Baltic Birch Plywood Vs Birch Plywood: Essential Guide

Baltic birch plywood vs birch plywood? The simple truth is that while both are great, high-quality wood panels made from birch trees, true Baltic Birch plywood is known for its superior void-free core, durability, and finer layering that makes the edges look truly beautiful for exposed finishes. Read on to find exactly what makes each panel tick for your next DIY project.

Fellow DIY friends and woodworkers, welcome back to the workshop! Choosing the right sheet material is the first big win on any project. Wood isn’t just wood, and plywood confuses many of us. You see stacks of two kinds labeled “Birch Plywood”—one is plain, and one proudly boasts “Baltic Birch.” Confused about which beautiful wood sheet product is best worth your wallet and time? Don’t worry a bit. Figuring out the often fuzzy difference between Baltic birch plywood vs birch plywood is hard when you are starting out. Let’s clear up this confusion calmly and easily today. We will explore exactly what these panels are, how they stack up side-by-side, and I’ll show you exactly how to pick the perfect one based on the project you want to build at home. Grab your tape measure; let’s unlock quality craftsmanship together!

Unpacking Plywood Basics: Why We Use It in the Shop

To appreciate quality, we must know where we start. Plywood might look simple, but it’s actually a smart engineering product for construction and DIY beauty alike.

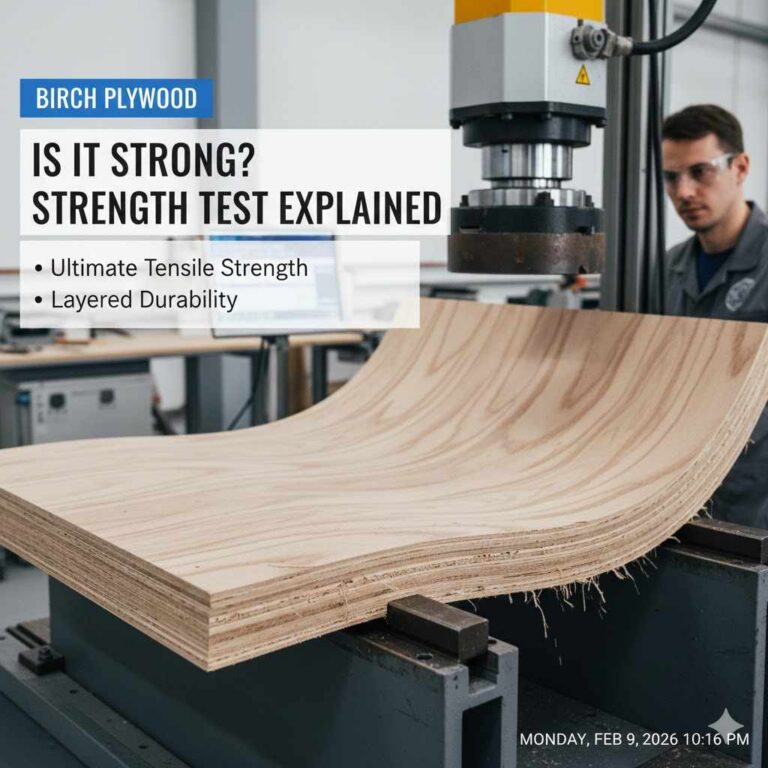

What actually makes plywood look uniform and strong? It’s all about slicing thin layers of wood veneer called plies and gluing them together. These layers look very interesting at the edge, as you can see the alternating stacks.

Here’s the special trick: the grain pattern is deliberately crossed between these layers, or plies. This opposing pattern is what gives plywood an amazing strength to resist warping, changing size with moisture changes, and splitting compared to regular solid wood boards. This cross-graining action is what lets DIY builders like us create super-stable cabinets, furniture, or workshop aides!

The Crucial Role of Core Material

When discussing any plywood, the makeup of the core—the stuff sandwiched inside the thin cover skins—matters hugely.

- Core Voids: Because plywood sheets are built of smaller layers glued around thicker parts, small empty gaps, called voids, can sometimes happen inside.

- Stress Points: Too many voids weaken the panel and can be stress points, especially when you fasten screws near edges or apply a finish, causing future problems.

- Grain Direction: The quality of the veneer and how the inner plies line up determines panel strength.

When we look at Baltic Birch plywood versus standard Birch plywood, we are largely talking about the amount and purity of those essential core veneers. This difference dramatically guides cost and, most importantly, visible project quality.

What IS Baltic Birch Plywood? Defining Premium Quality

Baltic Birch Plywood—sometimes confusingly just called “cabinet grade” or “plywood from Europe”—gets its name for a specific standard of manufacturing tied to wood sourced from the Baltic region (primarily Finland, Russia, Poland, and the nearby areas).

This type of plywood lives at the upper end of the quality and functional spectrum. When DIYers hear a cabinet shop murmuring praise, they are almost always talking about Baltic Birch. It’s the gold standard because of its internal construction features.

The Three Main Selling Points of Baltic Birch

When you flip over a sheet of the excellent Baltic Birch material, you are investing in specific core attributes that justify its cost:

- Void-Free Core: This is the game-changer. High-quality Baltic Birch plywood is made almost entirely without gaps or interior voids. Every interior layer runs whole from edge to edge.

- Number of Plies: You generally get vastly more thin cross-layered plies for the same thickness compared to others. A 3/4 inch standard sheet (18mm or standard metric equivalents) might have 9 individual plies layered together, whereas many standard birch alternatives might only have 5 or 7 internal layers. Fewer core materials means inherent structure strength!

- Face Veneer Quality: Even the outer layers must meet stricter hardwood standards, generally resulting in smoother, cleaner faces fewer blemishes or plugs than standard panels.

Mentoring Insight: Because the Birch wood itself has a relatively bright, fine grain, fewer core voids mean that you also avoid that terrible pock-marking or fuzzy layer appearing unexpectedly when you route (cut decorative edges) into the sides of your finished work. That means edges look sharp, clean, and totally ready for anything from a varnish to clear oil finish.

Understanding Standard Birch Cabinet or Furniture Plywood

Now, let’s talk about “regular” Birch Plywood. Sold widely across North America, this version varies wildly in quality depending on what plant produces it. It offers a cost-effective shortcut for jobs where sheer quality visibility isn’t the absolute end goal.

Standard Birch plywood is primarily useful because… well, in America specifically, solid cabinet woods like true hard Maple or Ash can get very expensive, very fast in large sheets! Birch offers a nice, light tone with moderate grain to make functional furniture without absolutely spending a fortune. But you are usually trading internal composition for the cost savings.

Why the Layers Differ in Standard Birch

The compromise occurs right in the middle of your panel’s thickness.

- Core Voids are Common: Standard panels, especially cost-sensitive ones, generally have empty pockets or overlapping layers within the core plies used because those layers are glued with less focused intent.

- Warp Risk Is Higher: Those internal voids mean tension often won’t distribute evenly a result is that cheaper panels look flatter when standing but can sometimes warp (bow or cup) surprisingly over time or when exposed to seasonal humidity shifts in your home—especially a problem for tall cabinet sides.

- Number of Plies Needed: To hide those voids and reach the necessary thickness standards (like exactly 3/4 inch), fewer, thicker core plies are often used, reducing its stiffness factor only marginally against Baltic Birch’s multi-ply layering.

The Head-to-Head Showdown: Baltic Birch Vs Commercial Birch Plywood

This is where we pull out the side-by-side guide so you can see, on paper, why these differences impact everything from hanging a floating shelf to building intricate desk drawers carved with complex details.

Key Comparison Quick Table

Here looks at the two varieties across measurements crucial to a woodworker achieving quality longevity and looks:

| Feature | Baltic Birch Plywood (BB) | Standard Birch Plywood (SB) |

|---|---|---|

| Internal Consistency | Virtually void-free; core layers are continuous and numerous. | May include interior voids and hidden gaps in core plies. |

| Dimensional Stability (Warp Resistance) | Excellent. Highly resistant to seasonal movement. | Moderate to Fair. Susceptible once installed in fluctuating environments. |

| Edge Appearance (Mouthfeel) | Beautiful, tight, uniform edge grain excellent for clear finishes. (No fuzzy strips!) | Can show discoloration or distinct alternating wood glue lines; may require patching or edge banding. |

| Ideal Exposure Use | Projects where edges will be highly visible; fine detail cutting. | Covered projects | Utility shelving | Interior cabinet parts out from view. |

| Relative Cost | Higher (Significantly). Best performance dictates higher price. | Moderate to Lower cost for similar apparent (visual) thickness. |

Visual Quality—What an Average DIYer Needs to Watch For

If you are new to woodworking or working with budget constraints, edge visibility will guide most of your decisions, so heed my advice here!

Edge Banding Decisions

If you plan to stain the wood or use a completely clear coat over your final project—such as a simple floating pantry shelf or a stunning tabletop—the exposed wood edge must look incredible.

- Since Baltic Birch plies alternate light heartwood and the slightly darker sapwood, the edges present a cool alternating striped look when left bare inside clear finish coatings due to the cross-grain glue-up schedule this gives.

- With Standard Birch often, the edge will show large, shadowy voids where pieces of wood filler might just be dumped instead of matched full layers. When you stain this type, any void catches stain differently, creating noticeable dark shadows, spots, or holes.

This visibility often forces beginners using standard birch into one of two steps: adding an applied veneer strip edge banding (wood tape) or physically covering the raw edge with solid hardwood trim before staining the rest of the piece. This extra finishing step adds time, skill requirement, and cost, often negating the initial savings!

Weight and Hardness Ratings

Both types use Birch wood veneer, which averages around a 1260 on the Janka hardness scale (for similar relative samples, as different regional species vary). The real differences lie in dimensional stability dictated by density and layering:

Because Baltic Birch features more plies packed tightly and glued skillfully, engineered panels often end up:

1. Thicker for the same published nominal size calculation.

2. Less responsive side-to-side to humidity, meaning they just sit more stably on trestles or as table legs throughout the drier vs. humid cooking of the household climate environment.

For building structural framework, storage projects, workshop fixtures, or building up large doors, that stability difference is critical assurance for the peace of mind. You can investigate structural plywood standards and engineered wood standards overseen by organizations like the U.S. Forest Products Laboratory (FPL) to understand how these assemblies pass required stress tests.

Your Decision Chart: Choosing the Perfect Birch Plywood Type

When balancing cost, required finish longevity, and the visible wow-factor you hope for down the road, there’s an appropriate panel for nearly every task found in your garage or basement—we mentor goal is simple: only pay for what you truly need.

When Should You Absolutely Be Buying Baltic Birch Plywood (BB)

Save an ounce of trouble by choosing Baltic Birch whenever you cannot mask the edge or when the structural integrity during heavy load variation needs maximum support.

- Outdoor furniture components guaranteed to flex some due to weather/humidity change.

- The visible outer carcass side of kitchen cabinets, entertainment centers, or modular wall systems.

- Any project requiring heavy pocket-holing or specialized fine carpentry joints near thick material edges, such as perfect rabbets.

- Laser cut models or craft projects where the edge visibility is the entire art (this might even refer to specialty, highly prized material classified under “Wisa-S or equivalent standard that utilizes only ultra-thin, highly aligned imported core materials”).

- Highly sensitive acoustic or speaker enclosure components that must eliminate vibration introduced by voids.

When Is It Totally Okay To Use Standard Grade Birch Plywood (SB)

Smart woodworking often involves optimizing material choice for cost; using cheap materials where no one—including you—will honestly see that core material is economical woodworking!

Here is where standard plywood shines safely over its European counterpart:

- Simple shelf linings inside built-in bookcases behind stored books.

- Cabinet parts that will be completely concealed by doors or drawer faces, or the hard bottom lining of deep under-sink drawers or utility storage systems.

- Temporary items constructed in damp environments now that you want sturdy (like mold preparation forms) where cosmetics definitely DO NOT matter.

- Substructures for upholstering large projects where you simply need a secure mounting surface you will attach batting material over.

- Jigs and fixtures for the workshop only which won’t hold heavy clamps in place longterm spanning big un-saddled segments.

Proactively avoid: If a section of standard layered board gets wet (like maybe from a discovered ceiling plumbing breach high in a utility closet wall backing), an internal void fills up and creates much more noticeable structural bloom across the surface than a tighter, more dense structure would.

Handling and Saw Safety in the Shop

We must respect all engineered wood products! Whether you step up the import quality or sticking to good domestic sheets, proper handling is necessary for success and safety (our workshop #1 rule, every time!). Birch wood material often needs a more aggressive technique when cutting to prevent burning through those hard cores cleanly, which causes smoke and dull blade tips rapidly on a bad piece.

Important Safety Practices

Before you wheel that heavy sheet into the cross-cut sled: wear your protective gear!

Always observe maximum permissible load capacities if stacking panels—referencing safety documentation when available, like the material safety protocols found through relevant trade associations:

General Wood Product Safety Note: Always consult a local OSHA-aligned guidance regarding ventilation when cutting sawdust-producing wood in any setup.

Here’s an efficient plan for getting predictable, quality cuts no matter which plywood rests on your table outfeed when routing curves:

| Desired Edges | Blade/Bit Recommendation (For Plywood Edge) | Why Not the Starter Tool? |

|---|---|---|

| Factory Clean Cut (Using Table Saw) | 10-inch Carbide Tipped Blade (Higher Tooth: 80 T-type or an actual 0.108 Kerf blades) | Cheap hardware store blades burn the edge, especially dark Russian birch panels. |

| Curved Edge Profiles | 72T or 80T high primary tooth blade on your Circular Saw or specialized Straight Trim Router Bit. | Standard router profiles introduce excess pressure per tooth leading them not to “eat” the hard edge material. |

| Shaping for Edge Aesthetics | A highly balanced Round Over or Chamfer (A top-quality bit is critical here – avoid overly abused bits!). | Poor assembly tolerances in cheaper construction invite blowout when the router runs over internal void pockets attempting this specific kind of detail finish work on standard panels. |

Even on affordable birch sheets, you learn very quickly to listen: a singing hum means clean cutting; a ragged sound ripping, chuffing noise implies the lack of layers means your saw setup can ruin the structural assembly trying to muscle thru that void layer right near the machine mouth path.

Sealing and Finishing Expectations

The excitement builds once fabrication concludes! You have your cabinet sitting dry for an hour—what now preserves your work and showcases those beautiful Birch grain lines between those cross-hatched layers you worked so hard on?

Finishing Advice Tailored Per Plywood Type

Finishing brings out the grain definition between Baltic Birch vs Birch Plywood usage standards beautifully—but preparation (which we skip sometimes!) varies slightly.

If You Choose Baltic Birch

You might be tempted to just wipe on an oil or just rattle can simple sealer on it! Resist that temporary urge; treat it nicer!

We use:

Light orbital sand preparation, possibly going up to 220 grit for high clarity.

Staining, clear varnish, or polyurethane application. Do this evenly!

Because BB is usually so clean and uniform, stains take very evenly with little blotching, demanding much less pre-finish sealer—a huge win for workflow quality where clear sealant is desired over solid color coverage due to low porosity on the best layers.

If You Chose Standard Birch

Always plan some pre-finish steps regardless of the sealer color you pick out for surface cosmetics to hide any potential core inconsistencies glimpsed on edges.

Work through:

1. Careful sanding until grit hits 150. Do not start higher!

2. Apply a liberal sanding sealer—oil-based works effectively here. This fills minor pores. You might need two coats depending on how dense the core looks! Orbital sanding between coats (400 grit minimum).

Skip sanding sealer? Watch common interior plywood materials soak up uneven finishes worse since the layers themselves show more absorption irregularity than expertly matched exterior-glued BB panels.

Real-World Application Examples

As your building buddy, I see readers struggle most often with storage and specialized structures, so let’s pin down specific recommendations now you know the inherent difference in the material composition of <a href="https://www.wood Magazine.com/" rel="noopener noreferrer" target="_blank link intended when they shop.

Project 1: Fine Cabinet Built-INS (E.g., High-End Bookcases)

If the sides, glass doors, and drawer fronts are all visible—GO Baltic Birch. The professional flush sides, precision of dovetails that hide any depth/reveal anomalies cut into the plies show the real benefit here across heavy loading from expensive books over twenty years onward because structure is more consistent. Don’t skimp if a large piece stays with you for five homes!

Project 2: The Workbench Top or Shop Jigsaw Factory Stand

If you just need a flat, stiff flat top (even if you are wrapping it edge banding later)—Budget Standard Birch is great! If the thickness required is significant (4 or 5 ply edge glued on that side might require more budget money) look carefully at ply composition details—if the listing says “7/PLY LVL Structure Built” you generally move towards the better quality realm of what used to cost famous prices. Otherwise, a simpler structure may require basic bracing beneath during installation phase if it spans 60” or more unsupported for best function prevention during maximum load application test!

Understanding Metric Nomenclature (The Confusion of Thicknesses)

In many stores overseas or specialized domestic importers for these fantastic Baltic Birch imported panels, sizes list as metric: 12mm, 15mm, 18mm. For North American measurement conversions, remember your nominal inches conversion; this matters heavily when sizing fittings for drawer slides!

12mm plywood sheet $approx$ 1/2 Inch

15mm $(text{or 14 layers often split}) approx$ A dense 5/8 Inch sheet. (Close enough might not be good enough!)

18mm Plywood sheet $approx$ Close look close to 3/4 Inch

Always double-check the actual written measurement stamp near the edge of whatever panel you are handling, regardless of the label if it is used for structural fitting into already squared dimensions.

Frequently Asked Questions (FAQ) – Simplified Answers For Beginners

Having clear, dependable answers removes panic; here are common things I hear new woodworkers ask:

Q1: Is Baltic Birch Plywood really that much $$/lb. more costly than Standard Birch?

A: Typically, yes. Expect the premium to often cost 50% to 100% higher per sheet depending on grade thickness selection and current shipping costs from European ports which heavily effect price stability depending on global logistics performance during that specific quarter vs low commodity domestic alternatives. You pay significantly more for guaranteed internal uniformity of core layers.

Q2: Can you use Standard Birch Plywood if you plan to paint everything completely solid color?

A: Absolutely! Solid painting seals all edges effectively from humidity infiltration if done via spray or liberal brush applications of primer first, and it completely obscures appearance flaws inside core plies beautifully. If sanding sealer followed by minimum two paint coats shields the finished structure, Standard Birch provides far cheaper filler material for that need alone).

Q3: Which one is best suited for outdoor projects or high-moisture areas (kitchen)?

A: PROFESSIONAL NOTE: Regardless of quality decision about B/B or C/C+ grade selection—IF it’s not specific EXTERIOR-RATED MEROTTI BONDING (WBP), neither is suitable for exposure to true, prolonged outdoor exposure yet. For controlled interior dampness like kitchens or bathrooms, choose BOTH grades and use HIGH-QUALITY moisture-resistant sealers/Varnish seals because the BB core handles minor ambient fluctuations dramatically better than general boards because solid layers resist ingress).

Q4: How do the label or grading letters for Baltic Birch work again? (A/B, B/BB, etc.)

A: Grading dictates face appearance, often listed face grade over back grade! Higher letter grades follow vowels closest to “A or better side!” (i.e., Baltic Birch stock might read a clean “AAA Ply” facing Grade on both layers or often “Birch B/BB”. The B is visual quality; BB stands for two visually acceptable outer plies, meaning you get superior faces! Higher letters, nicer veneer visuals).

Q5: If I use Baltic Birch, do I still need to use edge banding?

A: If you desire staining a uniform darker, specific color that isn’t a natural oak tone simulation, yes, maybe. Leaving bare coats shows the vertical stripe layer assembly perfectly, which most people love for a bright look! Hiding those lighter interior visible plies is exactly why some still purchase light wood edge tape. It speeds up covering up those alternating wood tone lines upon staining.

Q6: Can Standard Plywood that twists on me later be fixed with clamps?

A: A slight bow or modest twist can sometimes be minimally reduced after finish installation by clamping edge constraints strongly, yet substantial warp caused by internal voids often causes mechanical fasteners (screws!) to slip out over long stretches spanning unsupported base pieces across humidity areas. Better prevention using Baltic plywood than remedial repair!

Embrace Your Choice and Start Building Now

Alright builder friends, you now truly see that the competition between a standard Birch panel and fine-grade Baltic Birch Plywood vs standard Birch Plywood boils almost entirely down to four easy factors: your budget available, internal layer density, required stability for large spans, and critically—how visible will the raw physical edges on the material actually be once that piece finishes residing in its final space indoors.

If cash flow allows, picking correct Baltic material right gets you one exciting step forward—a true hallmark of high craftsmanship that reduces rework later because layer breaks or unexpected de-lamination surprises simply do not usually happen. It rewards your effort with immediate dimensional truth for intricate routing detail or tight joints. Use standard birch smartly—for concealed structural elements or simple enclosures where covering faces completely rules and that slight internal inconsistency will remain unseen beneath a dense primer layer!

<Until next time in the shop, keep those cutting blades perfectly sharp, check your push sticks constantly, and enjoy using beautiful, strong sheet materials to conquer those ambitious Saturday projects!]**