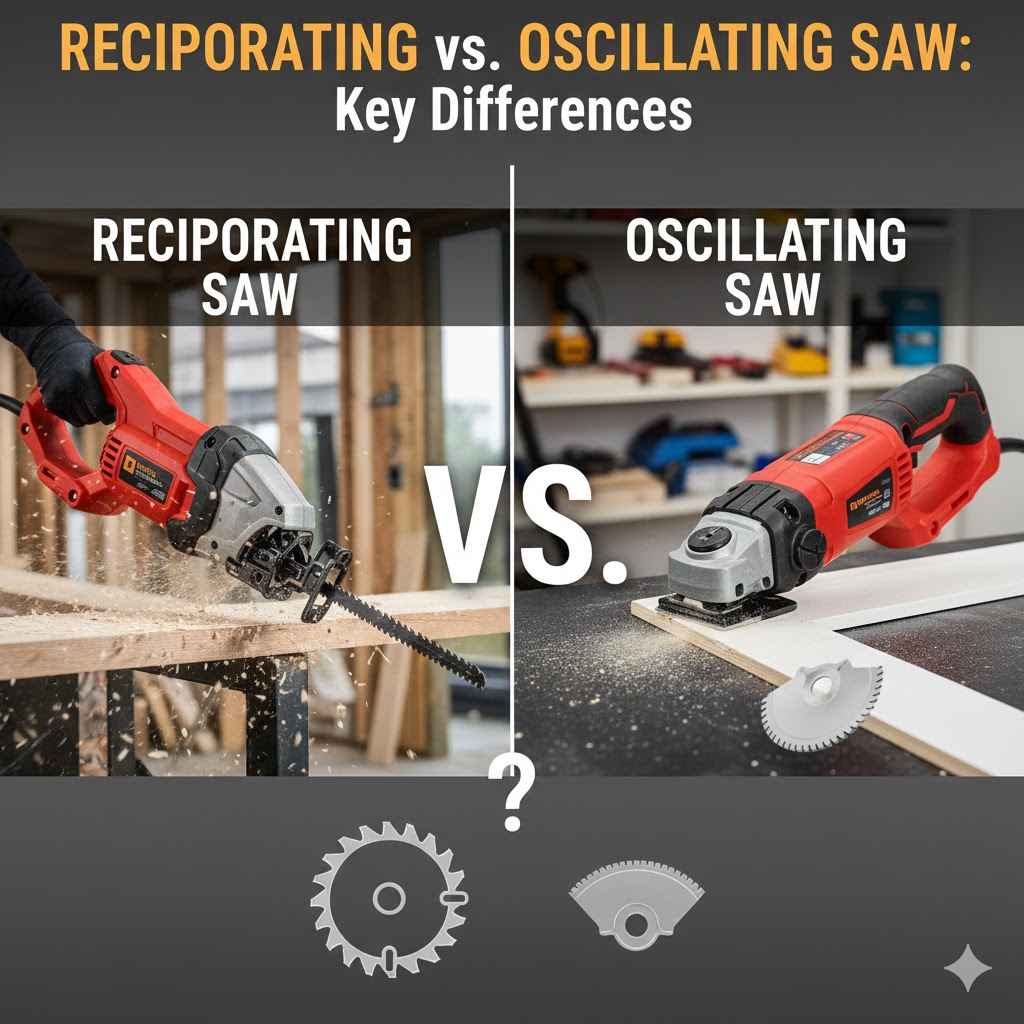

Reciprocating vs Oscillating Saw: Key Differences

Choosing the right saw can feel tricky when you’re new to DIY projects. You might see tools that look similar but do different jobs. The Reciprocating vs Oscillating Saw: Key Differences are important to know.

This can make a big difference in how well your project turns out. Don’t worry, though! We’ll break it down easily so you can pick the best tool for your needs.

Let’s get started and make your next project a success.

Reciprocating Saws vs Oscillating Tools Explained

When you’re looking at power tools for cutting and demolition, two types often come up: reciprocating saws and oscillating tools. While they both involve a back-and-forth cutting action, their designs and applications are quite distinct. Understanding these differences is key to selecting the right tool for your specific task.

This section will help you see how they are alike and where they diverge, setting the stage for a clearer choice.

What is a Reciprocating Saw

A reciprocating saw, often called a “Sawzall” (a popular brand name), is a handheld power saw. It uses a push-and-pull motion of its blade. This motion is much like that of a handsaw.

The blade moves forward and backward in a straight line. This action allows it to cut through a variety of materials. It is commonly used for demolition work, rough cuts, and pruning.

The power behind a reciprocating saw comes from an electric motor, either corded or battery-powered. This motor drives a piston that moves the blade. The length of the blade stroke and the speed of the motor determine its cutting power and speed.

Blades are interchangeable and come in various lengths and tooth configurations. These are designed for specific materials like wood, metal, plastic, or drywall.

Think of a reciprocating saw as a powerful, aggressive cutter. It’s not designed for fine detail work. Its strength lies in its ability to make quick, rough cuts.

This makes it ideal for tearing down structures or cutting through pipes and studs. Its size and design also allow it to reach into tight spaces where other saws cannot. This versatility makes it a go-to tool for many contractors and DIYers.

Blade Design and Action

The blade of a reciprocating saw is typically long and slender. It is attached at one end to the saw’s mechanism. The other end of the blade is free to move.

The cutting action happens on both the forward and backward strokes, depending on the blade’s tooth design. This dual-action cutting makes it very efficient.

Blades can be made of high-speed steel (HSS) for metal cutting or bi-metal for a combination of durability and flexibility. The teeth themselves vary greatly. Large, aggressive teeth are for fast wood cutting.

Finer teeth are for metal or plastic. Some blades have special coatings to reduce heat buildup during tough cuts.

The stroke length of the blade also plays a role. A longer stroke means more material is removed with each pass, leading to faster cutting. Shorter strokes offer more control but are slower.

The variety of blades means you can customize the saw’s performance for almost any cutting job you encounter. This adaptability is a major advantage.

Common Uses for Reciprocating Saws

Reciprocating saws excel at demolition. They can quickly cut through walls, floors, and framing. Removing old structures or making openings for renovations is a common task.

They are also used for cutting pipes, rebar, and other metal objects. Pruning thick tree branches is another application where their power is beneficial.

- Demolition work: This includes tearing down walls, removing old cabinets, or cutting up debris for disposal. The saw’s power and ability to cut through mixed materials make it very effective.

- Plumbing and electrical work: Cutting through pipes (PVC, copper, steel) and making openings in walls for new wiring or fixtures is straightforward.

- Woodworking: While not for precise joinery, they can be used for rough cuts in lumber, cutting out sections of plywood, or clearing out unwanted wood.

- Gardening and landscaping: Thick branches on trees and shrubs can be trimmed with the right blade.

For example, a homeowner renovating a bathroom might use a reciprocating saw to cut out an old cast-iron tub. This is a tough job for many other saws. The reciprocating saw, with a suitable metal-cutting blade, can make quick work of it.

This saves significant time and effort compared to manual methods.

What is an Oscillating Tool

An oscillating tool, sometimes called a multi-tool, works differently from a reciprocating saw. Instead of a long blade moving back and forth in a straight line, an oscillating tool uses a smaller, shaped head that moves rapidly in a small arc. This arc motion is called oscillation.

The tool vibrates or “wobbles” side to side at high speeds.

This precise, controlled movement allows for a different kind of cutting and scraping. Oscillating tools are known for their versatility and ability to perform detailed work. They can cut into materials without necessarily needing to start from an edge.

This is a significant advantage for many tasks. They can also scrape, sand, and grout removal.

The head of an oscillating tool typically accepts various attachments. These include scraper blades, grout removal blades, sanding pads, and cutting blades. The blades are often semi-circular or triangular.

They are designed to oscillate at high frequencies, typically between 10,000 and 20,000 oscillations per minute. This high speed and small motion provide control and allow for plunge cuts.

Attachment Variety and Functionality

The true strength of an oscillating tool lies in its wide array of attachments. These accessories transform the tool for a multitude of tasks. The oscillating head allows these attachments to work effectively.

- Cutting blades: These come in various shapes and sizes for wood, plastic, metal, and drywall. Their small size and oscillating motion allow for plunge cuts – starting a cut in the middle of a material.

- Scraping blades: These are used to remove old paint, adhesive, caulk, or wallpaper. The rapid oscillation helps to break the bond between the material and the surface.

- Grout removal blades: These specialized blades are designed to fit into grout lines between tiles. They can efficiently remove old grout without damaging the surrounding tiles.

- Sanding attachments: These come in various forms, such as triangular or rectangular pads. They are used with sandpaper to sand small areas or hard-to-reach corners.

For example, if you need to remove old caulk around a bathtub, an oscillating tool with a scraping blade is perfect. It can get into the joint and scrape away the old caulk cleanly. This is much faster and less labor-intensive than using a utility knife or putty knife.

The controlled scraping action prevents damage to the tub or wall tiles.

Precision and Control

The oscillating motion provides a high degree of control. Because the blade or attachment moves in a small arc, it’s less likely to jump or wander. This precision is invaluable for tasks that require accuracy.

For instance, if you need to cut a small hole in a wall to access an electrical outlet, an oscillating tool is ideal. You can make a precise plunge cut directly into the drywall. You don’t need to drill a starter hole.

This makes the job cleaner and faster. It minimizes damage to the surrounding wall area.

This level of control also makes oscillating tools great for detail work. Sanding in tight corners or cutting intricate shapes in wood can be achieved with the right attachment. The small vibration is manageable for extended use, allowing for comfortable operation.

Reciprocating vs Oscillating Saw Key Differences

The core differences between reciprocating saws and oscillating tools come down to their design, motion, and intended applications. While both tools offer power and versatility, they are built for very different types of work. Understanding these distinctions is crucial for making the right choice for your DIY or professional needs.

Let’s break down the main points.

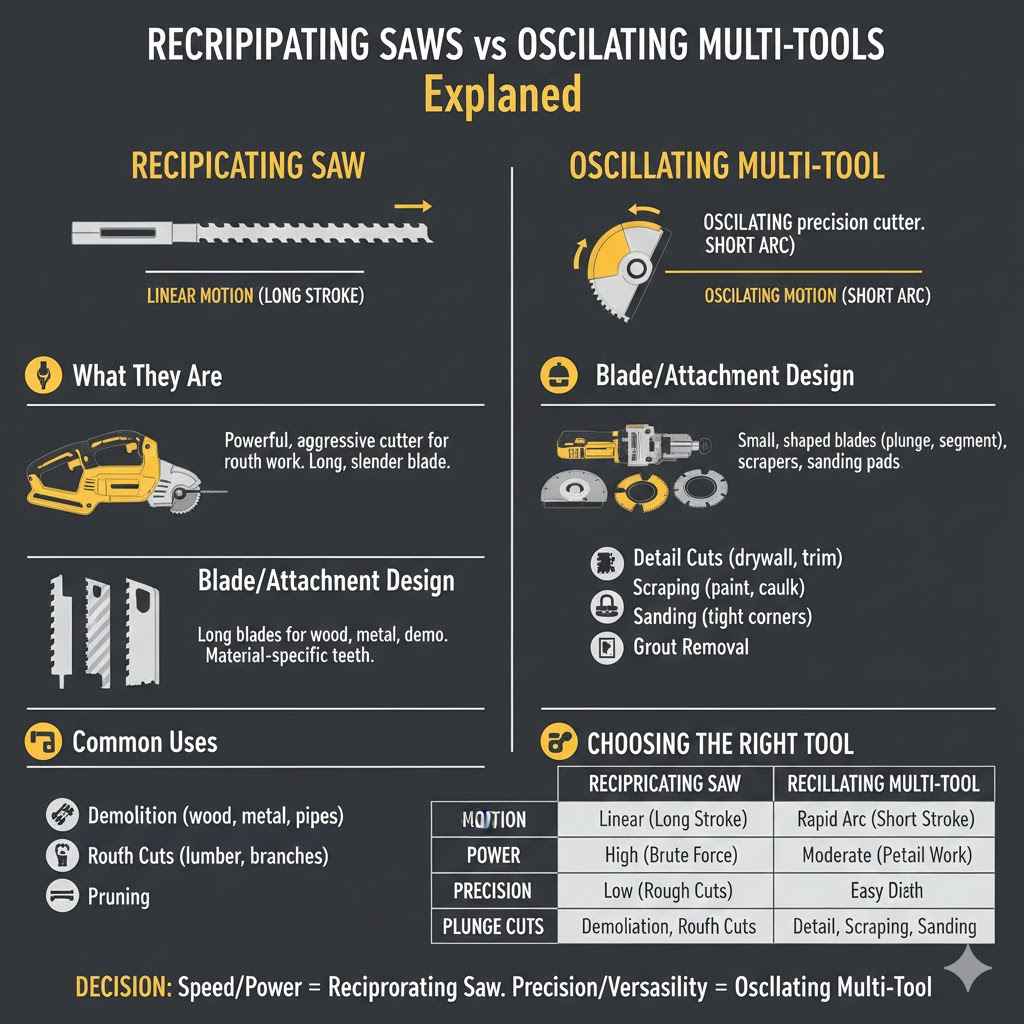

Motion and Power Output

The primary difference lies in their motion. A reciprocating saw has a long blade that moves in a straight, linear back-and-forth motion. This stroke can be several inches long, providing significant force and speed for aggressive cutting.

This power is ideal for demolition and cutting through thick materials.

An oscillating tool, on the other hand, features a head that rapidly vibrates side-to-side in a small arc. This oscillation is typically very fast, in the thousands of cycles per minute. The stroke length is very short, usually only a few degrees.

This motion provides control and precision rather than raw power for brute force cutting.

Because of this, reciprocating saws are often more powerful for large-scale cutting tasks. They can chew through wood and metal quickly. Oscillating tools are less about sheer power and more about the ability to perform delicate or precise tasks.

Their strength is in their adaptability and control.

Blade/Attachment Design

The design of the cutting element is another major difference. Reciprocating saws use long, sturdy blades. These blades are often one to two feet in length.

They are designed to withstand the stresses of powerful, linear cutting.

Oscillating tools use much smaller attachments. These can be blades, scrapers, or sanding pads. They are typically shaped to fit into tight spaces or perform specific actions.

The shape is often semi-circular or triangular, allowing for plunge cuts and precise edge work. The attachment system on oscillating tools is designed for quick changes.

The variety of blades for reciprocating saws focuses on material type and cut aggressiveness. For oscillating tools, the variety of attachments goes beyond just cutting blades to include scraping, sanding, and grouting tools. This broadens the functionality of the oscillating tool significantly.

Applications and Best Use Cases

Reciprocating saws are best suited for demolition, rough cutting, and pruning. They are excellent for cutting through studs, pipes, and branches where precision is not the main concern. Their power makes them ideal for removing old building materials or clearing overgrown vegetation.

Oscillating tools shine in tasks requiring precision and detail. They are perfect for making plunge cuts in drywall, cutting around obstacles, removing caulk or paint, and sanding in tight corners. They are also useful for trimming doors or baseboards without removing them.

A good rule of thumb: if you need to cut through something quickly and don’t mind a rough edge, grab a reciprocating saw. If you need to make a precise cut, scrape something off cleanly, or sand a difficult spot, an oscillating tool is likely the better choice. They are not interchangeable for most tasks.

Comparison Table

| Feature | Reciprocating Saw | Oscillating Tool |

|---|---|---|

| Motion | Linear back-and-forth (long stroke) | Rapid side-to-side vibration (short arc) |

| Power | High, for aggressive cutting | Moderate, for precision work |

| Blade/Attachment | Long, sturdy blades | Small, varied attachments (blades, scrapers, sanders) |

| Primary Use | Demolition, rough cuts, pruning | Detail cuts, scraping, sanding, grout removal |

| Precision | Low | High |

| Plunge Cuts | Difficult without a starter hole | Easy |

Choosing the Right Tool for Your Project

Deciding between a reciprocating saw and an oscillating tool depends entirely on what you plan to do. Each tool has its strengths, and using the wrong one can lead to frustration, poor results, or even damage to your workpiece. Consider the nature of the cut or task you need to perform before you grab a tool.

When to Use a Reciprocating Saw

If your project involves taking things apart, making rough cuts, or working with thicker materials, a reciprocating saw is likely your best bet. Think about demolition work in your home renovation. You might be cutting through old wooden studs, metal pipes, or even concrete blocks.

A reciprocating saw’s power and aggressive cutting action will get the job done efficiently.

For example, if you’re replacing a window and need to cut away old framing, a reciprocating saw is perfect. You can quickly sever the wood without worrying too much about a perfectly clean edge. It’s also great for landscaping tasks like pruning thick branches that a manual saw or even a chainsaw might struggle with in tight spots.

The key is to match the tool’s power and action to the material and the desired outcome. If speed and raw cutting force are needed, the reciprocating saw is the champion. It’s a tool designed for heavy-duty tasks where precision is secondary to speed and brute force.

- Demolition: Taking down walls, cabinets, or old framing.

- Rough cuts in wood or metal: Cutting lumber to length for framing or pipes for removal.

- Pruning thick branches: Clearing overgrown trees and shrubs.

- Cutting through nails and screws: Removing old structures that are held together with fasteners.

When to Use an Oscillating Tool

An oscillating tool is the choice for jobs that require accuracy, detail, or working in confined spaces. If you need to make a precise cut in drywall for an electrical box, or trim the bottom of a door without removing it, an oscillating tool is ideal. Its ability to perform plunge cuts is a major advantage here.

Consider removing old grout between tiles. An oscillating tool with a specialized grout blade can do this quickly and cleanly, without chipping the tiles. Or imagine scraping off old paint from a window frame; the controlled scraping action of an oscillating tool makes this task far easier and safer than using a razor blade.

This tool is also fantastic for sanding in tight corners or around intricate moldings where a larger sander cannot reach. The variety of attachments means you can switch from cutting to scraping to sanding with just a quick swap, making it incredibly versatile for fine-tuning and finishing work.

- Detail cutting: Making precise cuts in wood, metal, or plastic.

- Scraping and paint removal: Taking off old caulk, adhesive, or paint.

- Grout removal: Cleaning out old grout lines for re-grouting.

- Sanding in tight spaces: Reaching corners and edges that other sanders miss.

- Trimming materials in place: Like cutting a door for new flooring without removing the door.

Making the Final Decision

To make your final decision, ask yourself these questions: What materials will I be cutting? How precise do my cuts need to be? Do I need to get into tight spaces?

Will I be doing demolition or fine-tuning work?

If the answer leans towards rough cuts, demolition, and speed, a reciprocating saw is your answer. If precision, detail work, scraping, or accessing difficult areas is your goal, an oscillating tool will serve you better. Many DIYers find value in owning both tools, as they complement each other well and cover a wide range of project needs.

Ultimately, the Reciprocating vs Oscillating Saw: Key Differences guide you to the right choice. By understanding their distinct motions, designs, and applications, you can equip yourself with the best tool for the job and achieve professional-looking results. Don’t be afraid to invest in the right equipment; it will save you time and effort in the long run.

Understanding Technical Terms

To fully grasp the capabilities of reciprocating and oscillating tools, it’s helpful to understand some of the technical terms used to describe them. These terms explain how the tools operate and what makes them effective for different tasks. Knowing these details will give you a deeper appreciation for their design and function.

Oscillation Frequency

Oscillation frequency refers to how rapidly an oscillating tool’s head moves back and forth. It is measured in oscillations per minute (OPM). A higher OPM means the tool vibrates more times per minute.

This generally leads to faster cutting and scraping.

For example, a typical oscillating tool might operate at 10,000 to 20,000 OPM. This rapid vibration is what allows the small cutting or scraping edges to quickly remove material. A higher frequency can make tasks like cutting drywall or removing grout much faster.

However, very high frequencies might also generate more heat and vibration for the user.

Understanding oscillation frequency helps in choosing a tool that is suitable for your needs. Some tools offer variable speed control, allowing you to adjust the OPM. This is useful for working with different materials.

Softer materials might require a lower frequency to prevent overheating or damage. Harder materials can benefit from the maximum speed.

Stroke Length

Stroke length is a term primarily associated with reciprocating saws. It describes the distance the blade travels forward and backward in one complete cycle. A longer stroke means the blade moves further, removing more material with each pass.

This generally translates to faster, more aggressive cutting.

Reciprocating saws commonly have stroke lengths ranging from 1/2 inch to 1 1/4 inches, and sometimes even longer for heavy-duty models. For example, a saw with a 1-inch stroke length will cut through wood or metal more quickly than one with a 1/2-inch stroke. This is because it covers more ground with each movement.

The stroke length is a key factor in a reciprocating saw’s power and efficiency. Longer strokes are better for demolition and cutting thick materials. Shorter strokes offer more control and are useful for more precise cuts, although reciprocating saws are not typically chosen for precision.

The stroke length is a defining characteristic of a saw’s performance.

Plunge Cuts

A plunge cut, also known as a plunge saw cut or drop saw cut, is a type of cut where the saw blade enters the material from the middle, rather than starting from an edge. This is particularly useful for making openings within a surface, like cutting a hole for an electrical outlet in drywall or creating a window in a wooden panel.

Oscillating tools are exceptionally good at making plunge cuts. Their small, oscillating head can be pressed directly into the material. The rapid vibration then allows the blade to quickly cut a clean path.

This eliminates the need to drill a starter hole, which is often required for other types of saws.

Reciprocating saws can also make plunge cuts, but it is generally more difficult and less precise. Because of their longer blade and more powerful motion, they can be harder to control for accurate plunge cuts. This is one of the key advantages of oscillating tools for certain applications.

Variable Speed Control

Variable speed control is a feature found on many power tools, including both reciprocating saws and oscillating tools. It allows the user to adjust the speed at which the tool operates. This is typically done through a trigger that can be squeezed more or less, or a dial that sets a specific speed range.

For reciprocating saws, variable speed control is useful for starting cuts smoothly. It also allows for better control when cutting different materials. For instance, you might want to use a slower speed when cutting thin metal to prevent it from overheating or binding.

A faster speed is preferred for demolition in wood.

With oscillating tools, variable speed control is crucial for adapting to a wide range of tasks. A lower speed might be used for delicate scraping or sanding, while a higher speed is ideal for aggressive grout removal or cutting through tough plastics. This feature enhances the tool’s versatility and prevents damage to materials.

Ergonomics and Vibration Dampening

Ergonomics refers to how comfortable and efficient a tool is to use. This includes factors like the grip, weight distribution, and overall design of the tool. For power tools, especially those used for extended periods, good ergonomics are essential for reducing fatigue and improving safety.

Vibration is a common issue with power tools. Prolonged exposure to vibration can lead to hand-arm vibration syndrome (HAVS), a serious health condition. Tools with good vibration dampening systems are designed to absorb and reduce the amount of vibration that is transferred to the user’s hands.

Both reciprocating saws and oscillating tools can generate significant vibration. Manufacturers often incorporate rubber grips, counter-balance mechanisms, and other dampening technologies to make these tools more comfortable and safer to use. When choosing a tool, consider how it feels in your hand and how much vibration it produces during operation.

Real-Life Examples and Scenarios

Seeing how these tools are used in real situations can help solidify your understanding of their differences. These examples illustrate practical applications where one tool is clearly superior to the other. They highlight the unique strengths of each saw type.

Scenario 1 Home Renovation Plunge Cut

Imagine you are renovating your kitchen and need to install new electrical outlets. You have the drywall in place, and you need to cut out precise rectangular openings for the outlet boxes. You don’t want to damage the surrounding drywall.

In this case, an oscillating tool is the perfect choice. You would attach a drywall cutting blade. Then, you can simply place the blade against the drywall where the outlet needs to be.

You press the tool down, and the oscillating motion cleanly cuts through the drywall, allowing you to make an accurate plunge cut. This is quick, clean, and leaves a perfect opening.

Using a reciprocating saw for this task would be much more difficult. You would first need to drill a large starter hole. Then, trying to control the long, powerful blade of a reciprocating saw to make a neat rectangle would be very challenging.

It would likely result in a rougher cut and potential damage to the surrounding wall.

Scenario 2 Demolishing an Old Deck

Now, let’s say you need to remove an old wooden deck. The goal is to break it down into manageable pieces for disposal. This involves cutting through thick lumber, possibly with nails embedded in it.

A reciprocating saw is the ideal tool for this job. You would select a long wood-cutting blade, preferably one designed for demolition work. The saw’s powerful, linear motion and long stroke length will allow you to cut through the deck boards and support beams quickly and efficiently.

You can easily cut through any nails or screws encountered along the way.

An oscillating tool would be too slow and underpowered for this task. While it could eventually cut through the wood, it would take a very long time. The small attachments are not designed for the aggressive, heavy-duty cutting required for deck demolition.

It would be an inefficient and frustrating experience.

Case Study: A Plumber’s Toolkit

A plumber often works with various materials like PVC pipes, copper tubing, and sometimes metal conduits. They frequently need to cut pipes in tight spaces, such as under sinks or in wall cavities. They also need to make precise cuts to ensure a good fit for connections.

A plumber’s toolkit would ideally include both a reciprocating saw and an oscillating tool. The reciprocating saw, equipped with appropriate metal or plastic cutting blades, is used for quickly cutting through larger diameter pipes or for making rough cuts when dismantling old plumbing systems. Its power is essential for swiftly cutting through robust materials.

The oscillating tool, with its smaller cutting blades and precise plunge-cutting ability, is invaluable for working in confined spaces. It can be used to trim pipes flush with a wall or to cut out sections of pipe without disturbing adjacent fittings. Its versatility also allows for tasks like scraping away old sealant or removing stubborn fittings.

Statistics show that plumbers report a significant time saving when using both types of tools. One survey indicated that using specialized cutting tools like reciprocating and oscillating saws could reduce rough plumbing cut times by up to 40% compared to manual methods or less suitable power tools.

Case Study: A Woodworker’s Detail Work

Consider a woodworker who specializes in crafting intricate furniture or custom cabinetry. Precision and clean cuts are paramount. They might need to make small inlays, cut delicate joinery, or sand hard-to-reach areas without marring the surrounding wood.

An oscillating tool becomes indispensable for such a woodworker. They can use specialized fine-tooth wood cutting blades for precise detail work. The ability to make plunge cuts allows for creating openings for decorative elements or for routing small channels.

The sanding attachments are perfect for smoothing edges in tight corners of a cabinet door.

A reciprocating saw would be entirely unsuitable for this kind of work. Its aggressive cutting action and long blade would inevitably lead to rough edges and potential damage to delicate workpieces. It is simply not designed for the fine tolerances required in detailed woodworking.

A study on woodworking efficiency found that artisans using oscillating tools for detail sanding and cutting tasks reported an increase in project completion speed by approximately 25% for intricate projects. They also noted a significant improvement in the quality of finish in challenging areas.

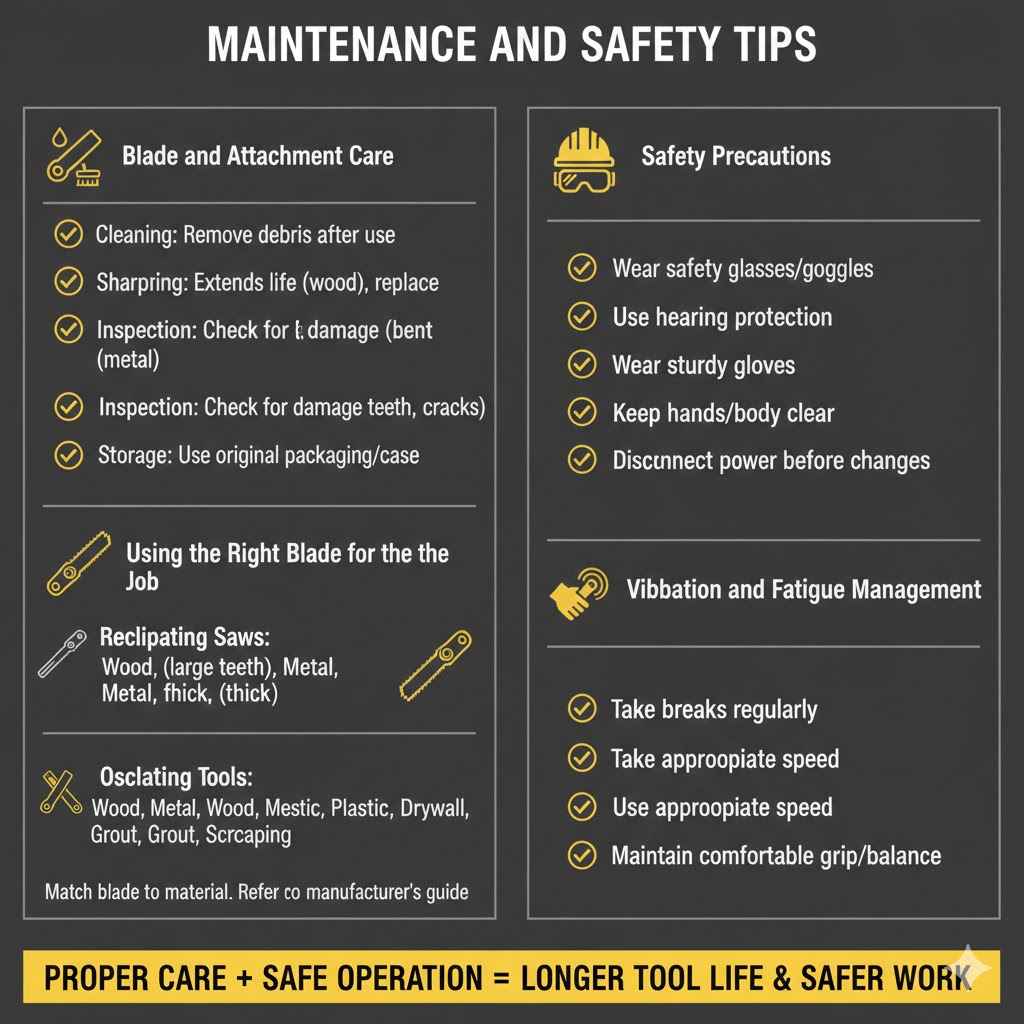

Maintenance and Safety Tips

Proper care and safe operation are vital for any power tool, including reciprocating saws and oscillating tools. Following these guidelines will help ensure your tools last longer and that you stay safe while using them.

Blade and Attachment Care

The cutting performance of both reciprocating saws and oscillating tools heavily depends on the condition of their blades and attachments. Keeping them clean and sharp is essential.

- Cleaning: After each use, remove any debris, sawdust, or material residue from the blades and attachments. A stiff brush or compressed air works well.

- Sharpening: For wood-cutting blades, regular sharpening can extend their life and improve cutting performance. Metal-cutting blades are often disposable and should be replaced when dull.

- Inspection: Before each use, inspect blades and attachments for any signs of damage, such as bent teeth, cracks, or chips. Damaged blades can be dangerous and should be replaced immediately.

- Storage: Store blades and attachments properly to prevent damage and ensure safety. Keep them in their original packaging or in a dedicated blade storage case.

A dull blade requires more force to cut, leading to increased user fatigue and a higher risk of the tool slipping. Replacing worn-out blades promptly is a key aspect of safe and effective tool usage. For oscillating tools, ensure the attachments are securely fitted to the head before operation.

Using the Right Blade for the Job

Selecting the correct blade or attachment for the material you are cutting is crucial. Using the wrong blade can lead to poor results, premature wear, or even damage to the tool and workpiece.

For reciprocating saws, blades are categorized by the material they are designed for: wood, metal, demolition, or general purpose. Wood blades often have larger teeth for faster cutting. Metal blades are typically finer-toothed and made of harder steel.

Demolition blades are often thicker and more durable to withstand rough use and embedded nails.

Oscillating tools have an even wider range of attachments. There are specific blades for wood, metal, plastic, drywall, grout removal, and scraping. For example, when removing caulk, a metal scraping blade is ideal.

When cutting out a section of tile, a carbide-grit blade designed for masonry would be used. Always refer to the tool and blade manufacturer’s recommendations.

Safety Precautions

Safety should always be your top priority when using power tools. Both reciprocating saws and oscillating tools require careful handling.

Always wear appropriate personal protective equipment (PPE). This includes safety glasses or goggles to protect your eyes from flying debris. Hearing protection is also recommended, especially when operating the tools for extended periods.

Gloves can provide a better grip and protect your hands.

- Wear safety glasses.

- Use hearing protection.

- Wear sturdy gloves.

- Secure your workpiece.

- Keep hands and body clear of moving parts.

- Disconnect power before changing blades or attachments.

It is also important to ensure your workpiece is securely clamped or held in place. This prevents it from moving during the cut, which could cause the blade to bind or the tool to slip. Keep the work area clean and well-lit.

Never force the tool; let its speed and power do the work for you.

Vibration and Fatigue Management

Both tools can produce significant vibration, leading to fatigue over long periods. Taking breaks is essential. If your tool has variable speed settings, using a speed appropriate for the material can help reduce excessive vibration.

Good ergonomics also play a role. Ensure you have a comfortable grip on the tool. Position yourself so you can maintain balance and control without straining your body.

Some advanced models include specialized vibration-dampening features to make them more comfortable for prolonged use.

If you experience numbness, tingling, or pain in your hands or arms, stop working immediately and rest. Long-term exposure to vibration can lead to serious health issues. Always follow the manufacturer’s guidelines for operation and maintenance to minimize risks.

Frequently Asked Questions

Question: Which saw is better for cutting metal

Answer: For cutting metal, a reciprocating saw with a metal-cutting blade is generally more effective for larger or thicker metal pieces. An oscillating tool with a metal-cutting attachment can be useful for smaller cuts or details in metal, especially in tight spaces.

Question: Can I use a reciprocating saw for detailed woodworking

Answer: No, reciprocating saws are not designed for detailed woodworking. Their powerful, linear motion makes them unsuitable for precise cuts and they tend to create rough edges. An oscillating tool is much better for detailed woodworking tasks.

Question: How do I make a plunge cut with an oscillating tool

Answer: To make a plunge cut with an oscillating tool, place the edge of the cutting attachment onto the surface where you want to start the cut. Then, apply light pressure and squeeze the trigger to allow the tool to vibrate and cut into the material.

Question: What is the main difference between a reciprocating saw and an oscillating tool

Answer: The main difference is their motion. A reciprocating saw has a long blade that moves linearly back and forth. An oscillating tool has a head that vibrates rapidly side-to-side in a small arc.

This leads to different applications and levels of precision.

Question: Do I need both tools

Answer: Many DIYers and professionals find it beneficial to have both a reciprocating saw for demolition and rough cuts, and an oscillating tool for detail work, scraping, and precision tasks. They complement each other well.

Wrap Up

Reciprocating saws offer power for demolition and rough cuts, while oscillating tools provide precision for detail work and scraping. Understanding their motion, blades, and best uses helps you choose the right tool. Equip yourself wisely for better project outcomes.