How to Ream Out a Hole in Wood: Expert Tips & Tricks

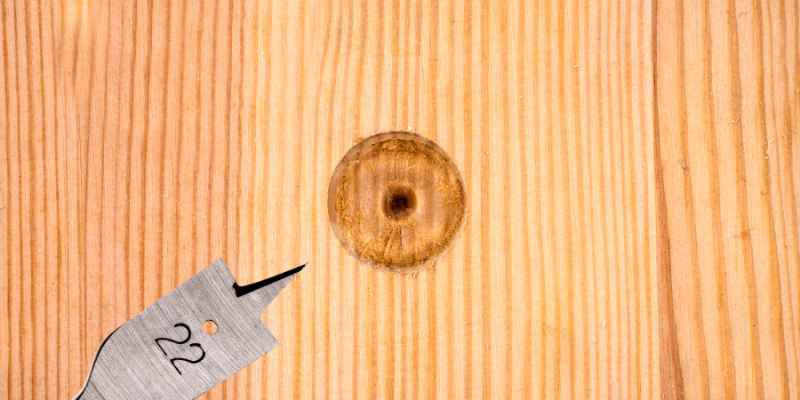

To ream out a hole in wood, use a reamer or drill bit slightly larger than the current hole size. Gently enlarge the hole by twisting the reamer or drill bit in a circular motion.

Reaming out a hole in wood is a simple process that can be done with the right tools and techniques. Whether you need to adjust the size of an existing hole or create a smoother surface, knowing how to ream out a hole in wood is a valuable skill for any DIY enthusiast or professional woodworker.

By following a few simple steps, you can achieve a clean and precise result without damaging the surrounding wood. In this guide, we’ll explore the tools and methods necessary to ream out a hole in wood effectively, ensuring that you can tackle this task with confidence and precision.

Introduction To Reaming In Woodworking

Reaming in woodworking is an essential process that involves enlarging and smoothing out existing holes in wood to achieve a precise fit for various applications. This technique ensures that the final piece fits together seamlessly, creating a professional and polished result.

The Basics Of Reaming

Reaming is the process of enlarging and refining a hole in wood to achieve a precise fit for a dowel, screw, or other fastening component. It involves using a specialized tool called a reamer, which is designed to remove small amounts of material from the hole, resulting in a smooth and accurately sized opening.

Importance Of Precision

Precision is crucial in woodworking, especially when it comes to reaming holes. Ensuring that each hole is precisely reamed contributes to the structural integrity and overall quality of the final product. It also allows for proper alignment and secure fastening of components, preventing any potential issues or misalignments

Selecting The Right Tools For Reaming

When it comes to reaming out a hole in wood, selecting the right tools is crucial for achieving accurate and clean results. The process of reaming involves enlarging a hole to a specific size and ensuring it is smooth and precise. There are various types of reamers available, as well as different options for manual and power tools. In this section, we will explore the different types of reamers and the advantages of manual and power tools.

Types Of Reamers

Before diving into the selection of tools, it is essential to understand the different types of reamers available:

- Hand Reamers: These reamers are typically used for small holes and are operated manually by rotating them in a clockwise direction.

- Machine Reamers: Designed for larger holes, machine reamers are used with a drill press or milling machine to ensure precision and efficiency.

- Tapered Reamers: As the name suggests, tapered reamers are used for creating tapered holes, such as those required for fitting dowels or conical pins.

- Adjustable Reamers: These versatile reamers come with adjustable blades, allowing for flexibility in hole size and precision.

Manual Vs. Power Tools

When it comes to reaming, you have the option to choose between manual and power tools. Each has its own advantages:

| Manual Tools | Power Tools |

|---|---|

|

|

Depending on the specific project requirements, you can select the appropriate tool for reaming out the hole in wood. Manual tools are suitable for smaller, intricate tasks, while power tools are preferred for larger or tougher materials. Consider the size of the hole, the level of precision needed, and the available resources before making your decision.

Preparing The Wood Before Reaming

To ream out a hole in wood, it’s important to properly prepare the wood beforehand. This includes ensuring the wood is free from knots or other obstructions, and using a pilot hole to guide the reamer. Taking these steps can help ensure a clean and accurate hole.

Marking The Area

Use a pencil to mark the spot on the wood where you need to create the hole.

Securing The Wood

Place the wood on a stable surface to prevent it from moving while reaming.

Step-by-step Guide To Reaming A Hole

This step-by-step guide provides a clear and concise method for reaming out a hole in wood. With easy-to-follow instructions and tips, you’ll be able to achieve precise and accurate results in no time. Say goodbye to uneven holes and hello to professional craftsmanship.

Reaming a hole in wood is an important process that ensures a proper fit for screws, bolts, and dowels. While drilling is a straightforward process, reaming requires more precision, patience, and attention to detail. In this step-by-step guide, we will walk you through the process of reaming a hole in wood, from starting the process to adjusting for depth and angle.

Starting The Process

To start the reaming process, you will need a reamer tool, which is a tapered cutting tool used to enlarge and shape a hole in wood. Follow these steps to begin:

- Secure the wood piece in a vice or clamp to prevent it from moving during the reaming process.

- Select a reamer tool that is slightly smaller than the desired size of the hole.

- Insert the reamer tool into the existing hole, and make sure it is centered.

- Apply a small amount of lubricant or oil to the reamer tool to reduce friction and prevent overheating.

- Slowly turn the reamer tool clockwise, applying gentle pressure, until the hole is enlarged to the desired size.

Adjusting For Depth And Angle

Once you have started the reaming process, you will need to adjust the depth and angle of the tool to achieve the desired size and shape of the hole. Follow these steps to make adjustments:

- To adjust the depth, stop the reamer tool periodically and check the depth of the hole with a depth gauge or ruler.

- If necessary, adjust the depth of the tool by tightening or loosening the chuck or adjusting the stop collar.

- To adjust the angle of the tool, tilt the tool slightly in the direction you want to enlarge the hole.

- Continue reaming the hole, making adjustments as needed, until you achieve the desired size and shape.

In conclusion, reaming a hole in wood is a process that requires patience, precision, and attention to detail. By following this step-by-step guide, you can ensure a proper fit for screws, bolts, and dowels, and achieve a professional-looking finish for your woodworking projects.

Expert Tips For Smooth Reaming

Reaming out a hole in wood can be tricky if you don’t have the right tools and technique. To ensure a smooth reaming process, use sharp reamers, apply consistent pressure, and rotate the tool gently in a clockwise direction.

Maintaining Tool Sharpness

To ensure smooth reaming, it is crucial to maintain the sharpness of your tools. Dull tools can cause splintering and rough edges, resulting in an unsatisfactory finish. Sharpening your reaming tool regularly will not only enhance its performance but also extend its lifespan. Here are a few expert tips to keep your tools sharp:

- Use a sharpening stone or sandpaper to remove any burrs or nicks from the cutting edge.

- Hold the tool at the correct angle while sharpening to maintain its original bevel.

- Apply a lubricant or honing oil to prevent overheating and ensure a smooth sharpening process.

By following these tips, you can keep your reaming tools sharp and ready for smooth hole creation.

Controlling Speed And Pressure

The speed and pressure at which you ream a hole greatly affect the final result. Here are some expert tips to help you achieve a smooth reaming process:

- Start with a slower speed and gradually increase it as you progress. This allows for better control and prevents the tool from catching or causing damage.

- Apply consistent and moderate pressure while reaming. Avoid excessive force, as it can lead to splintering or breaking the wood.

- Take breaks periodically to prevent overheating. This will also give you a chance to assess the quality of the hole and make any necessary adjustments.

By controlling the speed and pressure, you can ensure a smooth and precise reaming process, resulting in clean and professional-looking holes in wood.

Troubleshooting Common Reaming Issues

Correctly reaming out a hole in wood can be tricky. Troubleshooting common reaming issues involves checking the reamer’s sharpness and alignment to ensure smooth hole creation. Using proper technique and a steady hand is key to achieving precise results.

Dealing With Splintering

Splintering is a common issue that occurs during the reaming process. It happens when the wood fibers tear away from the hole’s edge, leaving a rough and uneven surface. To prevent splintering, you can try the following:

– Use a sharp reamer: A dull reamer can cause the wood to tear and splinter. Ensure your reamer is sharp and well-maintained.

– Apply masking tape: Placing a strip of masking tape over the area to be reamed can help prevent splintering.

– Drill a pilot hole: Drilling a pilot hole before reaming can help guide the reamer and prevent it from wandering, which can lead to splintering.

Correcting Uneven Holes

Uneven holes can be frustrating, especially if you’re working on a project that requires precise measurements. Here are a few tips to correct uneven holes:

– Use sandpaper: Sandpaper can help smooth out any rough edges and even out the hole’s shape.

– Ream from both sides: If the hole is uneven, try reaming from both sides until it’s the desired shape.

– Use a chisel: A chisel can help remove any excess wood and create a clean, even hole.

By troubleshooting common reaming issues like splintering and uneven holes, you can ensure your project turns out just how you want it. Remember to use a sharp reamer, apply masking tape, drill a pilot hole, use sandpaper, ream from both sides, and use a chisel to create the perfect hole.

Finishing Touches After Reaming

After reaming out a hole in wood, don’t forget the finishing touches. Smooth the edges with sandpaper and apply a coat of varnish or paint for a polished look.

Sanding And Smoothing

After reaming out a hole in wood, sanding is essential.

Smooth the edges using fine-grit sandpaper.

Remove any rough spots for a polished finish.

Applying Finishes

Seal the wood with a clear coat for protection.

Consider staining or painting for a decorative touch.

Ensure the finish is evenly applied for a professional look.

Advanced Techniques And Considerations

Working With Different Wood Types

Different wood types require varying reaming techniques for optimal results.

Reaming For Joinery

For strong joinery, ensure the hole is precisely reamed to fit the fastener securely.

Frequently Asked Questions

How Do You Ream Out A Hole In Wood?

To ream out a hole in wood, start by selecting the appropriate reamer for the job. Secure the wood and the reamer, then slowly and steadily rotate the reamer in the hole. Ensure that the reamer is sharp and lubricated for smooth reaming.

What Tools Are Needed To Ream Out A Hole In Wood?

To ream out a hole in wood, you will need a reamer, clamps to secure the wood, and lubricant. The type of reamer you use will depend on the size and type of hole you are working with. Ensure that your tools are in good condition for effective reaming.

Why Is It Important To Ream Out A Hole In Wood?

Reaming out a hole in wood is important to ensure a precise and smooth finish. It helps to remove any imperfections and burrs, resulting in a clean and accurately sized hole. This is crucial for applications where accuracy and a professional finish are required.

Conclusion

Reaming out a hole in wood requires precision and patience. By following the proper steps and using the right tools, you can achieve a clean and accurate result. Remember to measure twice, cut once, and practice your technique for best outcomes in your woodworking projects.