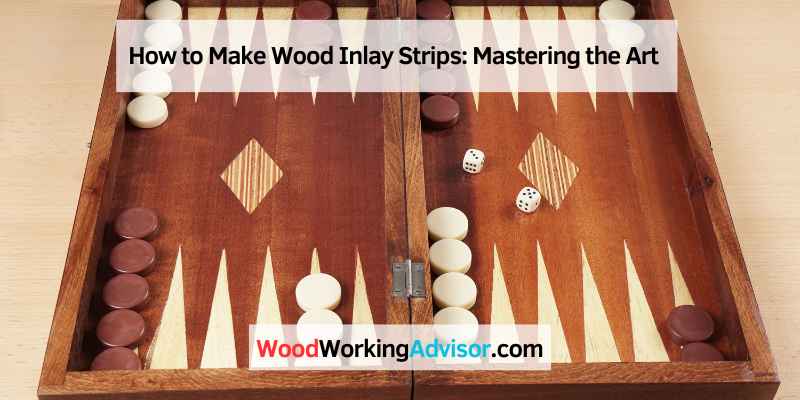

How to Make Wood Inlay Strips: Mastering the Art

To make wood inlay strips, select contrasting wood species, cut thin strips, and glue them together. This creates a unique pattern.

When combined with woodworking projects, inlay strips add decorative flair and visual interest. The process involves precision cutting and careful alignment to achieve professional-looking results. By following these steps, you can create beautiful wood inlay designs to enhance your woodworking projects.

Introduction To Wood Inlay Strips

Create stunning wood inlay strips with these easy steps. Crafting your own inlay strips allows for unique designs and personalization. By following simple techniques, you can make beautiful wood inlay strips for your woodworking projects.

The Beauty Of Inlaid Wood

Wood inlay strips are an exceptional way to add beauty and elegance to a woodworking project. The art of inlaying wood has been around for centuries and has been used to create intricate designs and patterns. Inlay strips are thin pieces of wood that are cut and shaped to fit into a groove in a larger piece of wood. These strips can be made from a wide variety of woods, and the variations in color and grain patterns make them ideal for creating stunning designs. In this article, we will explore the beauty of inlaid wood and how to make your own inlay strips.

Potential Applications For Inlay Strips

Inlay strips can be used in a variety of woodworking projects to add a touch of sophistication and style. Here are some potential applications for inlay strips:

- Add a decorative border to a tabletop or cabinet

- Create a stunning design on a jewelry box or picture frame

- Add a personalized touch to a cutting board or serving tray

Inlay strips can also be used to repair damaged woodwork. For example, if a piece of furniture has a scratch or dent, an inlay strip can be used to cover the imperfection and add a decorative element at the same time.

How To Make Wood Inlay Strips

Making your own inlay strips is a simple process that requires a few basic tools and materials. Here’s how to do it:

- Select the wood species you want to use for your inlay strips.

- Cut the wood into thin strips using a band saw or table saw.

- Plane the strips to the desired thickness using a thickness planer.

- Use a scroll saw or coping saw to cut the strips into the desired shape and size.

- Sand the strips to a smooth finish.

- Apply a finish to the strips to protect the wood and enhance its natural beauty.

In conclusion, inlay strips are a beautiful and versatile addition to any woodworking project. Whether you’re adding a decorative border to a tabletop or repairing a scratch on a piece of furniture, inlay strips are an excellent way to add style and sophistication to your work. With a few basic tools and some patience, you can create your own inlay strips and take your woodworking to the next level.

Essential Tools And Materials

When it comes to creating beautiful wood inlay strips, having the essential tools and materials is crucial. From selecting the right wood to using cutting tools and safety gear, each step plays a vital role in the process. Let’s dive into the key elements you’ll need to get started on your wood inlay project.

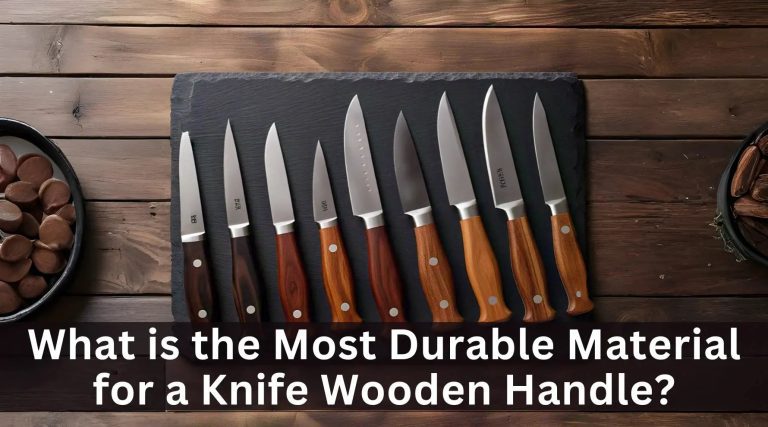

Selecting The Right Wood

Choosing the right wood for your inlay strips is essential to achieve the desired look and durability. Look for hardwoods such as maple, walnut, or cherry as they are sturdy and offer beautiful grain patterns. Select pieces that are free of knots and imperfections to ensure a smooth and consistent finish.

Cutting Tools And Safety Gear

- Band Saw: Ideal for cutting thin strips of wood with precision.

- Table Saw: Useful for creating consistent thickness inlay strips.

- Safety Glasses: Protect your eyes from wood dust and debris.

- Ear Protection: Minimize exposure to loud noise when using power tools.

- Push Sticks: Ensure safe and controlled feeding of wood through cutting tools.

Always wear safety glasses and ear protection when operating cutting tools to safeguard yourself from potential hazards. Additionally, using push sticks can help maintain a safe distance from the cutting blade while ensuring precise control over the wood.

Designing Your Inlay Pattern

Designing the perfect inlay pattern requires careful consideration and planning. By following these steps, you can create a stunning wood inlay that will truly stand out:

Drawing And Planning

The first step in designing your inlay pattern is to draw it out on paper. Take the time to sketch out your desired design, paying attention to the intricate details. This will help you visualize the final result and make any necessary adjustments before starting the actual inlay process.

Choosing Complementary Woods

Selecting the right combination of woods is crucial to achieving a visually appealing inlay pattern. Consider using contrasting woods that complement each other in terms of color and grain. This will enhance the overall aesthetic and make your inlay stand out.

When choosing woods for your inlay, keep in mind their durability and stability. Some woods are more prone to expansion and contraction, which can affect the longevity of your inlay. Research the characteristics of different woods to ensure you select ones that are suitable for your project.

Creating a table to compare the properties of different woods can be helpful:

| Wood Type | Color | Grain | Durability |

|---|---|---|---|

| Walnut | Dark brown | Straight or wavy | High |

| Maple | Light beige | Straight or curly | Medium |

| Cherry | Reddish brown | Straight or curly | Medium |

Once you have chosen your woods, consider creating a test piece to see how they look together. This will allow you to make any necessary adjustments before committing to the final design.

Designing your inlay pattern requires careful attention to detail and the right combination of woods. By following these steps, you can create a visually stunning wood inlay that will impress all who see it.

Preparing The Wood

Before you can begin creating beautiful wood inlay strips, it’s important to properly prepare the wood. This involves cutting the wood strips to the desired size and sanding them for a smooth finish. By following these steps, you’ll ensure that your wood inlay project turns out stunning and professional-looking.

Cutting The Wood Strips

To start, you’ll need to select the type of wood you want to use for your inlay strips. Choose a high-quality hardwood that complements the overall design of your project. Once you have the wood, follow these steps to cut the strips:

- Measure and mark the desired width of the strips on the wood.

- Secure the wood firmly in a vise or clamp to ensure stability during cutting.

- Using a table saw or a band saw, carefully cut along the marked lines to create the strips.

- Ensure that the strips are uniform in size and thickness for a consistent look.

Sanding For A Smooth Finish

After cutting the wood strips, it’s essential to sand them to achieve a smooth and polished surface. Follow these steps to sand the strips effectively:

- Start with a low-grit sandpaper, such as 80 or 120, to remove any rough edges or imperfections.

- Gradually move up to higher grits, such as 220 or 320, to refine the surface and achieve a smoother finish.

- Sand in the direction of the wood grain to avoid creating scratches or marks.

- Wipe off any dust or debris from the sanding process using a clean cloth.

By preparing the wood properly through cutting the strips accurately and sanding them thoroughly, you’ll have a solid foundation for creating stunning wood inlay designs. Remember to take your time and pay attention to detail to achieve the best results.

Creating The Inlay Groove

To create an inlay groove for wood inlay strips, first mark the area where the groove will be cut. Use a router to carefully cut the groove to the appropriate depth, ensuring that it is straight and clean. Sand the edges of the groove to smooth them out and remove any imperfections.

Measuring And Marking

Routing Techniques

Assembling The Inlay

Crafting wood inlay strips involves carefully assembling the pieces to create intricate designs. Start by cutting thin strips of contrasting wood and arranging them to form the desired pattern. Glue the strips together and then sand them down to create a smooth and seamless inlay.

Gluing Strategies

Apply wood glue evenly on the inlay strips.

Press the strips firmly together for a secure bond.

Clamping For Precision

Use clamps to hold the inlay strips in place.

Ensure even pressure across the entire surface.

Finishing Touches

To add the perfect finishing touches to your woodworking project, consider creating custom wood inlay strips. This process involves cutting thin strips of wood and carefully fitting them together to create unique designs. With patience and precision, you can elevate your project to the next level.

Trimming Excess Material

Carefully trim the excess inlay material with a sharp chisel.

Sanding And Sealing The Inlay

Sand the inlay flush with the surface before sealing it with a clear finish.

Advanced Inlay Techniques

Discover the artistry of advanced inlay techniques to elevate your woodworking projects.

Curved Inlays

Create intricate designs with curved inlays by bending strips to fit unique shapes.

Using Inlay Kits

Inlay kits simplify the process, providing precision tools for seamless integration.

Troubleshooting Common Problems

Wood inlay strips can sometimes present challenges during the crafting process. Here are some common problems and how to address them:

Dealing With Wood Expansion

- Ensure wood strips are properly dried before inlaying.

- Store wood in a climate-controlled area to prevent warping.

- Use a sealant to protect against moisture and humidity.

Fixing Imperfections

- Sand down uneven areas for a smooth finish.

- Fill gaps with wood filler and sand flush for seamless inlay.

- Apply a topcoat to enhance the overall look and durability.

Preserving Your Inlay Work

Regular Maintenance Tips

Regular maintenance is essential for preserving the beauty and integrity of your wood inlay strips. Here are some simple yet effective tips to keep your inlay work looking its best:

- Keep the surface clean and free from dust and dirt.

- Use a soft, dry cloth to gently wipe the inlay strips.

- Apply a thin layer of high-quality furniture wax to protect the wood and enhance its natural luster.

- Avoid using harsh chemical cleaners that can damage the inlay or the surrounding wood.

Restoring Aged Inlays

Over time, wood inlay strips may show signs of aging or wear. To restore the beauty of aged inlays, follow these steps:

- Clean the surface thoroughly to remove any dirt or grime.

- Gently sand the inlay strips to remove any surface imperfections.

- Apply a fresh coat of stain or varnish to rejuvenate the color and protect the wood.

- Buff the inlay strips with a soft cloth to bring out their natural shine.

Incorporating Inlays Into Furniture

Learn how to enhance furniture by creating intricate wood inlay strips for a unique touch. Incorporating inlays into furniture adds elegance and craftsmanship, elevating the overall aesthetic appeal of the piece. Master the art of making wood inlay strips to personalize your furniture with a professional finish.

Design Ideas

When it comes to incorporating inlays into furniture, the design possibilities are endless. Whether you want to add a touch of elegance or make a bold statement, inlays can enhance the overall aesthetic appeal of your furniture. Here are some design ideas to consider:

- Geometric Patterns: Create eye-catching designs using geometric shapes such as squares, triangles, or diamonds. These patterns can add a modern and sophisticated look to your furniture.

- Nature-Inspired Motifs: Incorporate elements from nature, like leaves, flowers, or vines, into your inlays. This can bring a sense of organic beauty and tranquility to your furniture.

- Marquetry: Combine different types of wood veneers to create intricate patterns and images. Marquetry allows for detailed designs that can truly make your furniture stand out.

- Contrasting Colors: Experiment with contrasting wood colors to create a striking visual impact. The contrast between light and dark woods can add depth and dimension to your furniture.

- Inlay Borders: Use inlays to create decorative borders around the edges of your furniture. This can serve as a frame and draw attention to the craftsmanship of the piece.

Structural Considerations

When incorporating inlays into furniture, it’s essential to consider the structural aspects to ensure durability and longevity. Here are some key factors to keep in mind:

- Wood Selection: Choose a wood species that is suitable for both the base and the inlay. Different woods have different hardness and stability properties, so it’s important to select compatible materials.

- Inlay Thickness: Determine the appropriate thickness for your inlay strips. This will depend on the overall design and the depth of the grooves or recesses in the furniture.

- Glue and Adhesive: Use a high-quality adhesive that is specifically designed for woodworking. This will ensure a strong bond between the inlay and the base wood.

- Finishing: Consider how the inlays will be integrated into the finishing process. Plan the sanding and finishing steps accordingly to avoid damaging or obscuring the inlay strips.

- Expansion and Contraction: Take into account the natural movement of wood due to changes in temperature and humidity. Allow for slight movement of the inlay strips to prevent cracking or warping over time.

By carefully considering design ideas and structural considerations, you can successfully incorporate inlays into your furniture, adding a unique and visually appealing element that will impress anyone who sees it.

Taking Your Skills To The Next Level

Once you have mastered the basics of making wood inlay strips, it’s time to take your skills to the next level. By expanding your knowledge and experimenting with different materials, you can create unique and stunning designs that will truly showcase your expertise. Additionally, participating in community classes and workshops can provide valuable insights and opportunities to learn from experienced artisans. Let’s explore these avenues to help you enhance your wood inlay craftsmanship.

Experimenting With Materials

One way to elevate your wood inlay skills is to experiment with different materials. While traditional wood inlay typically involves using contrasting wood species, you can push the boundaries by incorporating other materials such as metal, shell, or even acrylic. By combining different textures and colors, you can create eye-catching designs that add depth and dimension to your work.

Here are a few materials you can consider:

- Metal: Brass, copper, or silver can add a touch of elegance and sophistication to your wood inlay strips. Experiment with different gauges and finishes to achieve the desired effect.

- Shell: Mother-of-pearl or abalone shells can create a mesmerizing effect when paired with wood. Their iridescent qualities can add a captivating shimmer to your designs.

- Acrylic: Transparent or colored acrylic can offer a modern twist to traditional wood inlay. Its versatility allows you to create bold and vibrant designs.

Community Classes And Workshops

Another way to enhance your wood inlay skills is by attending community classes and workshops. These educational opportunities provide a platform for you to learn from experienced artisans and exchange ideas with fellow craftsmen. Whether you are a beginner looking to expand your knowledge or an experienced woodworker seeking to refine your techniques, community classes and workshops can offer valuable insights and inspiration.

Here are some benefits of participating in community classes and workshops:

- Learn from experts: Experienced instructors can share their expertise and provide guidance on advanced techniques and best practices.

- Hands-on experience: Engaging in practical exercises under the supervision of professionals allows you to refine your skills and gain confidence in your abilities.

- Networking opportunities: Interacting with other woodworkers and artisans can lead to valuable connections, collaborations, and the sharing of ideas.

- Access to specialized tools and equipment: Community classes and workshops often provide access to tools and equipment that may be expensive or difficult to acquire on your own.

By embracing these opportunities to experiment with materials and engage in community learning, you can take your wood inlay skills to new heights. Pushing the boundaries of traditional techniques and learning from experienced artisans will allow you to create intricate and captivating designs that showcase your craftsmanship and passion for woodworking.

Frequently Asked Questions

What Is Wood Inlay And How Is It Made?

Wood inlay is a decorative technique of inserting pieces of contrasting wood into a base to create patterns or images. It is made by cutting thin strips of wood and fitting them into a recessed area of the base material, such as furniture or flooring.

What Tools Are Needed To Make Wood Inlay Strips?

To make wood inlay strips, you will need a table saw, a bandsaw, a planer, a thickness sander, and a variety of hand tools such as chisels and scrapers. These tools are essential for cutting, shaping, and smoothing the wood to create the desired inlay strips.

What Types Of Wood Are Suitable For Inlay Strips?

Various types of wood can be used for inlay strips, including exotic hardwoods like ebony, rosewood, and mahogany, as well as domestic hardwoods like maple, cherry, and walnut. The choice of wood depends on the desired color, grain pattern, and suitability for the specific inlay project.

How Are Wood Inlay Strips Applied To A Surface?

Wood inlay strips are applied to a surface by first creating a recessed area or groove for the strips to fit into. The strips are then glued into place and trimmed flush with the surface. The entire inlay is sanded and finished to achieve a smooth, seamless look.

Conclusion

Wood inlay strips are a beautiful and unique way to add a personal touch to any woodworking project. With the right tools and techniques, anyone can create their own inlay strips and take their woodworking skills to the next level.

Remember to choose contrasting woods for the best effect, and take your time with each step to ensure a flawless finished product. With practice and patience, you can master the art of wood inlay and create stunning designs that will impress for years to come.