How Wood Veneers are Made: Unveiling the Craftsmanship

Wood veneers are made by cutting thin slices off a log to create a sheet of wood, resulting in different grain patterns. Various methods like rotary cutting and quarter sawn are used for this process.

Veneer is a thin layer of real wood, distinct from laminate, and can be made from fast-growing tropical species. The sheets are then processed, dyed if needed, and laminated to create the final product. Making your own veneers is possible, involving precision cutting and finishing techniques.

Understanding the craftsmanship behind wood veneer production sheds light on the artistry and skill involved in creating these exquisite wood surfaces.

The Art Of Wood Veneers

Wood veneers are crafted by cutting thin slices from logs to create sheets of wood with distinct grain patterns. Methodologies like Rotary cutting and Slicing produce varied designs, enhancing the aesthetic appeal of the final product. Veneer emerges as a sophisticated technique to elevate woodworking projects through its intricate detailing.

Experience The Craftsmanship

Wood veneers are a masterpiece of craftsmanship, where skilled artisans transform raw logs into exquisite sheets of wood. It involves precision, expertise, and an in-depth understanding of the unique characteristics of different wood species.

Understanding Wood Veneers

Wood veneers are thin slices of wood that are used to cover other wood products. They are made by cutting thin layers from a log, resulting in different grain patterns. The slicing methods commonly used are plain sawn or flat cut, rotary cut, rift cut, and quarter sawn/cut, each producing a specific grain pattern.

It’s important to note that wood veneer is real wood, unlike laminate which is a material other than wood with a coating made to look like wood. Wood veneers offer the beauty and authenticity of natural wood, adding a touch of elegance to furniture and interiors.

The Making Process

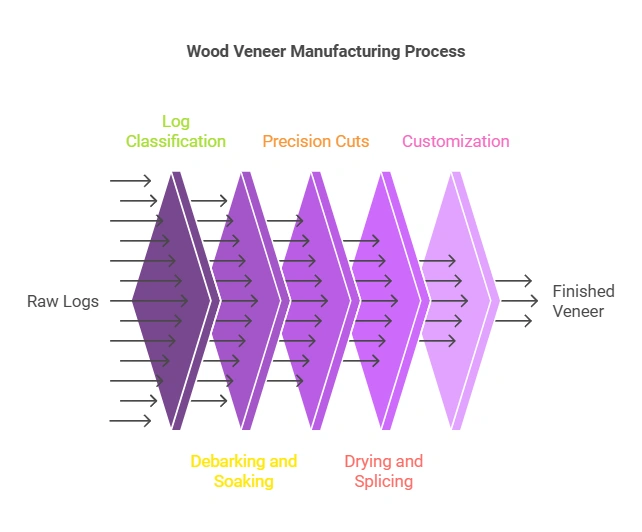

Wood veneers are produced through a meticulous process that begins with the proper classification of logs. Let’s delve into the intricate steps involved in creating these stunning sheets of wood.

Log Classification

Logs are classified based on their quality and intended use in the veneer manufacturing process.

Debarking And Soaking

Once logs are selected, they undergo debarking to remove the outer layer, and then soaking to make them pliable for slicing.

Precision Cuts

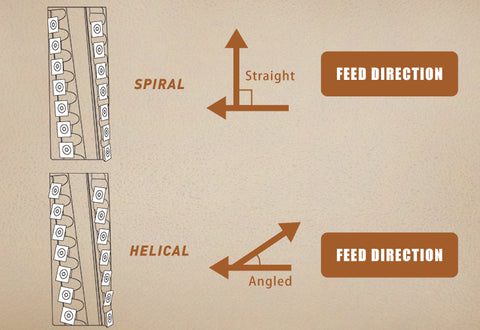

Wood veneers are made through a method of cutting thin slices from the log, resulting in different grain patterns. Slicing methods, such as plain sawn or flat cut, rotary cut, rift cut, and quarter sawn, each produce specific patterns. Veneer is an actual slice of wood, offering a unique and elegant finish for furniture and interiors.

Flat Slicing

One of the methods used to create wood veneers is flat slicing. In this process, a log is placed horizontally and sliced perpendicular to its growth rings. The log is mounted on a slicing machine and a sharp knife cuts thin slices, known as leaves, from one end to the other.

This method produces a veneer with a consistent grain pattern, resulting in a uniform appearance across the entire sheet. The flat slicing technique is commonly used for producing highly figured veneers, where the natural beauty of the wood grain is emphasized.

Half Round Slicing

Another method of creating wood veneers is half round slicing. In this technique, the log is cut in half along its length, and each half is placed on a slicing machine. The knife cuts thin slices as the log is slowly rotated, resulting in a continuous piece of veneer with a half-round appearance.

Half round slicing is often used for producing burl veneers, which showcase the unique patterns found in burl wood. The natural irregularities and swirls of the burl are highlighted, creating a visually striking veneer.

Drying The Veneer

After the slicing process, the veneer sheets need to be dried to remove excess moisture. This is important to prevent warping or buckling of the veneer. The sheets are typically placed in a climate-controlled drying room, where they are carefully monitored to ensure an even and gradual drying process.

Once the veneer is completely dry, it is ready for further processing, such as splicing or matching, before being utilized in various woodworking applications.

Crafting The Veneer

Wood veneer is made by cutting thin slices from a whole log to create a sheet of wood. The sheets can be cut using different methods such as rotary cutting, slicing, and quarter sawing, resulting in various grain patterns. Veneer is a thin slice of real wood that is pressed onto the surface of furniture pieces, unlike laminate which is a non-wood material made to resemble wood.

ow Wood Veneers are Made: Crafting the Veneer

Crafting a wood veneer involves several key steps, including drying techniques, splicing, and matching. Each step contributes to the final product, creating a beautiful and versatile material that can be used in various woodworking projects.

Drying Techniques

Once the logs are cut into thin slices, they must go through a drying process. This step is crucial as it helps eliminate moisture from the wood, making it more stable and less likely to warp or crack. There are different drying techniques used in the industry, including air-drying and kiln-drying.

– Air-drying: In this traditional method, the wood veneer is stacked and left to dry naturally in the open air. This process can take several months and requires proper storage conditions to ensure optimal drying.

– Kiln-drying: Kilns use controlled heat and airflow to quickly dry the wood veneer. This method is more efficient and can be completed in a matter of days or weeks, depending on the type of wood and thickness of the veneer.

Splicing and Matching

Once the wood veneer is dry, it undergoes splicing and matching to create larger sheets. Splicing involves joining smaller pieces of veneer together to form a continuous sheet. This process requires precision to ensure seams are nearly invisible, giving the appearance of a single piece of wood.

– Slip match: In slip matching, consecutive pieces of veneer are joined side by side in a bookmatched pattern, creating a consistent grain pattern along the entire sheet. This method is commonly used and creates a visually pleasing effect.

– Random match: In random matching, veneer pieces come together in a more irregular pattern, creating a unique and natural look. This approach allows for more creativity and variation in the final appearance of the wood veneer.

– Diamond match: Diamond matching involves arranging veneer pieces in a diamond-shaped pattern, resulting in a distinct and eye-catching design. This method is often used for decorative purposes.

Matching the grain and color of the veneer pieces is also crucial to create a consistent and harmonious look. Experienced craftsmen carefully select and arrange veneer pieces to ensure a seamless transition between each sheet.

Crafting a wood veneer is a meticulous process that requires skill and expertise. From drying the wood to splicing and matching, each step contributes to creating a high-quality veneer that showcases the natural beauty of wood. Whether you’re using wood veneers for furniture, cabinetry, or other woodworking projects, understanding the craftsmanship behind them adds an appreciation for the artistry involved.

Custom Veneer Creation

In the intricate process of crafting wood veneers, custom veneer creation plays a crucial role in achieving unique and tailored designs for various woodworking projects. Through the art of customizing veneers, artisans can transform raw wood materials into stunning, one-of-a-kind surfaces.

Choosing Your Wood

When creating custom wood veneers, the first step is selecting the type of wood that will be used. From rich mahogany to elegant cherry, the choice of wood species sets the tone for the final appearance of the veneer.

Customizing Veneer Thickness

One key aspect of custom veneer creation is the ability to adjust the thickness of the veneer sheets. By customizing the thickness, woodworkers can achieve specific aesthetic and functional requirements for their projects.

Utilization In Woodworking

Experienced craftsmen create wood veneers by carefully cutting thin slices from whole logs to form sheets of wood, resulting in distinct grain patterns. Common methods include Rotary cutting, Slicing, and Quarter sawn techniques, offering various grain textures for creative woodworking projects.

Wood veneers are widely utilized in the field of woodworking due to their versatility, aesthetic appeal, and cost-effectiveness. Whether it’s for cabinetry, furniture, or decorative elements, wood veneers offer a range of benefits over solid wood. Additionally, their application in design allows for unique and creative possibilities. In this section, we will explore the benefits of wood veneers over solid wood and the various applications in design.

Benefits Over Solid Wood

Wood veneers provide several advantages over solid wood, making them a popular choice among woodworkers. These benefits include:

- Cost-effectiveness: Wood veneers are more affordable compared to solid wood, allowing woodworkers to create stunning pieces without breaking the budget.

- Environmental sustainability: Wood veneers make efficient use of timber resources as only a thin layer of wood is needed to cover larger surfaces. This reduces the demand for solid wood, thereby promoting environmental conservation.

- Enhanced stability: Veneered wood is less prone to warping and splitting compared to solid wood. The process of creating veneers involves slicing thin layers of wood, which are then applied to a substrate. This results in increased stability and durability.

- Unlimited design choices: Wood veneers come in a wide variety of species, shades, and patterns. This allows woodworkers to experiment with different looks and textures, giving them the freedom to create unique designs that may not be possible with solid wood alone.

- Easy maintenance: Wood veneers are easy to clean and maintain. They can be treated and finished just like solid wood, making it convenient for homeowners to keep their furniture and cabinetry looking pristine.

Applications In Design

Wood veneers find extensive use in various design applications, enabling woodworkers to bring their creative visions to life. Whether it’s adding a touch of elegance to a piece of furniture or creating intricate patterns on cabinetry, wood veneers offer endless possibilities. Some notable applications include:

- Furniture: Wood veneers are commonly used to create stunning furniture pieces such as tables, chairs, and cabinets. The versatility of veneers allows for intricate inlay work, adding a unique aesthetic appeal to the furniture.

- Cabinetry: Veneered wood is frequently utilized in kitchen and bathroom cabinetry, where durability and visual appeal are essential. With a range of veneer options available, woodworkers can achieve different finishes and styles to suit any design preference.

- Interior design: Wood veneers can be used to create beautiful accent walls, ceilings, and flooring. They can also be applied to doors, creating a warm and inviting atmosphere in residential and commercial spaces.

- Decorative elements: Wood veneers can be used to create decorative panels, moldings, and veneered art pieces. These elements add a touch of sophistication and elegance to any space, enhancing the overall design.

In conclusion, wood veneers offer numerous benefits over solid wood, making them a favored choice in the field of woodworking. Their cost-effectiveness, environmental sustainability, stability, and unlimited design possibilities make them a versatile material. When utilized in design, wood veneers bring an aesthetic appeal and versatility that adds value to any woodworking project.

Differentiating Veneers

Wood veneers are made by cutting thin slices from a whole log, resulting in different grain patterns. The three basic methods for cutting veneers are rotary cutting, slicing, and quarter sawn, each producing unique patterns.

Veneer vs. Laminate

When it comes to differentiating veneers, one important comparison is between veneer and laminate. While both are used to enhance the appearance of furniture pieces, there are some key differences between the two.

Veneer: Veneer is made from actual, thin slices of wood that are carefully cut from a log. These slices, also called leaves, are then pressed onto the surface of a furniture piece, giving it the natural beauty and grain patterns of real wood. Veneer offers the warmth and authenticity of solid wood without the hefty price tag.

Laminate: On the other hand, laminate is not made from wood. It is a synthetic material, usually composed of layers of resin-infused paper, that is designed to mimic the look of wood. Laminate is manufactured by applying a printed image of wood grain to the surface and then coating it with a protective layer. While laminate can be an affordable and durable option, it lacks the natural charm and character of real wood veneer.

In summary, veneer is crafted from thin slices of wood, providing an authentic, natural look, while laminate is a synthetic material that imitates the appearance of wood. Each option has its own benefits and considerations, so it’s important to understand the differences when choosing between them.

Wood Veneer vs. Solid Wood

Another important distinction to make when it comes to veneers is the difference between wood veneer and solid wood. While both options offer the beauty of natural wood, there are some important factors to consider.

Wood Veneer: Wood veneer, as mentioned earlier, is a thin slice of wood that is applied onto the surface of furniture. This method allows for the use of exotic or expensive woods, making it a cost-effective alternative to solid wood. Additionally, veneer is highly versatile and can be used to create intricate patterns and designs, adding a unique touch to furniture pieces. However, it’s worth noting that veneer is not as durable as solid wood and may require more care and maintenance.

Solid Wood: Solid wood, on the other hand, is exactly what it sounds like – furniture pieces made entirely from solid wood planks. This option offers unmatched durability and longevity, as well as a rich and natural beauty. Solid wood furniture pieces can be sanded, stained, and refinished multiple times over the years, allowing for a timeless and customizable look. However, solid wood furniture can be more expensive and may be prone to natural variations in color and grain.

In conclusion, wood veneer is a cost-effective and versatile option that allows for the use of exotic woods, while solid wood offers unmatched durability and customizable appeal. The choice between the two ultimately depends on personal preferences, budget, and the desired look and functionality of the furniture piece.

Exploring Veneer Types

Wood veneers are crafted using various techniques to bring out distinct patterns and textures. Let’s delve into different veneer types to understand their unique characteristics.

Reconstituted Veneer

Reconstituted veneer involves the process of creating veneers by using real wood fibers adhered to a backing material. This method allows for the replication of rare or exotic wood species, offering a more sustainable alternative.

Specialty Wood Veneers

Specialty wood veneers encompass a wide range of unique veneers, including burls, crotches, and figured grains. These veneers showcase extraordinary natural patterns, adding a touch of elegance and individuality to any project.

Frequently Asked Questions On How Wood Veneers Are Made

How Is Wood Veneers Made?

Wood veneers are made by cutting thin slices from a whole log to create a sheet of wood. There are different cutting methods, including rotary cutting and slicing, each resulting in different grain patterns. Veneer is real wood, unlike laminate, which is a non-wood material made to look like wood.

You can also make your own wood veneer.

What Is The Method Of Wood Veneer?

Wood veneers are made by cutting thin slices off a log to create sheets of wood. Different slicing methods produce diverse grain patterns, such as plain sawn, rotary cut, rift cut, and quarter sawn.

Is A Wood Veneer Real Wood?

Wood veneer is real wood. It is made by cutting thin slices from a log and pressing them onto the surface of a furniture piece. Veneer comes in different patterns of grain, depending on the method of cutting used.

Can You Make Your Own Wood Veneer?

Yes, you can make your own wood veneer by cutting thin slices from a log to create sheets.

Conclusion

Wood veneers are crafted by cutting thin slices from logs to create unique patterns. Different cutting methods yield various grain patterns adding charm to woodwork. Understanding the process helps appreciate the craftsmanship behind wood veneers. Experimenting with veneers offers creative woodworking possibilities.