How to Making a Wooden Jointer Plane: DIY Mastery

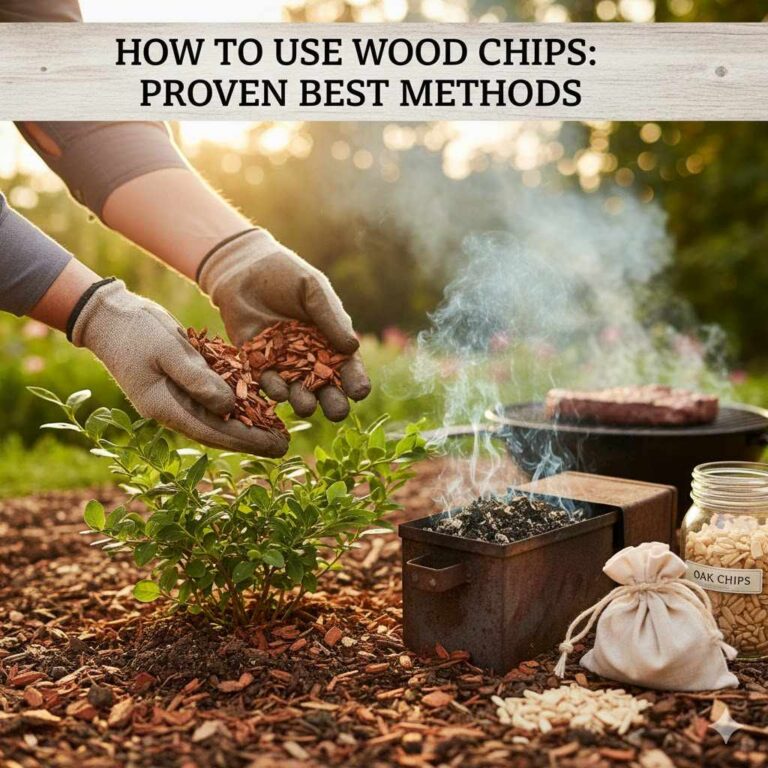

To make a wooden jointer plane, start by selecting high-quality hardwood for the body and blade. Shape the body to ensure smooth gliding and precise cuts.

Crafting a wooden jointer plane combines traditional woodworking skills with modern techniques. This tool is essential for achieving flat surfaces and straight edges on lumber. A well-made jointer plane enhances your woodworking projects, providing accuracy and efficiency. Choosing the right materials and design is crucial for optimal performance.

You’ll appreciate the tactile experience of hand-tool woodworking as you create this essential tool. Whether you’re a beginner or an experienced woodworker, making your own jointer plane can be a rewarding project. Enjoy the satisfaction of creating a custom tool tailored to your specific needs and preferences.

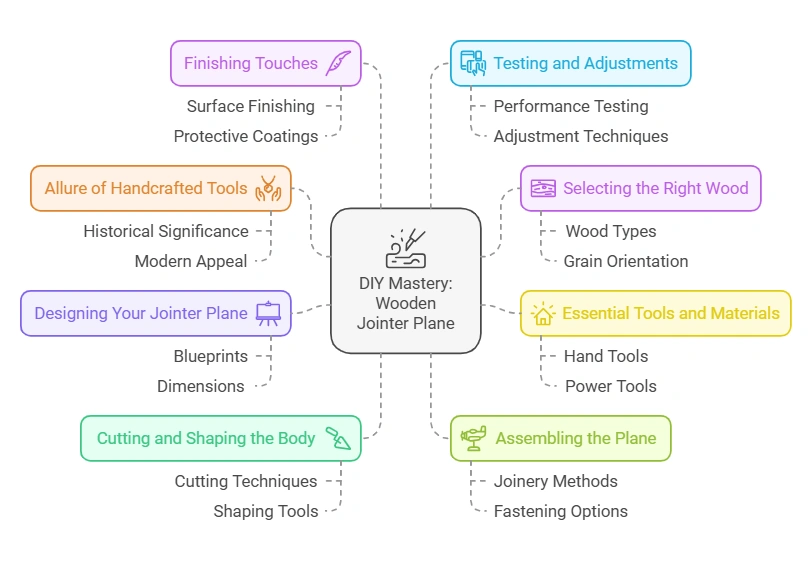

The Allure Of Handcrafted Tools

Handcrafted tools like wooden planes hold a special charm. They connect you with tradition and craftsmanship. Choosing wooden planes offers a unique experience. These tools are often lighter and easier to handle.

Wooden planes provide a smoother finish than metal ones. They are also more environmentally friendly. Many woodworkers find joy in making their own tools. The satisfaction of DIY projects is unmatched.

Creating a wooden jointer plane can be a rewarding task. It teaches valuable skills and enhances creativity. Using a handcrafted tool can improve your woodworking experience. Embrace the art of making your own tools today!

Selecting The Right Wood

Choosing the right wood is crucial for a wooden jointer plane. Hardwoods are often preferred for their durability. Maple, Beech, and Mahogany make excellent choices.

Consider the following factors:

- Grain Structure: Look for straight grain for stability.

- Moisture Content: Use wood that is well-dried to prevent warping.

- Weight: Heavier woods offer better control during use.

Recommended types for durability include:

| Wood Type | Durability |

|---|---|

| Maple | High |

| Beech | Medium |

| Mahogany | High |

Essential Tools And Materials

Making a wooden jointer plane requires some essential tools and materials. Basic woodworking tools include:

- Hand saw

- Chisels

- Wooden mallet

- Ruler or square

- Sandpaper

Additional supplies needed for this project are:

- Wood (choose a hardwood)

- Wood glue

- Clamps

- Varnish or finish

Gathering these items will help in creating a sturdy and effective jointer plane.

Designing Your Jointer Plane

Designing a jointer plane requires careful thought. Start by choosing the right dimensions. Common sizes include:

| Length | Width | Thickness |

|---|---|---|

| 18 inches | 2.5 inches | 1.5 inches |

| 22 inches | 3 inches | 2 inches |

Consider custom features for better performance. You might want a curved sole for versatility. A comfortable handle is essential for grip. Different blade angles can change the cut type. Personalizing these aspects can enhance your woodworking experience.

Cutting And Shaping The Body

Start by selecting a piece of hardwood. Maple or birch works well for this project. Cut the wood to your desired size. Use a straight edge for accuracy.

Next, ensure your cuts are smooth and clean. A table saw or hand saw can help with this. Measure carefully before cutting. Always use proper safety gear while cutting.

Shaping the body requires special attention. Use a plane or chisel to refine the edges. Round the corners for a comfortable grip. Sand the surface for a smooth finish.

Assembling The Plane

Assembling a wooden jointer plane involves precise steps. Start with the main body. Attach the iron to the cap. Use a screw to secure it tightly. Make sure the blade can move freely.

Joining the parts requires careful attention. Align the front and rear parts perfectly. Use clamps to hold them together. This keeps everything steady while you work.

Ensuring alignment is vital for functionality. Check that the blade is parallel to the bottom. Adjust as needed for a smooth cut. A well-aligned plane creates better results.

Finishing Touches

Start by using medium-grit sandpaper to smooth the wooden surface. Focus on areas with rough spots. Gradually move to fine-grit sandpaper for a softer finish. Always sand in the direction of the wood grain. This prevents damage to the wood.

After sanding, clean the surface with a damp cloth. This removes dust and debris. Once dry, apply a protective finish like varnish or oil. This keeps the wood safe and enhances its beauty. Choose a finish that suits your project style.

Allow the finish to dry completely. Check for any missed spots and touch them up. A well-finished wooden jointer plane will last longer and perform better.

Testing And Adjustments

Start testing your wooden jointer plane by checking its flatness. Use a straightedge to find any gaps. Place the straightedge across the sole. Look for light shining through. This shows uneven areas.

After initial testing, make adjustments as needed. Use a file or sandpaper to smooth high spots. Ensure the blade is sharp for best results. A sharp blade cuts cleanly and efficiently.

Fine-tuning takes practice. Test the plane on different types of wood. This helps you understand its performance. Adjust the blade depth for various tasks. A shallow cut is good for finishing touches.

Frequently Asked Questions

How Do I Start Making A Wooden Jointer Plane?

Begin by gathering necessary materials like hardwood, a blade, and screws. Use a jointer plane plan to ensure accuracy. Cut the wood to size, shape the body, and create a comfortable handle. Install the blade securely and perform test runs for optimal performance.

What Tools Are Needed For A Jointer Plane?

Essential tools include a bandsaw, chisels, hand saws, and a drill. You’ll also need clamps for stability. A good set of measuring tools ensures precision. Finally, sandpaper will help achieve a smooth finish on your jointer plane.

How Long Does It Take To Make One?

Creating a wooden jointer plane typically takes several hours. The time depends on your skill level and the complexity of your design. Beginners may need more time for adjustments and refinements. Plan for at least a day to complete the project thoroughly.

Can I Use Any Wood Type For A Jointer Plane?

While you can use various hardwoods, some are more suitable. Maple and beech are popular choices for durability and workability. Avoid softwoods as they may wear down quickly. Choosing the right wood enhances the plane’s performance and longevity.

Conclusion

Creating a wooden jointer plane is a rewarding project. It combines craftsmanship with practical benefits. With the right tools and techniques, anyone can build a functional and beautiful tool. Embrace the process and enjoy the satisfaction that comes from making something with your own hands.

Happy woodworking!