What Size Hole Saw for 3/4 EMT: Perfect Fit Guide

For a 3/4″ EMT (Electrical Metallic Tubing), a 1-inch hole saw is recommended. This size accommodates the conduit while providing enough clearance for installation.

Choosing the right hole saw size is crucial for electrical installations. A 3/4″ EMT requires careful planning to ensure proper fit and function. Using an appropriate hole saw not only simplifies the installation but also minimizes potential issues later. Selecting a 1-inch hole saw allows for efficient cutting through various materials, including wood and drywall.

This size provides a snug fit, helping to maintain the integrity of the conduit. Understanding your needs before starting a project can save time and effort. Accurate measurements and the right tools lead to a smoother installation process. Prioritize quality tools for the best results.

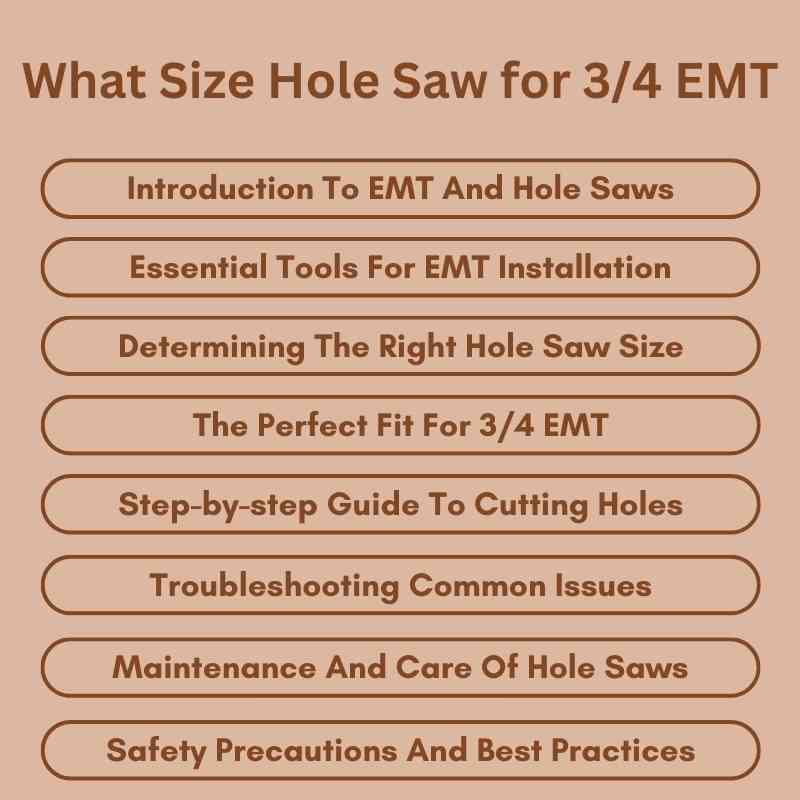

Introduction To EMT And Hole Saws

Electrical Metallic Tubing (EMT) is a type of conduit. It protects electrical wires and cables. EMT is lightweight and easy to install. Choosing the right size hole saw is crucial for proper installation.

The correct hole size allows for smooth wire passage. A hole that is too small can cause damage. A hole that is too big may reduce support. For a 3/4 inch EMT, a 1 inch hole saw is recommended. This size allows for easy wire pulling.

Using the right hole saw saves time and effort. It helps maintain the integrity of the EMT. Always check the specifications before starting your project.

Essential Tools For EMT Installation

Choosing the right hole saw for 3/4 EMT is vital. A hole saw with a diameter of 7/8 inches works best. This size ensures a snug fit for EMT conduit.

Measuring tools help achieve precise cuts. Always use a tape measure for accurate measurements. A level ensures the hole is straight.

Consider using a drill with adjustable speed. This helps control the cutting process. Safety glasses are important for protection during installation.

Here’s a quick overview:

| Tool | Purpose |

|---|---|

| Hole Saw | Cutting holes in EMT |

| Tape Measure | Measuring lengths |

| Level | Ensuring straight cuts |

| Drill | Creating holes |

| Safety Glasses | Protecting eyes |

Determining The Right Hole Saw Size

Choosing the right hole saw size for 3/4″ EMT is important. The diameter of the hole saw must match the outer diameter of the EMT. Most 3/4″ EMT has an outer diameter of 0.825 inches. Therefore, a 7/8″ hole saw is the best choice. This size allows for easy insertion and removal of EMT.

Several factors influence the selection of a hole saw:

- Material: Choose between bi-metal or carbide for durability.

- Thickness: Consider the thickness of the material being cut.

- Power Tool: Ensure compatibility with your drill or saw.

- Depth: Check the depth of the hole saw for deeper cuts.

The Perfect Fit For 3/4 EMT

Choosing the right hole saw size for 3/4 EMT is crucial. A hole saw with a diameter of 7/8 inch is generally recommended. This size allows for a snug fit around the EMT. Adjustments may be needed for different materials.

For softer materials like wood, a standard size works well. Harder materials like metal require a slightly larger hole saw. Drilling speeds should also vary based on the material type.

| Material Type | Recommended Hole Saw Size |

|---|---|

| Wood | 7/8 inch |

| Metal | 15/16 inch |

| Plastic | 7/8 inch |

Step-by-step Guide To Cutting Holes

To cut a hole for a 3/4 inch EMT, choose a hole saw with a diameter of 7/8 inches. This size allows for a snug fit. Always secure the EMT in place before drilling. Use a clamp or vise to hold it steady.

For clean cuts, use a slow speed on the drill. A slow speed prevents the hole saw from binding. Apply light pressure while drilling. Let the saw do the work, avoiding excessive force.

| Drilling Techniques | Benefits |

|---|---|

| Use a pilot bit | Guides the hole saw for accuracy |

| Keep the drill straight | Prevents uneven holes |

| Use cutting oil | Reduces heat and friction |

Troubleshooting Common Issues

To avoid overheating your hole saw, keep the speed low. High speeds can cause the saw to heat up quickly. Use cutting oil to cool the blade while drilling. This helps reduce friction and extends the life of your tool.

Dealing with hole saw jams is common. If the saw gets stuck, stop immediately. Gently twist the saw back and forth to free it. Using a pilot bit helps keep the saw centered and reduces the chance of jamming. Always check for debris in the hole before starting to drill again.

Maintenance And Care Of Hole Saws

Cleaning your hole saw after each use is very important. Remove any debris and sawdust. Use a brush or cloth to clean the teeth. This helps maintain the saw’s sharpness and performance.

Sharpening the teeth of your hole saw can extend its life. Use a file or sharpening stone for this task. Focus on the cutting edges to ensure they are sharp. Regular maintenance will help achieve cleaner cuts.

Safety Precautions And Best Practices

Wearing the right Personal Protective Equipment (PPE) is crucial. Always use safety goggles to protect your eyes. Use ear protection to guard against loud noises. Wear gloves to keep your hands safe from sharp tools.

Ensure your work area is clear of obstacles. Keep all tools organized to prevent accidents. Use a dust mask to avoid inhaling harmful particles. Proper footwear will help prevent slips and falls.

Check your equipment for any damages before starting. Always follow the manufacturer’s safety instructions. Remember to keep children and pets away from the work area.

Frequently Asked Questions

What Size Hole Saw Do I Need For 3/4 EMT?

For a 3/4 EMT conduit, you typically need a 1-inch hole saw. This size allows for sufficient clearance and easy installation. Using the correct size ensures a snug fit without damaging the conduit. Always double-check your measurements before cutting to avoid mistakes.

Can I Use A Standard Hole Saw For EMT?

Yes, you can use a standard hole saw for EMT. However, ensure that the hole saw is designed for metal cutting. It’s crucial to use the right teeth configuration for efficiency. Using the wrong type may lead to poor performance or damage to the conduit.

How Deep Should I Drill For 3/4 EMT?

When drilling for 3/4 EMT, a depth of around 1 inch is generally sufficient. This depth allows for secure mounting without compromising structural integrity. Always ensure that the hole is clean and free from burrs. A clean hole promotes better fitting and safer installations.

What Tools Do I Need For Cutting EMT?

To cut EMT, you will need a hole saw, drill, and possibly a conduit reamer. A hole saw is essential for making precise holes. A drill provides the necessary power, while a reamer smooths out edges for safer handling. Always wear safety gear while working.

Conclusion

Choosing the right hole saw size for 3/4 EMT is crucial for effective installation. A 1-inch hole saw typically works best for this purpose. This ensures a snug fit for your conduit while minimizing any potential damage. Proper tools lead to smoother projects and better results.

Always prioritize precision for a successful outcome.