Hardwood Floor Cracks Between Boards: Essential Fixes

Tackling hardwood floor cracks between boards is manageable! For minor gaps, wood filler or putty works wonders. For larger cracks, consider wood glue and shims, or even replacing a damaged board. Follow these simple steps for a smoother, more beautiful floor.

Hey there, fellow DIYers! Md Meraj here. Ever run your hand over your beautiful hardwood floors and feel a little… uneven? Those nagging cracks between the boards can be more than just a little annoying; they can collect dust, snag socks, and even signal bigger moisture issues. But don’t worry! Fixing these gaps is totally achievable, even if you’re new to woodworking. We’re going to walk through it step-by-step, from understanding why they happen to making them disappear, leaving you with the gorgeous, smooth floors you love.

We’ll start by figuring out what’s causing those cracks and then dive into the easiest ways to fix them. Ready to give your floors a little TLC?

Understanding Hardwood Floor Cracks Between Boards

Seeing cracks appear between your hardwood floorboards can be a bit of a surprise. It’s a common issue that pops up over time, and it’s usually not a sign of a major disaster. Understanding why these gaps form is the first step in fixing them. Think of wood as a living material; it breathes! It expands when it’s humid and contracts when it’s dry.

This natural expansion and contraction, especially with changes in your home’s humidity levels, is the main culprit. When the wood dries out and shrinks, those tight seams between the boards can open up, creating those unsightly cracks. Other factors, like improper installation, excessive moisture, or general wear and tear, can also contribute.

The good news is that most of these cracks are cosmetic and can be fixed without needing a complete floor overhaul. Let’s explore the signs and common causes.

Common Causes of Gaps

- Seasonal Humidity Changes: This is the number one reason. In drier winter months, wood shrinks. In humid summer months, it expands. Repeat this cycle enough, and gaps can form.

- Improper Acclimation: If hardwood wasn’t allowed to adjust to your home’s environment for a few days before installation, it might have been too wet or too dry, leading to premature shrinking and gapping.

- Excessive Moisture: Spills, leaks, or high humidity can cause wood to swell. When it dries out, it might not return to its original size, leaving gaps.

- Subfloor Issues: An uneven or unstable subfloor can cause floorboards to flex and shift, leading to gaps over time.

- Defective Wood or Installation: While less common, poorly milled boards or faulty installation techniques can also contribute to gaps.

Signs It’s Time for a Fix

You’ll usually notice these gaps pretty quickly. They can:

- Accumulate Debris: Dust, dirt, pet hair, and small crumbs love to hide in these spaces.

- Snag Items: Thin items like socks, shoelaces, or even vacuum cleaner attachments can get caught.

- Create Noise: Sometimes, the wood shifting in these gaps can lead to squeaky floors.

- Look Unattractive: Gaps simply detract from the overall beauty and smoothness of your hardwood floors.

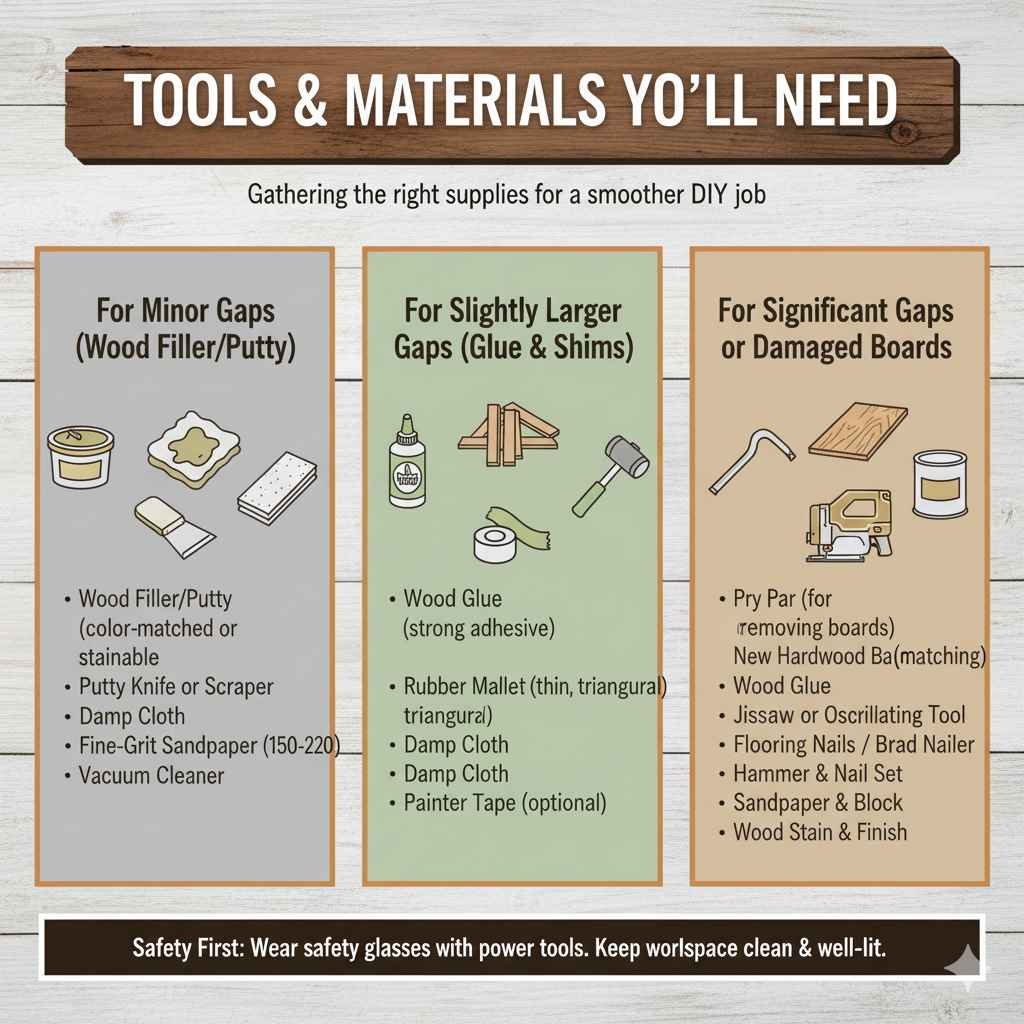

Tools and Materials You’ll Need

Gathering the right supplies before you start will make the job much smoother. Don’t worry, most of these are standard DIY items you might already have or can easily find at your local hardware store.

For Minor Gaps (Wood Filler/Putty):

- Wood Filler or Wood Putty: Choose a color that closely matches your flooring. Some are stainable, which gives you more flexibility.

- Putty Knife or Scraper: For applying and smoothing the filler.

- Damp Cloth: For wiping away excess filler.

- Fine-Grit Sandpaper (150-220 grit): For gentle smoothing after drying.

- Vacuum Cleaner: To clean up dust.

For Slightly Larger Gaps (Glue and Shims):

- Wood Glue: A good quality, strong wood adhesive.

- Wood Shims (thin, triangular pieces of wood): To help close the gap while the glue dries.

- Rubber Mallet or Hammer: To gently tap in the shims.

- Damp Cloth: To clean up any squeezed-out glue.

- Painter’s Tape: To hold shims in place if needed.

For Significant Gaps or Damaged Boards:

- Pry Bar: To carefully remove damaged boards.

- New Hardwood Board: Ideally, from the same wood species and grade as your existing floor to ensure a good match.

- Jigsaw or Oscillating Multi-Tool: For cutting out damaged sections.

- Wood Glue: For securing new boards.

- Flooring Nails or Brad Nailer: To fasten new boards.

- Hammer and Nail Set: To set nails below the surface.

- Sandpaper (various grits) and Sanding Block: For final smoothing.

- Wood Stain and Finish (or a clear coat): To match the existing floor’s color and sheen.

Always make sure your workspace is clean and well-lit. Safety first: if you’re using power tools, remember to wear safety glasses. OSHA has great resources on workplace safety that apply to DIY projects too!

Fixing Hardwood Floor Cracks: Step-by-Step

Now that you’ve got your gear ready, let’s get straight to fixing those gaps. We’ll cover the most common scenarios, from the tiny hairline cracks to those that need a bit more attention.

Method 1: Using Wood Filler or Putty for Minor Cracks

This is your go-to for small gaps that aren’t actively moving or causing significant issues. It’s quick, easy, and can make a big difference visually.

- Clean the Gap: First, thoroughly clean out the crack. Use a vacuum cleaner with a crevice tool or a stiff brush to remove all dust, dirt, and debris. A clean surface helps the filler adhere properly.

- Test Filler Color: If you have a stainable filler, test it on an inconspicuous area to ensure it matches your floor as closely as possible. Sometimes, wood filler dries a shade lighter or darker than expected.

- Apply the Filler: Squeeze or scoop a small amount of wood filler or putty directly into the crack. Don’t overfill; you want it to be flush with the board surface.

- Smooth It Out: Use your putty knife to press the filler firmly into the crack and then smooth the excess away. Aim to make the surface level with the surrounding floor. For stubborn bits, a damp cloth can help clean up.

- Let It Dry: Allow the filler to dry completely according to the manufacturer’s instructions. This can take anywhere from a few hours to overnight.

- Gentle Sanding: Once dry, lightly sand the filled area with fine-grit sandpaper. The goal is to make it perfectly smooth and level with the floor. Don’t sand too aggressively, or you might create a divot.

- Clean Up: Vacuum away any sanding dust. If you used a stainable filler and need to touch up the color, now is the time. Apply a matching wood stain carefully to the repaired area.

- Apply Finish (if needed): If your floor is finished with a protective coating, you may need to apply a compatible clear coat to the repaired spot to protect it and match the sheen.

Method 2: Using Wood Glue and Shims for Slightly Larger Gaps

If the gap is a bit wider, or you suspect some slight movement, wood glue can help stabilize the floorboards. This method is best for gaps that are still relatively narrow but too large for simple filler.

- Clean the Area: As before, thoroughly clean the gap and surrounding floorboards.

- Apply Wood Glue: Carefully inject or spread wood glue into the gap. You want enough to coat the sides of the boards that are pulling apart. A syringe applicator can be very useful here for precise application.

- Close the Gap: Gently work a thin wood shim into the gap, next to where you applied the glue. The shim’s purpose is to help push the boards back together, tightening the seam. Place the shim so its widest part is facing outwards.

- Tap and Secure: Lightly tap the shim deeper into the gap with a rubber mallet or hammer. You want to close the gap as much as possible without forcing it severely, which could damage the boards.

- Wipe Away Excess Glue: Immediately wipe away any glue that squeezes out with a damp cloth. Dried glue can be difficult to remove and unsightly.

- Let It Cure: Allow the glue to cure fully, usually for at least 24 hours. You might want to leave the shims in place for this duration to keep the gap closed. For very stubborn gaps, you might use painter’s tape to gently hold the boards together while the glue dries.

- Remove Shims: Once the glue is fully cured, carefully slide or tap the shims back out of the gap. They should come out relatively easily if they did their job.

- Final Touches: Fill any small voids left by the shims with wood filler, sand smooth, and clean as described in Method 1.

Method 3: Replacing a Damaged Board for Significant Gaps

This is a more involved process, but sometimes necessary for wide, persistent gaps or if a board is actually broken. It’s a great way to build your confidence with more advanced DIY tasks.

Important Note: This is best done when you have a spare board that matches your existing flooring. If not, you may need to carefully harvest one from a closet or inconspicuous area.

- Mark the Board: If the gap is caused by a board that’s damaged or has warped significantly, you’ll need to remove it. Mark the board to be removed carefully.

- Cut the Board: Using a jigsaw or oscillating multi-tool, carefully cut the damaged board lengthwise down its center. Cut only through the board you want to remove, not into the subfloor or adjacent boards. Make relief cuts (short cuts perpendicular to the long cuts) to make it easier to remove pieces.

- Remove the Board: Once cut, use a pry bar to carefully lift and remove the damaged sections of the board. Work slowly to avoid damaging the surrounding boards or tongue-and-groove connections. Sometimes, cutting out just the center section is enough, leaving the edges intact to be pried up. For boards nailed down, you might need to carefully pry them up, potentially sacrificing some of the nails.

- Prepare the Space: Clean out the cavity left by the removed board. Ensure the subfloor is clean and level.

- Fit the New Board: If your new board has a tongue and groove, you may need to cut off the tongue or groove on the edges that will meet the existing boards. This allows it to fit more easily into the space. Test fit the board to ensure it sits flush and at the correct height.

- Glue and Secure: Apply wood glue to the edges of the adjacent good boards where the new board will connect. Carefully place the new board into the gap.

- Fasten the New Board: You can nail the new board in place using flooring nails or brad nails. Drive them at an angle through the edge of the board into the subfloor. Use a nail set to sink the nail heads slightly below the surface. Alternatively, if you’ve carefully cut off edges or are working in a tight spot, construction adhesive applied to the subfloor and the edges of the board can also help secure it.

- Sanding and Finishing: If the new board sits slightly proud, or the nail holes are visible, you’ll need to sand it flush with the surrounding floor. Start with a medium-grit sandpaper if needed, then move to finer grits. Clean thoroughly. Finally, stain and apply a finish that matches your existing floor. Getting a perfect match on stain and finish can be tricky, so consider testing on scrap wood first, or focus on getting a good sheen match.

Preventing Future Cracks

Once you’ve fixed your floors, you’ll want to keep them looking great! Prevention is key to maintaining the beauty and integrity of your hardwood.

Maintain Consistent Humidity

This is the most effective way to prevent wood from shrinking and expanding excessively. Aim to keep your home’s humidity level between 35% and 55% year-round. A home humidity monitor can help you track this.

- Use a Humidifier: During dry winter months, use a humidifier to add moisture to the air.

- Use a Dehumidifier: In humid summer months, a dehumidifier can help prevent excessive swelling.

- Ensure Proper Ventilation: Good airflow helps regulate moisture levels.

Protect from Moisture

Always clean up spills immediately. Use mats near sinks, entryways, and under pet bowls. Avoid over-wetting your floors when cleaning; use a damp mop rather than a soaking wet one.

Careful Cleaning Practices

Use cleaning products specifically designed for hardwood floors. Excessive water or harsh chemicals can damage the wood and its finish, potentially leading to future issues.

Avoid Extreme Temperatures

While challenging, try to avoid drastic temperature fluctuations within your home, as these can contribute to the expansion and contraction cycle of wood.

Regular Maintenance

Periodically inspect your floors for any early signs of gapping or issues. Addressing small problems quickly can prevent them from becoming major ones.

Consider Rugs and Mats

Area rugs and doormats can protect high-traffic areas from wear and tear and also help buffer against minor moisture exposure at entryways.

When to Call a Professional

While many hardwood floor crack issues are DIY-friendly, there are times when it’s best to call in the experts. If you notice:

- Widespread Gapping: If a large portion of your floor has gaps, it might indicate a more significant issue with the subfloor or installation.

- Cupping or Warping: If boards are significantly curved (cupping) or twisted (warping), especially across many boards, it’s a sign of major moisture problems or structural issues.

- Squeaking Floors that are widespread and don’t improve with localized fixes.

- Rot or Mold: Any sign of fungal growth or soft, decaying wood means you need professional assessment and remediation immediately.

- You’re Uncomfortable or Unsure: If a repair feels beyond your skill level, or if you’re worried about causing more damage, a professional flooring contractor is your best bet.

Professionals have specialized tools and expertise to diagnose and repair more complex flooring problems, ensuring a lasting and beautiful solution.

FAQ About Hardwood Floor Cracks

Q: Are hardwood floor cracks between boards normal?

A: Yes, some minor gapping due to seasonal humidity changes is normal for solid hardwood floors. However, excessively large or rapidly developing cracks may indicate other issues.