5 32 vs 7 32 Drill Bit: Essential Guide

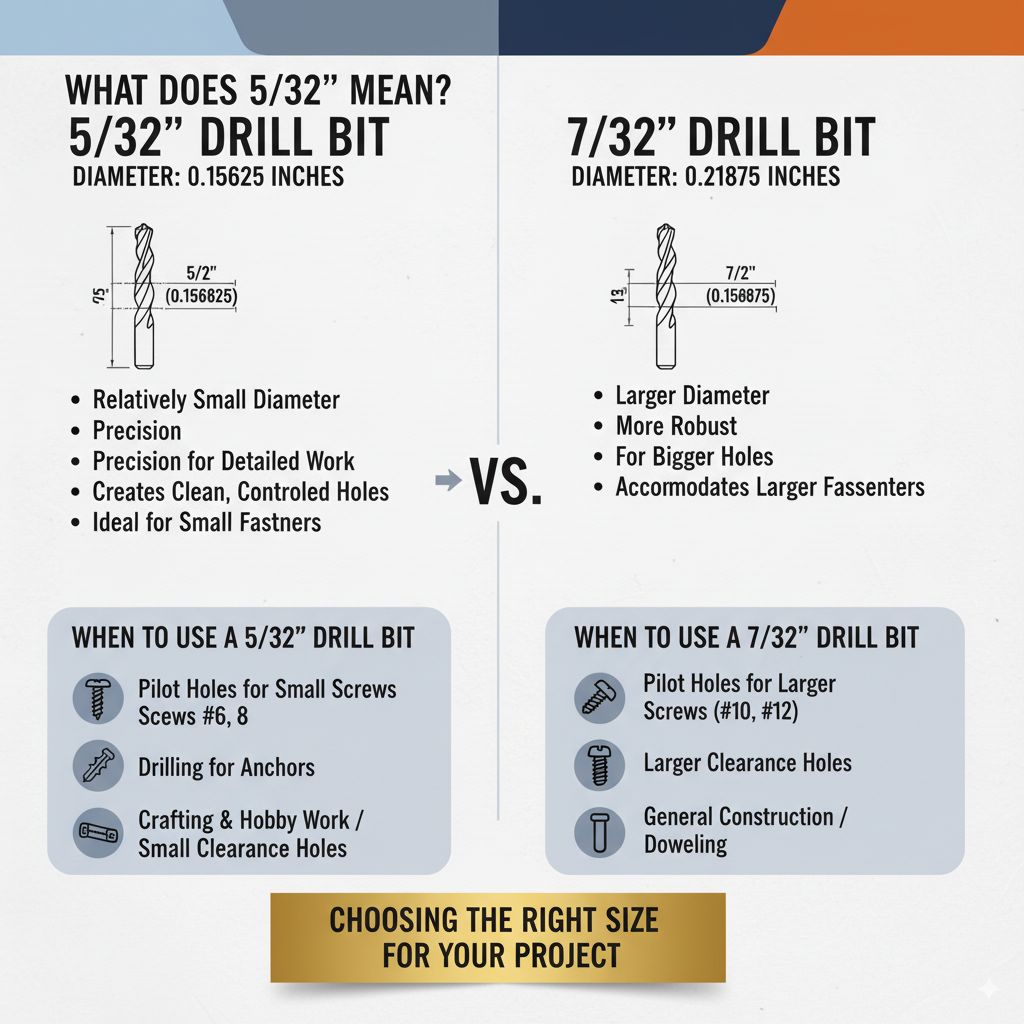

The main difference between a 5/32″ and 7/32″ drill bit lies in their diameter. A 5/32″ bit creates a smaller hole (0.156 inches), ideal for smaller screws, pilot holes, and detailed work. A 7/32″ bit creates a larger hole (0.218 inches), suitable for larger screws, more robust pilot holes, and general drilling tasks. Choosing the right size ensures a strong, clean, and accurate result for your project.

Hey there, fellow DIY enthusiasts and woodworkers! Ever stared at a toolbox, or maybe just a tiny drawer filled with drill bits, and wondered which one is the right one for the job? It’s a question that pops up more often than you might think, especially when you’re starting out. Today, we’re going to demystify two common drill bit sizes: the 5/32″ and the 7/32″. They might seem similar, just a little bit different in size, but that small difference can be crucial for the success of your project. We’ll break down exactly what they are, when to use each one, and how to pick the perfect bit every time. Get ready to gain some serious confidence in your drilling!

Understanding Drill Bit Size Matters

Drill bits are the workhorses of any drilling task. They’re the part that actually makes the hole. The size of a drill bit, denoted by its diameter, is the most important characteristic to consider. Using the correct size is like using the right key for a lock – it ensures everything fits together perfectly. Too small, and your screw won’t go in or will split the wood. Too large, and your screw will be loose and won’t hold anything securely.

For beginners, particularly in woodworking, making that perfect pilot hole or drilling for fasteners can feel a bit daunting. You want a hole that’s just right: not too tight, not too loose. This is where understanding specific sizes, like the difference between a 5/32″ and a 7/32″ drill bit, becomes incredibly helpful. It’s a small detail, but it makes a world of difference in the quality and durability of your finished project. Let’s dive into what makes these two bits distinct and how you can use them to your advantage.

What Does 5/32″ Mean?

When we talk about a 5/32″ drill bit, we’re referring to its diameter. The “5/32″ is a fraction of an inch, indicating the width of the hole the bit will create. To be precise, 5/32” translates to approximately 0.15625 inches. This is a relatively small diameter, making it a go-to for tasks that require precision and don’t need to accommodate large fasteners.

Think of it as a fine-tipped pen compared to a marker. It’s for detailed work, for making neat, controlled holes. It’s often used to create pilot holes for smaller screws, like those you might find in furniture assembly, electronics, or delicate woodworking projects. It’s also perfect for drilling smaller clearance holes or for tasks where you need to be extra careful not to split thin or brittle materials.

When to Use a 5/32″ Drill Bit

The 5/32″ drill bit is your friend for many smaller, detail-oriented tasks around the workshop and home. Here are some common scenarios where it shines:

- Pilot Holes for Small Screws: If you’re attaching small hinges, drawer pulls, or assembling furniture with smaller screws (often #6 or #8 wood screws), a 5/32″ bit is typically the ideal size for creating a pilot hole. This prevents the wood from splitting and makes driving the screw much easier.

- Drilling for Anchors: For small wall anchors used for hanging lightweight pictures or decorations, a 5/32″ bit is often the specified size to ensure a snug fit.

- Creating Smaller Clearance Holes: If you need a hole that a small bolt or screw can pass through easily without being threaded, this bit size is perfect.

- Crafting and Hobby Work: For delicate craft projects, model building, or any situation where you need to make small, clean holes in materials like thin plywood, plastic, or even certain metals, the 5/32″ bit is a great choice.

- Starting Holes for Larger Bits: Sometimes, you might use a 5/32″ bit to create a pilot hole for a larger bit if you need to be very precise about where the larger hole will start.

It’s essential to consult the screw or fastener manufacturer’s recommendations for pilot hole sizes, as these can vary slightly. However, for general woodworking purposes with common small screws, 5/32″ is a very frequent recommendation.

What Does 7/32″ Mean?

Moving on to the 7/32″ drill bit, we’re stepping up in size. This bit creates a hole with a diameter of 7/32″, which is equivalent to approximately 0.21875 inches. As you can see, it’s noticeably wider than the 5/32″ bit. Imagine trading that fine-tipped pen for a slightly bolder marker – it covers more ground and is suitable for slightly more substantial tasks.

This bit size is excellent for creating pilot holes for medium-sized screws, particularly wood screws in the #10 to #12 range. It’s also a good choice for drilling clearance holes for bolts and machine screws of comparable size. It strikes a balance between being large enough for many common fasteners and small enough to still provide a good amount of material for the threads of your screw to grip onto.

When to Use a 7/32″ Drill Bit

The 7/32″ drill bit enters the scene when your project demands slightly larger fasteners or holes. Here’s where it’s most commonly used and why:

- Pilot Holes for Medium to Large Screws: When you’re working with sturdier wood, assembling larger furniture pieces, or attaching hardware that requires more strength, the 7/32″ drill bit is an excellent choice for pilot holes. This is particularly true for wood screws in the #10 to #12 size category.

- Clearance Holes for Bolts and Machine Screws: If you need a hole for a bolt or machine screw that you don’t want to be threaded, a 7/32″ bit provides a clean, slightly larger opening for these fasteners to pass through.

- General Drilling Tasks: For many everyday drilling tasks that don’t require the extreme precision of smaller bits, but aren’t massive jobs either, the 7/32″ bit is a reliable workhorse.

- Punching Holes in Thicker Materials: When working with slightly thicker planks of wood or even some softer metals where a larger hole is required for a fastener or clearance, this bit can be very effective.

- Preparing for Larger Fasteners: If you’re using screws that are explicitly recommended to have a pilot hole drilled with a bit around 0.2 inches in diameter, the 7/32″ is often the closest standard size.

Remember, the goal of a pilot hole is to guide the screw and prevent splitting, not to make it a loose fit. The 7/32″ bit helps achieve this for a range of common fasteners before you move to larger projects.

5/32″ vs. 7/32″ Drill Bit: Key Differences at a Glance

To make it super clear, here’s a table summarizing the crucial differences between these two popular drill bit sizes. Understanding these distinctions will help you grab the right bit from your toolbox without a second thought.

| Feature | 5/32″ Drill Bit | 7/32″ Drill Bit |

|---|---|---|

| Diameter (Fractional) | 5/32 inches | 7/32 inches |

| Diameter (Decimal) | Approximately 0.156 inches | Approximately 0.219 inches |

| Hole Size Comparison | Smaller | Larger |

| Ideal For | Small screws, delicate work, precise pilot holes, small anchors. | Medium to larger screws, general-purpose pilot holes, clearance holes for bolts. |

| Common Screw Sizes (Pilot Holes) | #6 to #8 wood screws (approx.) | #10 to #12 wood screws (approx.) |

| Pressure Required to Drive Screw | Less pressure needed; screw has more material to grip. | More pressure usually needed; screw has less material to grip, but still secure. |

| Risk of Splitting Wood | Lower, especially in softer woods or thin stock. | Slightly higher than 5/32″ if driven into very thin material without care. |

How to Choose the Right Drill Bit Size (The Smart Way!)

Picking the correct drill bit is more about understanding the relationship between the material, the fastener, and the hole size. Here’s a simple guide to help you make the right choice every time:

- Check Your Fastener: Always look at the screw, bolt, or anchor you plan to use. Most fasteners, especially those you buy from reputable brands, will have packaging that suggests the appropriate pilot hole size. This is your golden rule!

- Consider the Material: Are you drilling into soft pine, hardwood, plywood, metal, or plastic? Softer materials require smaller pilot holes to prevent splitting, while harder materials can often accommodate slightly larger pilot holes, or sometimes no pilot hole at all for very small screws.

- Understand Pilot Holes vs. Clearance Holes:

- Pilot Hole: This is a hole drilled before inserting a screw. It guides the screw and prevents the material from splitting. The pilot hole should be slightly smaller than the screw’s minor diameter (the diameter of the shaft without the threads). This allows the threads of the screw to bite into the material.

- Clearance Hole: This is a hole drilled for a bolt or screw to pass through freely. It should be slightly larger than the screw’s major diameter (the diameter including the threads). You want the fastener to slide through without resistance.

- Match Bit Size to Fastener Thread: For pilot holes, the general idea is to drill a hole that’s about 60-75% of the screw’s thread diameter. This equation gets complex quick, which is why consulting fastener packaging is so helpful. A 5/32″ bit is often good for smaller diameter screws where the thread is relatively thin, while a 7/32″ bit is suitable for screws with a meatier thread.

- When in Doubt, Test It: If you’re unsure, grab a scrap piece of the same material you’re working with. Drill a hole with the bit you think is right, then try to drive in your screw. If it splits the wood, the pilot hole was too small. If the screw feels loose and doesn’t tighten properly, the pilot hole might be too large (or the screw is stripped). Adjust your bit size and try again. This is the essence of learning and practice!

A Note on Screw Numbers and Sizes

Are you familiar with those wood screws labeled with just a number, like #6, #8, #10, or #12? These numbers are standardized ways to indicate the screw’s diameter. This is where our drill bit sizes often come into play:

- #6 Screws: Typically have a diameter of around 0.138 inches. A 1/8″ or 5/32″ drill bit is often recommended for pilot holes.

- #8 Screws: Have a diameter of about 0.164 inches. A 7/32″ drill bit is a common choice here, or sometimes a slightly smaller 9/64″ bit depending on wood hardness.

- #10 Screws: Measure around 0.190 inches in diameter. A 7/32″ drill bit is frequently used as a pilot hole.

- #12 Screws: Are about 0.216 inches in diameter. A 15/64″ or 1/4″ (which is 8/32″) bit might be used, with 7/32″ sometimes being a good starting point for softer woods.

Note: These are general guidelines. Wood hardness, grain direction, and specific screw thread pitch can influence the ideal pilot hole size. For serious woodworking, resources like the Woodworker’s Source blog offer comprehensive charts that can be very useful.

Drill Bit Materials and Types

While we’re talking about size, it’s worth a brief mention that drill bits come in different materials and types, which affect their performance. For general home and woodworking tasks, you’ll most often encounter:

- High-Speed Steel (HSS): This is the most common material for drill bits. HSS bits are durable, can withstand high temperatures generated during drilling, and are suitable for drilling wood, plastics, and many metals. They are a great all-around choice for anyone starting out.

- Twist Drill Bits: This is the standard, helical-fluted bit you likely think of when you hear “drill bit.” They are excellent for creating round holes in a variety of materials.

For most DIY projects, a good set of HSS twist drill bits in various common sizes (including 5/32″ and 7/32″) will serve you well. Always ensure your drill bit is sharp; a dull bit works harder, produces poorer results, and can be dangerous.

Safety First! Essential Drilling Tips

Drilling is a fundamental skill, but safety should always be your top priority. Here are some essential tips to keep you safe and ensure successful drilling:

- Wear Safety Glasses: Always, always, always wear safety glasses. Wood chips, dust, and even broken drill bits can fly at high speeds.

- Secure Your Workpiece: Use clamps or a vise to hold your material firmly in place. This prevents the material from spinning with the drill bit, which could cause injury or damage. Never try to hold small pieces by hand while drilling.

- Choose the Right Speed: Most drills have variable speed settings. For larger bits or harder materials, slower speeds are generally better. For smaller bits and softer materials, higher speeds can be more efficient. Refer to your drill’s manual if unsure.

- Apply Steady Pressure: Let the drill bit do the work. Apply firm, steady pressure, but don’t force it. Forcing a bit can cause it to overheat, break, or cause the drill to snag.

- Keep Drill Bits Sharp: As mentioned, sharp bits drill cleaner holes, require less effort, and are safer. Learn how to tell if your bits are dull (they’ll tend to heat up quickly, create dust instead of shavings, and require more force).

- Proper Grip: Hold the drill firmly with both hands if possible, especially when drilling larger holes or at an angle. If your drill has an auxiliary handle, use it.

- Be Aware of What’s Behind: Before drilling, know what’s on the other side of the material. You don’t want to drill through a wall and hit a wire or pipe. For example, the Occupational Safety and Health Administration (OSHA) provides guidance on electrical safety hazards, which is crucial when drilling near potential wiring.

Frequently Asked Questions (FAQ)

Q1: What’s the main difference between a 5/32″ and a 7/32″ drill bit?

A1: The primary difference is their diameter. A 5/32″ bit creates a smaller hole (about 0.156 inches), while a 7/32″ bit creates a larger hole (about 0.219 inches). This difference directly impacts what size screws or fasteners they are best suited for.

Q2: When should I use a 5/32″ drill bit instead of a 7/32″ bit?

A2: Use a 5/32″ bit for smaller tasks, such as creating pilot holes for small wood screws (like #6 or #8), drilling small clearance holes, or for detailed work in crafts. It’s for when you need a finer, more precise hole.