How to Cut MDF: Tips for Smooth & Accurate Cuts

To cut MDF, use a circular saw for straight cuts and a jigsaw for curved cuts. A high-quality carbide-tipped blade is ideal.

When cutting MDF, a table saw offers precise cuts with minimal chipping. Adding a jig to the platform ensures accuracy and repeatability. For curved or irregular shapes, a utility knife can be used, although it requires more effort. Medium density fiberboard (MDF) is challenging to cut straight by hand, so power tools are recommended for better results.

Beginners and DIYers can benefit from learning the right tools for cutting MDF effectively.

Choosing The Right Tools

For cutting MDF, using a circular saw ensures precise, straight cuts every time. To minimize splintering and chipping, opt for a high-quality carbide-tipped blade. A table saw is also a great choice for achieving accurate and repeatable cuts, especially when working with multiple MDF sheets.

Choosing the Right Tools for cutting MDF is essential for achieving a clean and precise cut. The two most commonly used tools for cutting MDF are a Circular Saw and a Jigsaw. Each tool has its own purpose and is ideal for specific cuts. In this article, we will explore the benefits of using a Circular Saw for Straight Cuts and a Jigsaw for Curved Cuts.

Circular Saw For Straight Cuts

A Circular Saw is the perfect tool for cutting straight lines in MDF. A high-quality carbide-tipped blade is recommended, as it will provide a clean and precise cut. The optimal type is a narrow blade featuring numerous teeth, which will prevent the blade from wandering off course. Here are the steps to follow when using a Circular Saw for cutting MDF:

- Mark the line that you want to cut on the MDF sheet.

- Set the depth of the blade to match the thickness of the MDF sheet.

- Place the MDF sheet on a stable work surface and clamp it down to prevent it from moving during the cut.

- Turn on the Circular Saw and guide it along the marked line, ensuring that the blade stays on track.

- After completing the cut, sand the edges of the MDF sheet to remove any roughness or splinters.

Jigsaw For Curved Cuts

A Jigsaw is the ideal tool for cutting curved lines in MDF. It is a versatile tool that can make intricate cuts with ease. A bi-metal cutting blade is recommended for use with a Jigsaw, as it will prevent the blade from overheating and breaking. Here are the steps to follow when using a Jigsaw for cutting MDF:

- Mark the line that you want to cut on the MDF sheet.

- Attach the bi-metal cutting blade to the Jigsaw and set the speed to match the thickness of the MDF sheet.

- Place the MDF sheet on a stable work surface and clamp it down to prevent it from moving during the cut.

- Turn on the Jigsaw and guide it along the marked line, ensuring that the blade stays on track.

- After completing the cut, sand the edges of the MDF sheet to remove any roughness or splinters.

In conclusion, choosing the right tool is crucial for achieving a clean and precise cut when working with MDF. A Circular Saw is perfect for straight cuts, while a Jigsaw is ideal for curved cuts. By following the steps outlined above, you will be able to cut MDF sheets with ease and precision.

Preparation Steps

To cut MDF, start by marking the cut line and using a circular saw with a high-quality carbide-tipped blade for straight cuts. For curved cuts, a jigsaw with a bi-metal cutting blade can be used. Using a table saw can also result in less splintering and chipping.

Additionally, a utility knife or box cutter can be used for curved or irregular shapes.

Before you start cutting MDF, it is essential to make sure you have all the necessary tools and equipment. MDF is a dense material, and cutting it requires precision and accuracy. In this section, we will discuss the preparation steps that you need to take before cutting MDF.

Marking Your Cut

The first step in cutting MDF is marking your cut. You can use a pencil or a marker to draw a line on the MDF where you want to make your cut. Make sure that the line is straight and that it is the correct length. You can use a straight edge or a ruler to ensure that your line is straight.

Measuring For Accuracy

Once you have marked your cut, the next step is to measure for accuracy. Using a measuring tape or a ruler, measure the distance from the edge of the MDF to the line you have drawn. Make sure that your measurement is accurate and that it is the same distance all the way down the line.

Clamping The Mdf

Before you start cutting, it is essential to clamp the MDF to a stable surface. This will prevent the MDF from moving while you are cutting and will ensure that your cut is straight and accurate. You can use a couple of good clamps to secure the MDF to a workbench or table.

Choosing The Right Blade

When it comes to cutting MDF, choosing the right blade is crucial. A high-quality carbide-tipped blade is the optimal type for cutting MDF. It is narrow and features numerous teeth that ensure a clean and precise cut.

Cutting The MDF

With the MDF clamped down and the right blade in your saw, it’s time to start cutting. Whether you are using a circular saw or a table saw, make sure that the blade is set to the correct depth. Start the saw and slowly guide it along the line you have drawn. Make sure to keep the saw blade straight and steady, and let the blade do the work.

In conclusion, by following these preparation steps, you can ensure that your MDF cutting project is a success. Remember to mark your cut accurately, measure for accuracy, clamp the MDF securely, choose the right blade, and cut the MDF carefully. With the right tools and techniques, you can achieve a clean and precise cut every time.

Cutting Techniques

When it comes to cutting MDF (medium density fiberboard), it’s important to use the right techniques to ensure clean and precise cuts. In this section, we will explore two popular cutting techniques: Using a Table Saw and Hand Cutting with Precision.

Using A Table Saw

If you are looking for a more precise cut with minimal chipping or splintering, a table saw is the ideal tool for cutting MDF. The table saw allows you to make accurate and repeatable cuts, making it perfect for cutting numerous sheets of MDF.

To ensure a clean cut, it is recommended to use a high-quality carbide-tipped blade. This type of blade, especially a narrow one with numerous teeth, will ensure smooth and straight cuts through the MDF sheet every time.

Additionally, you can add a jig to your table saw platform, which will provide you with even more accuracy and control over your cuts. This jig allows you to make precise measurements and achieve consistent results with MDF panels.

Hand Cutting With Precision

If you don’t have access to power tools or prefer a more hands-on approach, you can still achieve precise cuts with MDF using basic hand tools. While it may require more patience and effort, it is possible to cut MDF straight by hand.

For straight cuts, a utility knife or box cutter can be an excellent option. However, it’s important to note that MDF is not easy to cut straight by hand, so it’s crucial to take your time and start the cut as straight as possible.

For curved or irregular shapes, a jigsaw with a bi-metal cutting blade can be a suitable choice. This tool allows for more flexibility in cutting curved lines accurately.

Remember, when cutting MDF by hand, it’s crucial to have a steady hand and take your time to ensure the best results.

In conclusion, whether you choose to use a table saw or hand tools, it’s important to follow the appropriate techniques for cutting MDF. By using the right tools and taking the time to make precise cuts, you can achieve clean and professional results in your DIY projects.

Achieving Smooth Cuts

Achieving smooth cuts on MDF sheets can be done efficiently with a circular saw for straight cuts or a jigsaw for curved shapes. Opt for a high-quality carbide-tipped blade to ensure precise cutting without chipping, especially when using a table saw for cleaner edges.

Blade Selection

Choosing the right blade is crucial for achieving smooth cuts on MDF. Opt for a high-quality carbide-tipped blade with numerous teeth for precise cutting.

Cutting Speed And Motion

Maintain a steady cutting speed and smooth motion to prevent splintering and ensure a clean cut on the MDF board.

When cutting MDF, it’s important to pay attention to blade selection and cutting speed to achieve smooth cuts.

Minimizing Splintering

When cutting MDF, minimizing splintering is essential to achieve clean and professional-looking edges. By employing the right techniques and tools, you can significantly reduce the risk of splintering, ensuring a smooth and precise cut.

Pre-cut Scoring

One effective method to minimize splintering when cutting MDF is to pre-cut a scoring line along the cut line. This can be done by running a utility knife or a sharp blade along the cut line before making the full cut with a saw. The scoring helps to create a clean edge and reduces the likelihood of splintering.

Supporting The Mdf

Supporting the MDF properly during the cutting process is crucial for minimizing splintering. Using a stable work surface and ensuring that the MDF sheet is fully supported along the cut line can help prevent tear-out and splintering. Additionally, using sacrificial backing such as a piece of scrap wood beneath the MDF can further reduce splintering by providing support to the fibers as the cut is made.

Safety Measures

Learn how to cut MDF safely and efficiently without chipping or splintering. Use a circular saw or table saw for straight cuts, and a jigsaw with a bi-metal cutting blade for curved cuts. Make sure to use a high-quality carbide-tipped blade for optimal results.

Avoid using a utility knife for cutting MDF, as it may require more effort and patience.

Personal Protective Equipment

When cutting MDF, it’s crucial to prioritize safety by wearing the right personal protective equipment (PPE). The following PPE is recommended:

- Safety goggles: Protect your eyes from wood dust and potential wood particles.

- Dust mask or respirator: Prevent inhalation of MDF dust, which can be harmful to the respiratory system.

- Hearing protection: Reduce the noise produced by power tools, such as saws, to prevent hearing damage.

- Gloves: Protect your hands from sharp edges and splinters.

Dust Management

Effective dust management is essential for a safe and healthy working environment when cutting MDF. Implement the following measures to control dust:

- Dust extraction system: Use a dust extraction system or a vacuum connected to the cutting tool to capture MDF dust at the source.

- Dust collection bag: Attach a dust collection bag to the cutting tool to capture fine MDF dust particles.

- Clean work area: Regularly clean the work area to minimize the accumulation of MDF dust, reducing the risk of inhalation and fire hazards.

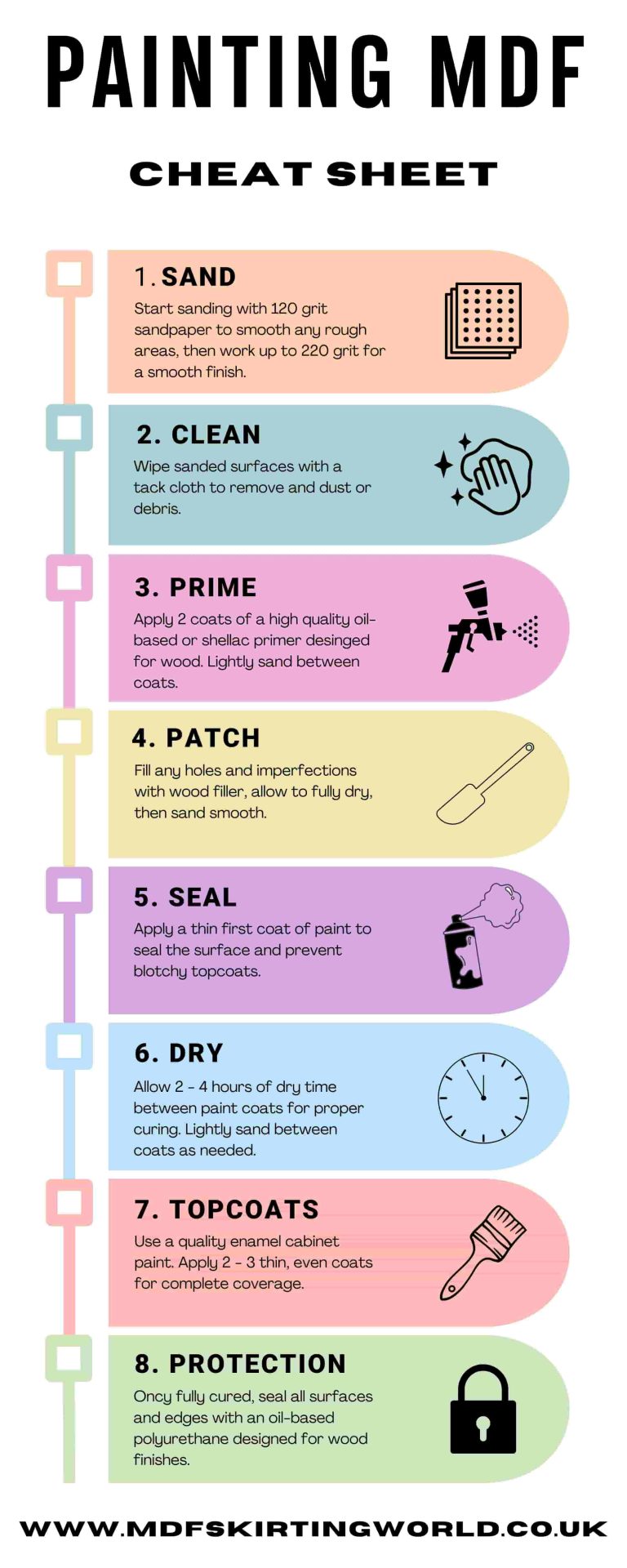

Post-cut Finishing

Achieving a smooth finish after cutting MDF requires proper post-cut finishing techniques. To avoid chipping and splintering, it’s best to use a high-quality carbide-tipped blade on a circular saw or table saw for straight cuts, while a jigsaw with a bi-metal cutting blade is ideal for curved cuts.

Additionally, using a straight edge as a guide and clamping the MDF down securely can help ensure precise cuts.

Sanding Edges

After cutting MDF, sanding the edges is crucial to ensure a smooth and professional finish. Use medium-grit sandpaper to gently sand the edges, removing any roughness or unevenness. Take care to sand in the direction of the wood grain to prevent splintering.

Sealing Cut Surfaces

Sealing the cut surfaces of MDF is essential for preventing moisture absorption and reducing the risk of swelling or warping. Apply a sealant or primer to the exposed edges and any cut surfaces to protect the MDF from environmental factors.

Advanced Tips

When it comes to cutting MDF, there are some advanced tips and techniques that can help you achieve precise and clean cuts, especially for more complex projects. Below are some advanced tips that can assist you in mastering the art of cutting MDF.

Using Jigs For Repetitive Cuts

If you need to make repetitive cuts on MDF, using a jig can significantly improve the efficiency and accuracy of your cuts. By creating a custom jig for your specific cutting needs, you can ensure that each piece is cut to the exact dimensions required, saving time and reducing the margin for error.

Dealing With Thick MDF

When working with thick MDF, it’s important to adjust your cutting techniques to accommodate the density and thickness of the material. Thicker MDF can be more challenging to cut, and it’s essential to use the appropriate tools and cutting methods to achieve clean and precise results.

Frequently Asked Questions

What Is The Best Thing To Cut MDF With?

For cutting MDF, a circular saw or table saw is the best option for straight cuts. A jigsaw with a bi-metal cutting blade can be used for curved cuts. It is recommended to use a high-quality carbide-tipped blade for optimal results.

A table saw can also be used for precise cuts with less splintering and chipping. Hand tools like a utility knife or box cutter can be used for irregular shapes, but require more patience and effort.

How Do You Cut MDF Without Chipping?

To cut MDF without chipping, use a table saw for precise cuts, reducing splintering. For curved shapes, a jigsaw works well.

Can You Cut MFD With A Utility Knife?

Yes, you can cut MDF with a utility knife, especially for curved or irregular shapes. However, it may require more patience and effort compared to using power tools. For straight cuts, a circular saw or table saw is recommended for more precise and accurate results, with less splintering and chipping of the edges.

Can You Hand Cut MDF?

Yes, you can hand cut MDF, but it’s not easy to get straight cuts without power tools.

Conclusion

Cutting MDF can be made easier by following the right techniques and using the appropriate tools. A circular saw or table saw is recommended for straight cuts, while a jigsaw is ideal for curved cuts. It is important to use a high-quality carbide-tipped blade for optimal results.

Additionally, using clamps and a straight edge can help ensure accurate cuts. By taking these precautions and practicing a slow and steady approach, you can achieve clean and precise cuts on your MDF projects.