MDF vs Plywood Weight: Essential Guide

MDF is generally heavier than plywood of the same size, but plywood’s weight can vary significantly based on its grade and type. For DIYers, understanding these weight differences is crucial for handling, transport, and project stability.

Hey there, woodworking friends! Md Meraj here. Ever found yourself wrestling with a sheet of wood, wondering if it’s going to be MDF or plywood, and how much it’s going to weigh? It’s a common puzzle when you’re starting out, and it can make all the difference in getting your projects done safely and easily. That’s why today, we’re diving deep into MDF versus plywood weight. We’ll break down what makes them different in terms of heft, and why that matters for your DIY adventures. Get ready to feel more confident about choosing the right material for your next build!

Why Does Wood Weight Matter for DIYers?

Choosing between Medium-Density Fiberboard (MDF) and plywood is a big decision for any DIY project. While both are popular engineered wood products used in countless applications, their weight can be a surprising factor that impacts how you work with them.

Imagine trying to lift a large sheet of material onto sawhorses, or maneuvering it into your car. If you’re not prepared for the weight, it can be a struggle, risk injury, or even damage your project. Knowing the difference helps you plan:

Handling and Transport: Heavier sheets are harder to move alone. Knowing the weight helps you decide if you need an extra pair of hands or a different transport method.

Structural Integrity: In some projects, the weight of the material itself contributes to stability. In others, you might want to keep things lighter.

Tooling: Heavier materials can put more strain on certain tools.

Installation: For things like wall panels or shelving, the weight directly affects how they are mounted and supported.

So, let’s get down to the nitty-gritty of MDF vs. plywood weight.

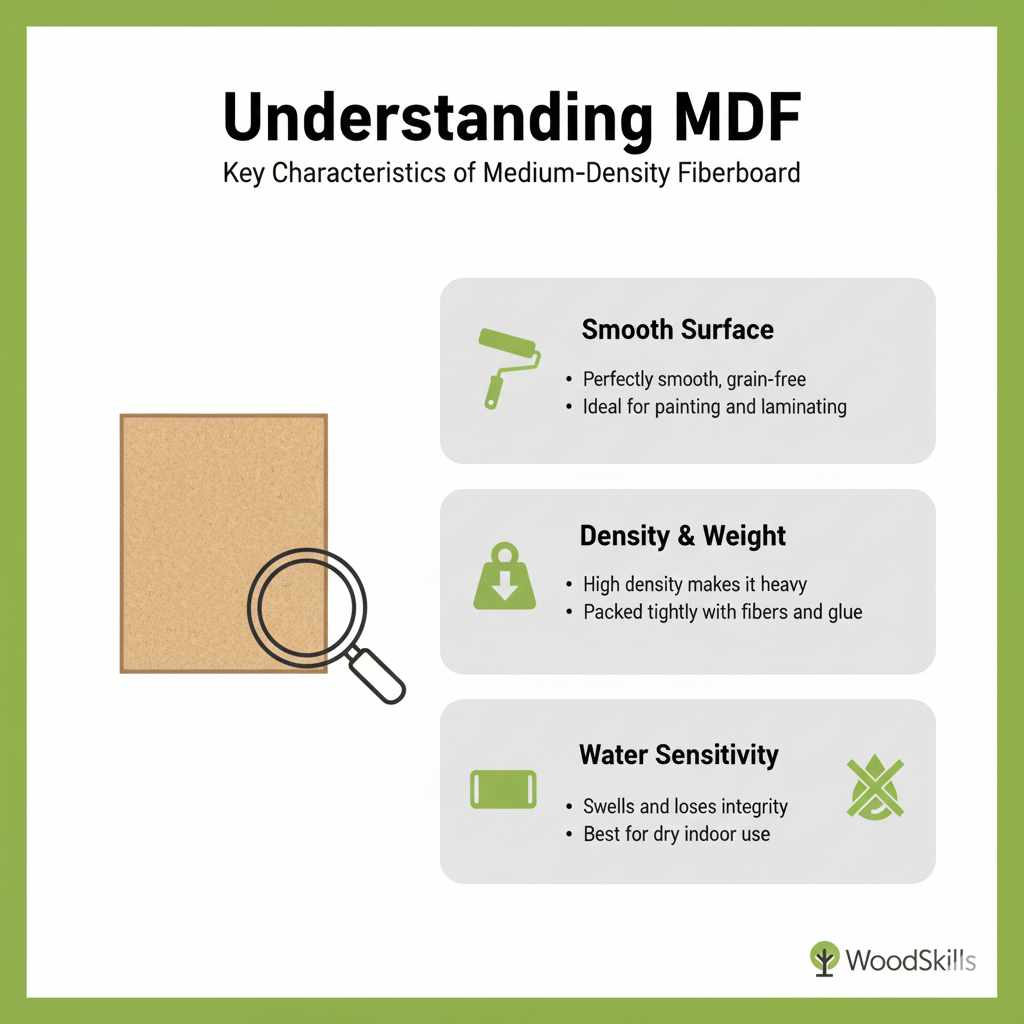

Understanding MDF

MDF, or Medium-Density Fiberboard, is an engineered wood product made from wood fibers. These fibers are combined with wax and resin binders, and then formed into panels by applying high temperature and pressure. The process creates a very dense, smooth, and uniform board.

Because of this dense, uniform composition, MDF tends to be quite heavy for its thickness compared to many types of plywood. The fine wood dust and glue are packed tightly together.

Key Characteristics of MDF

Smooth Surface: It has a perfectly smooth, grain-free surface, making it ideal for painting and laminating.

Density: This high density is a primary reason for its weight.

Uniformity: Unlike plywood, MDF has no internal voids or layers; it’s the same all the way through.

Water Sensitivity: MDF can swell and lose its integrity when exposed to moisture, so it’s best used in dry indoor environments.

Understanding Plywood

Plywood is also an engineered wood product, but it’s constructed differently. It’s made by gluing together thin sheets of wood veneer, called plies, in alternating directions. This cross-graining technique gives plywood significant strength and stability.

The weight of plywood can vary quite a bit. This is because there are many different grades and types of plywood, each with its own construction and potential weight.

Key Characteristics of Plywood

Layered Construction: The alternating grain direction of the plies is its defining feature.

Strength and Stability: This construction method makes plywood strong, resistant to warping, and able to hold screws well.

Grain Pattern: You can often see the wood grain on the surface, depending on the veneer used.

Variety: Plywood comes in many forms: hardwood plywood, softwood plywood, marine-grade, exterior-grade, etc., each with different properties and weights.

MDF vs. Plywood Weight: The Direct Comparison

So, how do they stack up when you put MDF and plywood side-by-side, using the same dimensions, like a standard 4’x8′ sheet?

Generally speaking, MDF is heavier than most common types of plywood when comparing sheets of the same thickness.

Let’s look at some typical weight ranges for common thicknesses. Keep in mind these are approximate, as manufacturers can have slight variations.

Typical Weight Comparison (Approximate per 4’x8′ Sheet)

| Material | Thickness | Approximate Weight (lbs) | Approximate Weight (kg) | Notes |

| :————— | :——– | :———————– | :———————- | :——————————————— |

| MDF | 1/4″ (6mm) | 30-40 | 13.5-18 | Dense and consistent |

| MDF | 1/2″ (12mm) | 60-80 | 27-36 | Noticeably heavier |

| MDF | 3/4″ (19mm) | 90-120+ | 40-54+ | Very heavy, requires careful handling |

| Plywood | 1/4″ (6mm) | 20-30 | 9-13.5 | Lighter, can vary by grade |

| Plywood | 1/2″ (12mm) | 40-60 | 18-27 | Good balance of weight and strength |

| Plywood | 3/4″ (19mm) | 60-90+ | 27-40+ | Weight depends heavily on wood species and grade |

As you can see, a 3/4-inch sheet of MDF can be significantly heavier than a 3/4-inch sheet of common pine plywood.

Factors Influencing Wood Weight

Why is there such a difference? Several factors contribute to the weight of both MDF and plywood:

For MDF:

Density: This is the primary driver. MDF is manufactured to be uniformly dense. A denser material means more mass packed into the same volume, hence more weight.

Binder Content: The amount of wax and resin used in its production also contributes to its overall weight.

For Plywood:

Wood Species: The type of wood used for the plies makes a big difference. Hardwood plywoods (like oak, maple, birch) are generally much heavier than softwood plywoods (like pine or fir).

Number of Plies: More plies for the same thickness can sometimes mean a denser, heavier board, though the alternating grain is the key strength feature.

Grade and Quality: Higher-grade construction plywood might use denser wood and more glue, leading to a heavier product. Exterior or marine grades can also have different densities.

Moisture Content: Like all wood products, humidity can slightly affect the weight.

When Weight Matters Most in Your Projects

Now that we know MDF is generally heavier, and why, let’s talk about when this weight difference really comes into play for us DIYers.

1. Shelving and Cabinetry

MDF: Its smooth surface is great for painted cabinets and shelves. However, because MDF sags more than plywood under load and is heavy, for long spans or heavy items, you’ll need to support it very well, often with a thicker panel and more frequent brackets. The weight itself means you need robust mounting hardware.

Plywood: Plywood is generally preferred for shelves that will hold significant weight or span longer distances without sagging. Its layered structure provides better strength-to-weight. Lighter softwood plywood can be great for garage shelving, while higher-grade hardwood plywood might be used for fine furniture cabinets. For wall-mounted shelves, you’ll still need strong anchors, but the material’s inherent stability is a plus.

2. Furniture Making

MDF: Often used for painted furniture carcasses, doors, or decorative elements where its smooth finish is advantageous. Its weight can actually help make the finished piece feel more substantial and stable. However, it’s not ideal for structural components that need to bear significant stress or joints that will be frequently moved.

Plywood: Plywood is a workhorse for furniture. It’s strong, holds screws well, and can be finished to look beautiful. For cabinet boxes, drawer sides, and tabletops, plywood often offers a better combination of strength, stability, and manageable weight, especially if you choose a hardwood plywood for its aesthetic and strength. A 1/2-inch or 3/4-inch birch plywood is a popular choice for its good balance.

3. Wall Paneling and Built-ins

MDF: Easy to cut and sand to a smooth finish, MDF is popular for wainscoting or decorative wall panels. Be prepared for the weight when cutting large sheets and especially when lifting them into place on the wall. The density means it holds paint very well, giving a professional look.

Plywood: Plywood panels can also be used for wall coverings. Their structural integrity means they’re less likely to warp or bow over time. If you’re creating built-in bookcases or entertainment centers, the structural strength of plywood is often a significant advantage for supporting the weight of books or electronics, and the plywood itself will be lighter than an equivalent MDF build-in.

4. Cabinet Doors and Drawer Fronts

MDF: Excellent for painted cabinet doors and drawer fronts. Its smooth, uniform surface is perfect for a flawless paint finish. While heavier, this weight can make doors feel high-quality. You need to ensure your hinges are rated to handle the extra weight.

Plywood: Plywood, especially hardwood plywood with a nice grain, can also be used for drawer fronts and cabinet doors, particularly if you plan to use a clear finish. It’s often lighter than MDF, which might be easier to handle when building multiple doors.

5. Structural Components and Subflooring

MDF: Generally not recommended for structural applications due to its poor performance in moist environments and tendency to sag over long spans. It can be used for non-structural elements within cabinets or as a substrate for flooring if kept perfectly dry.

Plywood: This is where plywood truly shines. Its layered construction and strength make it ideal for subflooring, roof sheathing, and structural framing elements. For subflooring, you’re looking for strength and rigidity, and plywood delivers without being excessively heavy. The U.S. Forest Products Laboratory (FPL) has extensive research on wood products, including stress and properties, which highlight plywood’s suitability for structural roles. You can find valuable data on wood properties from resources like the U.S. Forest Products Laboratory.

Pros and Cons of MDF vs. Plywood Weight

Let’s sum up the weight-related advantages and disadvantages of each material for your DIY projects.

MDF Weight: Pros and Cons

Pros:

Achieves a Substantial Feel: The weight can contribute to a feeling of solidity and quality in the finished piece, especially for painted furniture.

Good for Stable Surfaces: Dense MDF edges are excellent for routing when you want clean, sharp designs.

Cons:

Difficult to Handle: Heavy sheets can be hard to lift, transport, and position, increasing the risk of injury or damage, especially when working alone.

Requires Strong Mounting: For wall-mounted items, significantly heavier materials mean you need more robust anchors and supports.

Can Sag: Despite its density, MDF has less structural rigidity than plywood for its weight, meaning it can sag over spans.

Plywood Weight: Pros and Cons

Pros:

Easier Handling: Lighter grades of plywood, especially softwood, are easier to manage on your own.

Better Strength-to-Weight Ratio: Plywood offers excellent structural strength for its weight, making it ideal for shelves and load-bearing components.

Versatile Weight Options: You can often choose between lighter softwood plywood or denser hardwood plywood depending on your needs.

Cons:

Heavier Hardwood Varieties: High-quality hardwood plywood can be just as heavy, if not heavier, than MDF.

Inconsistent Weight: Weight can vary between brands and grades, making precise weight calculations for transport a bit trickier without checking.

Tips for Handling Heavy Wood Sheets

Working with heavy boards like ¾-inch MDF or dense hardwood plywood doesn’t have to be a daunting task. Here are some tips to make it safer and easier:

1. Always Get Help: For large or heavy sheets, a second person is invaluable. Two people can lift, carry, and maneuver sheets much more safely.

2. Use the Right Tools:

Hand Truck or Dolly: Essential for moving full sheets, especially around a workshop or garage.

Sheet Lifters: These tools attach to the edge of a panel and create leverage, making it easier to grip and lift.

Work Supports: Use adjustable sawhorses or a workbench that can support the weight and size of the panels you’re cutting.

3. Plan Your Cuts: Measure and mark your cuts on the board before you try to move it to the saw. If you can, cut larger sheets into more manageable sizes on a flat surface or workbench first.

4. Carry Safely:

Bend your knees and lift with your legs, not your back.

Keep the sheet upright when possible; it’s easier to manage on edge than flat.

Communicate with your helper about turns and obstacles.

5. Secure for Transport: Always secure sheets firmly in your vehicle. Use ratchet straps or strong rope to prevent shifting during transit. Consider cutting larger sheets down at the lumberyard if your vehicle is small.

6. Workshop Layout: Arrange your workspace so you don’t have to carry heavy sheets through tight spaces or up stairs.

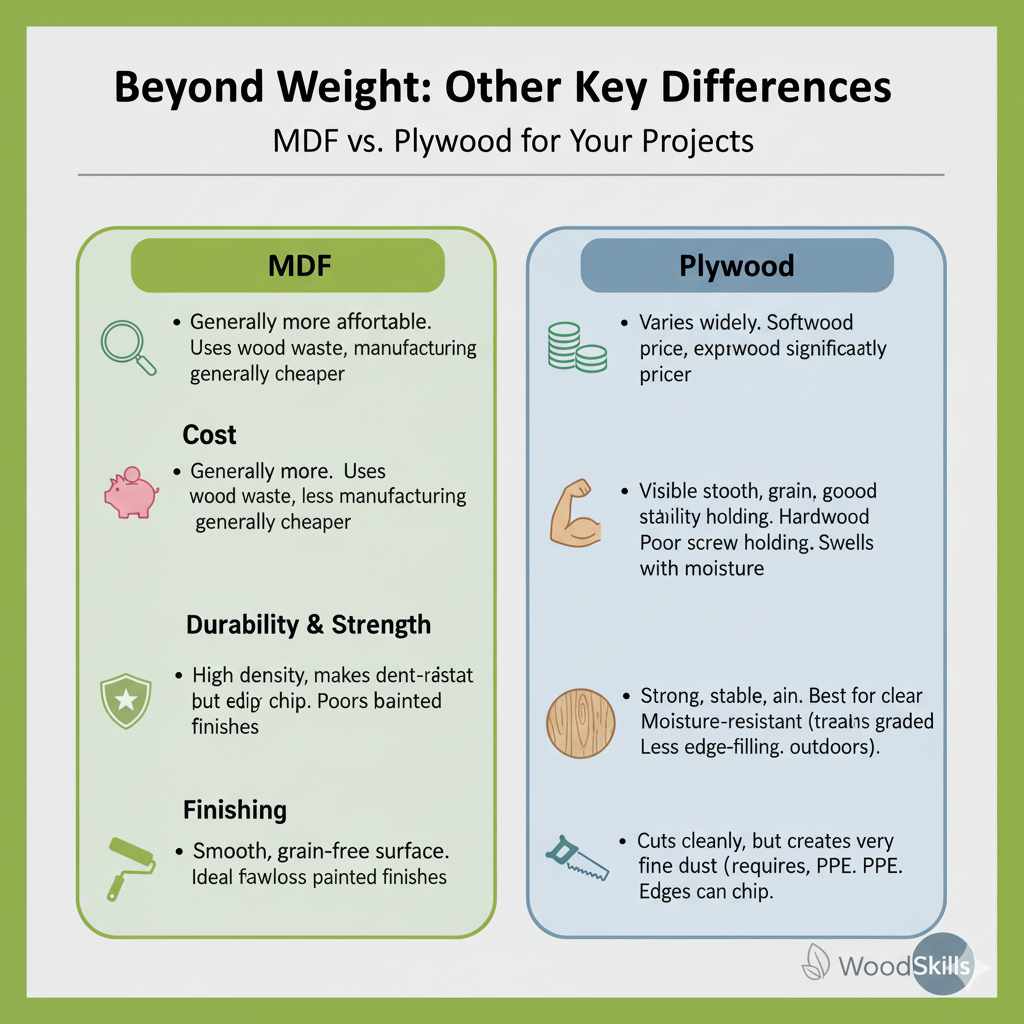

Beyond Weight: Other Key Differences

While weight is a significant factor, it’s important to remember other key differences between MDF and plywood that might influence your choice:

Cost

MDF: Generally more affordable than higher-grade plywood. Its uniform composition means less waste in manufacturing.

Plywood: Prices vary widely. Softwood plywood is often comparable to or slightly more expensive than MDF, while hardwood plywood can be significantly pricier.

Durability and Strength

MDF: High density makes it resistant to dents but susceptible to chipping on edges. It has poor screw holding strength compared to plywood and can swell and warp when wet.

Plywood: Known for its strength, dimensional stability, and good screw holding. It’s much more resistant to moisture (especially exterior or marine grades) and less prone to edge chipping.

Finishing

MDF: Provides an unparalleled smooth surface for painting, making it the go-to for a flawless painted finish.

Plywood: Can have a visible wood grain, which is desirable for clear finishes. Some grades have knots or imperfections that need filling for a smooth finish.

Machining and Cutting

MDF: Cuts cleanly with a sharp blade, but creates very fine dust that requires good dust collection and respiratory protection. Edges can chip.

Plywood: Can be prone to tear-out during cutting, especially on the surface veneer. Requires sharp blades and proper technique. Dust is less fine and potentially less hazardous than MDF dust, but still requires protection.

Frequently Asked Questions (FAQ)

1. Is MDF heavier than plywood of the same thickness?

Yes, typically MDF is heavier than most common plywood sheets of the same thickness and dimensions. This is due to MDF’s uniform, high-density composition of wood fibers and binders.

2. Why is MDF so heavy?

MDF is very dense because it’s made by compressing wood fibers, wax, and resin together. This process packs a lot of material into a small volume, resulting in a heavy board.

3. Can plywood be heavier than MDF?

While generally lighter, some types of plywood, particularly high-density hardwood plywoods, can approach or even exceed the weight of MDF of the same thickness. However, for standard construction or utility grades, MDF is typically heavier.

4. How much does a 4×8 sheet of 3/4 inch MDF weigh?

A 4×8 sheet of 3/4 inch MDF typically weighs between 90 and 120 pounds (approximately 40-54 kg), but this can vary slightly by manufacturer and specific product density.

5. How much does a 4×8 sheet of 3/4 inch plywood weigh?

The weight of a 4×8 sheet of 3/4 inch plywood varies more. A common pine plywood might weigh around 60-75 pounds (27-34 kg), while a hardwood plywood like birch could weigh 75-90+ pounds (34-40+ kg).

6. Which material is better for shelves based on weight and strength?

For shelves that need to support significant weight or span distances without sagging, plywood is generally the better choice due to its superior strength-to-weight ratio and structural stability. MDF can sag more and its weight requires excellent support.

7. Is it safe to handle heavy sheets of MDF or plywood alone?

It is generally not recommended to handle large, heavy sheets of MDF or plywood alone. The weight increases the risk of injury to your back, muscles, or joints, and can lead to accidents. Always try to have at least one helper or use appropriate lifting aids.