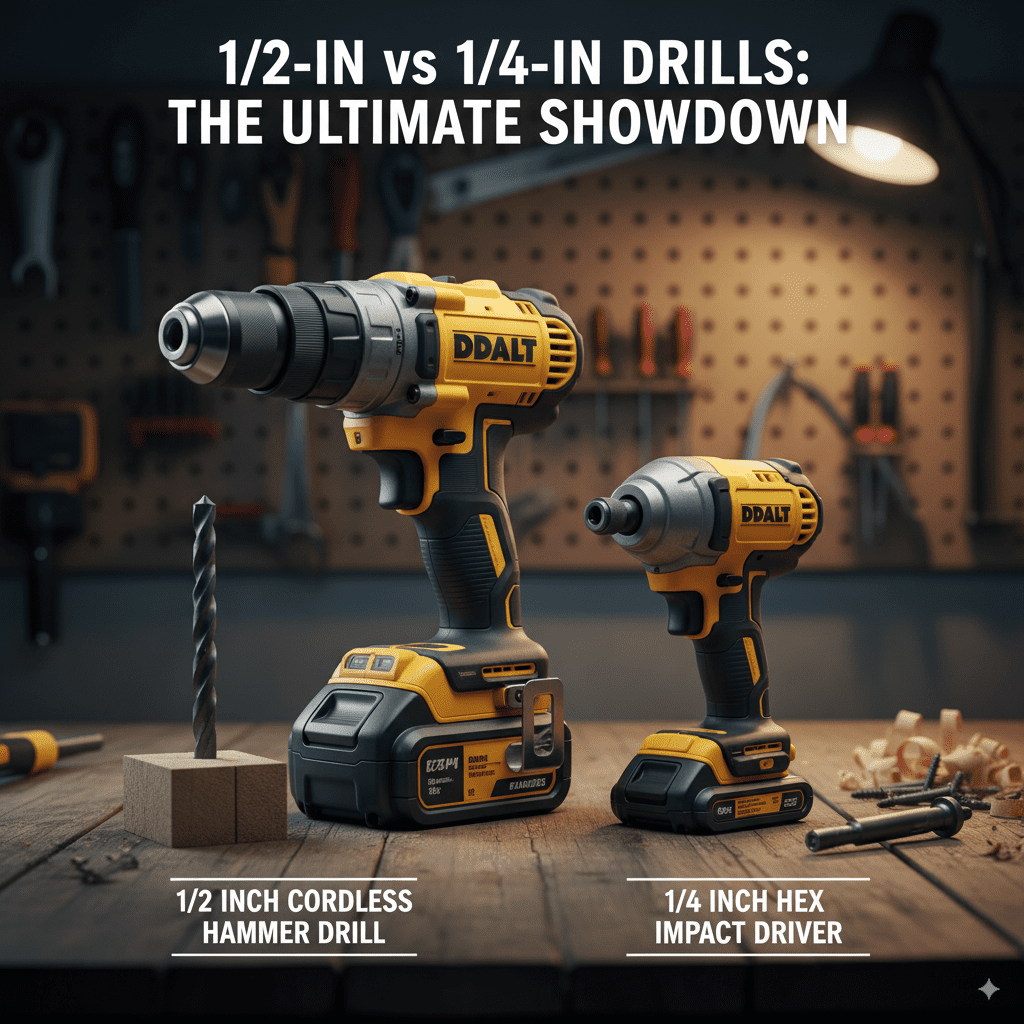

1 2 In Vs 1 4 In Drill: Essential Guide

Choosing between a 1/2 inch and 1/4 inch drill is crucial for your DIY projects. A 1/2 inch drill offers more power for tough jobs and larger bits, while a 1/4 inch drill is lighter and perfect for smaller tasks and precision. This guide will help you pick the right one for your needs.

Hey there, fellow makers and home improvers! Md Meraj here, ready to demystify a common question that pops up when you’re starting out with drilling: “What’s the big deal between a 1/2 inch and a 1/4 inch drill chuck?” It might sound technical, but choosing the right drill size is a simple step that can make your projects so much smoother and more enjoyable. Don’t worry if you’ve felt a little lost; many of us have been there! We’ll walk through what each size is best for, how they compare, and how to pick the perfect drill for your toolbox without any confusion. Get ready to feel confident about your next drilling task!

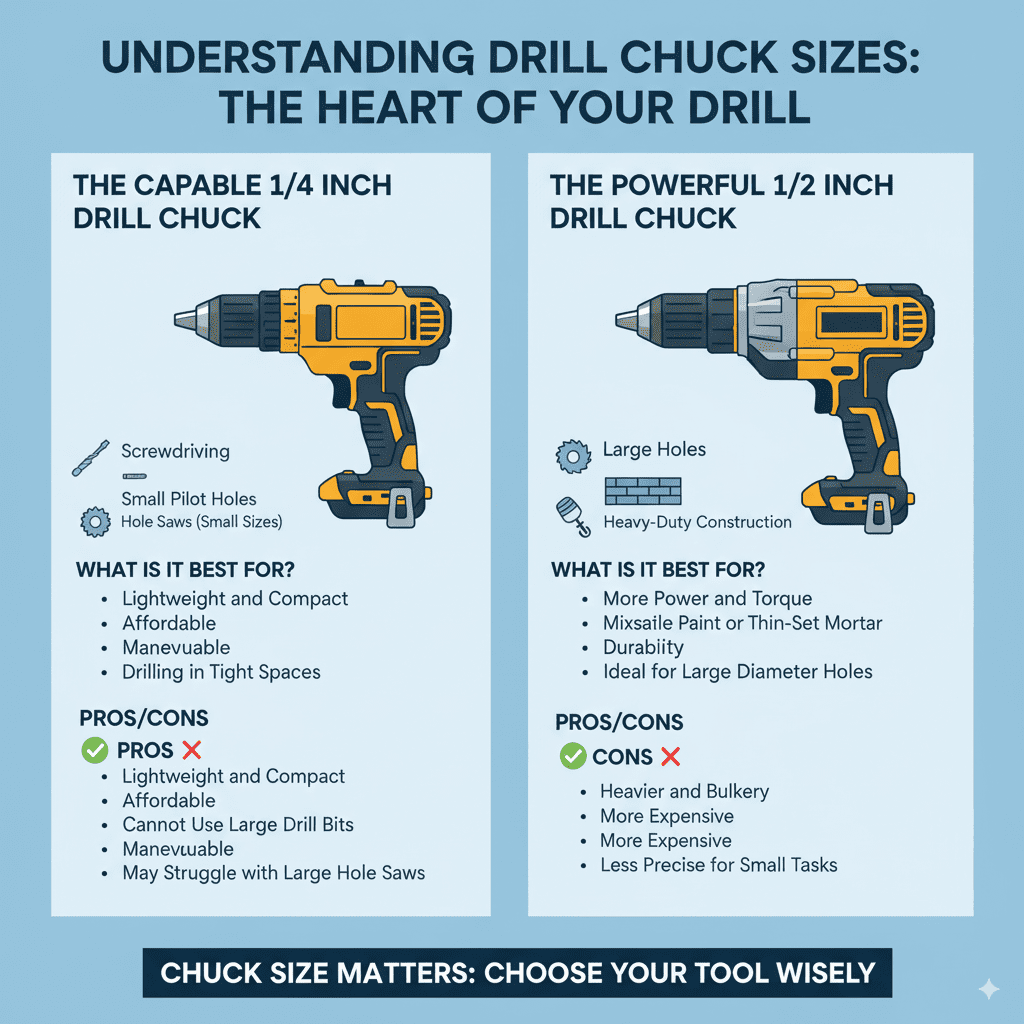

Understanding Drill Chuck Sizes: The Heart of Your Drill

At the core of every drill is its chuck – that handy clamping mechanism that holds your drill bits. The size of the drill chuck, often referred to by its largest drill bit capacity, is a primary indicator of a drill’s capabilities. When you see “1/2 inch drill” or “1/4 inch drill,” it’s usually talking about the maximum shank diameter of a drill bit that the chuck can securely hold. This isn’t about the speed or power directly, but it strongly suggests those things. Think of the chuck as the drill’s handshake; it needs to grip firmly to get the job done effectively.

For beginners, understanding this distinction is key to avoiding frustration. Using a drill that’s too small for a big job can lead to dull bits, stalled motors, and wobbly holes. Conversely, using an oversized drill for delicate work can result in accidental damage or imprecise results. Let’s break down what each size typically means for your DIY adventures.

The Capable 1/4 Inch Drill Chuck

The 1/4 inch drill, or more accurately, a drill with a 1/4 inch chuck capacity, is often your go-to for lighter duty tasks. These drills are generally smaller, lighter, and more maneuverable. They excel when you need precision and control, making them perfect for a wide range of household fixes and smaller woodworking projects.

What is a 1/4 Inch Drill Best For?

- Screwdriving: Many drills with 1/4 inch chucks are designed with variable speed and torque settings perfect for driving screws into drywall, wood, or even metal.

- Small Pilot Holes: Drilling small pilot holes for nails, screws, or hardware installation is a breeze with these drills.

- Hole Saws (Small Sizes): For creating small, clean holes for things like cabinet hinges or small pipe fittings.

- Drilling in Tight Spaces: Their compact size makes them ideal for working in cramped areas where larger drills just won’t fit.

- Craft Projects: For any intricate work where a lighter tool means better control, like model building or detailed decorative drilling.

Pros of a 1/4 Inch Drill:

- Lightweight and Compact: Easier to handle for extended periods and in awkward positions.

- Affordable: Generally less expensive than their larger counterparts.

- Maneuverable: Great for detailed work and tight spots.

- Excellent for Screwdriving: Often comes with clutch settings for precise screw insertion.

Cons of a 1/4 Inch Drill:

- Limited Power: Not suitable for heavy-duty drilling or very hard materials.

- Cannot Use Large Drill Bits: You’re restricted to bits that fit the 1/4 inch chuck opening and shank.

- May Struggle with Large Hole Saws: For holes larger than 1-2 inches, these drills might not have the torque.

The Powerful 1/2 Inch Drill Chuck

Now, let’s talk about the 1/2 inch drill. This size usually signifies a more robust, powerful tool designed for bigger challenges. Drills with 1/2 inch chucks are built to handle more demanding tasks, including drilling larger diameter holes and working with harder materials. They are the workhorses of many a toolkit.

What is a 1/2 Inch Drill Best For?

- Large Holes: Drilling holes of 1 inch or larger using hole saws or large spade bits. This is essential for running wires, plumbing, or creating larger openings in wood.

- Heavy-Duty Construction: Working with dense hardwoods, masonry (with the right type of drill and bit), or even light metal fabrication.

- Mixing Paint or Thin-Set Mortar: The extra power and torque make them suitable for mixing small batches thanks to the availability of mixing attachments.

- Auger Bits: These long, spiral bits are used for drilling deep, clean holes in wood, and 1/2 inch drills are ideal for powering them.

- Metalworking: While requiring specialized bits, these drills have the power to drill through metal.

Pros of a 1/2 Inch Drill:

- More Power and Torque: Can handle tougher jobs and overcome resistance better.

- Versatile Bit Capacity: Accommodates a wider range of drill bits, including large ones.

- Durability: Often built with heavier-duty components for longevity in demanding use.

- Ideal for Large Diameter Holes: The primary reason someone would opt for this size.

Cons of a 1/2 Inch Drill:

- Heavier and Bulkier: Can be tiring to use for extended periods or overhead.

- More Expensive: Typically costs more than 1/4 inch models.

- Less Precise for Small Tasks: Can be overkill and harder to control for delicate screwdriving or small pilot holes.

Comparing 1/2 Inch vs. 1/4 Inch Drills: A Quick Look

To make the choice even clearer, let’s look at a direct comparison. This will help you visualize the key differences in a glance. Remember, this is a generalization, and specific drill models can vary, but these are the typical distinctions.

| Feature | 1/4 Inch Drill Chuck | 1/2 Inch Drill Chuck |

|---|---|---|

| Max Drill Bit Size | Typically up to 1/4 inch shank diameter for standard bits. | Up to 1/2 inch shank diameter for standard bits. |

| Power & Torque | Lower to Moderate | Moderate to High |

| Best Use Cases | Screwdriving, small pilot holes, light drilling, tight spaces. | Large diameter holes, heavy-duty drilling, mixing, woodworking, metalworking. |

| Weight & Size | Lighter, more compact. | Heavier, bulkier. |

| Precision | Higher for small tasks. | Can be less precise for very small tasks without careful handling. |

| Cost | Generally lower. | Generally higher. |

As you can see, each drill size has its own strengths. The “best” one for you squarely depends on the kinds of projects you’ll be tackling most often. For DIY homeowners who are doing a bit of everything, a 1/2 inch drill is often the most versatile choice, as it can do everything a 1/4 inch drill can, albeit sometimes with less finesse, and also handles the heavier jobs.

Drill Driver vs. Hammer Drill: What’s the Difference?

It’s important to note that while chuck size is a significant factor, drills also come with different modes of operation. You’ll often see terms like “drill driver” and “hammer drill.” This is another layer of distinction that affects what your drill can do, regardless of chuck size, though these features are more common on 1/2 inch drills.

Drill Driver

A drill driver is your standard drill. It spins the bit to create holes or drive screws. It typically has settings for different torque levels (how tight a screw gets driven) and sometimes a drill-only mode. You’ll find both 1/4 inch and 1/2 inch chuck sizes on drill drivers.

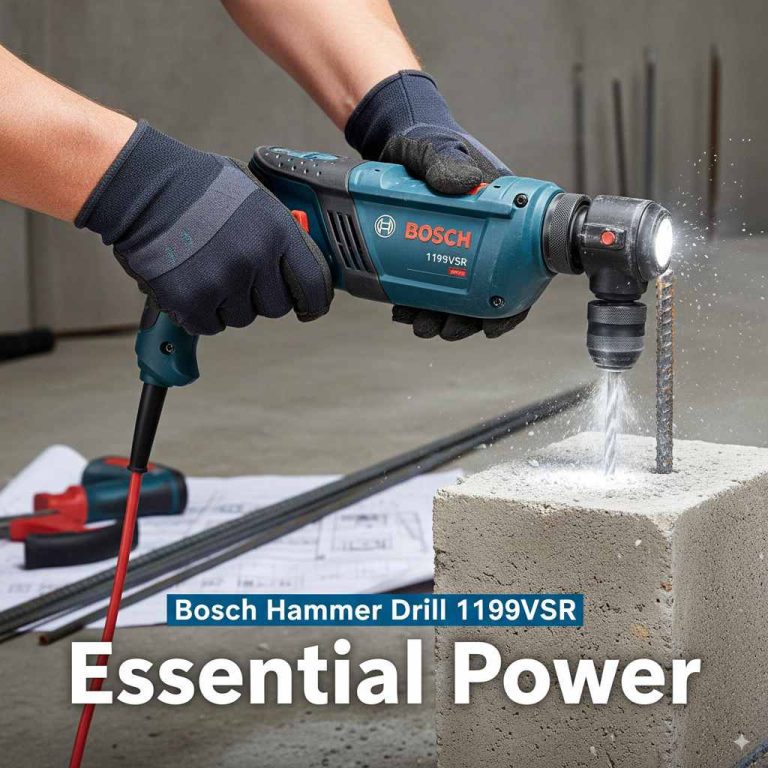

Hammer Drill

A hammer drill adds a “hammering” action to the spinning. This means it not only rotates the bit but also pounds it forward and backward rapidly, like a tiny jackhammer. This is incredibly useful for drilling into hard materials like brick, concrete, or stone. If you plan on any home renovations that involve masonry, like hanging shelves on a brick wall, you’ll want a hammer drill. Even a 1/2 inch hammer drill can be used for wood and screws, just turn the hammer function off!

Many modern 1/2 inch drills, especially corded and higher-end cordless models, will offer both drill/driver and hammer drill modes. Always check the specifications to see what features a drill has. For example, a cordless drill might have settings like:

- Screw Mode: Offers adjustable torque control for driving screws without stripping them or damaging the material.

- Drill Mode: Provides continuous rotation for creating holes in wood, plastic, and metal.

- Hammer Mode (on Hammer Drills): Engages the percussive action for efficient drilling into masonry.

Choosing the Right Drill for Your Toolkit

So, how do you make the final decision between a 1/4 inch and 1/2 inch drill? Consider these factors:

1. Your Typical Projects

This is the most crucial question. What will you be doing most often?

- Light DIY & Home Repairs: Assembling furniture, hanging pictures, minor fixes, driving screws – a good 1/4 inch drill driver might suffice, or a versatile 1/2 inch model will handle these tasks easily.

- Woodworking & General Renos: Building shelves, small furniture, drilling through dimensional lumber, running wires through walls, hanging heavier items – a 1/2 inch drill is strongly recommended.

- Masonry Work: Drilling into brick, concrete, or stone for mounting purposes – you’ll need a 1/2 inch hammer drill.

2. Power Source: Corded vs. Cordless

Both 1/4 inch and 1/2 inch drills come in corded and cordless (battery-powered) versions.

- Corded Drills: Offer consistent, unlimited power. They are generally less expensive and lighter for their power output. However, you’re tethered by the cord, which can limit your range and be a safety hazard.

- Cordless Drills: Provide ultimate liberdade of movement. Battery technology has advanced significantly, offering impressive power and runtime. The downside is the cost of batteries, required charging time, and that power can diminish as the battery drains. For most DIYers today, a good cordless drill is the way to go.

The good news is that powerful cordless 1/2 inch drills are readily available and are fantastic all-around tools for homeowners.

3. Budget

As mentioned, 1/4 inch drills are usually cheaper. However, a good quality 1/2 inch drill driver, especially a cordless model, is an investment that will serve you well for years across a wide variety of tasks. Think about the long-term value and versatility.

For instance, a reputable brand like DeWalt, Makita, or Milwaukee offers excellent 1/2 inch cordless drill drivers that are perfect for beginners needing a tool that can grow with their skills. You can often find starter kits that include a drill, battery, charger, and a basic bit set. For some budget-friendly options that still offer good performance, consider brands like Ryobi or Bauer (available at Harbor Freight).

4. Weight and Ergonomics

If you have smaller hands, limited upper body strength, or anticipate working overhead frequently, the weight of the drill is a significant factor. A lighter 1/4 inch drill might be more comfortable. However, many lighter 1/2 inch models are available now, and their balance can make them easier to handle than you might expect. Always try to hold a drill before buying if possible to see how it feels in your hand.

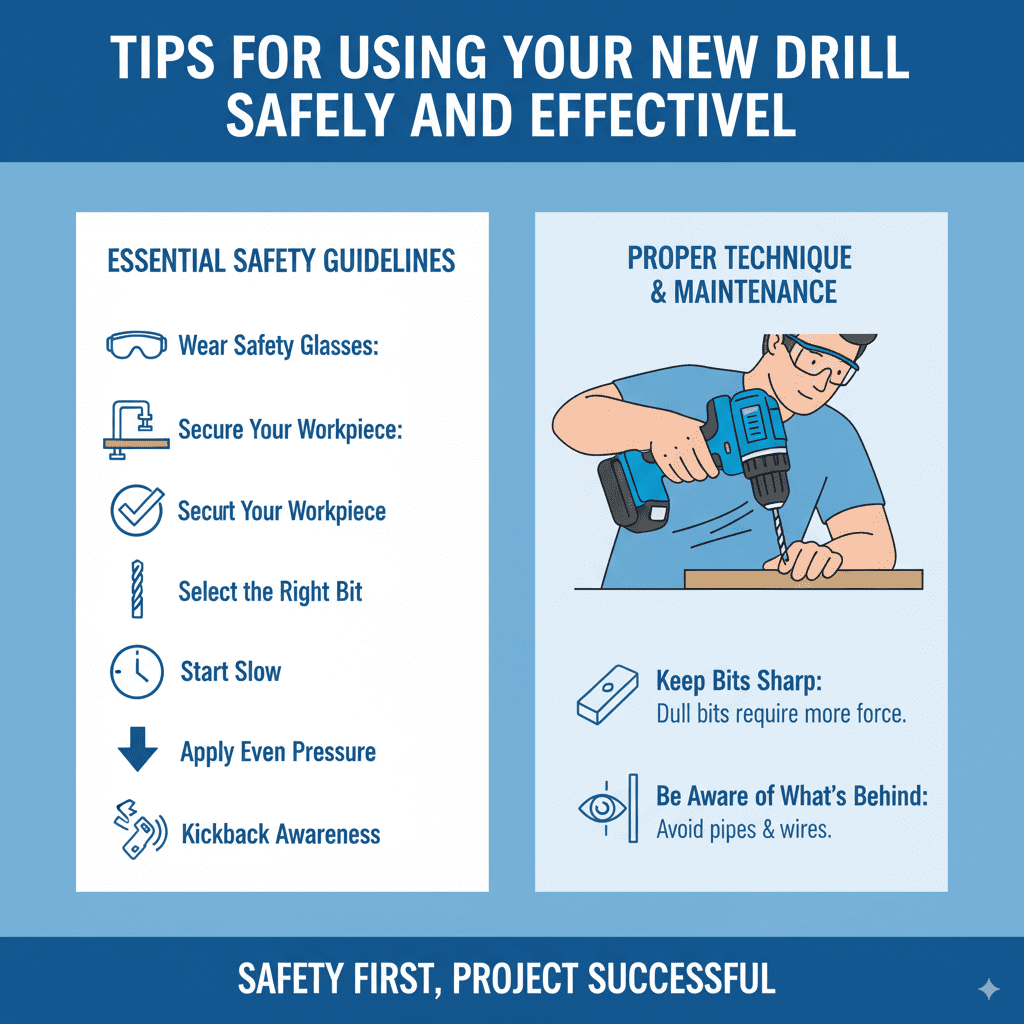

Tips for Using Your New Drill Safely and Effectively

No matter which drill you choose, safety and proper technique are paramount. Here are a few tips:

- Wear Safety Glasses: Always protect your eyes from flying debris.

- Secure Your Workpiece: Use clamps to hold your material steady, especially when freehand drilling.

- Select the Right Bit: Use drill bits designed for the material you’re working with. A wood bit won’t work well on masonry, and vice-versa. You can find great resources on choosing the right drill bit, like those from tool manufacturers or construction guides. For example, Popular Mechanics offers a comprehensive guide to different types of drill bits.

- Start Slow: Begin drilling at a slower speed, especially when starting a hole or working on hard surfaces. This prevents the bit from wandering and creates a cleaner entry point.

- Apply Even Pressure: Don’t force the drill. Let the tool do the work.

- Keep Bits Sharp: Dull bits require more force, can overheat, and produce rougher holes. A simple sharpening tool can extend the life of your bits.

- Kickback Awareness: Be aware of kickback (sudden, forceful jerking of the drill). This can happen if a bit binds in the material. Maintain a firm grip and be prepared. The Occupational Safety and Health Administration (OSHA) provides detailed safety guidelines for using power tools.

Frequently Asked Questions About 1/2 In Vs 1/4 In Drills

Q1: Can a 1/4 inch drill handle most household tasks?

Yes, for basic tasks like hanging pictures, assembling flat-pack furniture, and small repairs, a 1/4 inch drill driver is often sufficient. It excels at driving screws and drilling small pilot holes accurately.

Q2: Is a 1/2 inch drill too much for a beginner?

Not at all! A 1/2 inch drill, especially a cordless drill driver, is an excellent choice for beginners. It offers more versatility, allowing you to tackle a wider range of projects as your skills grow. You can still use it for small tasks; just be mindful of the power and leverage.

Q3: Do I need a special drill for mixing paint?

You can use a 1/2 inch drill with a mixing paddle attachment for small paint jobs. The key is the torque and power of the drill. Ensure the drill has a low-speed setting and a sturdy grip for this task.

Q4: What is the main difference in terms of power between a 1/4 inch and 1/2 inch drill?

While chuck size isn’t a direct measure of power (which is usually measured in volts for cordless or amps for corded), 1/2 inch chucks are typically found on more powerful, higher-torque drills. These drills are better equipped to handle resistance, larger bits, and tougher drilling jobs.

Q5: Can a 1/4 inch drill use larger drill bits if I buy an adapter?

It’s generally not recommended. While chucks can sometimes accept adapters for different shank sizes, using an adapter with a drill that isn’t designed for larger bits can put undue stress on the motor, gears, and chuck, potentially leading to tool damage or unsafe operating conditions. It’s best to get a drill with the appropriate chuck size for the bits you intend to use.

Q6: Should I buy a corded or cordless drill?

For most DIYers, cordless drills offer the best balance of convenience and power. Cordless drills provide freedom of movement, which is invaluable for most projects. Corded drills are great if you need unlimited power for extremely demanding, stationary tasks or if budget is the absolute primary concern and you don’t mind being tethered.

Q7: How do I know if I need a hammer drill?

If you anticipate drilling into brick, concrete, stone, or other masonry materials, you will need a hammer drill. If your projects are limited to wood, drywall, and lighter materials, a standard drill driver will suffice.