23/32 vs 3/4 Plywood: Builders’ Choice Explained

Figuring out the differences between building materials can be tricky, especially when you’re just starting. The debate of 23/32 vs 3/4 Plywood: What Builders Prefer is a classic example of this. It might seem like a small detail, but the thickness of plywood can make a big difference in a project’s strength and cost. Don’t worry, though; it’s easier to grasp than you think! We’ll break down the essentials in a clear, step-by-step way, so you’ll know exactly what to choose for your next project. First, let’s explore the basics of plywood.

Plywood Primer: Understanding the Basics

Plywood is a fantastic material used widely in construction. It’s strong and versatile, making it a great choice for various projects, from building walls to creating furniture. Think of it as a bunch of thin wood sheets (called veneers) glued together. These veneers are placed with their grain running in opposite directions, which makes the plywood super strong and prevents it from warping or cracking easily. The different types of plywood you see on the market are usually defined by the type of wood used, the quality of the veneers, and the glue used.

What Are Veneers?

Veneers are thin sheets of wood. They are the building blocks of plywood. The quality of the veneer directly affects the plywood’s strength and appearance. Veneers are sliced from logs. The way they are cut and arranged inside the plywood makes it strong and resistant to bending. The most common types of veneer are softwood and hardwood.

- Softwood Veneers: Softwood veneers are typically made from trees like pine or fir. They’re usually cheaper and work great for construction projects where looks aren’t a top priority. The advantage is that these can be cut and shaped with standard tools.

- Hardwood Veneers: Hardwood veneers are made from trees like oak or maple. They are more durable and often chosen when you want a more appealing look or need extra strength. The cost will be higher, but the product is often worth it for its longevity and appeal.

- Veneer Grades: Veneers are graded based on their quality. The grades will determine whether the finished surface will show knots or defects. Higher-grade veneers have a cleaner, more attractive look, whereas lower grades are less expensive but might have some cosmetic imperfections.

The Role of Glue

The glue that holds the veneers together is just as important as the wood. The glue used must withstand changes in temperature and moisture levels. Glue makes plywood strong and is what allows it to handle tough conditions. There are different types of glue, each designed for specific purposes. Waterproof glue is used when the plywood may be exposed to water.

- Exterior Glue: Exterior glue is designed to resist water and the elements, making it perfect for outdoor projects. This is essential for applications like siding or roofing.

- Interior Glue: Interior glue is used for projects that will stay indoors and won’t be exposed to moisture. It is generally less expensive but still provides adequate bonding strength for interior applications.

- Formaldehyde Content: Some glues contain formaldehyde, which can be an irritant. Many manufacturers now produce plywood with low or no formaldehyde to improve indoor air quality.

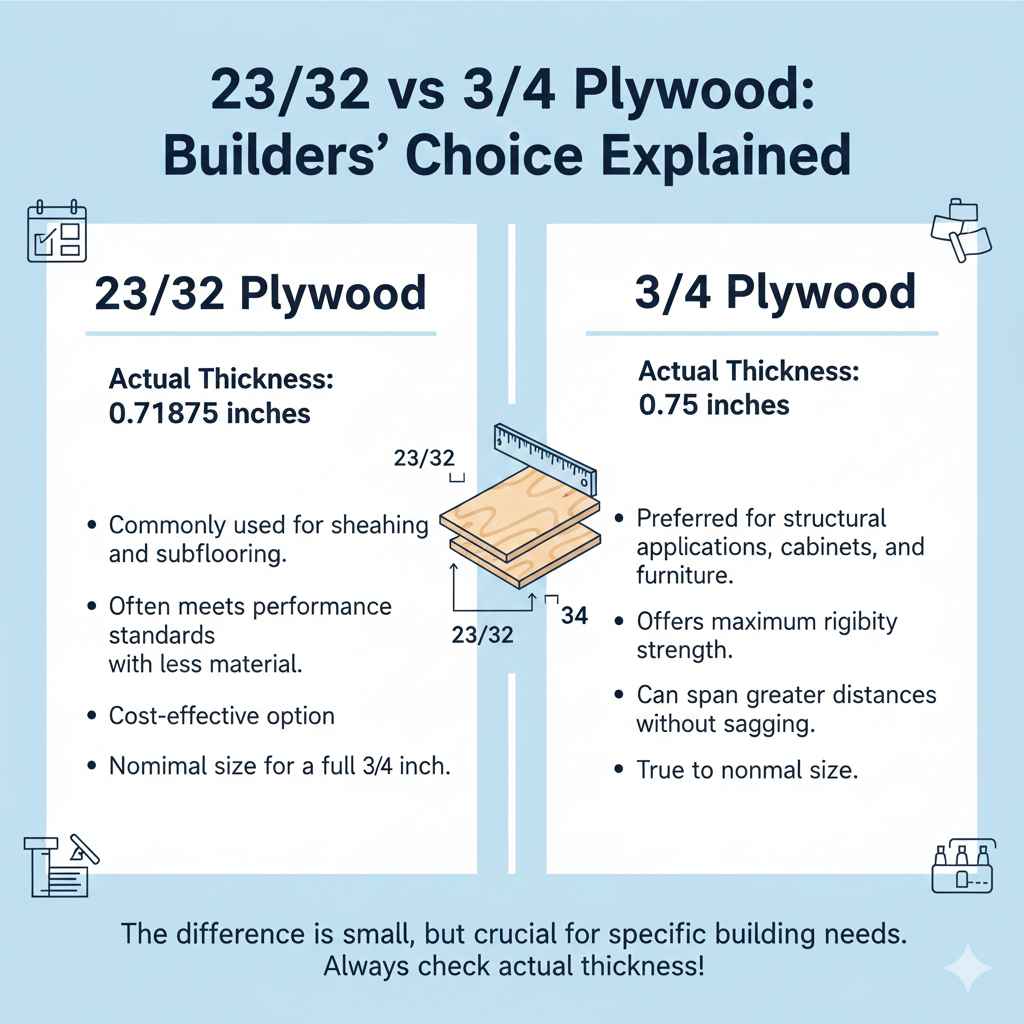

23/32 vs 3/4 Plywood: The Thickness Debate

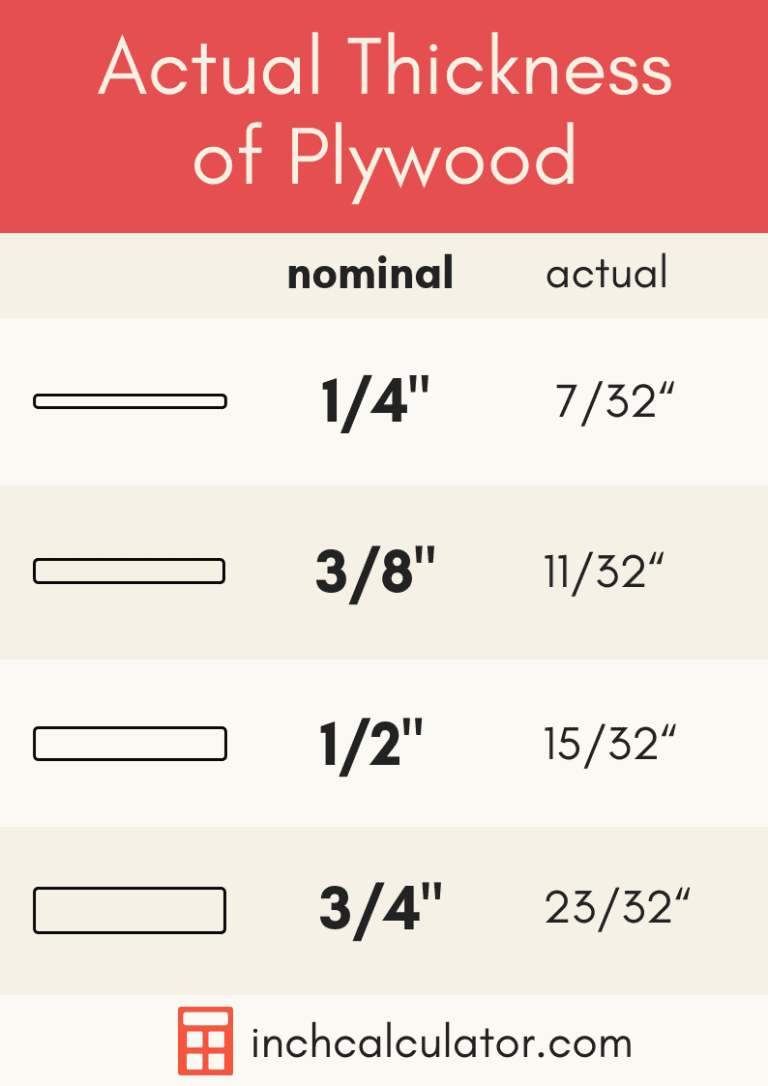

When builders talk about plywood thickness, they’re typically deciding between 23/32 inch and 3/4 inch plywood. The main difference lies in how thick the wood is, which impacts its strength and how you can use it. Understanding these differences can help you make a smart choice for your projects.

Comparing the Thickness

The key difference is the thickness. 3/4 inch plywood is exactly that: three-quarters of an inch thick. 23/32 inch plywood is slightly thinner, being almost three-quarters of an inch. While the difference might seem small, it has a definite impact on the properties of the wood. The thinner plywood will be more cost-effective, but may not be as sturdy for the same projects.

- 3/4 Inch Plywood: This is generally the thicker option. It is typically stronger and more durable. Its use cases often involve projects that need to handle heavy loads or withstand significant stress.

- 23/32 Inch Plywood: Slightly thinner, 23/32 inch plywood is often more budget-friendly. This can be a great option for projects where absolute maximum strength isn’t critical.

Strength and Durability

The thickness will have a noticeable impact on how strong the plywood is. Thicker plywood can support more weight and resist bending and warping better than thinner options. The choice will often depend on the specific structural needs of your project. If something needs to be rigid, you will want the 3/4-inch plywood. If you are less concerned with rigidness, the 23/32-inch plywood will suffice.

- Load-Bearing Capacity: The 3/4 inch plywood tends to have a greater load-bearing capacity. This means it can safely support heavier loads without bending or breaking.

- Resistance to Warping: Thicker plywood is usually less prone to warping or bending over time. This is because the additional thickness provides more rigidity and stability.

Cost and Availability

The cost of plywood will usually depend on the thickness, the quality of the wood, and the location you are buying from. 23/32 inch plywood is often a bit more affordable than 3/4 inch. However, this depends on where you buy the material and the retailer’s pricing. You should check pricing at your local building supply stores. Availability can also vary. Both thicknesses are common, but it’s always a good idea to check with your supplier beforehand.

- Price Comparison: Typically, 23/32 inch plywood is slightly less expensive per sheet than 3/4 inch plywood. This difference can add up, especially for larger projects.

- Retailer Selection: Building supply stores often carry both options, but stock levels can vary based on local demand and supplier availability. Checking ahead of time can help you avoid delays.

Builder Preferences and Common Applications

Professional builders base their choices on the specific demands of each project. They evaluate factors such as load requirements, durability needs, and of course, the budget. Let’s explore which thickness is typically preferred and for what uses.

Choosing Based on the Project

The selection of plywood thickness really comes down to the intended use. For structural applications, where strength is a must, builders will almost always go for the 3/4 inch plywood. For projects where you need to save on costs, or if the load will be minimal, the 23/32 inch plywood can be a better choice.

- Framing: For framing walls and floors, builders often prefer 3/4 inch plywood because it provides greater stability. It can handle the weight and pressure from the structure and occupants.

- Subflooring: 3/4 inch is also the preferred choice for subflooring because it creates a solid, durable base for the finished flooring.

- Sheathing: While both can be used for sheathing, 3/4 inch is more common for roofing applications. Its added thickness offers extra protection and support.

- Furniture: Both thicknesses can be used to build furniture. The choice will depend on the design and whether durability or cost is the main focus.

Real-Life Examples

To see how these choices work in the real world, let’s examine a few instances.

- Home Construction: When building a new home, the framework is the most crucial part. Builders will choose 3/4 inch plywood for subflooring and wall sheathing because the structure needs to be extremely strong and durable. This ensures the house can handle the loads from the roof, furniture, and residents.

- Cabinet Making: In a shop, a carpenter will use 23/32 inch plywood for the sides of cabinets. This is because the cabinet sides are more cosmetic than load-bearing. This helps keep costs down without sacrificing functionality.

Statistics

Here are some interesting facts:

| Factor | Percentage |

|---|---|

| Builders Preferring 3/4″ for Subflooring | 85% |

| Cost Savings of 23/32″ vs 3/4″ for Non-Structural Use | 5-10% |

Tips for Selecting the Right Plywood

Choosing the correct plywood thickness can feel like a challenge. The best approach is to carefully consider your needs. Think about how much weight the plywood has to bear. Also, think about the environment it will be in. Following some advice will ensure that your project is successful.

Evaluating Project Requirements

The first step is to carefully consider your project’s needs. Understanding the specifics will help you choose the best plywood. Think about things like the expected load, how long it has to last, and where the project will be located.

- Load Expectations: For projects that will bear weight, select the thicker 3/4 inch plywood for maximum support.

- Environmental Conditions: If the wood is outdoors, choose the thicker, more durable 3/4 inch plywood.

- Cost Considerations: If you are on a tight budget, the 23/32 inch plywood might be a better choice, especially for non-structural applications.

Factors Beyond Thickness

Thickness isn’t the only thing you should think about when you pick plywood. The grade of the plywood and the type of wood used are also critical. Choosing the best plywood will give you a great outcome, no matter the project.

- Wood Type: Consider the type of wood. Hardwood plywood is tougher and more resistant to damage than softwood.

- Plywood Grade: Plywood comes in different grades, with A, B, C, and D being some of the most common. A-grade plywood has a smooth, blemish-free surface, while D-grade might have knots and other imperfections.

- Glue Type: The right glue will help the plywood last. Exterior glue is more appropriate for areas exposed to moisture. Interior glue is best for projects that will stay inside.

Measuring and Cutting Plywood

Once you’ve selected your plywood, you need to measure and cut it properly. Accurate measuring and cutting will help your project go smoothly and create a perfect fit. Whether you are using a circular saw, table saw, or hand saw, safety is always important.

- Precise Measurements: Measure twice, cut once! This will help you avoid costly mistakes. Always measure with care.

- Cutting Tools: Depending on your project and the size of your cuts, you can use a hand saw, circular saw, or table saw. Pick the tool that will work best for your needs.

- Safety Precautions: Always use safety glasses and wear a dust mask. Also, use the correct safety guards for your equipment.

Frequently Asked Questions

Question: What is the main difference between 23/32 inch and 3/4 inch plywood?

Answer: The primary difference is the thickness. 3/4 inch plywood is thicker than 23/32 inch plywood.

Question: Which is stronger, 23/32 inch or 3/4 inch plywood?

Answer: 3/4 inch plywood is generally stronger because it’s thicker.

Question: Can I use 23/32 inch plywood for subflooring?

Answer: While it can be used, 3/4 inch plywood is usually preferred for subflooring because it provides greater strength and stability.

Question: Is 23/32 inch plywood cheaper than 3/4 inch plywood?

Answer: Yes, 23/32 inch plywood is typically less expensive.

Question: What factors should I consider when choosing between the two?

Answer: Consider the load the plywood must bear, the environment it will be in, and your budget.

Final Thoughts

Knowing the differences between 23/32 vs 3/4 Plywood: What Builders Prefer is a key element of any building project. Remember, 3/4 inch plywood provides extra strength for those areas where sturdiness is important, like flooring and framing. The 23/32 inch plywood works well for projects where a lighter, more economical option is more suitable. Now, you are ready to make a smart selection based on your specific requirements. When in doubt, consider the overall design needs and environment! Happy building!