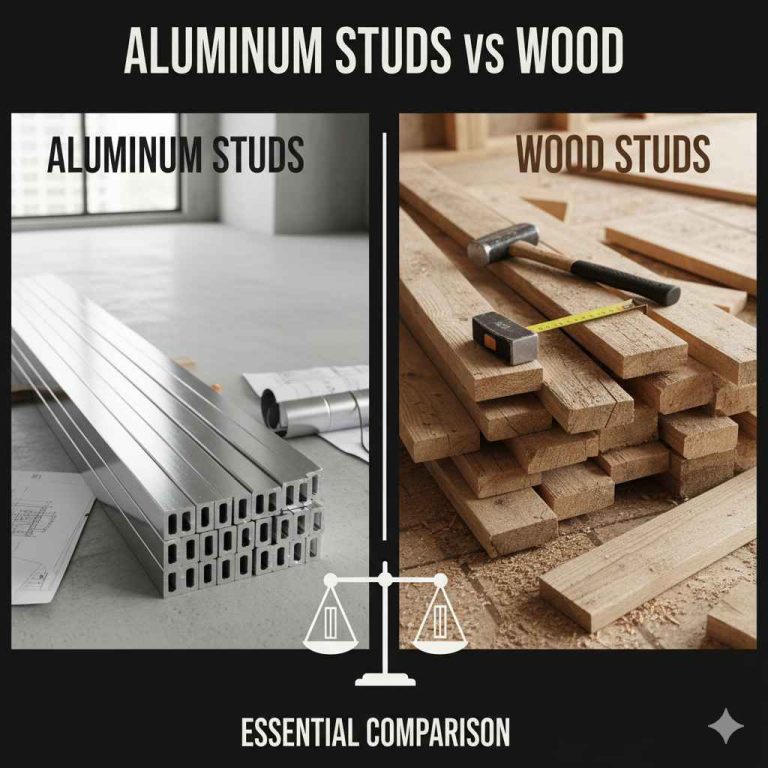

Metal Studs Versus Wood Studs Price: Which Is Cheaper

Deciding between metal and wood studs for your building project can be a bit confusing, especially if you’re new to construction. You might wonder about the cost differences and which option is better for your wallet. It’s a common question because prices can seem all over the place.

Don’t worry, we’ll break down the Metal Studs vs Wood Studs Price: Which Is Cheaper? in a super simple way. We’ll look at everything you need to know to make a smart choice without any headaches.

When planning any construction or renovation, one of the first decisions you’ll face involves the framing materials. This forms the skeleton of your walls, ceilings, and even floors. The two most common choices are traditional wood studs and modern metal studs.

While both serve the same fundamental purpose, their price points and associated costs can vary significantly. This is a key consideration for anyone working within a budget, making the question of Metal Studs vs Wood Studs Price: Which Is Cheaper? a very practical one.

Understanding these cost differences isn’t just about the initial purchase price of the studs themselves. It also involves looking at installation labor, the need for specialized tools, potential waste, and even long-term benefits like resistance to pests or fire. For homeowners undertaking DIY projects or small contractors, getting a clear picture of these financial aspects is essential for accurate budgeting and project success.

The Cost of Wood Studs

Wood studs have been the standard for residential construction for decades. They are readily available, easy to work with, and familiar to most builders. The price of wood studs can fluctuate based on lumber market conditions, timber availability, and the grade of wood you choose.

Generally, common pine or fir studs (like 2x4s and 2x6s) are priced per piece or per linear foot. These prices are often quoted for standard lengths, such as 8-foot or 10-foot studs. Factors that influence wood stud prices include:

- Lumber Market Fluctuations: The price of wood can change daily due to supply and demand, natural disasters affecting timber harvesting, and the global economy.

- Wood Grade: Higher grades of wood (like select structural) are stronger and more uniform but cost more. Standard construction grades are usually sufficient and more affordable.

- Wood Type: Different types of wood, such as spruce, pine, or fir, will have slightly different price points.

- Moisture Content: Kiln-dried lumber is more stable and less prone to warping but can sometimes be more expensive than air-dried options.

- Regional Availability: Prices can vary depending on where you are located and the cost of transportation.

For a typical residential project, the cost of wood framing often includes the studs, sheathing (like plywood or OSB), nails or screws, and labor. The ease of cutting and fastening wood with standard tools can make labor costs more predictable and often lower than for metal studs, especially for less experienced crews.

However, wood can be susceptible to moisture, rot, and insect infestation, which might lead to repair or replacement costs down the line if not properly protected. Warping or twisting can also occur, potentially affecting the straightness of walls.

The Cost of Metal Studs

Metal studs, typically made from galvanized steel, are a popular choice in commercial construction and are gaining traction in residential settings for their durability, consistency, and resistance to common building issues. The pricing of metal studs is often based on weight, gauge (thickness), and length.

When comparing Metal Studs vs Wood Studs Price: Which Is Cheaper?, it’s important to consider that metal studs often have a higher upfront material cost per linear foot compared to standard wood studs. However, this can be offset by other factors.

Key elements affecting metal stud prices:

- Gauge of Steel: Thicker gauge steel (lower number) is stronger and more expensive. Common gauges for interior walls are 25 or 27.

- Type of Metal: Galvanized steel is standard for its corrosion resistance.

- Length and Width: Like wood, they come in standard lengths and widths (e.g., 2×4 equivalents).

- Market Demand: While less volatile than lumber, steel prices can also be influenced by global commodity markets.

- Specialty Studs: Some metal studs have features like pre-punched holes for wiring and plumbing, which can add to the cost but save labor time.

The installation of metal studs requires specialized tools, such as metal snips, a screw gun with appropriate bits for metal, and sometimes crimping tools. While the tools themselves are an initial investment, they can lead to faster assembly once the crew is skilled. Metal studs are lighter than wood studs of comparable strength, which can reduce physical strain on workers and potentially speed up construction.

They also offer precise dimensions, leading to straighter walls and fewer call-backs for leveling or alignment issues.

Furthermore, metal studs are impervious to termites, rot, and fire, which can translate into lower insurance premiums and reduced risk of costly damage over the life of the building. They also do not warp or twist, ensuring long-term structural integrity.

Comparing Material Costs Directly

To directly answer Metal Studs vs Wood Studs Price: Which Is Cheaper? on a purely material basis, it’s often a close call or wood might edge out as slightly cheaper for the raw material in many common scenarios. Let’s look at an approximate comparison for a typical 8-foot stud:

| Material | Approximate Cost Per 8-Foot Stud (USD) | Notes |

|---|---|---|

| Standard Wood Stud (2×4 Pine/Fir) | $2.00 – $5.00 | Price varies greatly with lumber market, grade, and supplier. |

| Standard Metal Stud (2×4 equivalent, 25 gauge) | $3.00 – $6.00 | Price varies with manufacturer, gauge, and bulk purchasing. |

This table shows that the initial material cost for metal studs can indeed be higher. However, this is just one piece of the puzzle.

Considering Labor Costs

Labor is often the most significant portion of any construction budget. The difference in installation labor between metal and wood studs can be a deciding factor when comparing Metal Studs vs Wood Studs Price: Which Is Cheaper?

Wood Studs:

- Familiarity: Most general contractors and carpenters are highly experienced with wood framing.

- Tooling: Uses standard carpentry tools (saws, hammers, nail guns) that are widely available and affordable.

- Speed: For simple framing, experienced wood framers can work very quickly.

- Waste: Some waste can occur due to cutting errors or unusable pieces (knots, splits).

Metal Studs:

- Learning Curve: Less common for residential DIYers, requiring specialized knowledge.

- Tooling: Requires metal-cutting tools and specific screw guns.

- Speed: Can be faster for repetitive tasks or large-scale projects once mastered, especially with pre-cut or designed systems.

- Precision: The precision of metal studs can reduce the time needed for adjustments and squaring up walls.

- Less Waste: Typically, less material is wasted due to the uniformity and manufacturing process of metal studs.

In many residential projects, especially those done by experienced crews, the labor cost for wood framing might be lower due to familiarity and speed with standard tools. However, for large commercial projects or where extreme precision is required, metal stud framing can become more cost-effective due to reduced labor time in certain aspects and less rework.

Other Cost Factors to Consider

Beyond materials and labor, several other factors influence the overall cost when you look at Metal Studs vs Wood Studs Price: Which Is Cheaper?

Durability and Longevity

Metal studs are inherently more durable. They don’t rot, warp, or get eaten by pests like termites. This means fewer potential repair costs down the line.

While the initial cost might be slightly higher, the long-term savings on maintenance and potential damage can make metal studs a more economical choice over the building’s lifespan.

Fire Resistance

Metal studs are non-combustible. This can lead to lower fire insurance premiums and a safer building. Wood studs, while treated in some cases, are combustible and can contribute to fire spread.

Pest Resistance

Termites and other wood-boring insects can cause significant damage to wooden structures, leading to expensive repairs. Metal studs offer complete protection against such pests.

Environmental Impact

While wood is a renewable resource, its harvesting can have environmental consequences. Metal studs are often made from recycled steel and are fully recyclable at the end of their life. The carbon footprint of each material can vary depending on sourcing and manufacturing processes.

Soundproofing

Both metal and wood studs can be used to create soundproof walls. The effectiveness often depends more on the insulation used within the wall cavity and the type of drywall or sheathing installed. However, the precise nature of metal stud framing can sometimes lead to tighter seals, potentially improving sound isolation.

Weight

Metal studs are generally lighter than comparable wood studs. This can make handling and installation easier, potentially reducing labor costs and the need for heavy lifting equipment, especially in multi-story buildings.

Moisture Resistance

Wood is susceptible to moisture, which can lead to mold, rot, and structural weakening. Metal studs are unaffected by moisture, making them a better choice for areas prone to dampness or in flood-prone regions.

When Might Metal Studs Be Cheaper Overall?

While the initial material cost can sometimes be higher for metal studs, there are scenarios where they become the cheaper option when considering the entire project:

- Large-Scale Projects: For commercial buildings or large residential developments, the speed and precision of metal framing can lead to significant labor savings.

- Projects Requiring High Precision: If perfectly straight walls and exact dimensions are critical, metal studs offer consistency that can reduce rework.

- Areas Prone to Pests or Moisture: In regions with high termite activity or where moisture damage is a common concern, the long-term savings from using metal studs can outweigh the initial cost difference.

- Fire-Resistant Construction: If building codes or insurance requirements necessitate high fire resistance, metal studs are a clear advantage that can offset material costs through lower premiums.

- DIYers with Tool Access: If you already own or can easily access the specialized tools for metal framing, the labor savings might become more apparent.

When Might Wood Studs Be Cheaper Overall?

Wood studs typically remain the more economical choice in the following situations:

- Small Residential Projects: For smaller renovations or additions where the familiarity and speed of traditional carpentry are high.

- DIY Projects Without Specialized Tools: If you’re a homeowner tackling a project with basic tools and limited experience, wood is much easier to work with.

- Budget-Constrained Projects with Shorter Lifespans: If the primary goal is the lowest possible upfront cost for a structure that doesn’t need to last for many decades or face extreme conditions.

- Regions with Low Lumber Costs: In areas where lumber is abundant and inexpensive, the material cost advantage of wood can be significant.

Understanding Different Gauges and Sizes

Both metal and wood studs come in various sizes (e.g., 2×4, 2×6) and thicknesses or gauges. The ‘2×4’ designation for wood refers to its rough dimensions before finishing. For metal studs, the size (e.g., 2×4) refers to the depth and width of the profile, while the gauge refers to the thickness of the steel.

A lower gauge number indicates a thicker, stronger, and more expensive stud.

When comparing, it’s essential to match comparable strength and size. A 25-gauge metal stud might be equivalent in strength for certain applications to a standard grade wood stud, but its price will reflect its material and manufacturing. For load-bearing walls, thicker gauge metal studs or larger wood studs will be required, and their respective costs will increase accordingly.

The Impact of Local Pricing and Suppliers

The specific prices you encounter for both metal and wood studs will depend heavily on your geographic location and the suppliers you use. Lumber prices can fluctuate wildly, especially in recent years. Steel prices, while generally more stable, are also subject to global market forces.

It’s always recommended to get quotes from multiple suppliers for both materials in your area to get the most accurate comparison for Metal Studs vs Wood Studs Price: Which Is Cheaper?

Frequently Asked Questions

Question: Are metal studs more expensive than wood studs for framing a small shed?

Answer: For a small shed, wood studs are typically more cost-effective. The material cost of wood is often lower, and the ease of use with standard tools means less specialized labor or learning curve if you’re doing it yourself.

Question: What is the biggest advantage of using metal studs over wood studs?

Answer: The biggest advantage of metal studs is their resistance to moisture, pests, and fire, which leads to greater durability and lower long-term maintenance costs. They also offer dimensional stability and won’t warp.

Question: If I’m building a wall for a home office, which stud type is better for soundproofing?

Answer: Both metal and wood studs can be effective for soundproofing when combined with appropriate insulation and drywall. The precision of metal stud framing can sometimes offer a slight advantage in creating tighter seals, but the overall soundproofing performance is largely determined by the entire wall assembly.

Question: Can I use standard nails to attach drywall to metal studs?

Answer: No, you cannot use standard nails. Drywall must be attached to metal studs using specialized self-tapping screws designed for metal. This is a key difference in the tools and fasteners required.

Question: How does the weight of metal studs compare to wood studs?

Answer: Metal studs are generally lighter than wood studs of comparable structural strength. This can make them easier to handle on-site, potentially reducing labor costs and physical strain during installation.

Final Thoughts

When you weigh Metal Studs vs Wood Studs Price: Which Is Cheaper?, it’s clear that there isn’t a single answer that fits every situation. On the surface, wood studs often appear less expensive for the raw materials. This makes them a tempting choice for budget-conscious homeowners or smaller projects where time and specialized tooling might not be primary concerns.

The familiarity and ease of working with wood using common tools are significant advantages for many DIYers and contractors. Wood’s accessibility means that labor costs can also be more predictable and potentially lower in standard residential builds. However, it’s crucial to remember that wood’s susceptibility to moisture, pests, and fire can lead to unexpected repair costs and a shorter lifespan if not adequately protected and maintained.

On the other hand, metal studs, while sometimes carrying a higher upfront material cost, offer unparalleled durability and resistance to the elements. Their inherent resistance to rot, insects, and fire means fewer long-term maintenance expenses and potentially lower insurance premiums. For larger projects, or in environments where these issues are prevalent, the total cost of ownership for metal studs can become significantly lower.

Consider the specific demands of your project, your budget for both initial outlay and future upkeep, and the long-term value you expect from your construction. Getting multiple quotes and thinking beyond just the price tag of the studs themselves will help you make the most informed decision for your building needs.