How To Use Wood Filler On Large Holes: Proven & Effortless

To use wood filler on large holes, first clean the area of any loose debris. For deep holes, add a structural backer like a wood block. Mix a two-part epoxy or structural wood filler and press it firmly into the hole in layers, overfilling slightly. Once fully cured, sand the filler flush with the wood for a strong, permanent repair.

Have you ever found a big, ugly hole in a piece of wood? Maybe it’s in an old piece of furniture, a door frame, or even your deck. It can look like a disaster. You might think the only solution is to replace the whole piece. But I’m here to tell you there’s a much easier way!

Fixing large holes in wood is a common problem, and it’s something you can absolutely handle yourself. You don’t need to be a professional woodworker. With the right product and a few simple steps, you can make that damage disappear completely. In this guide, I’ll walk you through everything you need to know, from choosing the best filler to making your repair totally invisible.

Why You Can’t Just Pack Filler Into a Large Hole

Before we grab our tools, let’s talk about why filling a large hole is different from a tiny nail hole. If you just scoop a bunch of standard wood filler into a big gap, you’re setting yourself up for disappointment. Here’s why that approach fails:

- Shrinking and Cracking: Most common wood fillers shrink as they dry. When you use a lot of it at once, this shrinkage causes a sunken-in patch or, worse, a web of ugly cracks.

- Lack of Strength: A big glob of filler has no internal structure. It can’t support itself. It might feel solid at first, but it can easily break or fall out under pressure or with changes in temperature and humidity.

- It Can Fall Through: For a hole that goes all the way through a piece of wood, there’s nothing to stop the filler from simply oozing out the other side as you try to apply it.

The secret to a lasting repair is to give the filler a solid foundation and use a product designed for heavy-duty jobs. It’s not about just filling a void; it’s about rebuilding that part of the wood.

Choosing the Right Filler for Big Jobs

Not all wood fillers are created equal. The little tub you use for pinholes won’t work for a golf-ball-sized gouge. For large repairs, you need something with serious structural integrity. Your best bets are typically two-part epoxy fillers or polyester-based fillers, as they are designed for strength and durability.

These heavy-duty products cure through a chemical reaction rather than just air-drying, which makes them incredibly strong, resistant to shrinking, and waterproof once cured. They essentially become a new, solid part of the wood itself.

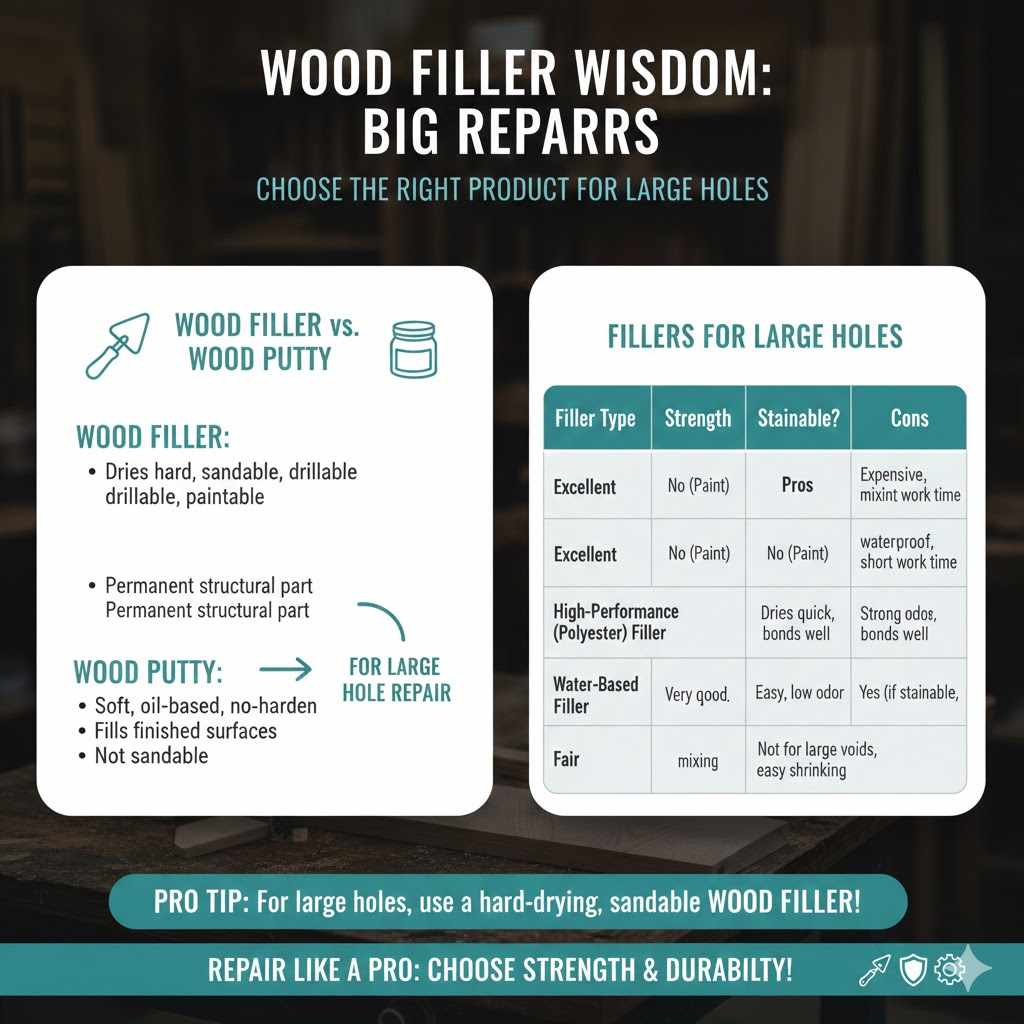

Wood Filler vs. Wood Putty: What’s the Difference?

This is a common point of confusion for beginners. It’s important to know the difference because using the wrong one will lead to a failed repair.

- Wood Filler: This product is applied before sanding and finishing a project. It dries hard and can be sanded, drilled, and painted just like real wood. It’s meant to be a permanent part of the structure. This is what you need for your large hole repair.

- Wood Putty: This product is applied after a project is finished and stained. It’s a soft, oil-based compound that doesn’t harden. It’s designed to fill small imperfections in a finished surface and is often color-matched to common wood stains. You can’t sand it effectively.

For a large hole repair, you must use a sandable, hard-drying wood filler.

Comparing Fillers for Large Holes

To help you decide, here’s a table breaking down the best options for large repairs.

| Filler Type | Best For | Strength | Stainable? | Pros | Cons |

|---|---|---|---|---|---|

| Two-Part Epoxy Filler | Large structural repairs, rotted wood, exterior projects | Excellent | No (Must be painted) | Incredibly strong, waterproof, won’t shrink or crack | More expensive, requires mixing, shorter working time |

| High-Performance (Polyester) Filler | Deep gouges, large holes, both interior and exterior use | Very Good | No (Must be painted) | Dries quickly, very strong, bonds well, sandable | Strong chemical odor, requires mixing |

| Water-Based Filler | Small cracks, nail holes, minor interior imperfections | Fair | Yes (if labeled stainable) | Easy to use, low odor, easy soap-and-water cleanup | Not strong enough for large voids, prone to shrinking |

Your Tools and Materials Checklist

Getting your workspace ready before you start makes the whole process smooth and stress-free. You won’t have to scramble for a tool mid-repair! Here is what you will need:

- The Right Filler: A two-part epoxy wood filler is my top recommendation for large, permanent repairs.

- Putty Knives: A flexible metal or plastic putty knife (around 1.5 inches wide) is perfect for application.

- Mixing Board: A scrap piece of cardboard, wood, or a plastic lid for mixing two-part fillers.

- Structural Backer (if needed): For holes that go all the way through, you’ll need something for the filler to stick to. This could be a small piece of wood, wire mesh, or even a couple of screws driven partially into the sides of the hole.

- Sandpaper: You’ll need a few different grits. Start with a coarse 80-grit to level the filler, move to a 120-grit for smoothing, and finish with a fine 220-grit for a perfect surface.

- Sanding Block or Orbital Sander: A sanding block will help you keep the surface flat. For very large repairs, an orbital sander will save you a lot of time and effort.

- Shop Vacuum or Stiff Brush: For cleaning out the hole and removing sanding dust.

- Tack Cloth or a Damp Rag: For the final cleanup before finishing.

- Safety Gear: Always wear safety glasses, a dust mask (especially when sanding), and disposable gloves when working with epoxy fillers.

- Primer & Paint/Stain: To match your repair to the rest of the surface.

The Step-by-Step Guide to Filling Large Holes Like a Pro

Alright, you have your tools, you’ve chosen your filler, and you’re ready to fix that hole. Just follow these steps, and I promise you’ll get a great result.

Step 1: Prepare the Hole

This is the most important step for a successful repair. The filler needs a clean, solid surface to grip onto. If you skip this, your patch will eventually fail.

- Clean Out Debris: Use a screwdriver, chisel, or utility knife to dig out any loose wood splinters, old paint, or dirt from inside the hole. If you’re dealing with rotted wood, you must remove all the soft, spongy material until you reach solid, healthy wood.

- Vacuum it Out: Use a shop vacuum with a narrow nozzle to suck out all the dust and debris. If you don’t have one, a stiff brush will also work. The cleaner the hole, the better the bond.

- Scuff the Edges: Lightly sand the inside edges of the hole with 80-grit sandpaper. This roughs up the surface and gives the filler more to grab onto.

Step 2: Add Structural Support (For Deep or Through-Holes)

This is the pro trick that makes all the difference for large repairs. You need to create a “floor” or an internal framework for the filler to rest on. This prevents it from falling out and adds massive strength.

- For Deep Holes: Drive a couple of short screws into the bottom or sides of the hole, leaving the heads sticking out. This gives the filler something solid to lock onto, acting like rebar in concrete.

- For Holes That Go Through: Cut a small piece of wood slightly larger than the hole. Apply some wood glue around its edges and push it just inside the back of the hole so it sits flush. Or, you can use a piece of fiberglass mesh tape (the kind used for drywall) across the back of the hole. This creates a solid backing.

By taking this extra step, you are ensuring the repair is integrated into the wood, not just sitting on top of it. As experts at the U.S. Forest Service’s Forest Products Laboratory note in their Wood Handbook, proper preparation and structural reinforcement are key to long-lasting wood restoration.

Step 3: Mix Your Filler

If you’re using a two-part epoxy filler, now is the time to mix it. Read the manufacturer’s instructions carefully!

- Scoop Out Equal Parts: On your scrap piece of cardboard, scoop out equal amounts of Part A (the filler) and Part B (the hardener).

- Mix Thoroughly: Use your putty knife to mix the two parts together until you get a single, uniform color. Scrape the board clean and keep folding the material onto itself. Don’t undermix, or it won’t cure properly.

- Work Quickly: Most epoxy fillers have a “working time” of about 15-20 minutes before they start to harden. Only mix as much as you can use in that time.

Step 4: Apply the Filler in Layers

Now for the main event! The key here is to build up the filler in layers, not to fill the entire hole at once. This ensures it cures properly all the way through.

- Press the First Layer Firmly: Take a small amount of filler on your putty knife and press it firmly into the bottom and sides of the hole. Make sure to force it into all the nooks and crannies to eliminate air pockets.

- Build Up Thin Layers: For very deep holes (more than half an inch), apply the filler in layers about a quarter-inch thick. Let each layer set for a bit before adding the next one (check the instructions for specific times).

- Overfill the Final Layer: When you apply the last layer, mound it up so it sits slightly higher than the surrounding wood surface. This is crucial because you’ll be sanding it down to be perfectly flush. It’s much easier to sand down extra material than to add more later.

Step 5: Let It Cure Completely

Patience is your best friend now. You have to let the filler cure completely. Don’t rush this, or you’ll ruin all your hard work. Curing time can vary from a couple of hours to a full day, depending on the product, the size of the repair, and the temperature/humidity. Read the product label and trust it. Tapping it gently can give you an idea of its hardness—it should feel rock-solid.

Step 6: Sand it Perfectly Smooth

Once the filler is fully cured, it’s time to make it disappear. This stage is all about sanding.

- Start with a Coarse Grit: Wrap a piece of 80-grit sandpaper around your sanding block. Sand the hardened filler down until it’s level with the wood surface. The block helps you keep the area flat and prevents you from creating a dip.

- Switch to a Medium Grit: Once the patch is level, switch to 120-grit sandpaper to remove the deeper scratches left by the 80-grit paper.

- Feather the Edges: As you sand, extend your sanding strokes slightly onto the surrounding wood. This is called “feathering,” and it helps blend the edges of the patch seamlessly.

- Finish with a Fine Grit: Finally, go over the entire area with 220-grit sandpaper. This will give you a beautifully smooth surface that’s ready for finishing. Run your fingers over the repair; you shouldn’t be able to feel the transition between the filler and the wood.

Step 7: Final Cleanup and Finishing

You’re almost there! Use a tack cloth or a damp rag to wipe away every speck of sanding dust. Dust will ruin your final finish. Now, you can prime and paint the repaired area to match. Primer is essential, as it seals the filler and ensures the topcoat of paint has a uniform look.

Frequently Asked Questions (FAQ)

Can I use regular wood putty for a large hole?

No, you should not use wood putty for large holes. Wood putty is a soft, oil-based compound that never truly hardens. It’s designed for filling tiny nail holes in finished surfaces. For a large structural repair, you need a hard-drying wood filler, preferably a two-part epoxy.

How deep can I apply wood filler at once?

For best results, you should apply wood filler in layers no more than 1/4 to 1/2 inch deep at a time. Applying it too thickly can prevent it from drying or curing properly, leading to a weak patch that might crack or fail. Always check the manufacturer’s specific instructions.

Why did my wood filler crack after it dried?

Cracking is usually caused by two things: applying the filler too thickly in one go, or using a standard water-based filler that shrinks significantly. For large holes, use a two-part epoxy or polyester filler, as they are formulated to not shrink or crack.

Can you drive a screw into wood filler?

It depends on the filler. You cannot drive a screw into standard water-based wood filler; it will just crumble. However, you can absolutely drill and drive screws into high-quality two-part epoxy or polyester fillers. Once cured, they are incredibly strong and act like a solid block of plastic or even harder-than-wood material.

How long does it take for wood filler to dry on a large hole?

Drying and curing time depends heavily on the type of filler, the depth of the repair, and the ambient temperature and humidity. A two-part epoxy filler can be sandable in a few hours, while some fillers may need to cure for 24 hours or more. Always refer to the product label for accurate times.

What is the best wood filler for exterior large holes?

For exterior repairs, you must use a waterproof and weather-resistant filler. A two-part marine-grade epoxy filler is the absolute best choice. It’s completely waterproof, won’t be affected by temperature changes, and is incredibly durable against the elements.

Your Repair is Complete!

And there you have it! That gaping hole is now a thing of the past. By following these steps—proper preparation, adding support, applying a strong filler in layers, and careful sanding—you’ve created a repair that is not only invisible but also incredibly strong and durable. It’s a skill that will save you so much time and money on future projects.

Don’t be afraid to tackle these kinds of fixes. Every project is a chance to learn and build your confidence. You took a damaged piece of wood and made it whole again, and that’s something to be proud of. Happy woodworking!