What Does MDF Stand for? Unveiling Its Secrets & Uses

MDF stands for Medium Density Fiberboard, an engineered wood composite. MDF is cost-effective but less durable than solid wood, susceptible to water damage, and contains VOCs.

While MDF is cheaper, plywood surpasses it in moisture resistance and strength. Due to its water-absorption properties, MDF furniture is not suitable for humid environments or exposure to moisture. When comparing MDF to real wood, the latter offers more durability and longevity.

Builders and DIY enthusiasts often choose between MDF and plywood based on their project requirements. Despite its affordability, MDF’s limitations make it less ideal for certain applications, especially those exposed to moisture.

Composition And Manufacturing

MDF stands for Medium Density Fiberboard, a composite wood material made from leftover hardwood or softwood. It is widely used in furniture manufacturing due to its cost-effectiveness and ease of manipulation. However, MDF is not as durable as solid wood and is prone to water damage and VOC emissions.

What’s In MDF?

MDF stands for Medium Density Fiberboard, which is an engineered wood composite made up of leftover hardwood or softwood. The wood fibers are combined with wax and a resin binder and then pressed into sheets under high pressure and temperature. The result is a dense, flat panel that is uniform in thickness and free from knots and grain patterns.

How Is MDF Made?

The manufacturing process of MDF involves several steps. First, the wood fibers are separated from the rest of the wood through a refining process, which involves grinding the wood into small particles. The wood particles are then mixed with wax and a resin binder, such as urea-formaldehyde, phenol-formaldehyde, or melamine-formaldehyde. The mixture is then formed into a mat, which is then pressed into sheets under high pressure and temperature.

During the pressing process, the resin binder is activated and bonds the wood particles together, forming a dense, flat panel that is uniform in thickness. The resulting MDF panel is then cut to size and sanded smooth, making it ready for use in a wide range of applications.

MDF is an engineered wood composite that is made up of leftover hardwood or softwood. The wood fibers are combined with wax and a resin binder, then pressed into sheets under high pressure and temperature. The result is a dense, flat panel that is uniform in thickness and free from knots and grain patterns. Knowing the composition and manufacturing process of MDF can help you make informed decisions about its use in your projects.

Advantages Of MDF

Medium Density Fiberboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. MDF is versatile, cost-effective, and provides a smooth surface for painting.

MDF, which stands for Medium Density Fiberboard, is an engineered wood composite made up of leftover hardwood or softwood. It has become a popular material in the furniture and construction industries due to its numerous advantages. Here are some of the key advantages of MDF:

Cost-effectiveness

MDF is a cost-effective material compared to solid wood. It is made up of wood fibers that are compressed and held together by resin, making it cheaper to produce than solid wood. This cost-effectiveness makes MDF a popular choice for furniture manufacturers who want to create affordable furniture without sacrificing quality.

Ease of manipulation

MDF is a versatile material that is easy to manipulate, making it a preferred choice for furniture designers. It can be easily cut, drilled, and shaped into any form, allowing designers to create unique and intricate furniture designs. Additionally, MDF is a consistent material that does not have knots or other imperfections that can affect the quality of the finished product.

Other advantages of MDF include its dimensional stability, which means it does not shrink or expand like solid wood, and its smooth surface, which makes it easy to paint or laminate. However, it is important to note that MDF also has some disadvantages, such as its lower durability and strength compared to solid wood, and its tendency to absorb moisture quickly.

In conclusion, MDF is a cost-effective and versatile material that has become increasingly popular in the furniture and construction industries. Its advantages make it an attractive option for furniture designers and manufacturers who want to create affordable, high-quality furniture.

Limitations And Disadvantages

MDF stands for Medium Density Fiberboard. While it is more economical and easier to manipulate, it is not as strong as solid wood and can crack or split under extreme stress. MDF also absorbs water more quickly and contains VOCs, which can cause irritation to the lungs and eyes.

Comparative Weakness To Wood

MDF, or Medium Density Fiberboard, is an engineered wood composite that is made up of leftover hardwood or softwood fibers. While MDF offers some advantages over solid wood, it also has its limitations and disadvantages. One of the main drawbacks of MDF is its comparative weakness to wood.

Unlike solid wood, MDF is not as strong and durable, which means it has a shorter lifespan compared to wood. Under extreme stress, MDF sheets can crack or split, compromising their structural integrity. This makes MDF less suitable for applications where strength and durability are crucial.

Susceptibility To Moisture

Another limitation of MDF is its susceptibility to moisture. Unlike solid wood, MDF absorbs water more quickly, making it prone to swelling and warping when exposed to high humidity or direct contact with water. This makes MDF unsuitable for use in areas with high moisture levels, such as kitchens, bathrooms, or outdoor environments.

Presence Of VOCs

One of the major concerns with MDF is the presence of VOCs, or volatile organic compounds. MDF is manufactured using adhesives that contain urea formaldehyde, a VOC that can emit harmful gases over time. These emissions can cause irritation to the lungs and eyes, especially in enclosed spaces with poor ventilation.

It is important to note that the level of VOC emissions can vary depending on the quality of the MDF and the specific manufacturing process used. However, for those with sensitivities or concerns about indoor air quality, it may be advisable to choose alternative materials that have lower VOC emissions.

In conclusion, while MDF offers affordability and versatility, it is important to consider its limitations and disadvantages. Its comparative weakness to wood, susceptibility to moisture, and the presence of VOCs are factors that should be taken into account when deciding whether MDF is the right choice for your project.

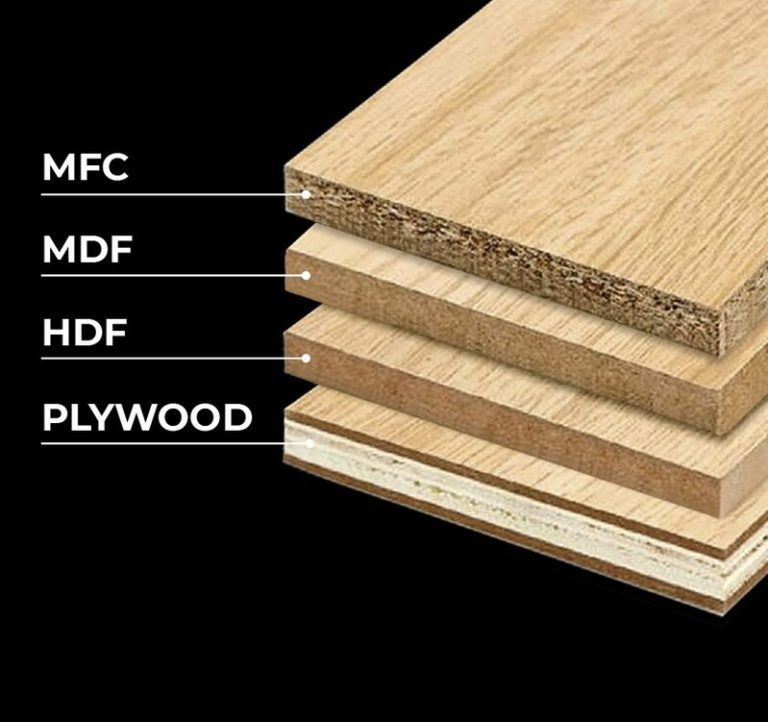

MDF Vs. Plywood

MDF stands for Medium Density Fiberboard, an engineered wood composite often used in furniture and cabinetry. It is cost-effective and easy to work with, but not as durable as plywood and can be prone to water damage.

Medium Density Fiberboard (MDF) and plywood are popular choices in the construction and furniture industries. Let’s compare them in terms of cost, moisture resistance, and durability.

Cost Comparison

When it comes to cost, MDF is generally cheaper than plywood. It is more economical and simpler to manipulate, making it a preferred choice for budget-conscious projects.

Moisture Resistance And Durability

Plywood excels in moisture resistance and durability compared to MDF. It is stronger, can handle screws better, and offers superior longevity, making it ideal for projects where these factors are crucial. On the other hand, MDF is prone to swelling and damage when exposed to moisture.

In conclusion, while MDF is a cost-effective option suitable for lightweight applications, plywood is the superior choice for projects requiring enhanced moisture resistance and durability.

Practical Uses Of MDF

MDF stands for Medium Density Fiberboard. It is an engineered wood composite made from leftover hardwood or softwood. While MDF is more economical and easier to manipulate than solid wood, it is not as strong and can’t handle screws as well.

Additionally, MDF has a shorter lifespan compared to wood and absorbs water more quickly.

In Furniture Making

MDF, or Medium Density Fiberboard, is extensively used in furniture making due to its versatility and cost-effectiveness. It is created by breaking down hardwood or softwood residuals into wood fibers, often in a defibrator, then combining it with wax and a resin binder. This composite material is then formed into panels using high temperature and pressure. The resulting MDF panels are smooth, uniform, and dense, making them ideal for various furniture applications.

For Lightweight Shelving

When it comes to creating lightweight shelving, MDF is a popular choice due to its consistent density and smooth surface. It can be easily cut, drilled, and shaped, making it suitable for customized shelving solutions. Whether for home storage or retail displays, MDF provides a stable and cost-effective option for creating lightweight shelving units.

Health And Environmental Concerns

Medium Density Fiberboard (MDF) is a popular choice in the construction and furniture industries due to its affordability and versatility. However, there are significant health and environmental concerns associated with the use of MDF. Understanding these concerns is crucial for making informed decisions about its usage.

VOC Emissions And Health Risks

MDF is known for emitting volatile organic compounds (VOCs), including urea formaldehyde, which can have adverse effects on human health. Prolonged exposure to VOC emissions from MDF can lead to respiratory issues, eye irritation, and other health risks. These emissions pose a significant threat to indoor air quality, especially in enclosed spaces.

Sustainability Issues

From an environmental perspective, the production and disposal of MDF raise sustainability concerns. The manufacturing process of MDF involves the use of adhesives and resins that may contain hazardous chemicals. Additionally, the disposal of MDF products can contribute to environmental pollution and waste accumulation, impacting ecosystems and natural resources.

Care And Maintenance

Proper care and maintenance are essential to ensure the longevity and durability of Medium Density Fiberboard (MDF) furniture and fixtures. By following some simple steps, you can protect MDF from water damage and repair any existing damage to keep it in pristine condition.

Protecting MDF From Water

Prevention is key to protecting MDF from water damage. Avoid placing MDF furniture in areas prone to moisture such as bathrooms and kitchens. Use coasters or mats to protect MDF surfaces from water rings or spills. Applying a water-resistant sealant to the surface of MDF furniture can also provide an extra layer of protection against moisture.

Repairing Damaged MDF

Small scratches or dents on MDF surfaces can be repaired using wood filler. Simply apply the wood filler to the damaged area, let it dry, and sand it down until smooth. For larger damages, such as water damage or delamination, it is best to consult a professional to assess the extent of the damage and recommend the appropriate repair method.

Frequently Asked Questions

Is MDF Better Than Wood?

MDF is more economical and easier to manipulate than wood, but it’s not as strong, can’t handle screws well, and lacks the beauty of natural lumber. MDF is also weaker, cracks or splits under extreme stress, absorbs water quickly, and contains VOCs that can cause irritation.

Plywood is better for moisture resistance, durability, and strength, but MDF is suitable for lightweight shelving and furniture. It’s not recommended to use MDF furniture near sources of water or heat.

What Is The Disadvantage Of Using MDF?

MDF has a shorter lifespan than solid wood and can crack under extreme stress. It also absorbs water quickly and contains VOCs that can cause lung and eye irritation. Additionally, it’s not as strong as wood and doesn’t match its natural beauty.

Is MDF Better Than Plywood?

MDF is more economical and easier to manipulate than plywood. However, it is not as strong, cannot handle screws as well, and lacks the natural beauty of wood. MDF also has a shorter lifespan, is prone to cracking and splitting, and absorbs water more quickly.

If you prioritize moisture resistance, durability, and strength, plywood is the better choice.

Should I Avoid MDF Furniture?

Avoid MDF furniture due to its tendency to swell, break, and lack water resistance, especially near heat sources or in humid environments.

Conclusion

MDF stands for Medium Density Fiberboard. It’s cost-effective and easy to work with but lacks the strength and natural appeal of solid wood. Be cautious as MDF is prone to water damage and contains VOCs that may cause health issues.

Consider your needs before choosing MDF over wood.