How To Apply Deck Stain And Sealer: Proven Best

Follow these proven steps to successfully apply deck stain and sealer: clean the wood thoroughly, ensure dry conditions, test the product, apply thinly using a brush or pad, and allow ample curing time for long-lasting, beautiful protection.

Is your beautiful wooden deck looking tired, gray, or weathered? Many homeowners worry that staining a deck is a complicated job only pros can handle. Don’t fret! Protecting your deck wood is one of the best ways to boost its looks and make it last for years. Applying stain and sealer correctly ensures it won’t peel or fade quickly.

As your workshop mentor, I am here to tell you that this is totally achievable for anyone with basic tools and a sunny weekend. We will walk through every simple step, making sure you pick the right products and apply them like a seasoned pro. Ready to transform your outdoor space? Let’s get started on making that deck shine!

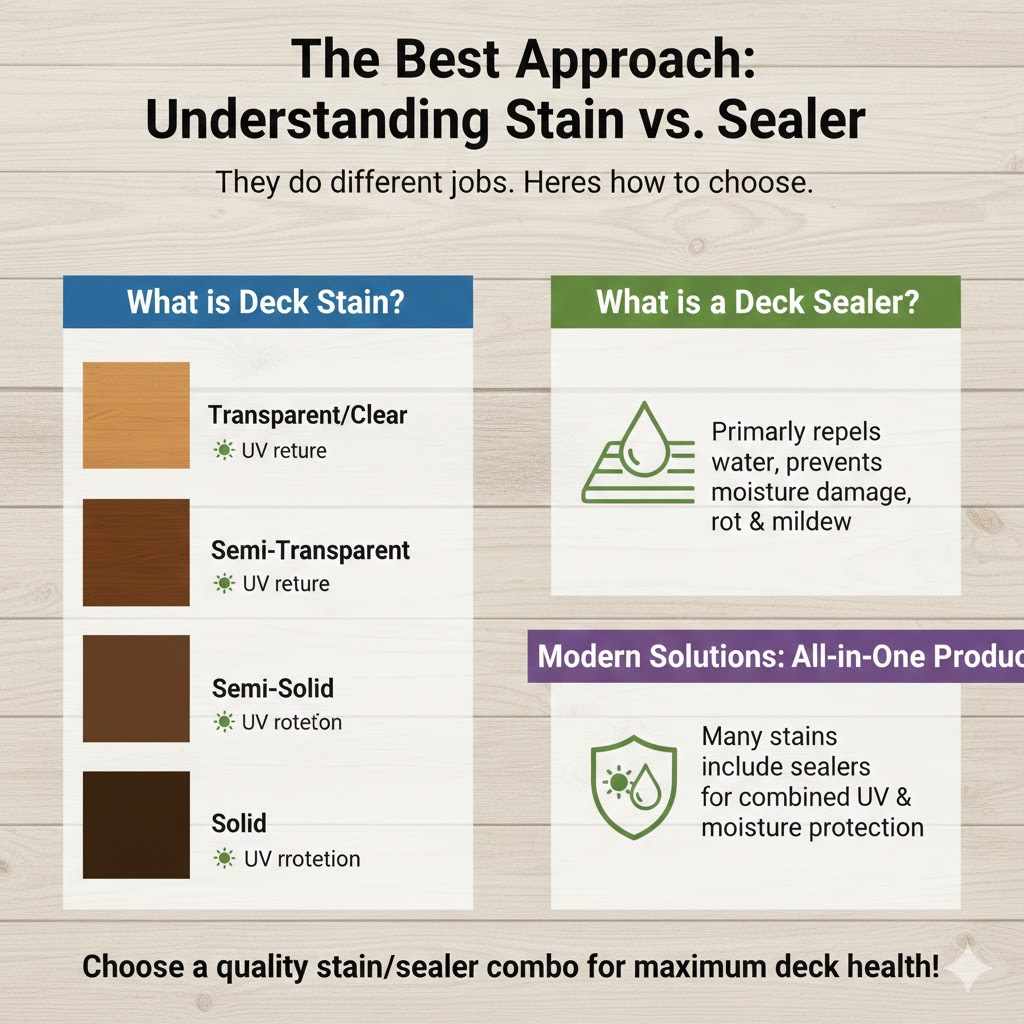

The Best Approach: Understanding Stain vs. Sealer

Before we dive into the “how-to,” let’s quickly clear up what you are actually applying. Often, people use the terms “stain” and “sealer” interchangeably, but they do different jobs. Understanding this difference helps you choose the best product for your needs.

What is Deck Stain?

Deck stain adds color and protects the wood from UV rays (sun damage). Stains penetrate the wood fibers. They come in different opacities:

- Transparent/Clear: Offers UV protection but almost no visible color change.

- Semi-Transparent: Allows some wood grain to show through while adding color. This is often the favorite for natural wood looks.

- Semi-Solid: More color hides the grain somewhat but still shows texture.

- Solid: Looks like paint; completely covers the grain. Great for older wood needing a facelift.

What is a Deck Sealer?

A sealer primarily works to repel water and prevent moisture damage, rot, and mildew growth. Many modern deck stains are “all-in-one” products that include high-quality sealing agents, which is what we focus on today. For maximum protection, using a dedicated sealer over a stain (or choosing a high-quality stain/sealer combo) is key to water repellency.

Phase 1: Preparation is Everything – Cleaning and Repair

If you skip prep work, even the most expensive stain will look terrible and peel off in months. Think of this as the most important step! If you rush this, you waste time and product later.

Step 1: Inspect and Repair Your Deck

Safety first! Before any wet work begins, ensure your deck structure is sound. You do not want a stain failure exposing a weak board later.

- Check for Nails/Screws: Use a hammer or impact driver to secure any loose boards or set raised nail heads below the surface so they don’t snag tools or feet.

- Replace Rotten Wood: If you find any boards that crumble or feel spongy, replace them immediately. For reference on safe replacement practices, consulting guides from organizations like the American Wood Council is helpful for understanding wood longevity.

- Sand Rough Spots: Use a pole sander or orbital sander (starting with 60 or 80 grit) just on rough patches, splintered areas, or bad stain areas. You do not need to sand the entire deck down to bare wood unless you are moving from a solid stain to a clear finish.

Step 2: Deep Clean the Wood Surface

Wood needs to be clean and bright for the stain to soak in properly. Dirt, mildew, and old finish act like a barrier.

Tool Checklist for Cleaning:

- Deck Cleaner (Oxygenated bleach formulas work well for mold, or look for specific wood brighteners)

- Stiff-bristled scrub brush (synthetic, not wire)

- Garden hose or a pressure washer (used with extreme caution)

- Safety glasses and gloves

The Cleaning Process:

- Choose the Right Cleaner: For general dirt, use a dedicated deck cleaner mixed according to the directions. For stubborn graying or mildew, use a cleaner containing an oxalic acid or wood brightener component.

- Apply Cleaner: Wet the entire deck surface first with a hose. Apply the cleaner evenly using a pump sprayer or by pouring directly onto the boards and scrubbing immediately. Work in manageable sections.

- Scrub Gently: Use your brush to scrub along the grain of the wood. Focus on high-traffic areas.

- Rinse Thoroughly: Rinse off all the soap and debris using clean water from a garden hose. Ensure absolutely no cleaner residue remains, as it will stop the stain from absorbing.

A Note on Pressure Washing

Pressure washers can be fantastic tools, but they are the number one cause of stripped, fuzzy, and damaged decks when used incorrectly by beginners. If you use one:

- Use a fan tip (40-degree minimum).

- Keep the pressure below 1200 PSI for softer woods like pine.

- Hold the wand at least 12 inches from the wood surface.

- Never hold it in one spot! Keep it moving in steady, overlapping passes along the wood grain.

Step 3: Allow the Wood to Dry Completely

This step cannot be overstated: the wood must be bone dry before staining. Applying stain to damp wood traps moisture underneath the protective coating, leading to blistering, peeling, and premature mildew growth.

After cleaning, allow the deck to dry for a minimum of 48 hours, ideally longer if the weather has been humid or rainy. You can use a simple moisture meter if you have one, but the best test is the “tape test”:

- Tape a small square of clear plastic sheeting securely onto the deck surface with strong tape.

- Leave it overnight.

- If moisture has condensed on the inside of the plastic the next morning, the wood is too wet. Wait another day and test again.

Phase 2: Choosing Your Perfect Deck Stain and Sealer

Selecting the right product dictates the look, longevity, and ease of maintenance. Since you are aiming for a great, beginner-friendly result, focus on high-quality oil-based or advanced water-based formulas.

Oil-Based vs. Water-Based Stains

In my experience, both have clear advantages. The best choice often depends on how much natural wood grain you want to see.

| Feature | Oil-Based Stain/Sealer | Water-Based Stain/Sealer |

|---|---|---|

| Penetration | Excellent penetration, sinks deep into the wood fibers. | Sits slightly more on the surface but good bonding when using modern formulas. |

| Drying Time | Slower drying (can take 24–72 hours). | Dries faster, often workable the next day. |

| Cleanup | Requires mineral spirits or specialized cleaners. | Simple soap and water cleanup. |

| Durability/Look | Natural, rich look; excellent UV protection. Harder to re-coat perfectly. | More color options; generally easier for touch-ups down the road. |

Testing the Product Before You Buy

Before you commit to a whole gallon, do a color test!

- Ask the paint store for a small sample of the shade you like best.

- Apply a small amount to an inconspicuous area (like under a stair tread).

- Wait 24 hours to see how the color looks in the sun and in the shade. Colors change dramatically when they dry!

Phase 3: The Proven Best Application Technique

You have a clean, dry deck, and you have your can of high-quality stain/sealer. Now for the fun part—bringing the color back!

Weather Check: When to Stain

Timing is critical for success. You need weather that lets the stain soak in but doesn’t dry it too fast.

- Temperature: Always stain when temperatures are between 50°F and 90°F, as recommended on the can.

- Sunlight: Apply on a partly cloudy day or when the area is completely shaded. Direct, hot sunlight will cause the stain to flash-dry on the surface, leading to blotchiness.

- Forecast: Ensure there is absolutely no rain forecast for at least 48 hours after application.

Tools Needed for Application

Keep these items handy:

- Chosen Stain/Sealer

- Natural bristle brush (for oil-based) or synthetic brush (for water-based)

- Pad applicator or stain pad (great for covering large, flat areas quickly)

- Roller (optional, often causes pooling—use sparingly)

- Stir stick (or cheap dowel rod)

- Paint tray and liners

- Clean rags

- Painter’s tape (to protect siding or steps)

Step 4: Stir, Don’t Shake!

This is a common beginner mistake that ruins stain jobs! Pigments settle heavily to the bottom of the can. If you shake the can, the pigment clumps up unevenly.

Use your stir stick and mix thoroughly for at least five minutes, scraping the bottom of the can to incorporate all solids. Even during application, stop every 10–15 minutes to stir again.

Step 5: Application Method – Work Top-to-Bottom

When staining a deck, we always work from the highest point down. If you stain the bottom rail first, drips onto the surface below will ruin your finish. Stain the vertical surfaces (like railings and fascia boards) before you start on the horizontal deck floorboards.

Applying to Vertical Surfaces (Railing, Posts)

Use a good quality brush here. Brush on a thin, even coat, working with the wood grain. Wipe away any visible drips or puddles immediately with a clean, dry rag.

Applying to Horizontal Decking Boards

This is where most beginners go wrong by applying too much product. Stain should soak in; it shouldn’t sit like a thick paint layer.

Best Technique for Decking: The “Wet Edge” Rule

- Start at one end of a board. Apply the stain in long, continuous strokes using your brush or pad applicator.

- The key is maintaining a “wet edge.” This means that as you move along a board, the new stain you apply slightly overlaps the previous wet application. This prevents visible lap marks (where you stopped and restarted a pass).

- Apply a thin coat. If you can see thick puddles forming, you are using too much! Immediately spread this excess out or wipe it off with a rag.

- Complete one full board, from end to end, before moving to the next board.

Step 6: Back-Brushing and Preventing Over-Application

No matter how carefully you use a pad or roller, you usually end up with a slightly thicker area where you started or finished brushing/rolling. This leads to premature wear.

The Master Trick: Back-Brushing

After applying the stain to one or two boards using your pad or roller (which is fast), take your natural bristle brush and go over the entire wet surface again, applying light, even pressure while brushing with the grain. This process:

- Forces the stain deeper into the wood pores.

- Eliminates bubbles, drips, and excessive product sitting on the surface.

- Guarantees an even finish that is less likely to peel.

Step 7: Monitor for Puddling and Blotchiness

Do a full walk-around immediately after staining the whole deck. If you spot any area where the stain looks glossy, pooling, or thicker than the rest—you have excess product. This will become a shiny, sticky spot that peels first.

Take a clean, dry, lint-free rag and lightly blot, blend, or wipe up any excess material. Allow the stain to absorb what it needs, and wipe the rest away. You want saturation, not pooling.

Phase 4: Curing, Maintenance, and Longevity Tips

Applying the stain correctly is only half the battle. Giving it the right environment to cure is the secret to long-term durability.

Drying vs. Curing

Drying time is when the surface is dry enough that you can walk on it carefully (usually 6–24 hours, depending on humidity). Curing time is the time needed for the chemicals to fully harden and bond with the wood, which can take several days or even weeks for heavy oil-based products.

- Light Foot Traffic: Usually safe after 24–48 hours. Keep furniture off for at least 72 hours.

- Heavy Use/Water Contact: Wait at least one full week, or as recommended by the manufacturer, before washing the deck or exposing it to standing water. Premature exposure compromises the new finish.

Quick Maintenance Guide for Longevity

A well-stained deck only needs a little TLC to stay beautiful. Prevention is easier than repair!

Yearly Light Cleaning: Wash off leaves and dirt using a mild soap and a soft brush once or twice a year. Avoid harsh chemical cleaners between major re-stains.

Spot Testing Water Repellency: Every few months, flick a few drops of water onto the deck. If the water beads up nicely, your sealer is still doing its job. If the water soaks in immediately, it is time to plan for another coat.

Know When to Re-Stain: Most semi-transparent stains last 2–3 years on horizontal surfaces and 3–5 years on vertical surfaces. Don’t wait until the wood looks completely gray—reapply when you notice the water isn’t beading anymore.

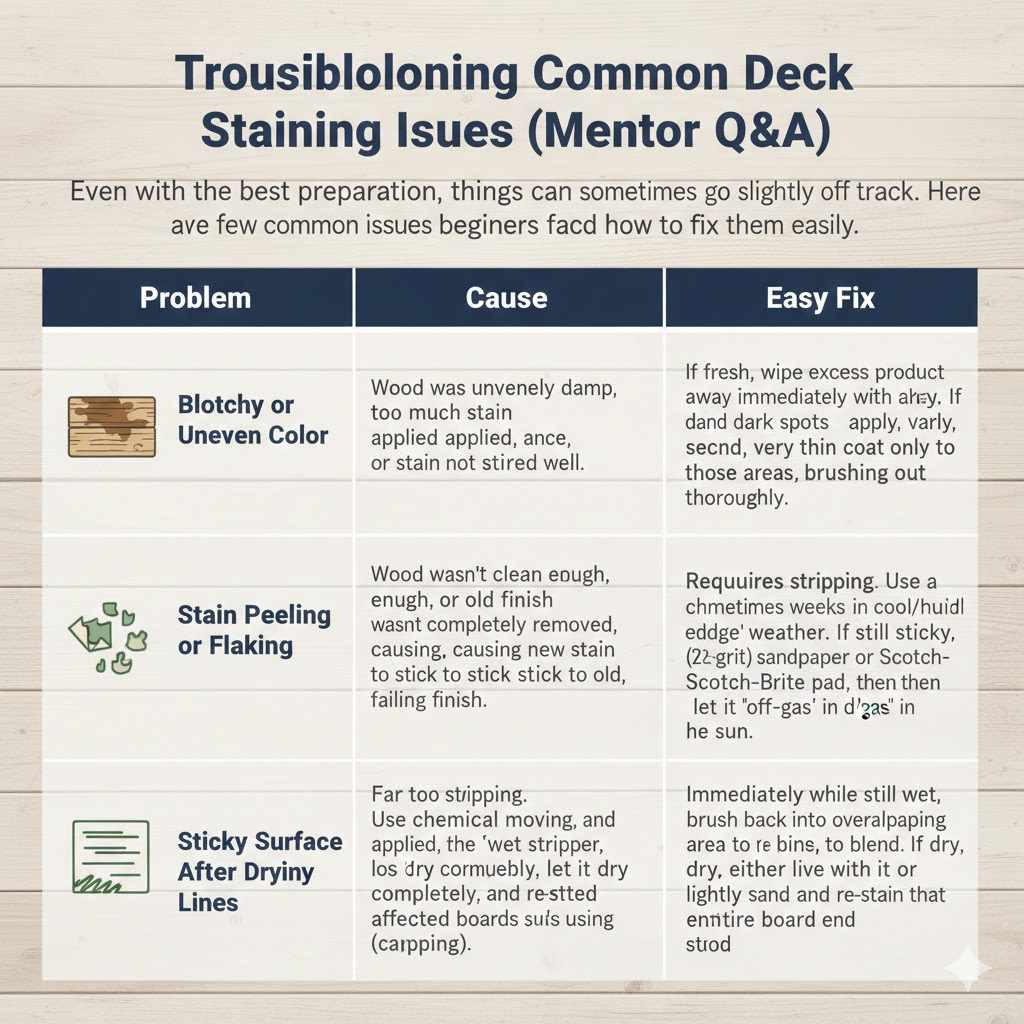

Troubleshooting Common Deck Staining Issues (Mentor Q&A)

Even with the best preparation, things can sometimes go slightly off track. Here are a few common issues beginners face and how to fix them easily.

| Problem | Cause | Easy Fix |

|---|---|---|

| Blotchy or Uneven Color | Wood was unevenly damp, too much stain applied at once, or stain not stirred well. | If fresh, wipe excess product away immediately with a clean rag. If dry, you may need to lightly sand the dark spots and apply a second, very thin coat only to those areas, brushing out thoroughly. |

| Stain Peeling or Flaking | This usually means the wood wasn’t clean enough, or the old finish wasn’t completely removed, causing the new stain to stick to the old, failing finish. | This requires stripping. Use a chemical deck stripper (following safety guidelines!), rinse thoroughly, let it dry completely, and re-stain the affected boards using the back-brushing technique. |

| Sticky Surface After Drying | Far too much product was applied, and it never cured properly (capping). | Allow more time—sometimes weeks in cool/humid weather. If it remains sticky, lightly buff the area with very fine (220-grit) sandpaper or Scotch-Brite pad, then wipe off dust and let it “off-gas” in the sun. |

| Brush Marks or Lap Lines | The applicator stopped moving, and the “wet edge” was lost, or you started staining in direct hot sun. | Immediately while still wet, brush back into the overlapping area to blend the line. If dry, you must either live with it or lightly sand the offending line and re-stain that entire board end-to-end. |

Frequently Asked Questions for Deck Finishing Beginners

Q1: Can I stain my pressure-treated wood immediately after installation?

A: No! Pressure-treated wood needs time to dry out and lose the excess moisture from the treatment process. Wait at least 4 to 6 weeks, or until the wood passes the water bead test (water soaks in, not beads up).

Q2: Do I need to sand the entire deck if I’m only reapplying a semi-transparent stain?

A: Generally, no. If the previous stain is still largely intact and has good adhesion, a simple deep clean and brightener are enough. Only sand areas that are significantly faded or peeling.

Q3: How long do I need to wait between the cleaning step and the staining step?

A: You must wait until the wood is completely dry. This usually means 48 hours, but humid conditions might require three to four days. Never rush this wait time!

Q4: Is it better to use a stain pad or a brush?

A: For speed on large areas, a high-quality stain pad is great. However, to ensure the stain gets pushed into every groove and grain line, you must follow up with a natural bristle brush (this is called “back-brushing”). A brush alone gives the best penetration.

Q5: What happens if the sun comes out halfway through my project?

A: Stop immediately! Direct sun forces the stain to dry on the surface instead of absorbing. Quickly finish the area you are on, work toward the edges of shaded sections, and cover the rest of the deck with a large tarp to shield it until the sun moves or conditions improve. Only proceed once the entire deck is back in the shade or the temperature drops.

Q6: Can I use the same product on the deck floor and the railing?

A: Yes, most high-quality combination stains/sealers are designed for all exterior wood surfaces. However, the floor wears down much faster than the railings, so you will likely need to re-coat the floor years before the railings need attention.

A Final Word of Encouragement From Your Mentor

Learning how to apply deck stain and sealer really comes down to patience during preparation and discipline during application. I know you might feel pressure to finish the entire deck in one sunny Saturday, but that pressure is what leads to peeling and patchiness later on.

By taking the time to deep clean, letting the wood fully dry (even if it takes an extra day), stirring your can constantly, and working in thin coats followed by that essential back-brushing step, you are ensuring that your beautiful deck finish will last for years. Remember, the prep is the difference between a weekend project and a decade of enjoyment. You have the guidance now; go build something beautiful and well-protected!