What Does MDF Stand for in Woodwork?: Expert Insights

When you’re diving into a woodworking project, understanding the materials you use is crucial. You may have come across the term MDF and wondered, “What does MDF stand for in woodwork?”

MDF is a key player in the world of woodworking, offering unique benefits that might surprise you. Imagine transforming your projects with a material that’s both versatile and cost-effective. By uncovering what MDF really means and how it can work for you, you’ll gain an edge in crafting pieces that not only look stunning but also stand the test of time.

Stay with us as we explore why MDF might just become your go-to choice in woodworking.

Credit: en.wikipedia.org

MDF In Woodwork

MDF stands for Medium Density Fiberboard. It’s a type of wood product. Made by breaking down wood into fibers. These fibers mix with wax and resin. Then, they are pressed into sheets. MDF is very smooth and dense. It is often used in furniture and cabinets. This makes it a popular choice in carpentry.

MDF plays an important role today. It is used in many home projects. It is easy to cut and shape. This makes it useful for making shelves or doors. It is affordable compared to real wood. Many choose MDF for its consistent look. It can be painted easily too. Thus, MDF is a go-to for builders and designers.

Composition Of MDF

MDF stands for Medium Density Fiberboard. It’s made from wood fibers. These fibers come from softwood trees. The fibers are mixed with resin. Resin helps to bind the fibers together. Water is also added to the mix. This creates a thick paste. The paste is pressed into sheets. These sheets are then dried. MDF is smooth and easy to cut.

The manufacturing process begins with collecting wood fibers. Fibers are then mixed with resin. This mixture is heated. Heat makes the resin sticky. The sticky paste is pressed into sheets. A machine presses the sheets. The sheets are very flat. After pressing, the sheets are dried. Drying makes the sheets strong. Strong sheets are used for furniture.

Benefits Of Using MDF

MDF is very affordable for projects. It costs less than solid wood. This makes it a smart choice for many. You save money without losing quality. Builders and homeowners like it for this reason. The savings can be used elsewhere.

MDF can be shaped easily. It is great for many designs. You can make cabinets, shelves, and more. This wood is smooth and nice to paint. Designers love it for its flexibility. You can create anything with it.

MDF uses wood fibers that might go to waste. This helps the environment by reducing waste. It is often made from recycled wood. This means less trees are cut down. Choosing MDF is a green choice.

Credit: agosandco.com.au

Common Applications

MDF, or Medium Density Fiberboard, is popular in furniture making. It’s easy to cut and shape. This makes it a favorite for cabinetry and shelves. MDF is smooth and takes paint well. This gives it a nice finish. Many tables and chairs use MDF. It’s strong and durable.

MDF is also used in interior design projects. Designers use it for wall panels and moldings. It adds a clean look to homes. MDF is cheaper than real wood. This makes it a cost-effective choice. Many people use MDF for decorative elements. It looks nice and is easy to work with.

In architecture, MDF is used for decorative pieces. It can be found in columns and ceiling details. Builders like MDF because it’s stable. It does not warp like real wood. This makes it great for detailed work. MDF is also used in doors and frames. It gives a polished look to any room.

Challenges With MDF

MDF is not very strong. It can break easily. Water can damage it fast. Heavy items can make it bend. MDF is weaker than solid wood. It needs special care.

MDF must be handled gently. Move it with care. Avoid dropping it. Clean spills right away. Use a dry cloth. Wet cloths can harm it.

Keep MDF away from water. Protect it from scratches. Use mats under heavy items. Regular checks help keep it safe.

Expert Recommendations

MDF, or Medium Density Fiberboard, is useful in many projects. But, using it needs care. Always seal edges to avoid moisture. This keeps MDF strong and durable. Use sharp tools for cutting. Dull tools can cause rough edges. Sand edges smoothly for a neat finish.

Ventilation is important when working with MDF. Dust can be harmful. Wear a mask to stay safe. Paint or varnish MDF to protect it. Choose quality products for the best results. These steps help your projects last longer.

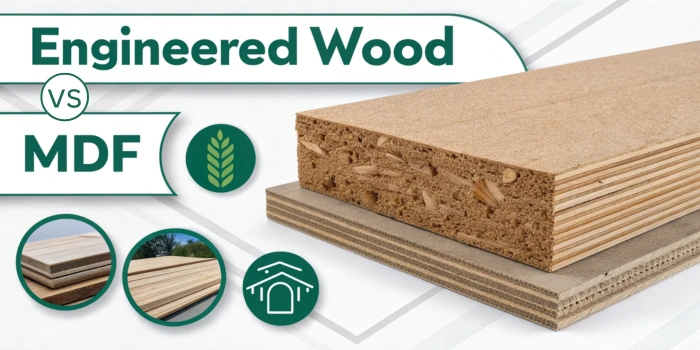

Sometimes other materials work better than MDF. Plywood is strong and versatile. It handles moisture better. Particleboard is another choice. It is cheaper but not as strong. Solid wood is durable but costly. Each material has its own benefits. Choose what fits your project best.

Credit: mrswoodcraft.com

Frequently Asked Questions

Why Is MDF Banned In The Us?

MDF isn’t banned in the US. Concerns exist about formaldehyde emissions, but regulations ensure safety standards. Consumers and manufacturers focus on low-emission MDF options to meet health guidelines.

Is MDF Wood Good Quality?

MDF wood is high-quality, offering smooth surfaces ideal for painting and veneering. It’s dense, durable, and resistant to warping.

What Are The Disadvantages Of MDF Wood?

MDF wood is less durable than solid wood. It easily absorbs water, causing swelling and damage. It emits formaldehyde, posing health risks. MDF is also heavier, making it challenging to handle and transport. It doesn’t hold screws well, limiting its use in certain applications.

Is MDF Better Than Plywood?

MDF offers smoother surfaces and is cheaper, ideal for painting. Plywood is stronger, durable, and resists moisture better. Choose MDF for indoor projects; opt for plywood for strength and outdoor use. Consider project needs to determine the best material.

Conclusion

MDF stands for Medium Density Fiberboard. It offers versatility in woodwork. This material is affordable and easy to work with. Perfect for cabinets, furniture, and more. MDF is smooth, making painting simple. It’s important to seal the edges for durability.

While not water-resistant, MDF is ideal for indoor projects. Many woodworkers appreciate its uniformity. For creative designs, MDF is a solid choice. It’s a staple in modern woodwork. Consider MDF for your next project. Discover its potential and benefits. MDF can be a valuable addition.

Explore its possibilities in woodwork.