Is Birch Wood Hard or Soft Full Breakdown

Many people wonder, is birch wood hard or soft? This question pops up a lot, especially when you’re new to woodworking or looking for the right material for a project. It can seem a bit tricky because some woods are obviously hard like oak, and others are clearly soft like pine.

Birch sits somewhere in the middle, and figuring it out can be confusing. Don’t worry, though! This guide makes it super simple.

We will break down Is Birch Wood Hard or Soft? Full Breakdown step by step so you know exactly what you’re working with.

Understanding Wood Hardness

Figuring out if a wood is hard or soft is key for any project. It helps you pick the best wood for furniture, flooring, or even crafts. Wood hardness isn’t just about how tough it feels; it’s measured in a specific way.

This measurement tells us how well the wood will resist dents, scratches, and wear. Knowing this helps you make smart choices and avoid problems later on.

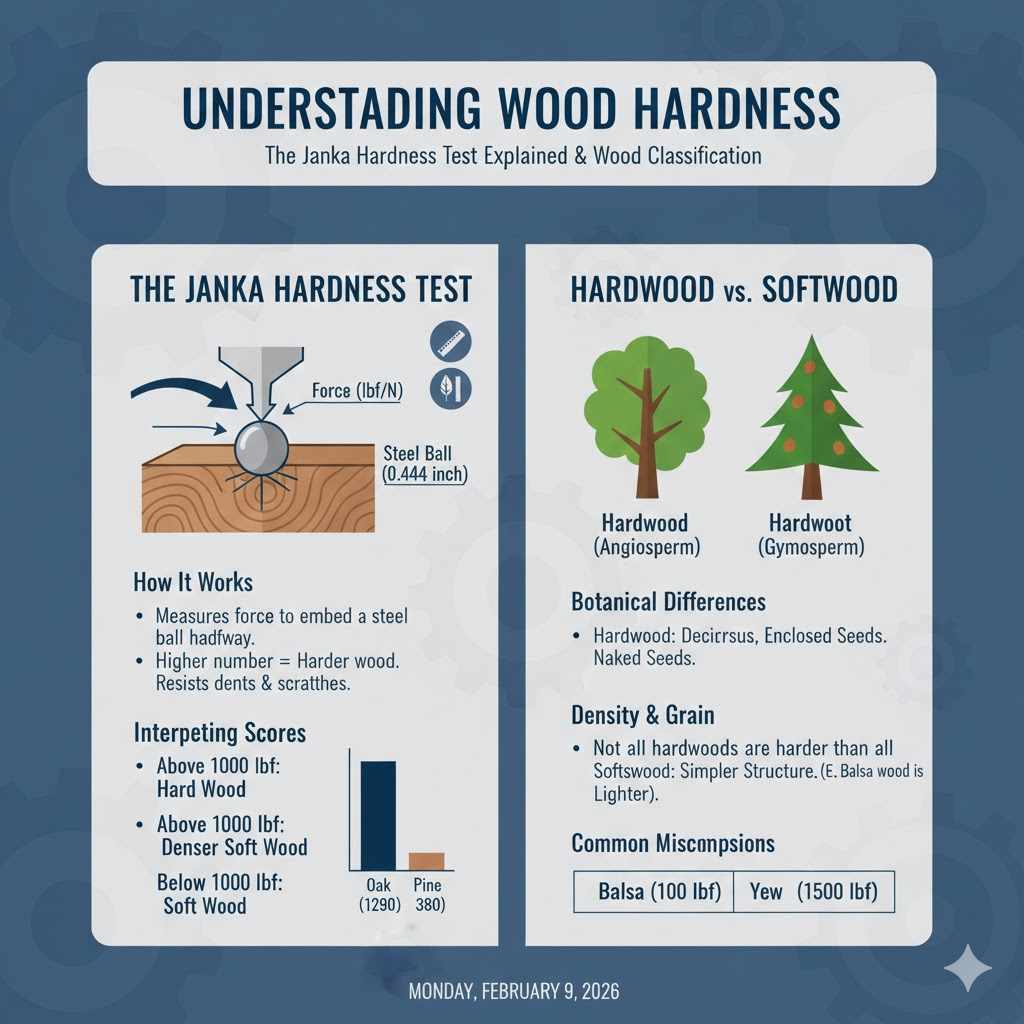

The Janka Hardness Test Explained

The main way wood hardness is measured is with the Janka Hardness Test. This test is pretty straightforward. It measures the force needed to embed a steel ball halfway into a piece of wood.

A higher number on the Janka scale means the wood is harder. A lower number means it’s softer. This test is used worldwide and gives us a standard way to compare different wood types.

- How the Test Works

In the Janka test, a small steel ball, typically 0.444 inches in diameter, is pushed into the wood. The amount of force, usually measured in pounds-force (lbf) or newtons (N), required to push the ball halfway into the wood is recorded. This gives us a precise number that represents the wood’s resistance to denting and wear.It’s a very reliable method.

- Interpreting Janka Scores

Generally, woods with a Janka score of 1000 lbf or higher are considered hard woods. Those below 1000 lbf are typically classified as soft woods. However, there’s a large range within both categories.Some woods are incredibly hard, while others are only slightly harder than the softest options.

- Why Janka Matters for Projects

For projects that need to withstand a lot of use, like flooring or tabletops, you want a wood with a high Janka rating. This ensures it won’t scratch or dent easily. For things like decorative trim or items that won’t see much wear, a softer wood might be fine and is often easier to work with.

Hardwood vs. Softwood Classification

The terms “hardwood” and “softwood” can sometimes be confusing because they don’t always match how hard the wood actually feels. Hardwoods come from deciduous trees, which are trees that lose their leaves each year. Think of oak, maple, and walnut.

Softwoods come from coniferous trees, which are evergreen trees with needles and cones, like pine, fir, and spruce.

- Botanical Differences

The primary difference is botanical. Hardwoods are from angiosperms, flowering plants with seeds enclosed in an ovary. Softwoods are from gymnosperms, plants with naked seeds, usually in cones.This difference in how the trees reproduce and grow affects the wood’s structure.

- Density and Grain Structure

Hardwoods tend to have a denser cellular structure and a more complex grain pattern. This often makes them stronger and more durable. Softwoods generally have a simpler structure and are less dense, making them lighter and easier to cut.

- Common Misconceptions

It’s important to remember that not all hardwoods are harder than all softwoods. For example, Balsa wood, a hardwood, is extremely soft. Conversely, some softwoods, like Yew, can be quite hard.The Janka test is the definitive measure of actual hardness.

Is Birch Wood Hard or Soft? The Verdict

Now, let’s get to the main question. Is birch wood hard or soft? Based on the Janka Hardness Test, birch wood is classified as a hardwood.

It falls into the medium-to-hard range, making it a very versatile wood for many applications. It’s not as hard as some tropical hardwoods, but it’s significantly harder than most common softwoods like pine.

Birch Wood’s Janka Hardness Score

Different species of birch have slightly different Janka scores, but they are all consistently in the hardwood category. For example, Yellow Birch is one of the hardest, while Paper Birch is a bit softer but still considered a hardwood. This range provides flexibility depending on the project’s needs.

- Yellow Birch

Yellow Birch (Betula alleghaniensis) is one of the hardest birches, with a Janka rating typically around 1,260 lbf. This puts it in a similar hardness category to some types of oak, like Red Oak.

- Paper Birch

Paper Birch (Betula papyrifera), also known as Canoe Birch, has a Janka rating around 910 lbf. While this is lower than Yellow Birch, it’s still firmly within the hardwood classification and harder than many common softwoods.

- Sweet Birch

Sweet Birch (Betula lenta), sometimes called Black Birch or Cherry Birch, has a Janka rating similar to Yellow Birch, around 1,200 lbf. It’s known for its strength and attractive grain.

Comparing Birch to Other Woods

To better understand where birch stands, let’s compare its Janka hardness to some other common woods. This will give you a clearer picture of its properties and suitability for various uses.

| Wood Type | Janka Hardness (lbf) | Classification |

|---|---|---|

| Red Oak | 1,290 | Hardwood |

| Yellow Birch | 1,260 | Hardwood |

| Maple (Hard) | 1,450 | Hardwood |

| Walnut | 1,010 | Hardwood |

| Paper Birch | 910 | Hardwood |

| Pine (Eastern White) | 380 | Softwood |

| Fir (Douglas) | 660 | Softwood |

As you can see from the table, birch wood falls comfortably within the hardwood range. It’s comparable in hardness to oak and walnut, making it a strong contender for many applications where durability is important. It is considerably harder than common softwoods like pine and fir.

Properties and Characteristics of Birch Wood

Beyond its hardness, birch wood has several other properties that make it a popular choice for woodworkers and manufacturers. Its appearance, workability, and stability are all factors that contribute to its widespread use.

Appearance and Grain

Birch wood typically has a fine, uniform texture and a straight grain. The color can vary from creamy white to light brown, often with a reddish tinge. It has a subtle, pleasing grain pattern that can be enhanced with stains and finishes.

This makes it adaptable to various design aesthetics.

- Color Variation

The sapwood, which is the outer part of the wood, is usually pale yellow or almost white. The heartwood, from the center of the tree, is a darker reddish-brown. The transition between these colors can create beautiful effects in furniture and cabinetry.

- Grain Patterns

Birch grain is typically straight and even. However, some variations like curly or wavy grain can occur, which are highly prized for their decorative appeal. These figured grains can add significant visual interest to projects.

- Finishing Qualities

Birch takes stains and finishes very well. It’s known for accepting a smooth finish, which makes it ideal for painted furniture or for achieving a high-gloss look. Its uniform texture helps stains penetrate evenly, providing consistent color.

Workability

Birch wood is generally considered to be moderately easy to work with. Its hardness means it requires sharp tools, but its fine texture prevents excessive splintering. It glues well and holds nails and screws effectively, making it practical for construction and assembly.

- Machining

When machined, birch cuts cleanly with sharp blades. It doesn’t tend to chip or tear easily, which is a big plus for creating smooth surfaces. Power tools work efficiently on birch, allowing for precise cuts and shaping.

- Hand Tools

While it can be worked with hand tools, its hardness may require more effort compared to softer woods. Sharp hand planes and chisels are essential for achieving the best results and preventing fatigue.

- Gluing and Fastening

Birch wood glues reliably, creating strong joints. For fastening, pre-drilling pilot holes is recommended, especially near edges, to prevent splitting. This is standard practice for most hardwoods.

Stability and Durability

Birch wood is known for its good stability, meaning it doesn’t warp or shrink excessively with changes in humidity. This makes it a durable choice for items that need to maintain their shape over time, such as furniture and cabinetry.

- Resistance to Wear

Its Janka hardness rating means birch is quite resistant to dents and scratches. This makes it a practical choice for high-traffic areas like kitchen cabinets, tabletops, and even some types of flooring, especially when a lighter wood color is desired.

- Structural Strength

Birch has good bending strength and stiffness. This means it can support weight without bowing or breaking, making it suitable for structural components in furniture and cabinetry.

- Moisture Considerations

Like all wood, birch can be affected by moisture. Proper sealing and finishing are important to protect it from excessive moisture, which can lead to swelling or shrinking. However, its overall stability means these changes are usually minor.

Common Uses of Birch Wood

Given its combination of hardness, appearance, and workability, birch wood is used in a wide variety of applications. From fine furniture to everyday items, its versatility makes it a staple in many woodworking projects.

Furniture Making

Birch is a very popular choice for furniture. Its clean, modern look, coupled with its durability, makes it ideal for everything from dining tables and chairs to bedroom sets and office furniture. It’s also a great base for painted finishes.

- Cabinets and Countertops

Birch is excellent for kitchen and bathroom cabinets. It can withstand the wear and tear of daily use, and its smooth surface is perfect for painted or stained finishes. For countertops, it offers a natural, warm look, though it requires proper sealing.

- Chairs and Tables

The strength and stability of birch make it suitable for chair legs, table frames, and tabletops. It can handle the weight and pressure of daily use without easily showing damage.

- Decorative Elements

Birch can be used for decorative trim, molding, and paneling, adding a touch of natural beauty to interiors. Its ability to take on different finishes allows it to blend with various decor styles.

Cabinetry and Millwork

The fine grain and uniform texture of birch make it a favorite for cabinetry and millwork. It provides a smooth, consistent surface that is ideal for both painted and stained finishes, allowing for a wide range of aesthetic possibilities.

- Kitchen and Bathroom Cabinets

Birch is a top choice for cabinet doors and drawer fronts. Its durability holds up well in kitchens and bathrooms, areas prone to moisture and heavy use. The clean look complements modern and traditional designs alike.

- Custom Millwork

For custom architectural features like wainscoting, trim, and custom shelving, birch offers a reliable and attractive material. Its workability allows for intricate designs and precise fits.

- Veneers

Birch is often used to create veneers. These thin sheets of wood can be applied to less expensive substrates, like particleboard or MDF, to give furniture and cabinets the look of solid birch at a lower cost. Birch veneer is popular for its smooth finish and light color.

Other Applications

Beyond furniture and cabinetry, birch wood finds its way into many other products due to its strength and attractive appearance. This includes musical instruments, toys, and even structural components in some applications.

- Musical Instruments

Higher grades of birch, especially those with figured grain, are used in the construction of musical instruments, particularly drum shells and guitar necks. Its resonant qualities and strength contribute to good sound production.

- Plywood and Laminates

Birch is a prime material for making high-quality plywood. Birch plywood is known for its strength, stability, and smooth surface, making it suitable for furniture, cabinetry, and structural applications where layers of wood are bonded together.

- Toys and Small Crafts

The non-toxic nature of finished birch wood and its smooth texture make it ideal for children’s toys and smaller craft projects. It’s durable enough to withstand play and offers a natural, appealing look.

Working with Birch Wood

When you’re ready to work with birch, understanding its characteristics can help you achieve the best results. From preparation to finishing, a few tips can make your projects smoother and more successful.

Preparation and Cutting

As a hardwood, birch requires sharp tools for clean cuts. Using a carbide-tipped saw blade is highly recommended for both rip and cross-cutting. This will prevent splintering and ensure a smooth edge.

- Sawing

When cutting birch, take your time. A slower feed rate with sharp blades will give you the cleanest results. For intricate cuts or curves, a bandsaw is effective.Always ensure your blades are clean and sharp.

- Planing and Sanding

For a smooth finish, start with a sharp plane. Sanding is also crucial. Begin with a coarser grit (like 80 or 100) to remove any milling marks, then progressively move to finer grits (up to 220 or 320) for a silky smooth surface.Pay attention to the grain direction when sanding to avoid scratches.

- Pre-drilling

To prevent splitting, especially when working with screws or nails near the edges of birch boards, always pre-drill pilot holes. The size of the pilot hole should be slightly smaller than the diameter of the screw or nail shank.

Finishing Birch Wood

Birch accepts a wide variety of finishes beautifully. Its fine grain and uniform texture allow for both transparent stains and opaque paints to create stunning results.

- Staining

Birch can sometimes be blotchy when stained, especially with oil-based stains. To achieve an even color, it’s recommended to use a pre-stain wood conditioner. This helps the wood absorb the stain more uniformly.Water-based stains also tend to be more forgiving on birch.

- Painting

Birch is an excellent candidate for painted finishes. Its smooth surface takes primer and paint exceptionally well, creating a flawless look. A good quality primer will ensure even coverage and enhance the durability of the paint.

- Clear Coats and Sealers

For a natural look, clear coats like polyurethane, lacquer, or shellac can be applied. These finishes protect the wood while allowing its natural beauty to show through. Multiple thin coats are better than one thick coat for durability and appearance.

Common Issues and Solutions

Like any wood, birch can present a few challenges. Being aware of these and knowing how to address them will lead to more successful projects.

- Blotching with Stain

As mentioned, blotching can occur. The solution is to use a wood conditioner before staining. Apply the conditioner according to the product’s instructions, allow it to dry, and then proceed with staining.This will promote a much more even color distribution.

- Tool Wear

Because birch is a hardwood, it can wear down tools faster than softwoods. Regularly sharpen your blades, bits, and chisels. This not only improves cut quality but also makes your work easier and safer.

- Joining Techniques

Birch glues well, but for complex joinery, consider techniques like mortise and tenon or dovetails. Its strength means these joints will be very durable. Ensure your glue is appropriate for hardwoods and follow proper clamping procedures.

Environmental Considerations

When choosing any wood, considering its environmental impact is important. Birch is a widely available wood, and sustainable forestry practices are common in regions where it grows.

Sustainable Sourcing

Much of the birch used today comes from responsibly managed forests. Look for certifications from organizations like the Forest Stewardship Council (FSC) to ensure the wood was harvested in an environmentally sound manner.

Availability and Cost

Birch is generally abundant in North America and parts of Europe, making it a cost-effective choice compared to some exotic hardwoods. Its availability contributes to its popularity for both large-scale manufacturing and smaller woodworking projects.

Frequently Asked Questions

Question: Is birch wood good for flooring

Answer: Yes, birch wood can be a good choice for flooring, especially species like Yellow Birch, which have a higher Janka hardness rating. It’s durable enough for moderate foot traffic and can be finished to match your decor.

Question: Does birch wood scratch easily

Answer: Compared to softwoods, birch wood does not scratch easily. Its hardwood classification means it has good resistance to dents and scratches, making it suitable for furniture and cabinetry that see regular use.

Question: Can birch wood be used outdoors

Answer: While birch is a hardwood, it is not as naturally resistant to moisture and decay as some other woods like cedar or redwood. It can be used outdoors if properly sealed and maintained, but it’s generally better suited for indoor applications.

Question: Is birch wood more expensive than oak

Answer: The price of birch and oak can vary depending on the specific species, quality, and regional availability. Generally, birch is often comparable in price to common oak species like Red Oak, and sometimes can be slightly less expensive.

Question: What is the difference between birch and maple

Answer: Both birch and maple are hardwoods with similar properties, but maple is generally harder and denser than birch. Maple often has a smoother, finer grain and can have more dramatic figure, like birdseye or curly grain, than birch.

Summary

To wrap it up, birch wood is indeed a hardwood, falling into the medium-to-hard category. It offers a great balance of durability, beauty, and workability. Its consistent Janka hardness, fine texture, and ability to accept finishes make it a prime choice for furniture, cabinetry, and various other wood projects.

You can confidently choose birch for its reliable performance and attractive appearance.