Do Saws Have Teeth: Essential Facts

Yes, most saws do have teeth! These “teeth” are actually sharp edges, carefully shaped metal protrusions on the blade designed to cut through materials like wood, metal, or plastic. Understanding these teeth is crucial for safe and effective sawing.

Ever looked at a saw and wondered about those jagged edges? You might be asking yourself, “Do saws even have teeth?” The simple answer is a resounding YES! These aren’t like the teeth in your mouth, of course, but they are the hardworking parts that do all the cutting. For anyone just starting out with woodworking or DIY projects, understanding these “teeth” is a big step towards using saws safely and getting great results. It can be confusing at first, but don’t worry! We’re going to break down exactly what these teeth are, why they matter, and how to work with them. By the end of this guide, you’ll feel much more confident about your sawing superpowers!

The Mighty Saw Tooth: More Than Just Sharp Bits

When we talk about saw teeth, we’re really talking about the cutting edge of the saw blade. Think of them as tiny, angled chisels working together to remove material and make a cut, often called a kerf. The shape, size, and spacing of these teeth are not random; they’re engineered for specific tasks and materials. Getting to know these details will help you pick the right blade for your project and use your saw more effectively.

What Exactly Are Saw Teeth?

Saw teeth are the precisely shaped protrusions along the edge of a saw blade that perform the cutting action. They are typically made of hardened steel to withstand the force of cutting and maintain their sharpness. Each tooth works like a miniature shovel or knife, scraping away material as the blade moves.

Why Are Saw Teeth Shaped Differently?

The shape of saw teeth is tailored to the type of material being cut and the desired outcome. Factors like hook angle, set, and gullet size all play a critical role. For instance:

- Hook Angle: A more aggressive hook angle (more forward-leaning) makes teeth cut faster, ideal for softer woods. A less aggressive or even negative hook angle is better for harder materials or for making smoother cuts.

- Set: This refers to how the teeth are bent outward from the blade. A wider set creates a wider kerf, preventing the blade from binding in the material, which is good for rough cuts. A narrower set is better for cleaner cuts where binding is not a concern.

- Gullet: This is the space between the teeth. Larger gullets are designed to clear sawdust more efficiently, which is important when cutting softwoods or making deep cuts. Smaller gullets are often found on blades for fine cuts.

The Anatomy of a Saw Tooth

Each tooth has several key features:

- Point/Tip: The very front edge that contacts and cuts the material.

- Face: The surface of the tooth that does the primary cutting.

- Back: The rear edge of the tooth.

- Gullet: The space behind the tooth, crucial for chip removal.

- Heel: The base of the tooth where it joins the blade body.

Types of Saw Blades and Their Teeth

The kind of saw you have, and the blade it uses, determines what kind of “teeth” it has. Different saws are designed for different jobs, and their blades reflect this. Let’s look at some common examples:

Hand Saws

These are the oldest type of saws. They rely on your muscle power to cut. The teeth are usually larger and more aggressive.

- Crosscut Saws: Have teeth shaped like tiny knives, angled to cut across the wood grain. They have a moderate set for clearing sawdust.

- Rips Saws: Have teeth shaped more like chisels, designed to cut along the wood grain. They have less set and larger gullets for efficient material removal.

Power Saws

Power saws use motors to do the hard work. Their blades have teeth designed for speed and precision, varying greatly depending on the saw type.

Circular Saw Blades

These are found on circular saws, miter saws, and table saws. They come with a wide variety of tooth configurations.

| Blade Type | Tooth Count (Typical) | Tooth Shape/Angle | Best For | Pros | Cons |

|---|---|---|---|---|---|

| General Purpose | 40-60 teeth | Combination of raker and ATB (Alternate Top Bevel) | Both ripping and crosscutting | Versatile, good balance of speed and finish | Not ideal for ultra-fine finishes or very fast ripping |

| Ripping Blade | 10-24 teeth | Large, square-ish teeth with a high hook angle | Cutting along the grain (ripping) | Fast material removal, efficient dust clearing | Rougher cut quality |

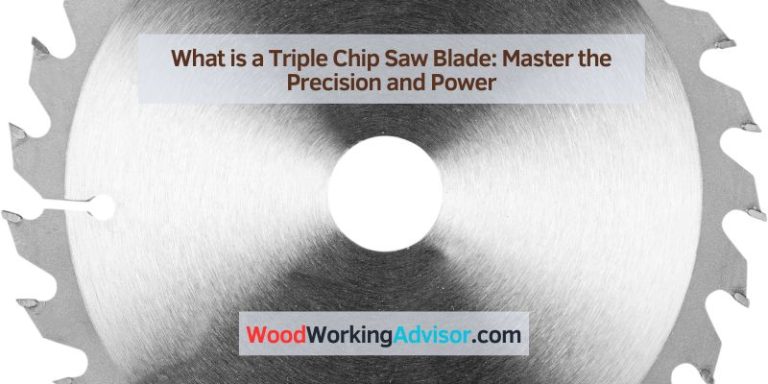

| Crosscutting Blade | 60-100 teeth | Smaller teeth, often ATB or TCG (Triple Chip Grind) for cleaner edges | Cutting across the grain (crosscutting) | Very clean, smooth cuts | Slower cutting, can’t handle ripping as well |

| Plywood/Melamine Blade | 80+ teeth | Fine-tooth, often TCG grind to minimize tear-out | Sheet goods, laminate, melamine | Minimizes chipping and splintering | Slow, can overheat if used for ripping thick lumber |

Jigsaw Blades

Jigsaws use thin, reciprocating blades. The teeth are often smaller and can be quite varied.

- Woodcutting Blades: Most common, with teeth designed for cutting wood. Some have fewer, larger teeth for faster cutting, while others have many small teeth for a smooth finish.

- Metalcutting Blades: Have very fine, hardened teeth designed to cut through metal.

- Scroll Blades: Extra-thin blades for intricate curves.

Reciprocating Saw Blades (Sawzall™)

These powerful saws use long, aggressive blades. They are built for demolition and rough cutting.

- Demolition Blades: Are thick and have large, aggressive teeth. They are made to withstand abuse and cut through nails, screws, and various materials quickly.

- Metal Cutting Blades: Have finer teeth than demolition blades but are still robust.

Band Saw Blades

Band saws use continuous loop blades. The teeth are consistent along the entire length.

- Wood Blades: Range from wide blades (for straight cuts) to narrow blades (for tight curves). Teeth vary in size and spacing depending on the material and cut type.

- Metal Blades: Have very fine, uniform teeth.

Chain Saw Chains

While not called “teeth” in the same way, a chainsaw chain is made up of many sharp cutting elements. These are small, raker-like cutters with a sharp “tooth” that bite into wood.

For more on saw blade types and their applications, you can refer to resources from organizations like the Toolopedia, which often provide detailed comparisons.

Tooth Count Matters: The Magic Number

One of the most significant factors in how a saw blade cuts is its tooth count. This is simply the number of teeth present on the blade. Generally, more teeth mean a smoother cut, while fewer teeth mean a faster cut.

Fewer Teeth = Faster Cuts

Blades with fewer teeth (e.g., 10-30 on a circular saw blade) have larger gullets. This means they remove material more quickly and eject sawdust efficiently. They are excellent for:

- Ripping lumber (cutting with the grain).

- Cutting thicker materials.

- Demolition or rough framing where speed is key and finish quality is less important.

More Teeth = Smoother Cuts

Blades with more teeth (e.g., 60+ on a circular saw blade) have smaller gullets and finer teeth. Each tooth removes less material, but you have many more happening at once. This leads to:

- Cleaner, splinter-free cuts on wood.

- Better performance on sheet goods like plywood and melamine.

- Ideal for trim work, furniture making, and projects where a smooth finish is desired.

The Sweet Spot: General Purpose Blades

For many DIYers and homeowners, a general-purpose blade with a moderate tooth count (around 40-60 teeth for a 10-inch circular saw blade) offers a good balance. It can handle basic ripping and crosscutting tasks reasonably well, making it a versatile choice for beginners.

The Importance of Tooth Sharpness and Maintenance

Even the best saw blade with ideal teeth won’t perform well if the teeth are dull or damaged. Dull teeth don’t cut; they scrape and tear, leading to:

- Increased effort required to make a cut.

- Poor cut quality with splintering and tear-out.

- Increased risk of the saw binding or kicking back, which is a significant safety hazard.

- Overheating of the blade and material.

When to Sharpen or Replace

You can tell it’s time to think about sharpening or replacing your saw blade when you notice any of the following:

- The saw struggles to move through the material.

- The cut edges are rough, frayed, or burned.

- You’re getting excessive splintering on the wood surface.

- The saw feels like it’s pushing or binding more than cutting.

How We Use Our Saws Safely (Even with Sharpened Teeth!)

Safety with any saw is paramount, and understanding its teeth is part of that. Here are some fundamental safety tips:

- Always Wear Safety Glasses: Sawdust and small chips of material can fly. Protect your eyes!

- Read Your Saw’s Manual: Familiarize yourself with your specific tool’s operation and safety features. The Occupational Safety and Health Administration (OSHA) provides general safety guidelines for power tool usage.

- Ensure the Blade is Secure: Double-check that the blade is properly installed and tightened before each use.

- Use the Correct Blade: Match the blade to the material and type of cut. Using the wrong blade can be inefficient and dangerous.

- Never Force the Saw: Let the teeth do the work. Forcing a dull or improperly set blade can lead to binding and kickback.

- Test Cuts: If you’re unsure about how a blade will perform, make a scrap cut first.

- Beware of Kickback: This is when the saw jumps back towards you. It often happens when the blade binds in the wood. Keep a firm grip, stand to the side of the blade’s path, and don’t overreach.

- Keep the Saw and Work Area Clean: Sawdust buildup can be a fire hazard and make it harder to control the saw.

Understanding Tooth Pitch (Teeth Per Inch – TPI)

For blades like those on jigsaws, reciprocating saws, and some hand saws, tooth pitch is a critical specification. It’s measured in Teeth Per Inch (TPI). TPI tells you how many teeth are present within one inch of the blade’s cutting edge.

High TPI (Many Teeth Per Inch)

Blades with a higher TPI (e.g., 14-32 TPI) have teeth that are much closer together. These are generally used for:

- Making finer, smoother cuts.

- Cutting thinner materials.

- Cutting harder materials like metal or plastics, where smaller teeth create less friction and heat.

Low TPI (Fewer Teeth Per Inch)

Blades with a lower TPI (e.g., 3-10 TPI) have teeth that are spaced further apart. These blades:

- Cut faster because there are larger gullets to clear material and sawdust.

- Are ideal for cutting softer materials like wood.

- Are perfect for general-purpose cutting or demolition where speed is prioritized over a fine finish.

Choosing the Right TPI

A good rule of thumb from woodworking experts is to ensure that you have at least two teeth in contact with the material you are cutting at all times. For example:

- If you are cutting 1/2 inch thick wood with a jigsaw, a blade with 6 TPI or higher would be appropriate (since 6 TPI * 0.5 inches = 3 teeth, which is more than 2).

- If you are cutting thin metal sheeting, you’d want a much higher TPI blade, possibly 24 TPI or more.

Saw Teeth in Different Materials

The type of material you’re cutting will heavily influence the type of saw teeth you need. Using the wrong teeth can lead to terrible results, damaged tools, and frustration.

Wood

Wood is the most common material for sawing. Saw teeth for wood vary greatly based on whether you’re cutting with the grain (ripping) or across the grain (crosscutting).

- Ripping: Requires fewer, larger teeth with aggressive angles to remove wood fibers quickly.

- Crosscutting: Benefits from more, finer teeth designed to slice through wood fibers cleanly.

- Sheet Goods (Plywood, MDF, Particle Board): Often require blades with a very high tooth count and a specialized grind (like triple-chip) to prevent chipping and splintering on the surface.

Metal

Cutting metal requires special blades with very hard, fine teeth. Metal produces more heat when cut, so a finer pitch (high TPI) helps:

- Reduce friction and heat buildup.

- Prevent the teeth from getting clogged with metal shavings.

- Provide a smoother cut and prevent the metal from deforming excessively.

- Materials like abrasive cut-off wheels are also used for metal, which use particles to grind through the material rather than distinct teeth.

For cutting metals, it’s essential to consult safety guidelines from manufacturers or organizations like the Health and Safety Executive (HSE).

Plastic

Plastics can be tricky because they can melt if too much heat is generated. For many plastics:

- A moderate to high tooth count blade is ideal.

- A slower cutting speed helps prevent melting.

- Sometimes blades designed for wood can work, while others require specialized plastic-cutting blades.

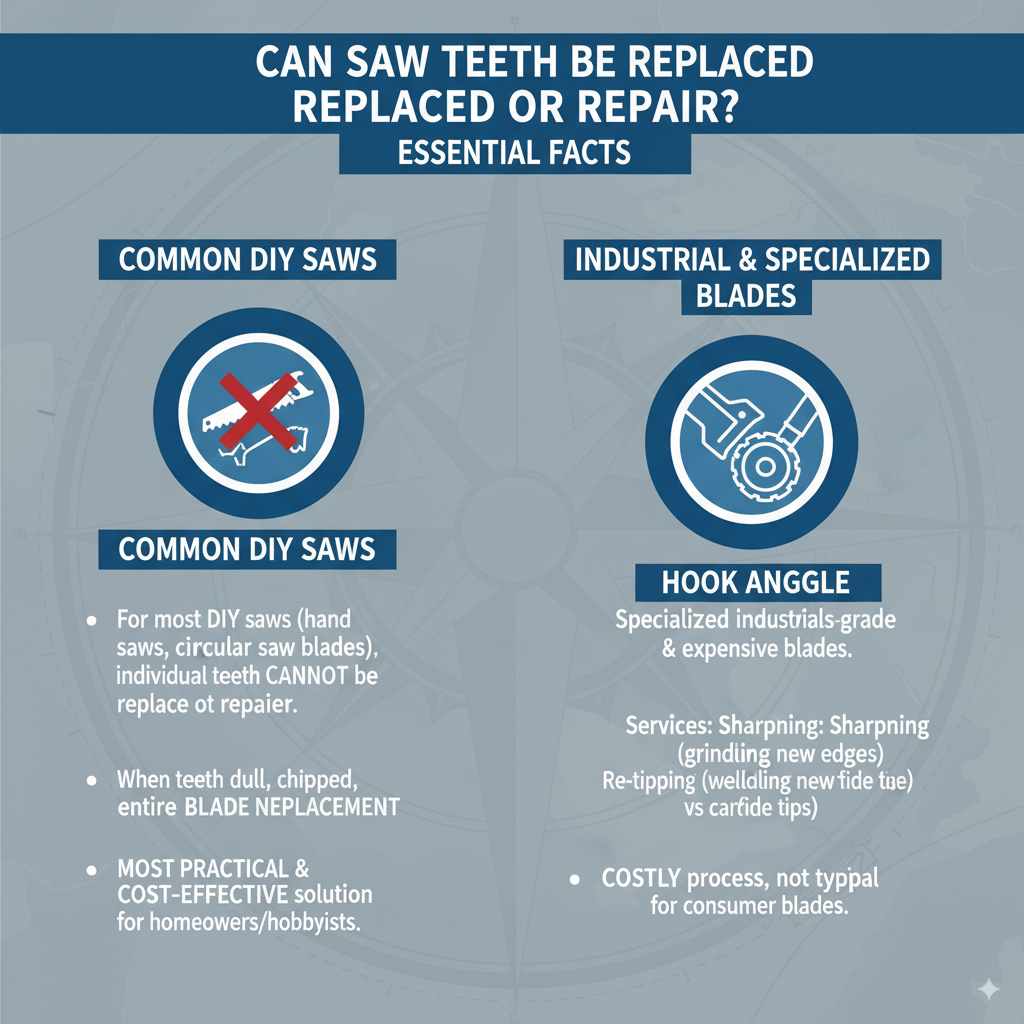

Can Saw Teeth Be Replaced or Repaired?

For most common DIY saws, individual saw teeth cannot be replaced or repaired. When the teeth become dull, chipped, or broken, the entire blade needs to be replaced. However, there are specialized services for sharpening and re-tipping blades, especially for industrial-grade or very expensive blades. They can grind new edges onto dull teeth or even weld new carbide tips onto blades if they’ve worn down. For the typical homeowner or hobbyist, purchasing a new blade is usually the most practical and cost-effective solution.

FAQ: Your Saw Tooth Questions Answered

Q1: Do all saws have teeth?

A1: Most saws designed for cutting purposes have teeth. However, some specialized cutting tools, like abrasive cutoff wheels or laser cutters, do not use traditional teeth. But for the hand saws and power saws you’ll commonly use, teeth are the cutting mechanism.

Q2: What’s the difference between many teeth and few teeth on a saw blade?

A2: Few teeth mean faster cuts but a rougher finish, as the larger teeth remove more material quickly. Many teeth mean slower cuts but a smoother, cleaner finish because each tooth takes a smaller bite.

Q3: How do I know when my saw blade is dull?

A3: Your saw blade is dull when it requires more effort to cut, the cut edges are rough or burned, or the saw feels like it’s pushing or binding instead of cutting cleanly.