How to Avoid Cracking in Drying Wood Slabs

To dry wood slabs without cracking, start by sealing the ends of the slabs with a commercial wood sealer to prevent moisture loss, and then stack them vertically with spacers between each slab for proper airflow.

Understanding The Importance Of Proper Drying Techniques

Proper drying techniques are crucial when it comes to preventing wood slabs from cracking. Learn how to effectively dry wood slabs without compromising their integrity.

Wood slabs are beautiful and unique additions to any space. Whether you’re working on a DIY project or a professional woodworking venture, it’s essential to understand the importance of proper drying techniques to avoid cracking in wood slabs. In this section, we will explore the significance of avoiding cracking and the role of proper moisture content in achieving desirable results.

Importance Of Avoiding Cracking In Drying Wood Slabs

Cracking in wood slabs can be disappointing and frustrating, especially after investing time and effort into the drying process. Understanding the importance of preventing cracking will help you preserve the structural integrity and aesthetics of your wood slabs. Here’s why it matters:

- Preservation of beauty: Cracks mar the natural beauty of wood slabs, diminishing their visual appeal and value.

- Longevity and durability: Properly dried wood slabs without cracks are more likely to withstand the test of time, ensuring their longevity and durability.

- Minimization of waste: Cracked wood slabs may become unusable or require extensive repairs, resulting in unnecessary waste of resources.

- Reduced cost: By avoiding cracking in wood slabs, you can save money by eliminating the need for costly repairs or replacements.

Significance Of Proper Moisture Content In Wood Slabs

Managing moisture content is crucial for successful wood slab drying. The right moisture content safeguards against cracking and contributes to the overall quality of the finished product. Consider the following points:

- Preventing stress buildup: Properly dried wood slabs have lower moisture content, minimizing stress buildup that can lead to cracking during the drying process.

- Maintaining stability: Achieving the right moisture content ensures that wood slabs maintain their stability and resist warping or twisting over time.

- Enhancing workability: Wood slabs with optimal moisture content are easier to work with, allowing for smoother woodworking operations and reducing the risk of damage caused by excessive moisture.

- Avoiding fungal growth: Controlling moisture content helps prevent fungal growth, which can compromise the integrity of wood slabs and degrade their quality.

Understanding the importance of proper drying techniques, including avoiding cracking and maintaining appropriate moisture content, is fundamental for successful wood slab projects. By following effective drying methods, you can ensure stunning, durable, and crack-free wood slabs that will stand the test of time.

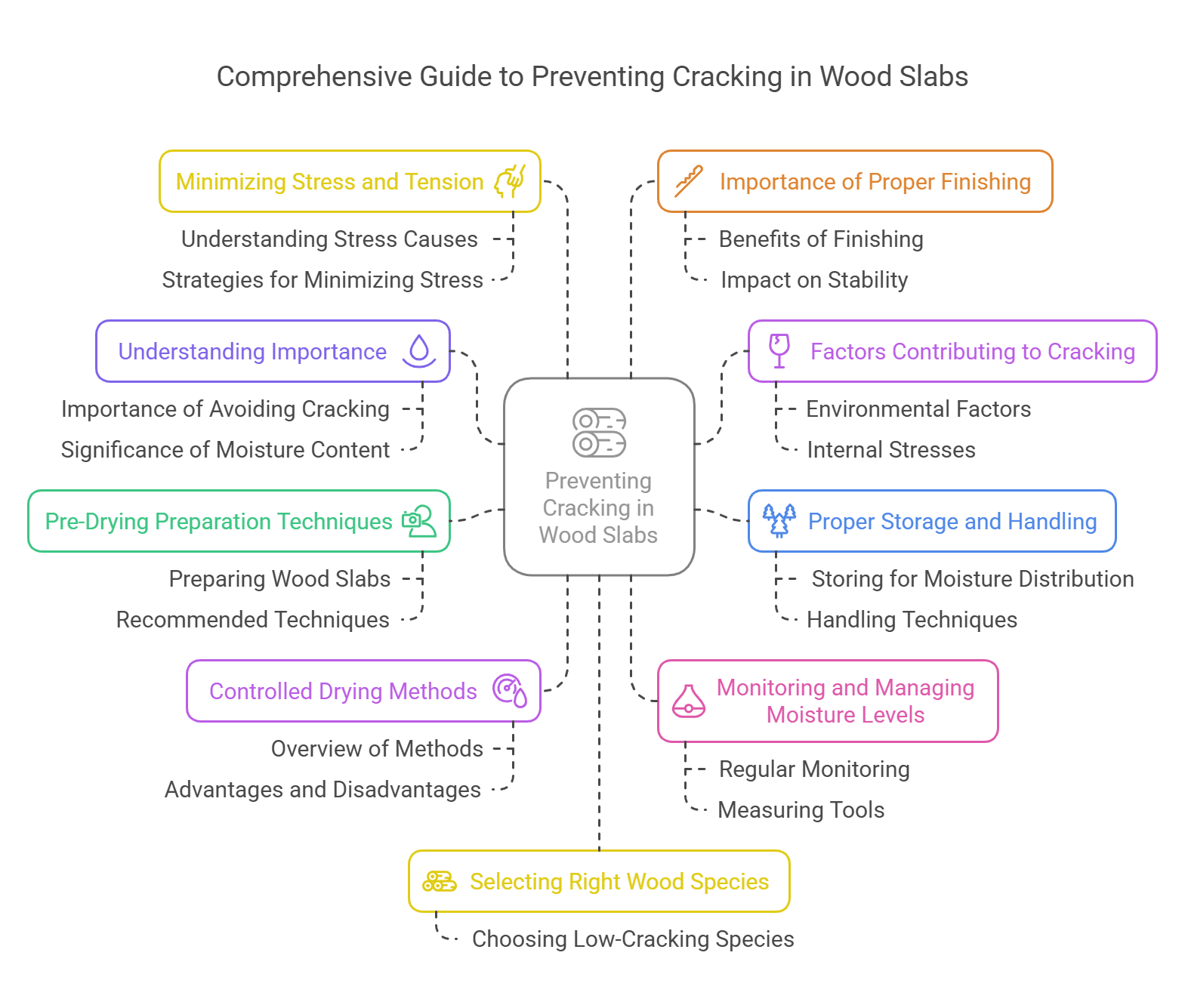

Factors Contributing To Cracking In Wood Slabs

Wood slabs are prone to cracking during the drying process, but there are ways to prevent this. Factors like proper moisture content, slow drying, and sealing the ends can help dry wood slabs without cracking.

Wood slabs are a popular choice for various woodworking projects, including furniture making and decorative pieces. However, one common issue that woodworkers encounter is cracking in wood slabs. Cracking can be unsightly and can potentially compromise the structural integrity of the wood.

Understanding the factors that contribute to cracking can help you take the necessary precautions to prevent it. Let’s delve into the environmental factors affecting wood moisture levels and the internal stresses and tension within the wood slab.

Environmental Factors Affecting Wood Moisture Levels:

Wood is a hygroscopic material, which means it can absorb and release moisture based on the surrounding environment. Changes in moisture content can lead to cracking in wood slabs. Here are the key environmental factors to consider:

- Temperature and humidity variations: Fluctuations in temperature and humidity levels can cause the wood to expand and contract. Rapid changes or extreme conditions can induce stress in the wood fibers, resulting in cracks.

- Exposure to direct sunlight: Intense sunlight can accelerate the drying process of wood slabs unevenly. The differential drying rates of the exposed and shaded areas can trigger cracks.

- Improper storage conditions: Storing wood slabs in a non-climate-controlled environment or in direct contact with the ground can expose them to excessive moisture, causing uneven drying and potential cracking.

- Air circulation and ventilation: Insufficient airflow and poor ventilation can impede moisture evaporation, prolonging the drying time and increasing the likelihood of cracks.

Internal Stresses And Tension Within The Wood Slab:

Apart from external environmental factors, internal stresses and tension within the wood slab itself can contribute to cracking. Here are some key points to consider:

- Natural defects: Wood slabs may contain natural defects such as knots, checks, or cracks, which are potential weak points. These defects can lead to uneven drying and subsequent cracking.

- Wood grain orientation: The orientation of the wood grain can influence how the wood slab dries. Boards cut against the grain, known as flatsawn, are prone to more significant shrinkage and cracking compared to quartersawn or riftsawn boards.

- Moisture content imbalance: If the wood slab has different moisture content across its thickness, it can create internal stresses during drying, leading to cracking. Evenly drying the wood slab helps minimize this risk.

Preventing cracking in wood slabs involves strategic drying techniques, such as air drying or kiln drying, and careful consideration of environmental factors and wood characteristics. By understanding these factors, you can take appropriate measures to avoid or minimize cracking, ensuring the longevity and quality of your wood projects.

Selecting The Right Wood Species For Slab Drying

Choosing the right wood species is crucial for preventing slab cracking during the drying process. Learn effective techniques to dry wood slabs without compromising their quality.

When it comes to drying wood slabs without cracking, selecting the right wood species plays a crucial role. Certain types of wood have minimal propensity for cracking, making them ideal for the drying process. By considering the following factors, you can ensure that you choose the most suitable wood species for successful slab drying.

Choosing Wood Species With Minimal Propensity For Cracking

- Dimensionally Stable Woods: Opt for wood species that are known for their dimensional stability, meaning they are less likely to undergo significant changes in size and shape when exposed to varying moisture levels.

- Tight Grained and Dense Woods: Select wood species that have tight grain patterns and high density. These characteristics contribute to better moisture retention and reduced cracking during drying.

- Slow-drying Woods: Certain wood species, such as oak and walnut, tend to dry more slowly compared to others. Slower drying allows for a more controlled release of moisture, minimizing the risk of cracking.

- Less Resin Content: Choose wood species with lower resin content, as resin can create internal stresses that lead to cracking during the drying process.

- Thick Sapwood: Prioritize wood species with thicker sapwood instead of a high heartwood-to-sapwood ratio. Sapwood has higher moisture content and can help balance drying rates between the center and outer layers of the slab, reducing the likelihood of cracking.

Considering these factors will help you select wood species that are more resistant to cracking during slab drying, ensuring successful and high-quality results. Remember to acquire the wood from reputable suppliers and employ proper drying techniques to further enhance the chances of drying wood slabs without cracking.

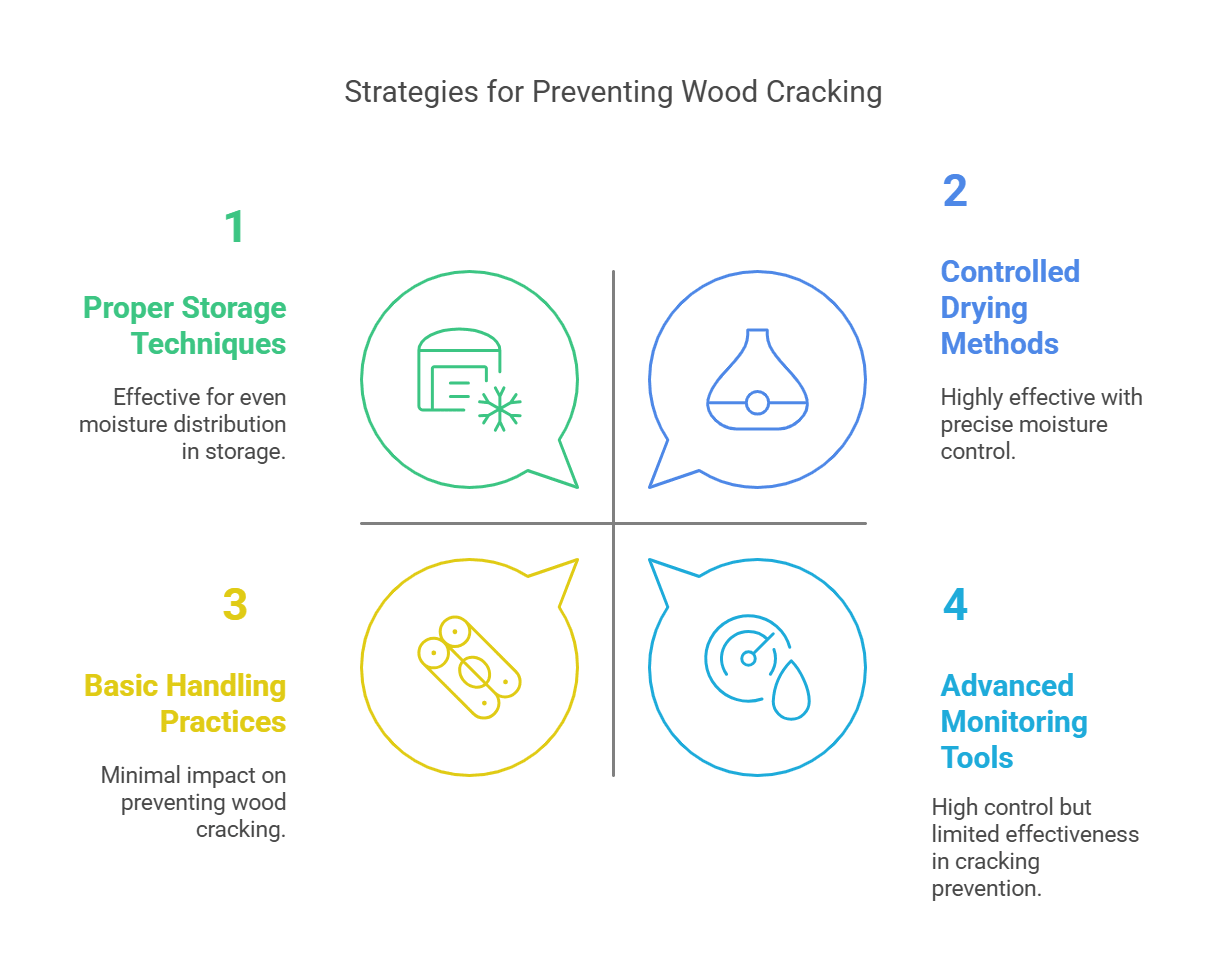

Proper Storage And Handling Of Wood Slabs

Properly storing and handling wood slabs is crucial to prevent cracking during the drying process. Following these guidelines ensures the preservation of the slab’s quality and integrity.

Wood slabs are valuable pieces of material that require proper storage and handling to ensure their integrity and prevent cracking. Whether you’re a woodworker, a furniture maker, or simply a DIY enthusiast, understanding the importance of storing wood slabs and employing the right techniques for their handling and transportation is essential.

In this section, we’ll explore why proper storage is crucial and share some effective techniques for handling wood slabs without causing any damage.

Importance Of Storing Wood Slabs To Ensure Even Moisture Distribution

Proper storage is paramount when it comes to preventing wood slabs from cracking. By following these guidelines, you can ensure even moisture distribution and maintain the overall quality of your wood slabs:

- Avoid exposure to direct sunlight: Sunlight can cause uneven drying and accelerate moisture loss, leading to cracks. Find a shaded space or use protective coverings to shield your wood slabs from the sun’s rays.

- Control humidity levels: Fluctuating humidity levels can wreak havoc on wood slabs. Maintain consistent humidity around your stored slabs by utilizing dehumidifiers or humidifiers as needed.

- Allow for adequate airflow: Air circulation is essential in preventing moisture buildup and promoting even drying. Place spacers between the slabs, allowing air to pass through and reach all surfaces.

- Regularly monitor moisture content: Use moisture meters to regularly check the moisture content of your wood slabs. Aim for a balanced moisture level that is suitable for your specific project, ensuring there is no excessive moisture or dryness.

- Stack slabs properly: When stacking wood slabs, ensure they are stacked evenly and straight, preventing any warping or unnecessary pressure that can lead to cracking.

Techniques For Handling And Transporting Wood Slabs Without Causing Damage

When it comes to handling and transporting wood slabs, a delicate touch and careful techniques are crucial to prevent any damage. Consider the following practices to ensure the safe movement of your wood slabs:

- Use proper lifting equipment: Depending on the size and weight of the slabs, employ appropriate lifting equipment such as cranes, forklifts, or straps. This will help distribute the weight evenly and prevent any mishandling accidents.

- Protect the edges: Wood slabs are vulnerable to damage along the edges. Utilize edge protectors or foam padding to safeguard these areas during handling and transportation.

- Secure the slabs: Use straps or clamps to secure the wood slabs and minimize movement during transportation. This will prevent unnecessary stress on the slabs that could result in cracking or other damage.

- Avoid dragging or sliding: Always lift the wood slabs rather than dragging or sliding them, as this can cause surface scratches or dents. Place them on a smooth, clean surface to avoid any abrasions during handling.

- Consider temperature changes: Extreme temperature fluctuations can affect the stability of wood slabs. Avoid exposing them to rapid temperature changes and allow the slabs to acclimate slowly to new environments when possible.

By adhering to these storage and handling techniques, you can ensure the quality and longevity of your wood slabs, preventing cracking and preserving their natural beauty. Whether you’re working on a woodworking project or simply storing slabs for future use, following these best practices will help you make the most of your valuable wood resources.

Pre-Drying Preparation Techniques

Learn effective pre-drying preparation techniques to dry wood slabs without cracking. Discover methods for minimizing moisture content while maintaining the integrity of the wood through careful handling and storage.

Understanding The Importance Of Preparing Wood Slabs Before Drying

Wood slabs are not ready to be dried immediately after being cut. Proper preparation is crucial to avoid cracking and ensure a successful drying process. By following recommended techniques for pre-drying preparation, you can enhance the stability and quality of the wood slabs.

Here’s what you need to know:

Recommended Techniques For Preparing Wood Slabs For Drying:

- Trimming: Before drying, trim the wood slabs to remove any excess branches, bark, or uneven edges. This ensures a consistent thickness and reduces stress on the wood as it dries.

- End Sealing: The ends of wood slabs have a higher moisture content, making them more prone to cracking. Apply a suitable end sealer, such as wax or specialized wood sealants, to prevent rapid moisture loss from the ends. This helps to achieve a balanced drying process and reduces the risk of end-checks.

- Air Drying Stacks: Proper stacking of wood slabs is essential for uniform drying. Arrange the slabs with sufficient spacing between each piece to promote adequate airflow. Place wooden sticks or spacers between the slabs to allow air circulation on all sides, helping to prevent mold growth and promote even moisture evaporation.

- Weight Distribution: Placing weight evenly on top of the stacked wood slabs aids in minimizing warping and ensures an even drying process. Use weights, such as cinder blocks or heavy boards, to apply gentle pressure throughout the stack. This helps to minimize cupping and twisting.

- Tracking Moisture Content: Regularly monitor the moisture content of the wood slabs during the drying process. Use a moisture meter to measure the moisture levels at various intervals. This helps to identify when the wood slabs have reached the desired moisture content for further drying or use.

- Controlled Environment: Choose an appropriate environment for drying wood slabs. Ideally, a well-ventilated, shaded area is optimal. Avoid exposing the slabs to direct sunlight or extreme temperature variations, as these can cause uneven drying and increase the risk of cracking.

Remember, proper preparation sets the foundation for successful wood slab drying. By following these recommended techniques, you can minimize the risk of cracking and ensure the wood slabs dry without compromising their integrity and quality.

Controlled Drying Methods For Wood Slabs

Learn how to dry wood slabs without cracking using controlled drying methods. These techniques ensure that the wood retains its structural integrity while minimizing the risk of cracks or warping, resulting in high-quality finished products.

Overview Of Different Controlled Drying Methods

Controlling the drying process is crucial when it comes to preserving the integrity of wood slabs and preventing cracks. There are various methods available, each with its own advantages and disadvantages. In this section, we will explore the different controlled drying methods and shed light on their pros and cons.

Plain Paragraph:

- Air drying: This traditional method involves stacking wood slabs in a dry, well-ventilated area and allowing them to naturally dry over time.

- Advantages: Cost-effective, easy to implement, and suitable for low moisture content removal.

- Disadvantages: Relatively slow process, higher risk of mold growth, and potential for uneven drying.

Bullet Points:

- Kiln drying: This method utilizes specialized drying chambers to control temperature, humidity, and airflow for accelerated wood slab drying.

- Advantages: Faster drying time, precise control over moisture content, reduced risk of mold and insect infestation.

- Disadvantages: Expensive equipment investment, high energy consumption, and potential for wood stress due to rapid drying.

- Solar kiln drying: Similar to kiln drying, solar kilns use the sun’s energy to heat and dry the wood slabs.

- Advantages: Energy-efficient and environmentally friendly, ideal for small-scale operations or DIY enthusiasts.

- Disadvantages: Limited control over drying conditions, longer drying time compared to conventional kilns, and dependency on weather conditions.

- Dehumidification drying: This method involves using dehumidifiers to extract moisture from the air within a controlled drying chamber.

- Advantages: Fast drying, precise control of humidity levels, reduced risk of drying defects.

- Disadvantages: Higher initial setup cost, ongoing maintenance requirements, and limited drying capacity for larger quantities.

- Vacuum drying: Vacuum chambers create low-pressure environments that accelerate the evaporation of moisture from the wood slabs.

- Advantages: Rapid drying, minimal risk of drying defects, improved stability of the wood.

- Disadvantages: Expensive equipment, limited drying capacity, and potential for wood distortion if not properly controlled.

Advantages And Disadvantages Of Each Drying Method:

To summarize, here’s a quick overview of the advantages and disadvantages of each drying method:

Air drying:

Advantages: Cost-effective, easy to implement.

Disadvantages: Slow process, risk of mold growth, and potential for uneven drying.

Kiln drying:

Advantages: Faster drying time, precise control over moisture content.

Disadvantages: Expensive equipment, high energy consumption, and potential for wood stress.

Solar kiln drying:

Advantages: Energy-efficient, suitable for small-scale operations or DIY enthusiasts.

Disadvantages: Limited control over drying conditions, longer drying time, and dependency on weather.

Dehumidification drying:

Advantages: Fast drying, precise humidity control.

Disadvantages: Higher initial setup cost, ongoing maintenance needs, and limited capacity.

Vacuum drying:

Advantages: Rapid drying, minimal risk of defects, improved wood stability.

Disadvantages: Expensive equipment, limited drying capacity, and potential for wood distortion.

By understanding the benefits and drawbacks of each method, you can choose the drying technique that best suits your needs and resources while minimizing the risk of cracking in your valuable wood slabs.

Monitoring And Managing Moisture Levels

Learn how to effectively monitor and manage moisture levels to dry wood slabs without the risk of cracking. Mastering this process is essential for preserving the integrity and quality of your woodwork projects.

Importance Of Regularly Monitoring Moisture Content During The Drying Process

It is crucial to regularly monitor the moisture content when drying wood slabs to prevent cracking and ensure a successful outcome. By understanding the importance of moisture levels throughout the drying process, you can avoid potential issues and maintain the quality of your wood slabs.

Here are some key points on why monitoring moisture content is essential:

- Prevents cracking: Regular monitoring allows you to identify when the wood slabs are drying too fast or unevenly, which can lead to cracking. By keeping tabs on the moisture levels, you can adjust the drying conditions accordingly.

- Improves stability: Controlling the moisture content helps to achieve optimal stability in the wood slabs. By carefully monitoring and adjusting the drying process, you can ensure that the moisture is uniformly distributed, minimizing the risk of warping and distortion.

- Preserves quality: Properly dried wood slabs will retain their color, strength, and overall quality. Monitoring moisture levels enables you to achieve the desired drying rate, preventing over-drying or under-drying, which can negatively impact the final product.

- Saves time and resources: Regular monitoring allows you to make any necessary adjustments promptly. This helps you avoid wasting time and resources on incorrect drying methods and reduces the risk of having to re-dry the wood slabs.

Techniques And Tools For Measuring And Managing Moisture Levels

Measuring and managing moisture levels is a critical aspect of drying wood slabs effectively. Utilize these techniques and tools to ensure accurate monitoring and efficient management:

- Moisture meters: Invest in a reliable moisture meter specifically designed for wood. These meters provide quick and accurate readings of the moisture content in the wood slabs, enabling you to assess the drying progress.

- Oven-drying method: This technique involves weighing a sample of the wood slabs, drying it in an oven, and re-weighing it until a constant weight is achieved. By comparing the initial and final weights, you can determine the moisture content.

- Pin-type moisture probes: These probes are inserted directly into the wood slabs to measure the moisture levels at various depths. This method is particularly useful for thicker slabs as it provides localized readings.

- Relative humidity (RH) monitoring: Monitoring the ambient humidity levels in the drying environment helps you assess the drying rate. By maintaining an optimal RH level, you can control the moisture loss in the wood slabs.

- Visual inspection: Regularly visually inspect the wood slabs for signs of over-drying or uneven drying. Cracking, splitting, or significant warping can indicate issues with moisture content that need to be addressed promptly.

By combining these monitoring techniques with proper management strategies, such as adjusting temperature, airflow, and humidity, you can ensure successful wood slab drying without compromising their quality or structure.

Credit: lancasterliveedge.com

Minimizing Stress And Tension In Wood Slabs

Learn effective techniques for drying wood slabs without the risk of cracking, reducing stress and tension. Discover step-by-step methods to ensure a successful drying process and preserve the integrity of your wood projects.

Understanding The Causes Of Stress And Tension In Drying Wood Slabs

When drying wood slabs, it is crucial to understand the causes behind stress and tension that can lead to cracking. By identifying these factors, you can implement strategies to minimize them and ensure successful drying without compromising the integrity of the wood.

To prevent cracking, consider the following causes of stress and tension:

- Moisture Imbalance: Wood contains moisture, and when drying, the outer layers lose moisture faster than the inner layers. This creates a moisture imbalance, leading to stress and potential cracking.

- Natural Forces: Wood responds to changes in temperature and humidity. When exposed to these natural forces, wood expands or contracts, resulting in stress. Rapid changes in temperature and humidity can be especially problematic.

- Internal Stresses: Wood slabs can have internal stresses caused by irregular grain patterns, knots, or tension wood. These internal stresses can become aggravated during the drying process, contributing to cracking.

Strategies For Minimizing Stress And Tension To Prevent Cracking

To minimize stress and tension and prevent cracking while drying wood slabs, it is essential to implement the following strategies:

- Sealing the Ends: Applying a sealant to the ends of the wood slabs helps slow down moisture loss. This prevents the outer layers from drying too quickly and reduces the risk of stress and cracking.

- Slow Drying: Gradual and controlled drying is key to minimizing stress. Avoid exposing the wood slabs to high temperatures or rapid changes in humidity. Opt for a slow drying method such as air drying or using a dehumidification kiln.

- Proper Stacking and Support: When stacking wood slabs for drying, ensure they are evenly spaced and supported to prevent warping or twisting. Use stickers or spacers between each slab to allow for proper airflow.

- Monitoring Moisture Content: Regularly measure and monitor the moisture content of the wood slabs as they dry. This allows you to adjust drying conditions if necessary and ensures a consistent and gradual moisture reduction.

- Timber Preparation: Properly preparing the wood slabs before drying can help minimize stress. This includes removing bark, debarking, and rough sawing the slabs to reduce potential tension areas.

- Patience and Time: Rushing the drying process increases the risk of stress and cracking. Patience is essential to allow the wood slabs to dry gradually over an extended period. The time required for drying can vary depending on the species and thickness of the slabs.

By understanding the causes of stress and tension in drying wood slabs and implementing these strategies, you can significantly reduce the likelihood of cracking. Remember to monitor the drying process closely and make any necessary adjustments to ensure the best possible outcome.

Importance Of Proper Finishing

Proper finishing is crucial for drying wood slabs without cracking. By using the right techniques and products, you can prevent moisture loss, maintain stability, and achieve a beautiful, crack-free result.

Wood slabs are a beautiful and versatile material that can be used for various woodworking projects. However, one common issue that woodworkers face when working with wood slabs is cracking. Cracks can not only ruin the aesthetic appeal of the finished piece but also compromise its structural integrity.

To avoid this problem, proper drying techniques are essential. We will explore the importance of proper finishing in preventing cracking and preserving the stability of wood slabs.

Benefits Of Applying A Finish To Dried Wood Slabs:

- Protection: Applying a finish to wood slabs creates a protective barrier that shields the wood from moisture and external elements. This helps prevent the wood from absorbing excessive moisture, which can lead to warping, cracking, and other forms of damage.

- Enhanced durability: A well-applied finish can significantly increase the durability and lifespan of a wood slab. It provides a layer of protection against scratches, stains, and wear and tear, making the slab more resistant to daily use and environmental factors.

- Accentuates natural beauty: Finishes can enhance the natural beauty of wood slabs by enriching their color, highlighting the grain patterns, and adding depth and dimension. A carefully chosen finish can bring out the unique characteristics of the wood, making it visually pleasing.

Impact Of Different Finishing Techniques On Wood Slab Stability:

- Moisture control: The choice of finishing technique can greatly impact the moisture content of the wood slab. Sealers and oils penetrate the wood fibers, reducing the chances of moisture absorption and subsequent cracking. On the other hand, film-forming finishes like varnish or polyurethane create a protective layer on the surface, further minimizing moisture ingress.

- Flexibility and movement: Wood is a living material that naturally expands and contracts with changes in humidity levels. Certain finishing techniques, such as using oils or wax-based finishes, allow the wood to breathe and move more freely. This flexibility helps prevent stress build-up and reduces the likelihood of cracking.

- Proper application: The skill and technique employed during the application of a finish can greatly impact the stability of wood slabs. Uneven application or inadequate coverage can result in areas with varying moisture levels, leading to differential drying and potential cracking. Consistent and thorough application is essential for maintaining stability.

- Regular maintenance: Regular maintenance and refinishing of wood slabs play a crucial role in their stability. Over time, finishes wear off, leaving the wood vulnerable to moisture. By consistently applying and renewing the finish, woodworkers can ensure the long-term stability and prevent cracking in wood slabs.

By understanding the benefits of applying a finish to dried wood slabs and the impact of different finishing techniques on their stability, woodworkers can effectively prevent cracking and maintain the beauty and integrity of their projects. So, next time you work with wood slabs, remember the significance of proper finishing techniques in preserving their quality and longevity.

Appropriate Finishing Products For Wood Slabs

Ensure the proper drying of wood slabs without cracking by using the right finishing products. Preserve the integrity of your project with these essential recommendations.

To ensure the quality and longevity of your wood slabs, choosing the right finishing products is crucial. These products not only enhance the natural beauty of the wood but also protect it from cracking and other damages. In this section, we will provide an overview of different types of finishing products and recommend the best options for preserving the quality of your wood slabs.

Overview Of Different Types Of Finishing Products

There are various types of finishing products available in the market, each with its own unique properties and benefits. Understanding the different options will help you make an informed decision when it comes to choosing the right finishing product for your wood slabs.

Here are some common types:

- Oil-based finishes: These finishes penetrate deep into the wood, providing excellent protection and enhancing the natural color and grain patterns. They are easy to apply but require multiple coats and longer drying time.

- Water-based finishes: These finishes are popular for their durability, fast drying time, and low odor. They offer good protection and do not alter the wood’s color significantly. They are also easy to clean up with soap and water.

- Wax finishes: Wax provides a soft, natural sheen and is often used as a topcoat over other finishes. It adds a layer of protection and enhances the wood’s natural beauty. However, wax finishes require regular maintenance and reapplication.

- Varnish finishes: Varnish is a durable and hard protective coating that provides excellent resistance to moisture, scratches, and UV rays. It enhances the wood’s appearance and can be applied in various sheen levels, from matte to high gloss.

- Polyurethane finishes: Polyurethane is a versatile finish that comes in both oil-based and water-based forms. It offers excellent protection and durability, making it suitable for high-traffic areas. It also comes in different sheen levels.

Recommended Finishing Products For Preserving Wood Slab Quality

When it comes to preserving the quality of your wood slabs and minimizing the risk of cracking, certain finishing products are particularly effective. Here are some recommended options:

- Wood conditioners: Before applying a finish, using a wood conditioner can help prevent cracking by sealing the wood’s pores and promoting even absorption of the finish.

- Epoxy resin: Epoxy resin is often used to fill voids, cracks, and knots in wood slabs. It provides a strong and durable seal, preventing moisture intrusion and reducing the risk of cracking.

- Wood stabilizers: Wood stabilizers penetrate the wood fibers, strengthening and reducing movement in the slab. They are especially useful for wet or freshly cut wood, minimizing the chances of cracking during the drying process.

- Outdoor/UV-resistant finishes: If your wood slabs will be exposed to sunlight or outdoor elements, choosing a finish with UV protection is essential. These finishes prevent fading, yellowing, and cracking caused by UV rays.

Remember to consider the specific needs of your wood slabs when selecting a finishing product. Additionally, always follow the manufacturer’s instructions for proper application and drying time to achieve the best results.

By choosing the appropriate finishing products for your wood slabs, you can ensure their long-term beauty and durability. Whether you opt for an oil-based finish, a water-based finish, or any other type, always prioritize their protective qualities to prevent cracking and maintain the natural majesty of your wood slabs.

Summary Of Key Points

Learn how to effectively dry wood slabs without the risk of cracking. Discover key tips and techniques to ensure a successful drying process for your woodworking projects.

Drying wood slabs without cracking is essential for maintaining their quality and integrity. Cracks can not only affect the aesthetic appeal of the slab but also compromise its structural stability. To help you prevent cracking and preserve the quality of your wood slabs, here is a summary of key points to keep in mind:

Recap Of The Importance Of Avoiding Cracking In Drying Wood Slabs:

- Cracking diminishes the quality and value of wood slabs.

- Cracks can compromise the structural integrity of the slab.

- Proper drying techniques are crucial for preventing cracks from forming.

Essential Steps And Techniques To Prevent Cracking And Maintain Wood Slab Quality:

Initial preparation:

- Remove the bark from the slab to allow for even drying.

- Seal the ends of the slab with a commercial wood sealer to prevent rapid moisture loss from the ends.

- Use stickering, or placing thin pieces of wood between the slabs, to allow for air circulation.

Controlled drying environment:

- Choose a well-ventilated and temperature-controlled area for drying.

- Maintain a consistent humidity level between 30% and 50%.

- Avoid exposing the slabs to direct sunlight and rapid temperature changes.

Slow and gradual drying:

- Air-dry the slabs for an extended period before using a kiln.

- Slow drying helps to evenly reduce the moisture content without causing stress on the wood.

Monitoring moisture content:

- Regularly measure the moisture content of the wood using a moisture meter.

- Aim for an equilibrium moisture content (EMC) of around 6-8% for indoor use.

Proper stacking and weight distribution:

- Stack the slabs with equal weight distribution to prevent warping and distortion.

- Place weights or heavy objects on top of the stack to keep the slabs flat.

By following these essential steps and techniques, you can minimize the risk of cracking and ensure the quality of your wood slabs. Remember to be patient and allow sufficient time for the slabs to dry properly. With proper care, you can enjoy beautiful, crack-free wood slabs for your projects.

Final Thoughts

Drying wood slabs without cracking is crucial. Follow these tips to prevent cracks and maintain the integrity of your wood slabs.

Encouragement To Implement Proper Drying Techniques For Successful Wood Slab Projects:

Properly drying wood slabs is essential to ensure their longevity and prevent cracking. By following the right techniques and taking the necessary precautions, you can achieve stunning results in your woodworking projects. Here are some reasons why it’s crucial to implement proper drying techniques for successful wood slab projects:

- Minimize cracking: Implementing the right drying techniques helps minimize the occurrence of cracks in wood slabs. This is particularly important for projects where the wood slab is the focal point, as cracks can significantly diminish the overall aesthetic appeal.

- Preserve wood quality: Proper drying techniques allow the wood to retain its natural color, texture, and structural integrity. By carefully controlling the drying process, you can ensure that the wood slab maintains its beauty and durability over time.

- Enhance project lifespan: Wood slabs that have been dried properly are more durable and less prone to decay or damage. By investing time and effort in implementing proper drying techniques, you can increase the lifespan of your projects, ensuring that they can be enjoyed for years to come.

Inspiring Readers To Explore The Beauty And Potential Of Dried Wood Slabs:

Dried wood slabs offer a world of possibilities for creativity and craftsmanship. Exploring the beauty and potential of these slabs can lead to remarkable projects and unique pieces. Here are a few reasons why you should consider working with dried wood slabs:

- Natural and distinctive: Dried wood slabs boast unique characteristics and natural beauty that cannot be replicated. Each slab has its own grain pattern, color variations, and imperfections that give it a one-of-a-kind appeal. By working with dried wood slabs, you can create stunning and individualistic pieces that stand out from the crowd.

- Versatile applications: From furniture and countertops to wall art and décor items, dried wood slabs can be used in a wide range of applications. Their natural charm and character can add warmth and a touch of nature to any space. Get inspired to experiment with different design ideas and create functional yet visually appealing pieces.

- Sustainable choice: By using dried wood slabs, you’re making an environmentally friendly choice. These slabs can often be sourced from reclaimed or salvaged wood, giving new life to materials that might have otherwise been discarded. By promoting sustainability in your woodworking projects, you can contribute to a greener and more conscious approach.

So, take the plunge and unlock the beauty and potential of dried wood slabs. By implementing proper drying techniques and exploring their endless possibilities, you can embark on an exciting woodworking journey that yields exceptional and long-lasting results.

Frequently Asked Questions For How To Dry Wood Slabs Without Cracking

How Long Does It Take To Dry Wood Slabs Without Cracking?

The drying time of wood slabs depends on various factors, such as the type of wood, thickness, and moisture content. On average, it can take several months to a year for wood slabs to dry properly without cracking. However, it is recommended to use effective drying methods, such as air-drying or kiln-drying, to speed up the process and minimize the risk of cracking.

What Are The Best Methods To Dry Wood Slabs Without Cracking?

There are two popular methods to dry wood slabs without cracking: air-drying and kiln-drying. Air-drying involves stacking the slabs with spacers to allow airflow and reducing moisture gradually. Kiln-drying, on the other hand, uses a controlled environment to speed up the drying process while minimizing cracking.

Both methods require regular monitoring and proper stacking techniques for successful drying.

What Are Some Tips To Prevent Wood Slabs From Cracking During Drying?

To prevent wood slabs from cracking during drying, follow these tips:

– Seal the ends of the slabs with a suitable sealer to reduce moisture loss.

– Stack the slabs using stickers to allow airflow between each slab.

– Use a moisture meter to monitor the moisture content regularly.

– Control the humidity levels in the drying area to avoid rapid or uneven drying.

– Avoid exposing the slabs to direct sunlight or extreme temperature changes.

Conclusion

To ensure wood slabs dry without cracking, it is crucial to follow the right steps and techniques. First and foremost, understanding the moisture content of the wood is essential. By using a moisture meter, you can accurately determine when the wood is ready for drying.

Next, proper air circulation is key to prevent moisture buildup and subsequent cracking. This can be achieved by placing the wood in a well-ventilated area or using fans to facilitate airflow. Additionally, sealing the ends of the wood with wax or a commercial end sealer helps to control moisture loss and minimize cracking.

Lastly, implementing a slow drying process, gradually reducing the moisture content over time, is highly recommended. By being patient and following these guidelines, you can successfully dry wood slabs without the fear of cracking, allowing you to create stunning and durable woodworking projects.