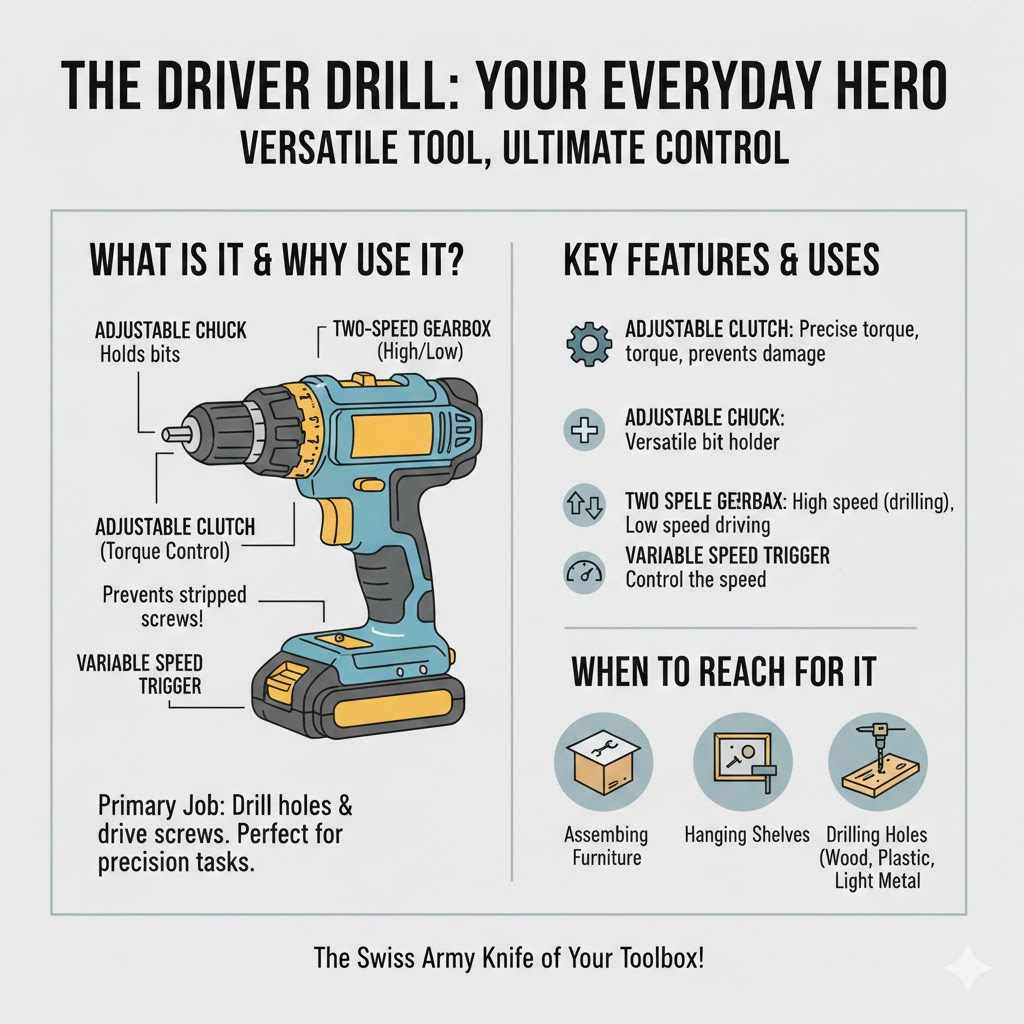

What is a Driver Drill? The Everyday Hero

Think of the driver drill, often just called a “cordless drill,” as the Swiss Army knife of your tool collection. It’s designed to be versatile and is probably the first power tool most people buy. Its main job is twofold: drilling holes and driving screws. What makes it so good for everyday tasks is its control.

The single most important feature of a driver drill is its adjustable clutch. That ring of numbers behind the chuck isn’t just for show! The clutch disengages the motor when a certain amount of rotational force (torque) is reached. This is your secret weapon against stripping screw heads or driving a screw too deep into a delicate piece of wood. You set the number, and when the screw is snug, the drill goes click-click-click instead of continuing to drive.

Key Features of a Driver Drill

- Adjustable Chuck: It has a three-jaw chuck that you can tighten or loosen by hand. It can hold a wide variety of round and hex-shank drill bits and screwdriver bits.

- Adjustable Clutch: This offers precise torque control, giving you the finesse needed for delicate jobs like assembling furniture or working with soft woods.

- Two-Speed Gearbox: Most drills have a switch for high speed (for drilling) and low speed (for driving screws).

- Variable Speed Trigger: The harder you press the trigger, the faster it spins, giving you ultimate control over the speed.

When to Reach for Your Driver Drill

Your driver drill is your go-to tool for a huge range of tasks around the house and workshop. It’s perfect for jobs that require precision over raw power.

- Assembling Flat-Pack Furniture: The clutch is a lifesaver here, preventing you from cracking that particle board.

- Hanging Pictures and Shelves: It drills perfect pilot holes in drywall and can gently drive the screws for the anchors.

- Drilling Holes: This is its primary purpose! Whether it’s wood, plastic, or even thin metal, the drill is the right tool for creating clean, precise holes.

- Cabinetry and Hinge Installation: These delicate jobs demand the light touch that a drill provides.

- Light-Duty Screw Driving: For most common screw-driving tasks, like putting together small woodworking projects, a drill is more than enough.

What is an Impact Driver? The Power Specialist

Now, let’s talk about the impact driver. If the drill is a versatile athlete, the impact driver is a powerlifter. It looks like a short, stubby drill, but its inner workings are completely different. Its sole purpose is to drive screws and bolts—especially long, thick ones—with extreme force and speed.

The magic of an impact driver comes from its internal impact mechanism. As you drive a screw and the tool feels resistance, a spring-loaded hammer inside begins to slam against an anvil, thousands of times per minute. This creates incredibly high rotational force (torque) in short, powerful bursts. This is what gives the tool its distinctive brrrap-brrrap-brrrap sound.

This hammering action does two amazing things: it drives fasteners that would stall a regular drill, and it transfers most of that force directly to the screw, not your wrist. You can drive a 6-inch lag bolt with one hand and almost no counter-force on your arm.

Key Features of an Impact Driver

- High Torque Output: It generates two to three times more torque than a typical driver drill.

- Quick-Change Collet: It has a 1/4-inch hexagonal collet. You simply push an impact-rated bit in to lock it. This means it only accepts hex-shank bits.

- Concussive Impact Action: Delivers power in bursts, making it less likely to strip screw heads on large fasteners.

- Compact and Lightweight: They are generally smaller and lighter than drills, making them great for getting into tight spaces.

When to Unleash the Impact Driver

You grab the impact driver when power and speed are more important than delicate precision. It’s for your big, tough jobs.

- Building a Deck: Driving hundreds of 3-inch deck screws is a breeze with an impact driver.

- Driving Lag Bolts or Screws: This is where an impact driver truly shines. It will sink a long lag screw into a 4×4 post without breaking a sweat.

- Working with Dense Hardwoods: The extra torque helps drive screws into tough materials without needing a pilot hole (though it’s still good practice!).

- Automotive Work: It’s great for removing stubborn nuts and bolts (this is often called an impact wrench in larger formats).

- Home Framing or Construction Projects: Any job that involves driving lots of large fasteners quickly.

Driver Drill vs. Impact Driver: A Head-to-Head Comparison

Seeing them side-by-side really helps clarify their differences. Let’s put them in the ring and see how they stack up across the most important categories. This quick-glance table should make things crystal clear.

| Feature | Driver Drill | Impact Driver |

|---|---|---|

| Primary Function | Drilling holes, driving screws with precision | Driving long/large screws and bolts with high torque |

| Power (Torque) | Lower (around 400-800 in-lbs) | Extremely High (1,500-2,200+ in-lbs) |

| Control Mechanism | Adjustable clutch for precise torque control | None; power is controlled by the variable speed trigger |

| Chuck/Collet | 3-jaw adjustable chuck (holds round and hex bits) | 1/4-inch hex quick-change collet (only hex bits) |

| Versatility | Very high; can drill, drive, and use various accessories | Specialized; primarily for driving fasteners |

| Noise Level | Relatively quiet | Extremely loud when impacting |

| Best For… | General home repairs, furniture assembly, precision work | Deck building, framing, driving lag bolts, repetitive driving |

The Battle of Power: Torque Explained

The numbers don’t lie. An impact driver has massively more torque than a drill. But more power isn’t always better. Think of it like trying to write your name. You wouldn’t use a giant paint roller; you’d use a fine-tipped pen. The drill is that pen—precise and controlled. The impact driver is the paint roller—it covers a lot of ground with brute force. Applying too much power with an impact driver on a small screw can easily snap its head off or completely bury it in the wood.

Speed and Precision: Who Does It Better?

While an impact driver often has a higher top RPM (Revolutions Per Minute), a driver drill gives you better control over that speed. The combination of the two-speed gearbox and the clutch makes the drill the undisputed champion of precision. You can slowly and gently set a brass screw in an oak cabinet without fear. An impact driver, by its nature, wants to go fast and hit hard, making it a poor choice for delicate finishing work.

Versatility: The Jack-of-All-Trades vs. the Master of One

This is where the driver drill really pulls ahead for beginners. Its adjustable chuck can hold countless types of accessories: standard drill bits, spade bits, hole saws, wire brushes, and more. An impact driver is a one-trick pony, albeit a very impressive one. It drives fasteners. While you can get hex-shank drill bits for it, they aren’t ideal. The impacting action can be rough on bits not designed for it, and the lack of a clutch means you can’t control drilling depth.

Which One Should You Buy First? A Practical Guide for Beginners

Okay, we’ve broken it all down. Now for the million-dollar question: which one should be your first purchase? My answer is simple and clear for 95% of people starting out.

For your first cordless tool, buy a quality driver drill.

Why? Because versatility is king when you’re building your tool collection. A driver drill can perform about 80% of the tasks you’ll encounter as a new homeowner or DIY enthusiast. It can drill the holes and drive the screws for almost any project, from hanging curtains to building your first bookshelf. Its precision and control will save you a lot of headaches (and ruined materials) as you learn.

Here’s a quick guide:

- Choose the Driver Drill if: You are a homeowner, a beginner woodworker, or your main tasks involve assembling furniture, hanging decor, and general home maintenance.

- Choose the Impact Driver if: You already own a good drill and are planning a large project like building a deck, fence, or shed. It is an amazing second tool that will save you time and energy.

The best option for many is to buy a combo kit. Most major tool brands offer kits that include both a driver drill and an impact driver, along with two batteries and a charger. This is often the most cost-effective way to get both tools and start your collection on the right foot.

Can You Use a Driver Drill for Impact Driver Jobs (and Vice Versa)?

The short answer is: sometimes, but it’s not ideal. Using the wrong tool for the job can lead to frustration, poor results, and even safety issues. According to safety experts at institutions like the Penn State Extension, using a tool for its intended purpose is a key principle of workshop safety.

Using a Drill for a Heavy-Duty Job

Can you build a deck with just a drill? Yes, but your wrist will hate you. You’ll have to push hard to keep the bit from slipping out of the screw head (cam-out), and you risk overheating the drill’s motor. It will be slow, tiring, and you’ll probably strip a few screw heads along the way.

Using an Impact Driver for a Delicate Job

Can you assemble a piece of IKEA furniture with an impact driver? I would strongly advise against it. The sheer power is likely to drive the screw right through the particle board before you can even react. It’s the definition of using a sledgehammer to crack a nut.

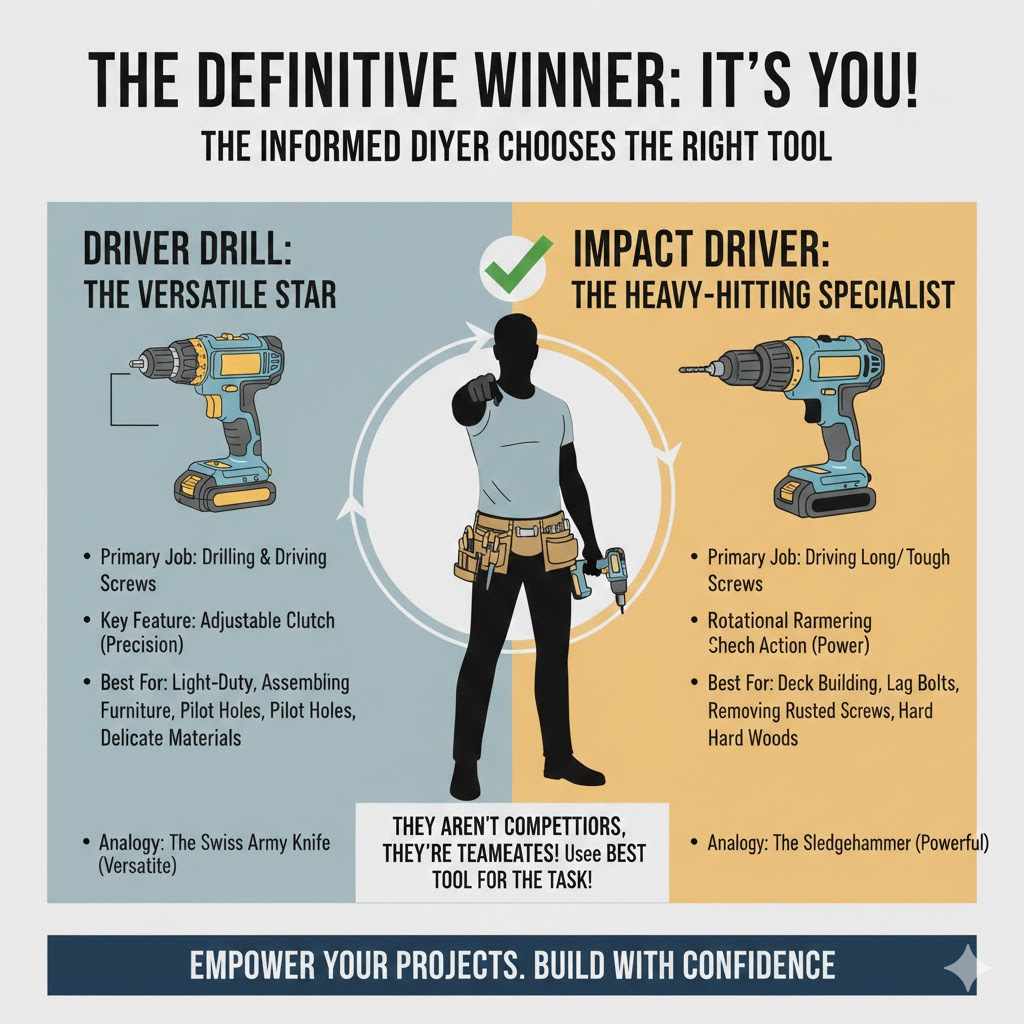

The Definitive Winner: It’s You!

So, after all that, who is the definitive winner in the “driver drill vs. impact driver” debate? The winner is you, the informed DIYer who now knows exactly which tool to grab for the job at hand.

There is no single “best” tool. There is only the “best tool for the task.” They are not competitors; they are teammates. The driver drill is your versatile and precise starter, perfect for the vast majority of projects. The impact driver is your heavy-hitting specialist, ready to be called in when the work gets tough.

Understanding this fundamental difference will not only make your projects go smoother but will also make you a more confident and capable woodworker. So, take a look at the projects you want to build, choose the right partner for the job, and get out there and make something amazing. You’ve got this!

Frequently Asked Questions (FAQ)

1. Is an impact driver too powerful for a beginner?

Not necessarily! While it is very powerful, an impact driver is often easier to control when driving long screws because it doesn’t transfer torque to your wrist. However, a beginner must learn trigger control to avoid over-driving screws in delicate materials. For general-purpose use, a drill is more forgiving for a novice.

2. Can I use regular drill bits in my impact driver?

No, you should not use standard round-shank drill bits. Impact drivers require bits with a 1/4-inch hex shank to fit in the collet. Furthermore, it’s highly recommended to use bits that are “impact-rated.” These are made from a more durable and flexible steel that can withstand the violent hammering action of the tool without shattering. The U.S. Occupational Safety and Health Administration (OSHA) always recommends using the correct accessories designed for your specific power tool.

3. What do the numbers on my drill’s clutch mean?

Those numbers represent different torque settings. A low number (like 1 or 2) means very little torque; the drill will stop turning with only a small amount of resistance. This is perfect for driving small screws into soft wood. A high number (like 20 or more) allows for much more force before the clutch engages, suitable for larger screws or harder materials. The symbol of a drill bit on the clutch ring means you’re in “drill mode,” which bypasses the clutch entirely for maximum power.

4. Why is my impact driver so loud?

The loud, rapid hammering sound is the tool doing its job! It’s the sound of the internal hammer striking the anvil to create torque. Because of this noise, it is extremely important to wear hearing protection every time you use an impact driver.

5. Is an impact driver the same as a hammer drill?

This is a common point of confusion, but they are very different tools. An impact driver uses rotational impacts (like a hammer hitting the side of a wrench) to drive screws. A hammer drill uses forward-and-back linear impacts (like a tiny jackhammer) to chip away at masonry while drilling, making it the right tool for drilling into brick, concrete, or stone.

6. Which tool is better for putting up drywall?

For a beginner or for just a few sheets, a standard driver drill with a drywall screw setter bit (a bit that stops the screw at the perfect depth) is a great choice. Professionals who hang drywall all day use a dedicated tool called a drywall screwgun, but an impact driver is often too powerful and will easily tear the paper face of the drywall.