Weight of Plywood vs MDF: Essential Comparison

Plywood is generally lighter than MDF of the same thickness and size. MDF tends to be denser and heavier due to its construction. The best choice depends on your project’s needs for weight, strength, and moisture resistance.

When you’re starting a woodworking project, choosing the right material can feel like a big decision. Two of the most popular sheet goods you’ll encounter are plywood and MDF (Medium-Density Fiberboard). They look similar at first glance, but they’re made differently and have different characteristics. One of the most common questions beginners ask is about their weight. Knowing the weight of plywood versus MDF is crucial because it affects how you’ll handle the material, how you’ll support it in your designs, and even how easy it is to move around your workshop. Don’t worry, we’ll break down everything you need to know in a way that makes perfect sense, so you can pick the right board for your next DIY adventure!

Plywood vs. MDF: Understanding the Basics

Before we dive into the nitty-gritty of weight, let’s get a clear picture of what plywood and MDF actually are. Both come in large sheets, typically 4 feet by 8 feet, and are used in countless applications from furniture making to wall paneling. However, their construction methods lead to very different properties, including their density and, therefore, their weight.

What is Plywood?

Imagine making a layered cake, but with thin sheets of wood veneer. That’s essentially what plywood is! Plywood is made by taking thin “peelings” of wood veneer and gluing them together with the grain of each layer running in a different direction. This cross-graining is key to its strength and stability. The more plies (layers) there are, the stronger and more stable the plywood usually becomes.

Common types of plywood you’ll see include:

- Pine Plywood: Often used for general construction and project work, usually lighter and less expensive.

- Birch Plywood: Known for its strength, smooth surface, and appealing grain, common in furniture.

- Hardwood Plywood: Used when a fine furniture look is desired, often with a decorative outer veneer.

- Structural Plywood: Engineered for building, very strong and durable.

What is MDF?

MDF, on the other hand, is made from wood fibers. These fibers are extracted from wood (often from wood chips and sawdust) and then combined with wax and a resin binder. This mixture is then heated and pressed into dense, flat panels. Because it’s made from uniform wood fibers, MDF has no grain pattern like solid wood or plywood. This uniform structure gives it some unique advantages but also some drawbacks.

MDF is also available in different forms, though less varied than plywood:

- Standard MDF: The most common type, good for general use.

- Moisture-Resistant MDF: Treated to withstand higher humidity environments, but not waterproof.

- Fire-Retardant MDF: Treated to slow the spread of flames.

- Thin MDF: Available in thicknesses as low as 1/8 inch for crafts and backings.

The Weighty Comparison: Plywood vs. MDF

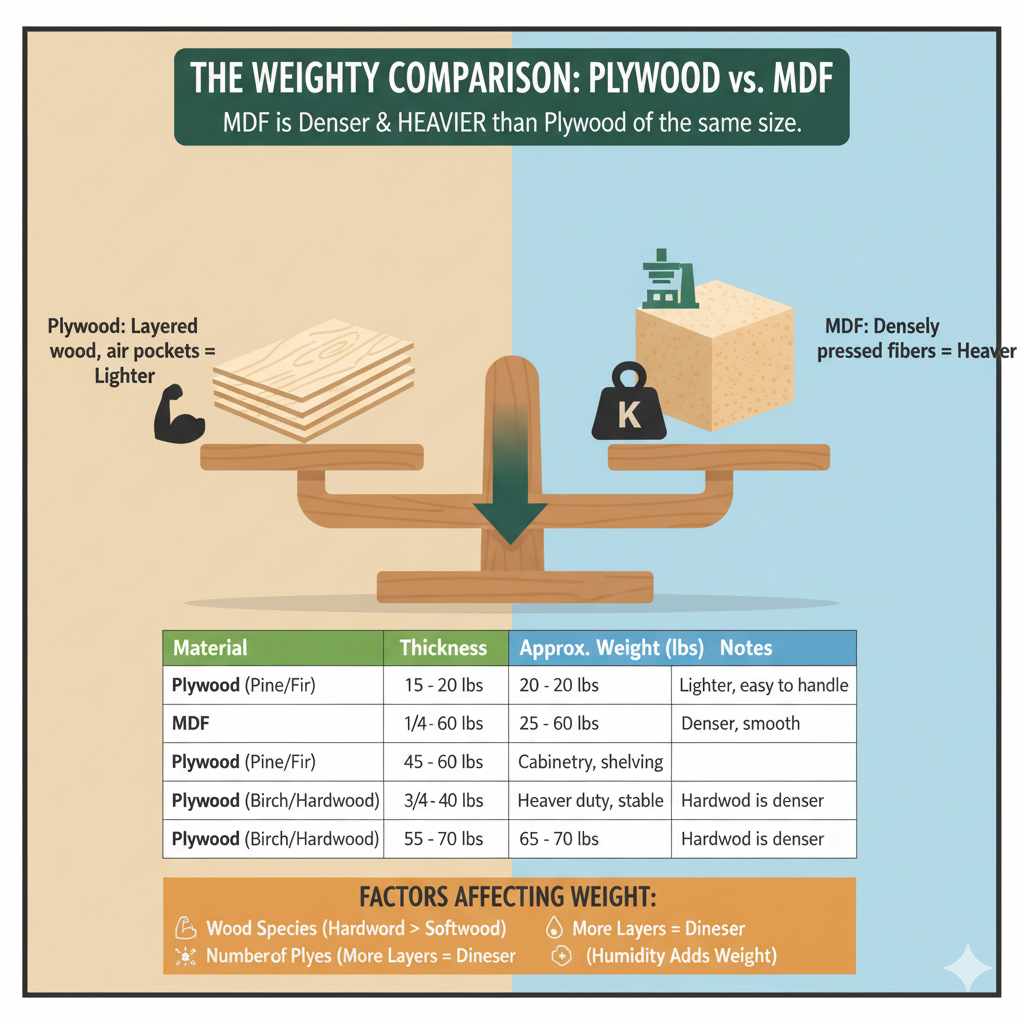

Now, let’s get to the heart of the matter: weight! When comparing the weight of plywood vs. MDF, several factors come into play, primarily the thickness of the sheet and the type of wood used. However, as a general rule, MDF is denser and therefore heavier than plywood of the same thickness and dimensions.

Why is this the case? MDF is pressed under extreme pressure with resin, creating a very compact and uniform material. Plywood, while layered tightly, still contains air pockets between the veneers and doesn’t achieve the same level of density as MDF.

Typical Weights (Approximate)

To give you a clearer idea, here’s a table showing the approximate weights for a standard 4 ft. x 8 ft. sheet of plywood and MDF at common thicknesses. These are estimates, as wood density can vary slightly.

| Material | Thickness | Approximate Weight (lbs) | Notes |

|---|---|---|---|

| Plywood (Pine/Fir) | 1/4 inch (6mm) | 15 – 20 lbs | Lighter, easier to handle, less structural strength. |

| MDF | 1/4 inch (6mm) | 20 – 25 lbs | Denser, smoother surface. |

| Plywood (Pine/Fir) | 1/2 inch (12mm) | 30 – 40 lbs | Good balance of weight and strength. |

| MDF | 1/2 inch (12mm) | 45 – 55 lbs | Significantly heavier than plywood, very stable. |

| Plywood (Pine/Fir) | 3/4 inch (18mm) | 45 – 60 lbs | Very common for cabinet carcasses, shelving. |

| MDF | 3/4 inch (18mm) | 65 – 80 lbs | Heavy duty, excellent for painted furniture and cabinets. |

| Plywood (Birch/Hardwood) | 3/4 inch (18mm) | 55 – 70 lbs | Often heavier than softwood plywood due to denser wood. |

| MDF | 1 inch (25mm) | 90 – 110 lbs | Very heavy; used for specialized applications. |

As you can see from the table, thicker sheets dramatically increase the weight for both materials. A 3/4 inch sheet of MDF can easily weigh 15-30 pounds more than a 3/4 inch sheet of standard pine plywood. This difference can matter a lot when you’re trying to maneuver a full 4×8 sheet by yourself.

Factors Affecting Weight

It’s important to remember these are general figures. The actual weight can vary due to:

- Wood Species Used in Plywood: Hardwoods like oak or birch are denser and thus heavier than softwoods like pine or fir.

- Number of Plies: More plies generally mean a denser, stronger, and often slightly heavier sheet.

- Manufacturing Process: Slight variations in pressing and binder amounts can affect MDF density.

- Moisture Content: Like all wood products, humidity can slightly alter the weight.

Handling and Safety: The Weight Matters!

The weight of these materials isn’t just a number; it has real-world implications for your projects and personal safety. When you’re starting out, it’s easy to underestimate how heavy a 4×8 sheet of material can be.

Tips for Handling Heavy Panels:

- Always Have Help: Never try to lift or carry a full sheet of 3/4″ MDF or even plywood by yourself if you’re not confident. A second person makes the job significantly safer and easier. Sometimes, even a third person is helpful.

- Use a Hand Truck or Dolly: For transporting sheets around your workshop or to your vehicle, a hand truck (also known as a furniture dolly) is invaluable. You can tilt the sheet and slide the dolley underneath.

- Invest in a Panel Lifter: For carrying sheets vertically, panel lifters can give you a better grip and leverage.

- Proper Lifting Technique: If you must lift: bend your knees, keep your back straight, and lift with your legs.

- Beware of Heights: When storing sheets, especially heavy MDF, make sure they are stored flat and securely. Falling sheets can cause serious injury.

For beginners, weighing the pros and cons of each material also includes considering how physically demanding it will be to work with. If you’re working alone or have physical limitations, opting for the lighter material (plywood) might be a wiser choice, even if MDF has other desirable qualities.

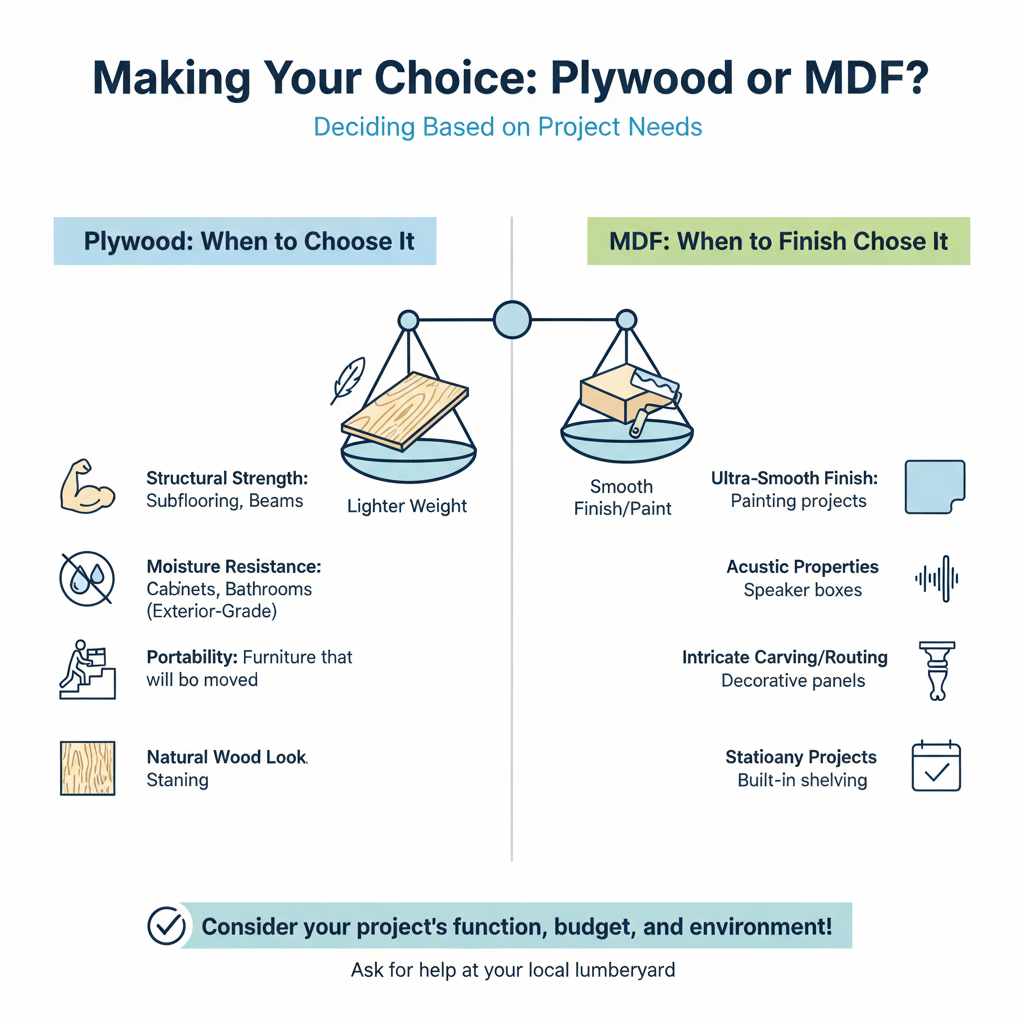

Project Applications: When Weight Becomes a Key Factor

The difference in weight can strongly influence which material is best suited for a particular project. This is where understanding the pros and cons beyond just weight comes in handy.

When Plywood Might Be the Better Choice (and Why Weight Matters):

- When you need lighter structural elements: For example, if you are building a large cabinet that needs to be moved, or incorporating it into a mobile project.

- When you need superior strength for its weight: Plywood’s cross-grained construction gives it excellent shear strength, making it ideal for applications where panels might be under stress, like subflooring or structural bracing. A well-made hardwood plywood can be very strong yet lighter than MDF of equivalent strength.

- When framing or non-visible structural components are needed: Construction-grade plywood is chosen for its balance of strength, flexibility, and weight.

- For projects exposed to some moisture (but not constant wetness): Exterior-grade plywood is designed to withstand some weather.

When MDF Might Be the Better Choice (and Why Weight is Less of a Concern):

- For furniture with a heavy, solid feel: MDF’s density gives furniture a substantial, high-quality feel that many appreciate.

- When painting is the primary finish: MDF’s smooth, uniform surface is perfect for painting, as there’s no wood grain to telegraph through or knots to deal with. Its weight means painted cabinets, for example, feel very robust. You can learn more about painting MDF from resources like This Old House.

- For speaker boxes and soundproofing: MDF’s density makes it excellent for reducing vibrations and providing good acoustic properties.

- When you need a highly stable, warp-resistant material: MDF is less likely to warp or swell than plywood in stable environments. Its weight contributes to its ability to stay flat.

- For detailed joinery or CNC projects: MDF machines beautifully, producing crisp edges and allowing for intricate designs. Its uniform density means cuts are consistent throughout the board.

When considering the weight, think about the final application. If your project will be mounted on a wall, a heavier MDF might require stronger wall anchors and mounting hardware than a lighter plywood. If it’s a piece of furniture that needs to stand firm and resist tipping, MDF’s weight can be an advantage.

Cost Comparison: Plywood vs. MDF

While not directly about weight, cost is always a consideration for DIYers. Generally, MDF is slightly less expensive than comparable grades of plywood. However, this can vary based on the type of wood used for plywood and any special treatments for MDF (like moisture resistance).

For standard 3/4 inch thick, 4×8 sheets:

- MDF: Often ranges from $25 – $45 per sheet.

- Pine/Fir Plywood: Can range from $30 – $55 per sheet.

- Birch/Hardwood Plywood: Can range from $50 – $100+ per sheet, depending on quality and veneer.

So, while MDF is typically heavier, it can sometimes be the more budget-friendly option, especially when compared to higher-grade hardwoods like birch plywood.

Strength, Durability, and Moisture Resistance

Beyond weight, let’s briefly touch on other critical differences:

Strength

- Plywood: Generally stronger in tension and shear due to its layered construction with alternating grain directions. It has better resistance to splitting, especially along the edges.

- MDF: Very strong in compression. It holds screws well within the face of the board but can be prone to edge blowout if screws are overtightened or placed too near the edge.

Durability

- Plywood: More resistant to impact than MDF, less likely to chip or dent.

- MDF: Dents and chips more easily. However, its uniform density means it doesn’t have voids or knots that can cause weak points.

Moisture Resistance

- Plywood: Standard plywood will swell and degrade when exposed to moisture, though exterior grades are more resistant.

- MDF: Standard MDF is highly susceptible to moisture. It will swell significantly and lose structural integrity when wet. Specialized moisture-resistant MDF is available, but it’s still not waterproof and can be more expensive. You can find more information on wood product moisture resistance on resources like the Forest Products Laboratory.

Making Your Choice: Plywood or MDF?

Deciding between plywood and MDF, once you understand their weight differences, comes down to your specific project needs. Ask yourself:

- What is the primary function of the project? Does it need high structural strength, a beautiful painted finish, or good acoustic properties?

- How will it be handled and moved? Will you need to carry it upstairs or install it alone?

- What is your budget?

- What kind of finish are you aiming for?

- Will it be exposed to any moisture?

If weight is a primary concern due to handling, plywood is often the lighter option. If you need a smooth, paintable surface for furniture or cabinetry and don’t plan on moving it much once assembled, MDF’s density and smooth finish might be ideal, even with its extra weight and susceptibility to moisture.

For many DIYers, especially those building cabinets, shelves, or furniture, a good understanding of these materials will help you make the most informed decision. Don’t be afraid to ask for help at your local lumberyard or hardware store – they can often provide specific weight information for the products they carry.

FAQ: Your Questions About Plywood and MDF Weight Answered

Let’s clear up some common questions:

Q1: Is MDF heavier than plywood?

A: Yes, generally MDF is heavier than plywood of the same size and thickness because it is a denser material.

Q2: How much does a 4×8 sheet of 3/4 inch MDF weigh?

A: A 4×8 sheet of 3/4 inch MDF typically weighs between 65 and 80 pounds, sometimes even more.

Q3: How much does a 4×8 sheet of 3/4 inch plywood weigh?

A: A 4×8 sheet of 3/4 inch pine or fir plywood usually weighs between 45 and 60 pounds. Hardwood plywood can be heavier.

Q4: Why is MDF heavier than plywood?

A: MDF is made from wood fibers mixed with resin and compressed under high pressure, creating a very dense, uniform material. Plywood is made by layering thin wood veneers, which usually results in a less dense product.

Q5: Does the type of wood affect plywood’s weight?

A: Absolutely! Plywood made from hardwoods like oak or birch will be significantly heavier than plywood made from softwoods like pine or fir.

Q6: Can I lift a 4×8 sheet of 3/4 inch MDF by myself?

A: It’s strongly advised not to lift a sheet of 3/4 inch MDF by yourself. It’s heavy, awkward, and can lead to injury. Always get help or use lifting aids.

Conclusion

Understanding the weight of plywood versus MDF is a fundamental step in any woodworking journey. We’ve seen that MDF is typically denser and heavier than plywood of the same dimensions, a characteristic stemming from its fiberboard construction versus plywood’s layered veneer design. This weight difference isn’t just a trivia fact; it directly impacts how you handle these materials safely and effectively, influences the structural integrity and portability of your projects, and helps you choose the right material for its intended purpose. Whether you prioritize strength-to-weight ratio, a smooth painting surface, or moisture resistance, knowing the weight is a key piece of information. By considering these factors alongside strength, cost, and durability, you’re well-equipped to make smart material choices that lead to successful, rewarding projects. Happy building!