Black Oxide vs Titanium Drill Bits: Making the Right Choice

Choosing the correct drill bit can feel like a puzzle, especially when comparing Black Oxide vs Titanium Drill Bits: Best Choice. It’s a common question for anyone starting a project, whether you’re building a birdhouse or fixing a car. Getting it wrong can lead to frustration and wasted time. Don’t worry, this guide will make it easy! We’ll explore the differences and show you how to pick the right drill bit for any job. Let’s get started!

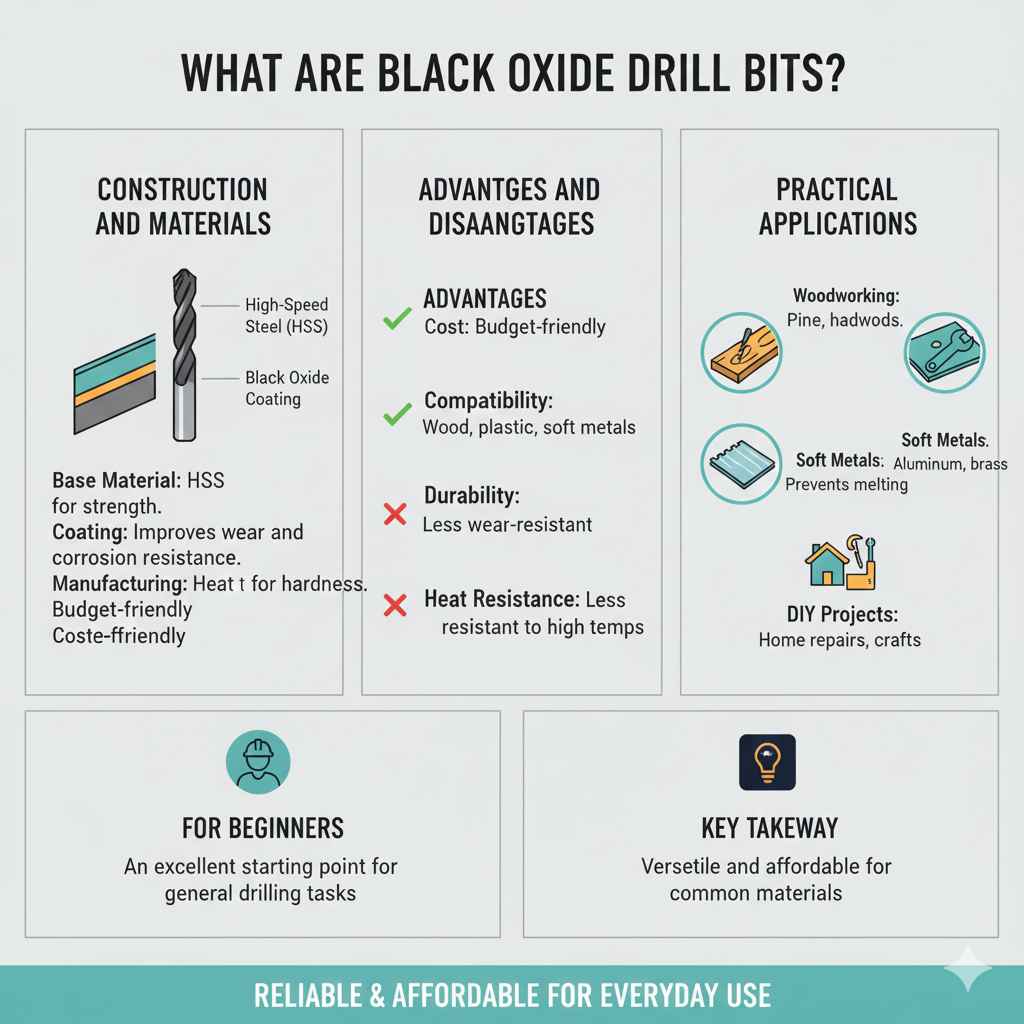

What Are Black Oxide Drill Bits?

Black oxide drill bits are a popular and affordable option for general-purpose drilling. They’re typically made from high-speed steel (HSS) and then coated with a black oxide finish. This coating gives them a darker appearance and provides some benefits. They are a good starting point for many drilling tasks. Black oxide bits are a workhorse in many toolboxes, perfect for beginners and seasoned DIY enthusiasts.

Construction and Materials

Black oxide drill bits begin their life as high-speed steel (HSS). HSS is a great material because it’s tough and can hold up against heat generated during drilling. The steel is then treated with a black oxide coating. This coating is applied through a chemical process that transforms the surface of the steel, giving it a characteristic black finish. The black oxide layer isn’t incredibly thick, but it does help with wear resistance and corrosion. These bits are generally stronger and can endure high temperatures compared to standard drill bits. Black oxide bits are usually found in sets, making them easy to acquire for various needs.

- High-Speed Steel (HSS): The base material providing the strength and durability of the bit. HSS allows the bit to maintain its integrity under the heat generated during drilling.

- Black Oxide Coating: A protective layer that improves wear resistance. It helps reduce friction and can extend the life of the drill bit.

- Manufacturing Process: The process includes heat treatment to harden the steel. This makes the drill bit more resistant to damage.

- Cost-Effectiveness: Black oxide bits are a budget-friendly option, making them a good choice for occasional use and general projects.

Black oxide bits are a good choice for projects requiring standard drill bits and are quite popular with the beginner crowd. This construction and material mix make them a solid starting point for many tasks. They handle materials such as wood, plastic, and soft metals. You’ll find them in most hardware stores at a reasonable price, suitable for a range of uses.

Advantages and Disadvantages of Black Oxide Bits

Black oxide drill bits have both positives and negatives. One of their biggest strengths is their price point. They are readily accessible, making them very appealing for home projects. However, they may not be the best pick for heavy-duty jobs. They also are not as durable or heat resistant as other types of bits. Knowing both the good and bad helps you decide if they’re right for your current project. This ensures a successful outcome.

- Cost: Black oxide bits are often more budget-friendly than their titanium counterparts.

- Material Compatibility: Suitable for use with wood, plastic, and softer metals.

- Durability: While durable, they are not as wear-resistant as other coatings.

- Heat Resistance: They are less resistant to high temperatures, potentially causing them to wear down quicker when drilling harder materials.

- Corrosion Resistance: Black oxide provides some protection against rust, but it’s not a complete barrier.

The advantages include easy access and affordability. They work well for wood, plastics, and softer metals. But, they have a lower heat and wear resistance. This can be a problem when working with tougher materials. While black oxide bits offer a cost-effective option for basic tasks, their limitations mean they might not be the best pick for all jobs.

Practical Applications for Black Oxide Drill Bits

Black oxide drill bits shine when used in the right situations. Knowing when to use them ensures you get the best outcome from your project. If you’re working with materials like wood, plastic, or even softer metals, these are a great go-to option. Think about building a small bookshelf, creating a craft project, or even installing basic electrical fixtures. These tasks are ideal for black oxide drill bits. They provide a good balance between cost, performance, and accessibility.

- Woodworking: Perfect for drilling into various types of wood, from soft pine to harder hardwoods.

- Plastics and Polymers: Great for creating holes in plastic materials without causing melting or cracking.

- Soft Metals: Useful for drilling into aluminum, brass, and other non-ferrous metals.

- DIY Projects: Great for home projects, crafts, and general repairs where precision is less important than cost.

For example, imagine you are building a simple wooden toy. Black oxide bits would work perfectly for this. However, if you’re working with steel or another hard metal, consider a more durable bit. Their suitability lies in their ability to perform well in the right situations. They’re a helpful tool for many common tasks.

Exploring Titanium Drill Bits

Titanium drill bits are an upgrade from black oxide, offering enhanced performance and durability. They are known for their heat resistance and longer lifespan, making them ideal for demanding projects. If you are doing a more demanding project, this is a better route to take. These bits will last longer and provide a better finish. Their premium construction makes them a favorite among professionals.

How Titanium Bits Are Made

Titanium drill bits gain their edge from the titanium coating applied to high-speed steel (HSS) or cobalt steel drill bits. The process involves bonding a thin layer of titanium nitride or titanium aluminum nitride to the bit’s surface. This coating changes the bit’s properties significantly. It reduces friction, improves heat resistance, and increases the hardness of the bit. The resulting bit is more wear-resistant. The coating process ensures the bits can cut through tougher materials. It also extends their useful life compared to uncoated bits.

- Base Material: Typically made from high-speed steel (HSS) or cobalt steel, which provides the base strength.

- Coating: A thin but strong coating of titanium nitride (TiN) or titanium aluminum nitride (TiAlN) is applied.

- Coating Method: The coating is usually applied using a process called physical vapor deposition (PVD).

- Heat Treatment: The bit undergoes heat treatment to increase its hardness and durability.

- Precision Grinding: The final step involves precision grinding to ensure accuracy and clean cutting.

The titanium coating is key to the bit’s superior performance. It allows the bit to maintain its sharpness and effectiveness, even when drilling tough materials. This manufacturing process produces a high-quality product that is tough. The manufacturing makes the bits more efficient.

Titanium Drill Bit Strengths and Weaknesses

Titanium drill bits offer advantages over black oxide bits. Their main strengths include enhanced durability and resistance to wear and heat. This lets them tackle more challenging materials with greater ease. However, they typically come at a higher cost. Knowing both sides helps you determine if these bits are the correct pick for your particular task. It ensures you get the best possible outcome.

- Durability: Titanium drill bits are more wear-resistant and last much longer.

- Heat Resistance: They can withstand higher temperatures, reducing the risk of dulling.

- Cutting Efficiency: They drill through hard materials faster and more cleanly.

- Material Versatility: Suitable for drilling into a wider range of materials, including harder metals.

- Cost: Generally more expensive than black oxide bits.

The main advantage is the ability to handle tougher materials. The cost can be a factor for the average homeowner. The increased durability and performance justify the higher cost for professionals and those working on demanding projects. Choosing the right bit for the job will help you get better results. It will also help you save time and money.

Optimal Uses for Titanium Drill Bits

Titanium drill bits are at their best in specific scenarios where their strength shines. They are the go-to pick when working with harder materials. They are well-suited for drilling into stainless steel, cast iron, and other tough metals. They also work for projects where longevity and precision matter. For example, installing metal hardware or working on automotive repairs. Their strength means they are able to handle difficult jobs. You will have a better outcome when using titanium drill bits for these tasks.

- Metal Fabrication: Great for drilling into steel, stainless steel, and other metals commonly used in construction and manufacturing.

- Automotive Repair: Useful for tasks like drilling out stripped bolts or creating new holes in vehicle parts.

- Hardware Installation: Ideal for installing screws and bolts into harder materials.

- Industrial Applications: Perfect for tasks that require frequent use and the ability to withstand high heat and wear.

Picture yourself working on a car repair that requires drilling through thick metal. Titanium bits will handle the job more easily than black oxide. If the project requires strength and durability, titanium drill bits are the correct pick. They will give you better results and help you finish the job more efficiently.

Comparing Black Oxide and Titanium Drill Bits

Understanding the key differences between Black Oxide vs Titanium Drill Bits: Best Choice is key to selecting the right bit for your needs. Both have their uses, but they differ in crucial ways. Considering performance, cost, and the materials you plan to work with is the key to a good choice. This table will clarify the differences.

| Feature | Black Oxide Drill Bits | Titanium Drill Bits |

|---|---|---|

| Material | High-speed steel (HSS) with a black oxide coating | High-speed steel (HSS) or cobalt steel with a titanium coating |

| Durability | Lower wear resistance | Higher wear resistance, longer lifespan |

| Heat Resistance | Lower heat resistance | Higher heat resistance |

| Cutting Performance | Suitable for softer materials like wood and plastic | Better for harder materials, including metals |

| Cost | More affordable | More expensive |

| Best Use | General purpose drilling in soft materials | Drilling in metals, and for projects demanding durability |

The comparison table shows the strengths and weaknesses of each type of drill bit. Black oxide bits are good for general use, while titanium bits are better for harder materials. The choice depends on the project’s specific needs. For example, if your job requires cutting metal, titanium is the superior pick. For basic wood or plastic projects, black oxide bits will usually suffice. The difference in performance is a key part of the decision.

Performance: Cutting Speed and Materials

The speed and materials that each type of drill bit can handle is where the differences are easily seen. Black oxide bits work well on softer materials. They do not cut as well on hard metals and can wear down quickly. Titanium drill bits offer a better cutting speed. They can also work on a wide variety of materials. If you’re often working with materials like steel, titanium drill bits will save you time and effort.

- Cutting Speed: Titanium bits generally cut faster and cleaner due to their coating.

- Material Compatibility: Titanium bits can handle a broader range of materials, including steel and cast iron.

- Drilling Efficiency: Titanium bits can drill through tougher materials with less effort, reducing the risk of breaking or damaging the bit.

- Hole Quality: Titanium bits often produce cleaner and more precise holes, especially in metal.

The performance differences between these two kinds of drill bits will become obvious as you work. Consider a home renovation project. Using black oxide bits on steel could lead to slow progress and damaged bits. Titanium bits cut through steel much faster and with better results. This makes them a better investment for such tasks. Your choice of bit will have a direct effect on your efficiency.

Cost Considerations: Value and Long-Term Investment

The cost is an important factor when deciding between Black Oxide vs Titanium Drill Bits: Best Choice. Black oxide bits are often less expensive. They are a great starting point for occasional users. Titanium drill bits have a higher price tag. They often last longer and perform better, making them a good value for heavy users. The total value is more than just the initial price. It also depends on how you use the bits and how long they last.

- Initial Cost: Black oxide bits have a lower upfront cost, appealing to budget-conscious users.

- Lifespan: Titanium bits last longer and maintain their sharpness, reducing the need for replacements.

- Project Frequency: If you only use drill bits occasionally, black oxide bits may suffice.

- Material Type: For professionals working with hard materials often, titanium bits offer a better return on investment.

- Overall Value: When assessing value, you should weigh the price against the durability, performance, and frequency of use.

Think about a construction worker versus a hobbyist. The construction worker will spend more time drilling tough materials. They can gain more from the durability and performance of titanium bits. The hobbyist might find that black oxide bits are adequate for their projects. While the upfront cost is lower, the true value depends on how often you use them and the materials you work with. This is a key part of the decision.

Durability and Lifespan

Durability is an important factor when choosing between drill bits. Titanium bits have a longer lifespan than black oxide bits. Their special coating helps them to handle heat. They also are more resistant to wear. Black oxide bits are useful for occasional jobs, but they can wear down more quickly. The right choice is based on the types of projects you take on and how often you drill.

- Wear Resistance: Titanium bits have a higher resistance to wear.

- Heat Resistance: Titanium bits can withstand higher temperatures.

- Longevity: Titanium bits will last longer.

- Material Impact: The material you work with also impacts durability.

Imagine using black oxide bits on a steel project versus a titanium bit. The black oxide bit might dull after a few holes. The titanium bit will still be sharp and effective. The increased durability of the titanium bit is clear. It provides long-term value. This affects project outcomes. This affects the overall value of each bit. The more you use them, the more the durability affects your cost.

Best Practices for Using Drill Bits

Using drill bits correctly is as important as choosing the right type. Correct use helps you get good results and increases the lifespan of your bits. Whether you are using a black oxide or titanium bit, a good technique will help. The proper way to use a drill bit will ensure clean cuts. These best practices will ensure the safety of you and your work. These tips will help you get the most from your drill bits.

Proper Techniques for Drilling

Following the correct techniques makes a big difference in how well your drill bit performs. Applying too much pressure or going too fast can damage the bit and the material. The right technique involves several key steps: using the right speed, applying steady pressure, and ensuring the material is secure. When drilling, it’s best to let the bit do the work. Avoid forcing it.

- Start Slowly: Begin drilling at a slower speed to make a pilot hole.

- Apply Steady Pressure: Apply even, consistent pressure to avoid bending or breaking the bit.

- Use the Correct Speed: Adjust the drill speed based on the material.

- Secure the Material: Make sure the material is stable to prevent it from moving while drilling.

Imagine you’re drilling into wood. If you push too hard, you could split the wood. If you go too fast, you might burn it. Following these basic rules helps you get a clean, precise hole. The best results start with the right skills. A bit will provide the result you desire with good technique.

Care and Maintenance for Drill Bits

Taking good care of your drill bits will make them last longer and work better. Proper maintenance involves cleaning the bits after each use and storing them correctly. Remove any debris that sticks to the bit. Store them in a dry place. This will protect them from corrosion and rust. By taking care of your drill bits, you ensure they are ready for future projects. This maintenance will save you time and money.

- Cleaning: Clean the drill bits after each use to remove any residue.

- Storage: Store your drill bits in a dry place to prevent rust.

- Inspection: Inspect the bits regularly for wear and tear.

- Sharpening: Sharpen your drill bits as needed to keep them effective.

Imagine you are done with a project. If you wipe down the drill bit after each use and keep it in a toolbox, you can protect it from damage. Regular care will help them last for years. The right care makes the bits more efficient.

Safety Precautions to Keep in Mind

Safety should be your first concern while using drill bits. Always wear safety glasses to protect your eyes from debris. Use gloves to protect your hands, and make sure your work area is free of clutter. Follow all the safety precautions. Keep your work area tidy. These things help prevent accidents. Following the rules helps make your projects safer and more enjoyable. These simple steps keep you safe.

- Eye Protection: Always wear safety glasses to shield your eyes from flying debris.

- Gloves: Wear gloves to improve your grip and protect your hands.

- Workspace: Keep your workspace tidy and free of obstacles.

- Material Security: Make sure the material is clamped down before you begin drilling.

- Tool Condition: Make sure your drill bits are not damaged.

If you’re drilling into a piece of wood, make sure it’s securely clamped down. This prevents it from moving and causing injury. Safety is important when you’re working with tools. Use the appropriate safety equipment. Taking these measures will help prevent accidents. Proper preparation helps create a safe environment. This will help make your work safer and more fun.

Frequently Asked Questions

Question: What’s the main difference between black oxide and titanium drill bits?

Answer: Black oxide bits are more affordable and suit softer materials, while titanium bits are more durable and work well on harder materials.

Question: When should I use a titanium drill bit?

Answer: Use a titanium bit when drilling metal, particularly tough materials like steel, or when you need a longer-lasting bit.

Question: Are black oxide drill bits good for metal?

Answer: Black oxide drill bits can work on softer metals, but they may not perform as well or last as long as titanium bits on harder metals.

Question: How can I tell if a drill bit is titanium-coated?

Answer: Titanium-coated bits often have a gold or bronze color, though some may have other coatings.

Question: How do I make my drill bits last longer?

Answer: Clean them after each use, store them in a dry place, and inspect them for wear and tear.

Final Thoughts

When you are deciding between Black Oxide vs Titanium Drill Bits: Best Choice, the right pick depends on what you’re working on. Black oxide bits are great for general use and for wood and plastics. These bits are budget-friendly. They offer a simple solution for many tasks. If you’re tackling tougher materials, such as metal, titanium bits are the better option. They last longer and work better. Consider the project, the material, and how much you plan to use the bits.

These factors will guide your decision. No matter what, you’ll be well-equipped. Armed with this knowledge, you are ready to pick the correct drill bit. Choose the right tool and start drilling with confidence!