1/2 vs 3/8 Drill: Essential Facts

Choosing between a 1/2 inch and 3/8 inch drill chuck size is simpler than it sounds. For most DIY and home projects, a 3/8 inch drill is perfectly capable and more common. A 1/2 inch drill is generally for heavier-duty tasks requiring larger bits. This guide will help you understand the differences so you can pick the right tool for your needs.

Hey there, woodworkers and DIY fans! Md Meraj here, ready to clear up a common question that pops up when you’re stocking your tool collection: what’s the real difference between a 1/2 inch drill and a 3/8 inch drill, and which one do you actually need? It can seem a bit confusing at first, especially when you’re just starting out. But don’t worry, we’ll break it down into simple terms you can easily understand.

Understanding this difference is key to making sure you have the right tool for the job, saving you frustration and helping you get projects done right the first time. You want a drill that works with the bits you have and tackles the tasks you plan to do. We’ll cover what those numbers mean, where each drill shines, and how to decide which one is best for your workshop or toolbox.

By the end of this guide, you’ll feel confident knowing exactly what to look for and why. Ready to dive in?

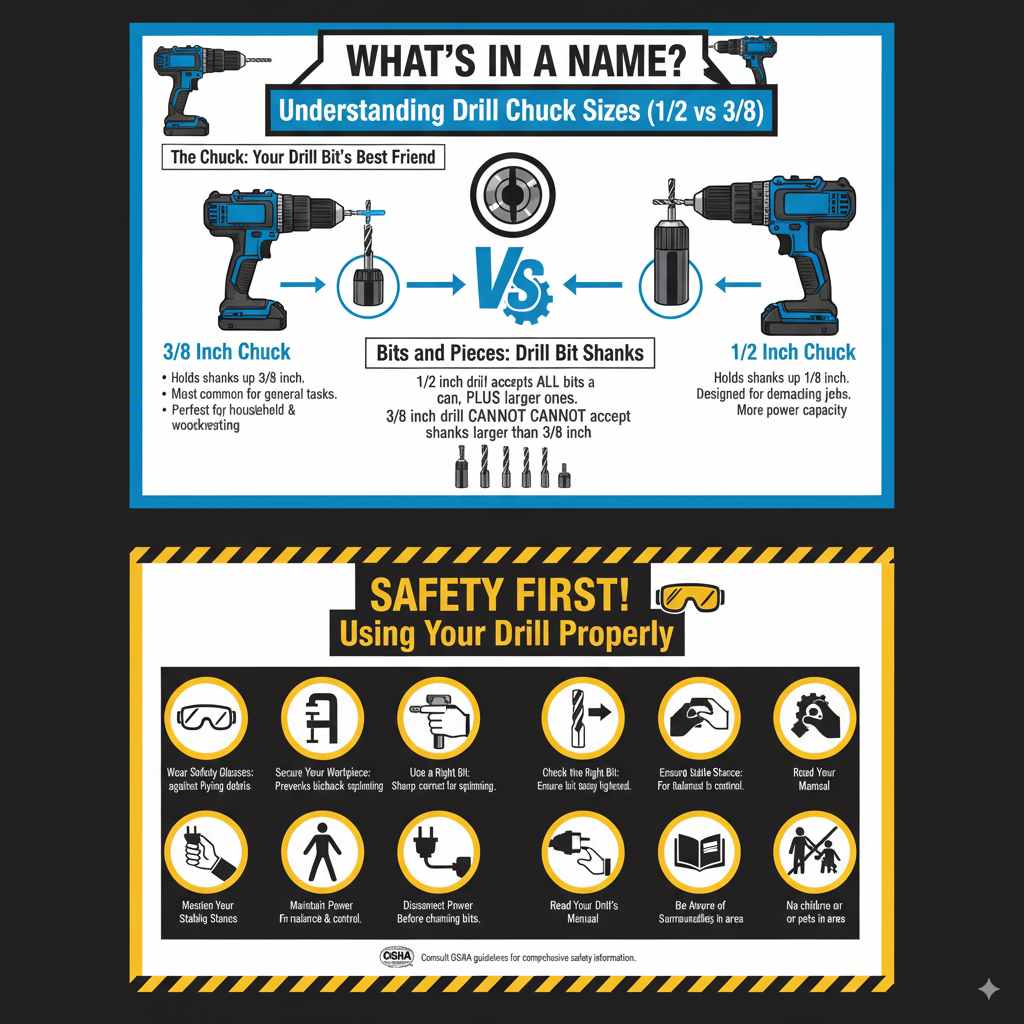

What’s in a Name? Understanding Drill Chuck Sizes (1/2 vs 3/8)

The numbers “1/2 inch” and “3/8 inch” refer to the maximum diameter of a drill bit shank that the drill’s chuck can securely hold. Think of the chuck as the drill’s “hand” that grips the drill bit. This size is a good indicator of the drill’s overall power and intended use.

The Chuck: Your Drill Bit’s Best Friend

The chuck is the part of the drill that tightens around the drill bit. It usually has jaws that move in and out to grip bits of different sizes. The size of the chuck opening tells you the largest bit shank it can accommodate.

- 3/8 Inch Chuck: This means the chuck can hold drill bits with shanks up to 3/8 of an inch in diameter. It’s the most common size for general-purpose drills, perfect for most household tasks and woodworking projects.

- 1/2 Inch Chuck: This chuck can grip bits with shanks up to 1/2 inch in diameter. This larger capacity usually means the drill is designed for more demanding jobs.

Bits and Pieces: Drill Bit Shanks

Drill bits come with different types of shanks, but for this discussion, we’re focusing on round shanks (or hex shanks that fit within the chuck’s capacity). The shank is the part of the bit that goes into the drill chuck. While you can often use smaller bits in a larger chuck, you generally cannot use a bit with a shank larger than your chuck’s maximum capacity.

This means a 1/2 inch drill can accept all the bits a 3/8 inch drill can, plus larger ones. A 3/8 inch drill, however, cannot accept bits made with shanks larger than 3/8 of an inch. This fundamental difference hints at the intended power and application of each tool.

The 3/8 Inch Drill: Your Everyday Workhorse

If you’re looking for a drill for around the house, for simple DIY projects, or light woodworking, a 3/8 inch drill is likely what you need. It’s versatile, lightweight, and perfectly suited for tasks that don’t require a lot of brute force.

Key Features and Benefits of a 3/8 Inch Drill:

- Versatility: It handles a wide range of everyday tasks, from hanging shelves and assembling furniture to drilling pilot holes for screws and basic wood drilling.

- Commonality: Most drill bits you find at hardware stores are designed for 3/8 inch chucks, making them readily available and more affordable.

- Maneuverability: Typically lighter and more compact than 1/2 inch drills, making them easier to handle in tight spaces or for extended use.

- Affordability: Generally less expensive than 1/2 inch models, making it a budget-friendly choice for beginners.

- Power for Most Jobs: For drilling through drywall, wood, plastic, or even light masonry, a 3/8 inch drill provides sufficient power.

Think of your 3/8 inch drill as your go-to tool for most of the things you’ll encounter as a DIYer. It’s comfortable, capable, and covers a vast majority of home improvement needs without overcomplicating things.

The 1/2 Inch Drill: For Tougher Jobs

When your projects get larger, your materials denser, or you need to use bigger, more powerful drill bits, that’s when a 1/2 inch drill comes into play. These drills are built for more demanding work.

When and Why You Might Need a 1/2 Inch Drill:

- Heavy-Duty Tasks: Ideal for drilling large holes through thick lumber, driving long, large-diameter screws, or using hole saws for bigger openings.

- More Power: Generally paired with a more powerful motor, allowing them to handle tougher materials and prolonged use before overheating.

- Larger Bit Capacity: The main advantage is accommodating bits with shanks up to 1/2 inch in diameter. This is crucial when you need bits like large spade bits, auger bits, or specific large-diameter hole cutters.

- Professional or Frequent Use: If you’re a contractor, a serious woodworker, or use your drill extensively, a 1/2 inch model often offers better durability and performance.

- Mixing Concrete or Paint: These drills can often be used with mixing paddle attachments for small batches of concrete, mortar, or paint.

A 1/2 inch drill is designed for those moments when your standard drill just isn’t cutting it. It’s about having the extra muscle and capacity for jobs that require more than just a gentle touch.

Direct Comparison: 3/8 Inch vs. 1/2 Inch Drill

Let’s lay it out side-by-side so you can see the key differences clearly. This comparison will highlight why one might be better than the other for specific scenarios.

| Feature | 3/8 Inch Drill | 1/2 Inch Drill |

|---|---|---|

| Max Bit Shank Diameter | 3/8 inch (approx. 9.5mm) | 1/2 inch (approx. 12.7mm) |

| Typical Use Cases | General home repairs, DIY projects, assembling furniture, small to medium drilling in wood, metal, plastic. | Heavy-duty construction, large-diameter holes, driving large screws, auger bits, hole saws, mixing small batches of material. |

| Power | Sufficient for most common tasks; can struggle with very dense materials or large bits. | More powerful motor; designed for tougher materials and sustained heavy use. |

| Weight & Size | Generally lighter and more compact; easier to handle and maneuver. | Often heavier and bulkier due to a larger motor and more robust construction. |

| Bit Availability | Widest selection of standard drill bits. | Can use all 3/8″ bits plus larger diameter bits. |

| Cost | Typically more affordable. | Generally more expensive. |

| Ideal User | Homeowners, beginner DIYers, crafters, hobbyists. | Professional tradespeople, serious woodworkers, those tackling frequent heavy-duty tasks. |

As you can see, the primary distinction lies in the maximum bit size they can handle, which is directly correlated with their intended power and application. A 3/8 inch drill is the versatile choice for the vast majority of users, while a 1/2 inch drill is a specialized tool for more demanding scenarios.

Choosing the Right Drill for Your Needs

So, how do you decide? It really comes down to what you plan to do with your drill. Think about your current projects and what you might tackle in the future.

Ask Yourself These Questions:

- What kind of materials will I be drilling into most often? Softwoods? Hardwoods? Metal? Masonry?

- How large will the holes I need to drill typically be? Are we talking about 1/4 inch holes for screws, or 1.5 inch holes for plumbing?

- How often will I be using the drill? For occasional weekend projects, or daily for work?

- What is my budget?

- Do I need to drive large screws into challenging material?

General Recommendations:

- For the average homeowner or beginner DIYer: A 3/8 inch drill is almost always the best choice. It’s cost-effective, versatile, and powerful enough for 90% of tasks you’ll encounter, like hanging pictures, assembling furniture, or starting a simple woodworking project. You can find great consumer guides on selecting power tools that often highlight this versatility.

- For serious woodworkers, contractors, or anyone who frequently deals with large holes or dense materials: A 1/2 inch drill might be a worthwhile investment. It offers the capacity for larger bits and the extra power needed for tougher jobs.

Don’t feel pressured to buy the biggest or most powerful drill if you don’t need it. Choosing the right tool for the job not only saves you money but also makes your work easier and more enjoyable.

Corded vs. Cordless: Another Important Consideration

While we’re talking about drill sizes, it’s worth mentioning the corded versus cordless debate, as this often goes hand-in-hand with drill power and chuck size.

Cordless Drills: Freedom to Move

Cordless drills are fantastic for convenience. Battery-powered, they give you the freedom to work anywhere without being tethered to an outlet. They come in both 3/8 inch and 1/2 inch chuck sizes.

- Pros: Portability, ease of use in remote locations, no tripping hazard from cords.

- Cons: Battery life limitations, batteries need charging, can be more expensive upfront (especially with extra batteries), often have slightly less raw power than corded counterparts in the same class.

Corded Drills: Uninterrupted Power

Corded drills plug into an outlet, providing consistent power without worrying about battery life. These can also come with either chuck size.

- Pros: Unlimited run time, often more powerful for their size, generally less expensive than cordless equivalents, lighter without a battery pack.

- Cons: Requires a nearby power outlet, cord management can be a hassle, limited to where you can reach with the cord.

For most DIYers, a cordless drill in the 3/8 inch size is the sweet spot. If you’re doing heavy-duty work that requires maximum, consistent power for long periods, a corded 1/2 inch drill might be superior. Many professionals opt to have both types!

Drill Bit Types and How They Relate

The type of drill bit you choose is just as important as the drill itself. Different bits are designed for different materials and tasks.

- Twist Bits: The most common type, used for drilling holes in wood, metal, and plastic.

- Spade Bits (Paddle Bits): Flat bits with a pointed tip, used for drilling larger diameter holes (typically 1/4 inch up to 1.5 inches or more) quickly in wood. These often have shanks that will fit in a 1/2 inch chuck.

- Auger Bits: These have a screw tip and spiral flutes to help efficiently bore large holes (often 1/2 inch up to 2 inches or more) through wood, clearing out material as they go. These almost always require a 1/2 inch chuck on the drill.

- Forstner Bits: Used for drilling clean, flat-bottomed holes in wood, often for mounting hinges. They can create precise holes for joinery.

- Masonry Bits: Designed for drilling into brick, concrete, and stone.

- Hole Saws: Cylindrical saws used to cut large-diameter holes in wood, metal, or plastic. They have a pilot bit in the center and a saw blade around the edge. Larger ones (over 1 inch) will usually require a 1/2 inch drill.

When selecting drill bits, always ensure their shank size is compatible with your drill’s chuck. Bits designed for 1/2 inch chucks are generally larger and meant for more substantial tasks, reinforcing the idea that a 1/2 inch drill is for heavier work. For a deeper dive into drill bits, resources like those from Wood Magazine offer excellent insights.

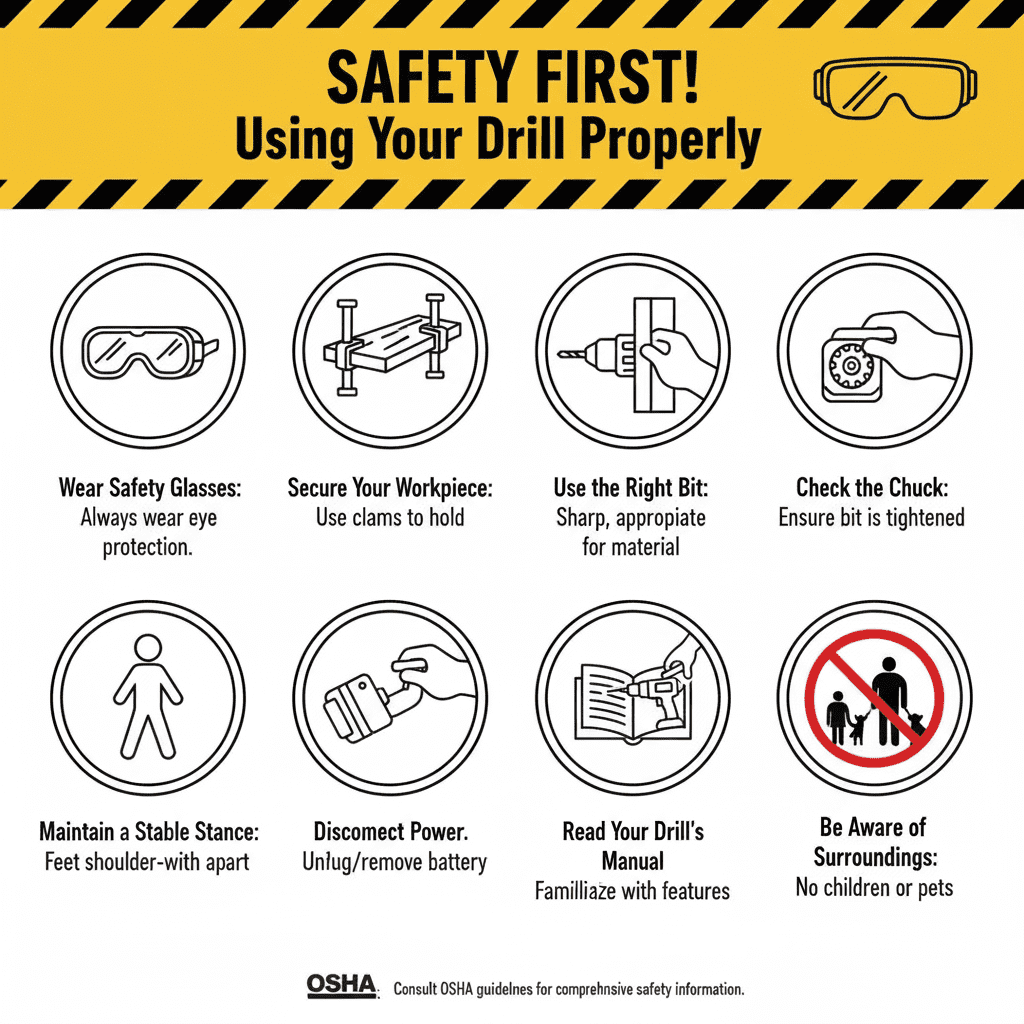

Safety First! Using Your Drill Properly

No matter which drill you choose, safety should always be your top priority. Working with power tools can be dangerous if precautions aren’t taken.

Essential Safety Tips:

- Wear Safety Glasses: Always wear eye protection to guard against flying debris.

- Secure Your Workpiece: Use clamps to hold your material firmly in place. This prevents the drill from kicking back or the material from spinning uncontrollably.

- Use the Right Bit for the Job: Ensure your drill bit is sharp, appropriate for the material, and its shank is compatible with your drill’s chuck.

- Check the Chuck: Make sure the drill bit is securely tightened in the chuck before you start drilling.

- Maintain a Stable Stance: Stand with your feet shoulder-width apart for balance.

- Disconnect Power When Changing Bits: For corded drills, unplug them. For cordless drills, remove the battery before changing bits.

- Read Your Drill’s Manual: Familiarize yourself with the specific features and safety instructions for your tool.

- Be Aware of Your Surroundings: Ensure no children or pets are in the immediate work area.

Following these simple steps will help ensure a safe and successful experience every time you use your drill, whether it’s a 3/8 inch or a 1/2 inch model.

Frequently Asked Questions (FAQ)

Q1: Can I use a 3/8 inch drill bit in a 1/2 inch drill chuck?

A: Yes, absolutely! A 1/2 inch drill chuck is designed to hold bits with shanks up to 1/2 inch. This means it can easily accommodate all smaller bits, including those with 3/8 inch shanks.

Q2: Can I use a 1/2 inch drill bit in a 3/8 inch drill chuck?

A: No, you cannot. A 3/8 inch drill chuck has a maximum capacity of 3/8 inch. A drill bit with a 1/2 inch shank will be too large to fit into and be gripped by the chuck.

Q3: Which type of drill is better for drilling into concrete?

A: For concrete, you’ll need a hammer drill or a rotary hammer, which are specialized tools designed for this purpose. While some powerful 1/2 inch drills might have a hammer setting, they are not as effective as dedicated hammer drills for masonry.

Q4: I’m just starting out with DIY. Should I buy a 3/8 inch or 1/2 inch drill?

A: For most beginners and general home use, a 3/8 inch drill is the best starting point. It’s versatile, more affordable, and sufficient for a wide range of common tasks. You can always add a specialized tool like a 1/2 inch drill later if your projects require it.

Q5: Does a 1/2 inch drill mean it’s more powerful than any 3/8 inch drill?

A: While 1/2 inch drills are often paired with more powerful motors, it’s not a direct guarantee. Power is also measured in amps (for corded) or voltage and amperage-hours (for cordless batteries). However, 1/2 inch drills are generally built for higher torque and sustained heavy use, suggesting more overall robust power.