Hardwood Flooring Gaps: Essential Fixes

Hardwood flooring gaps between boards are common! Don’t worry, these simple fixes can restore your floor’s beauty. Learn easy DIY methods for filling and preventing gaps, suitable for any homeowner. Get your floor looking smooth and solid again with these practical tips.

Hey DIY friends and fellow wood lovers! Md Meraj here. Ever look down at your beautiful hardwood floors and notice those little (or not-so-little!) gaps that have appeared between the boards? It’s a common sight in many homes, and it can be a bit frustrating. Wood naturally expands and contracts with changes in humidity and temperature, and over time, this movement can cause gaps to form. But before you start thinking about expensive professional help, let me reassure you: fixing these gaps is often a straightforward DIY project! With a few simple tools and techniques, you can effectively fill these spaces, prevent them from getting worse, and bring back that seamless, polished look to your floors. Let’s dive in and discover how to tackle hardwood flooring gaps between boards like a pro!

Understanding Why Hardwood Floor Gaps Appear

It’s like a wood whisperer’s first lesson: wood is alive! It breathes, in a way. When the air around your hardwood floor gets drier, like in winter when heating systems are running, the wood loses moisture and shrinks. When the air gets more humid, especially in summer, the wood absorbs moisture and expands.

This constant cycle of shrinking and expanding is the main culprit behind those pesky gaps between your hardwood flooring boards. Imagine a group of friends holding hands; if they all take a step back, there’s space between them. That’s what happens to your floorboards as they shrink. The faster and more extreme the changes in humidity, the more noticeable these gaps can become.

Other factors can contribute too:

- Poor Installation: If the wood wasn’t properly acclimated to your home’s environment before installation, or if it wasn’t nailed down securely, gaps can form more readily.

- Subfloor Issues: Problems with the foundation underneath your hardwood can also cause the boards to lift and create gaps.

- Heavy Furniture: While less common, very heavy furniture pressing down on a specific area can sometimes contribute to gaps over time.

Knowing the “why” helps us find the best “how-to” for fixing them. Don’t worry, identifying the cause is the first step to a beautiful, gap-free floor.

DIY Solutions for Hardwood Flooring Gaps

Alright, let’s roll up our sleeves! We’ve got a few go-to methods for tackling those gaps, ranging from super simple fixes for small gaps to slightly more involved solutions for wider ones. The best part? You likely have many of the tools and materials already, or they’re easy to find at your local hardware store.

Option 1: Filling Small Gaps with Wood Filler or Putty

For those narrow gaps – think the width of a dime or less – wood filler or wood putty is your best friend. These products are designed to fill voids and can often be matched to your floor’s color for a nearly invisible repair.

What You’ll Need:

- Wood filler or wood putty (choose a color that closely matches your floor, or a natural tone you can stain)

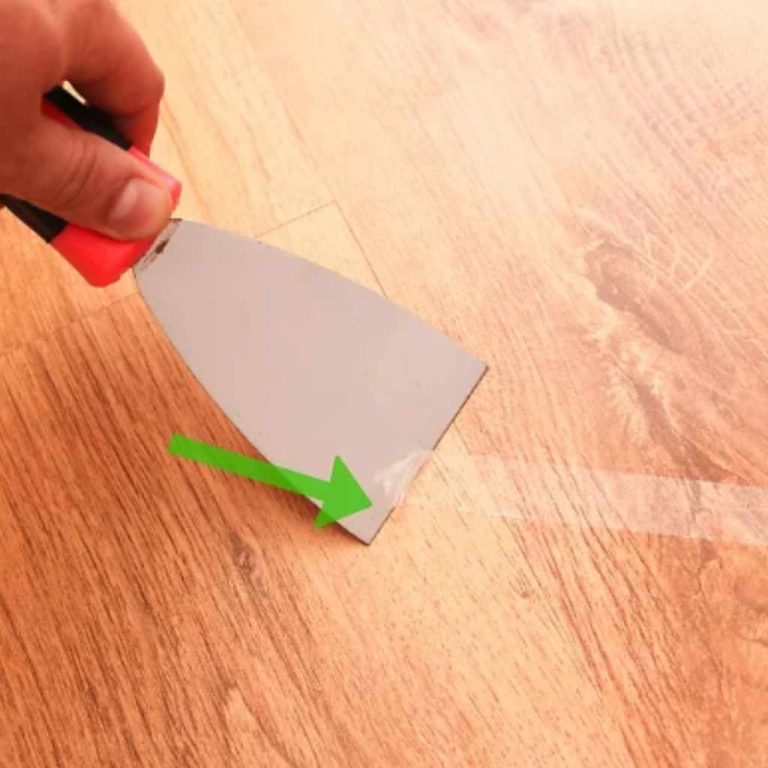

- Putty knife or flexible scraper

- Fine-grit sandpaper (180-220 grit)

- Clean cloths

- Optional: Wood stain and sealant matching your floor

Step-by-Step Guide:

- Clean the Gaps: First, use a vacuum cleaner with a crevice tool to thoroughly clean out each gap. You want to remove all dust, debris, or tiny particles. This ensures the filler adheres properly.

- Apply the Filler: Squeeze a small amount of wood filler or putty onto your putty knife. Press it firmly into the gap, working it down so it fills the entire void. Don’t overfill; you want it to be flush with the floor surface or slightly proud (a tiny bit higher) for sanding.

- Smooth and Level: Scrape away any excess filler from the surface of the wood. The goal is to leave the filler only within the gap.

- Let it Dry: Allow the filler to dry completely according to the manufacturer’s instructions. This is crucial for a durable repair. Rushing this step can lead to the filler cracking or pulling away later.

- Sand Smooth: Once dry, use your fine-grit sandpaper to gently sand the filled area. You want to make it perfectly smooth and level with the surrounding floorboards. Be careful not to sand away too much of the surrounding wood.

- Clean Again: Wipe away all sanding dust with a clean cloth.

- Color Match (Optional): If you used a natural-colored filler, now’s the time to apply a matching wood stain. Be precise and only stain the filled area. Once the stain is dry, apply a matching sealant (like polyurethane) to protect the repair. If you used a pre-colored filler, you might be able to skip this step if the color is a perfect match!

Option 2: Filling Wider Gaps with Wood Strips or Dowels

For gaps that are too wide for filler (generally wider than 1/4 inch or about the width of your pinky finger), you’ll need a more substantial solution. Using thin strips of matching wood or wooden dowels can create a strong, attractive fill.

What You’ll Need:

- Thin strips of hardwood or wooden dowels that match your flooring species and color

- Wood glue (a strong, waterproof formula is best)

- A sharp utility knife or chisel

- Hammer

- Sandpaper (medium and fine grit)

- Vacuum cleaner

- Clean cloths

- Optional: Wood stain and sealant

Step-by-Step Guide:

- Prepare the Gap: As before, thoroughly vacuum the gap. If there are any loose splinters, carefully trim them with a utility knife.

- Cut Your Wood Filler: If using wood strips, cut them to the exact length of the gap. If using dowels, you might cut them slightly longer. Aim for a snug fit – you want the wood to be the star of the repair! For a really clean look, consider using a power saw like a mitre saw for precise cuts.

- Apply Glue: Apply a generous bead of wood glue along the bottom and sides of the gap. Also, add a little glue to the wood strip or dowel you’re inserting. Safety in woodworking is paramount; wear safety glasses when using tools.

- Insert the Wood: Carefully wedge the wood strip or dowel into the glued gap. You might need to gently tap it in with a hammer. If using a strip, ensure it sits flush or slightly proud of the floor surface. If using dowels, you might need to drill small pilot holes to help seat them properly.

- Clamp (If Possible): If the gap is long and you’ve filled a section, you might be able to use painter’s tape to hold the strip in place while the glue dries.

- Let the Glue Cure: Allow the wood glue to dry completely. Check the glue manufacturer’s recommendations for curing time.

- Trim and Sand: Once the glue is fully cured, use a sharp utility knife or chisel to carefully trim any excess wood that sticks up above the floor surface. Be very careful not to damage the surrounding boards. Then, sand the filled area smooth, starting with medium-grit sandpaper and finishing with fine-grit.

- Clean and Seal: Vacuum up all dust. If your wood fill doesn’t perfectly match, now is the time to carefully stain and seal it to blend with the rest of your floor.

Option 3: Replacing Damaged Boards

Sometimes, boards are beyond simple filling. If a board is severely warped, cracked, or has multiple large holes, it might be time to replace it. This is a bit more advanced, but entirely doable with patience!

What You’ll Need:

- Matching hardwood board

- Pry bar

- Hammer

- Drill with drill bits

- Circular saw or jigsaw

- Chisel

- Wood glue

- Nail set or finishing nails

- Sandpaper

- Clean cloths

Step-by-Step Guide:

- Remove the Damaged Board: Carefully drill out the nails holding the damaged board in place. Use a pry bar to gently lift the board from its edges. Work slowly to avoid damaging adjacent boards. If nails are stubborn, a chisel might help free them.

- Prepare the Space for the New Board: Once the old board is out, clean the subfloor area. You may need to trim a bit of the tongue-and-groove on the adjacent boards to make room for the new board.

- Cut the New Board: Measure the opening and cut your replacement board to size. For boards with tongues and grooves, you’ll usually need to remove the tongue from one side and the groove from the other of the new board so it can be slid into place.

- Install the New Board: Apply wood glue to the edges of the subfloor and the adjacent boards where the new one will meet. Slide the new board into place.

- Secure the New Board: Carefully nail the new board into the subfloor using finishing nails. Use a nail set to drive the nails slightly below the surface.

- Sand and Finish: Once the glue is dry and nails are set, sand the new board flush with the surrounding floor. Then, carefully match the stain and sealant to the rest of your floor for a seamless finish.

Preventing Hardwood Floor Gaps: Proactive Steps

An ounce of prevention is worth a pound of cure, as they say! Once you’ve fixed those gaps, you’ll likely want to keep them from coming back. The key is controlling your home’s environment and being mindful of how you treat your floors.

1. Control Humidity Levels

This is the single most important thing you can do. Wood expands when it’s humid and shrinks when it’s dry. Aim to keep your home’s humidity at a steady level, ideally between 35-55%.

- Use a Humidifier: Especially during dry winter months, a humidifier can add much-needed moisture to the air.

- Use a Dehumidifier: In damp climates or during humid summer months, a dehumidifier can prevent wood from swelling too much.

- Monitor with a Hygrometer: A simple hygrometer (humidity meter) can help you track your home’s humidity levels and make adjustments as needed. You can find reliable ones online or at home improvement stores.

Consistent humidity levels mean less drastic wood movement, and fewer gaps!

2. Proper Acclimation During Installation

This is more for when you’re installing new floors or replacing boards, but it’s a crucial step to avoid future problems. Hardwood needs to adjust to the moisture and temperature levels of your home before it’s installed. Manufacturers recommend leaving the wood in the rooms where it will be installed for at least 72 hours (and often longer) before laying it. This is a fundamental part of ensuring durability, as highlighted by resources like the Forest Stewardship Council (FSC), which emphasizes sustainable and proper wood handling practices.

3. Gentle Cleaning and Maintenance

Harsh cleaning methods or excessive moisture can damage your floor and contribute to problems like gaps.

- Avoid Excess Water: Never use a soaking-wet mop. Opt for a damp mop or a microfiber mop specifically designed for hardwood floors.

- Use Recommended Cleaners: Stick to pH-neutral wood floor cleaners. Avoid abrasive cleaners or anything that could strip the finish.

- Wipe Spills Immediately: Don’t let liquids sit on your floor. Quick clean-ups prevent moisture absorption.

4. Protect Your Floors

Simple protective measures can go a long way:

- Use Felt Pads: Place felt pads on the bottom of all furniture legs. This prevents scratches AND reduces friction that can sometimes contribute to wood movement becoming more noticeable as gaps.

- Use Area Rugs: Place rugs in high-traffic areas, under dining tables, and in entryways to protect the wood from wear and tear, and to help manage moisture from tracked-in water.

Choosing the Right Filler for Your Floor

Selecting the correct filler material is key to a successful and lasting repair. Wood fillers come in different types, and knowing their strengths will help you choose wisely.

Types of Wood Fillers

| Type of Filler | Description | Best For | Pros | Cons |

|---|---|---|---|---|

| Wood Putty | A soft, pliable compound that doesn’t shrink once dry. It’s pre-mixed and ready to use. | Small to medium nail holes, minor dents, and small gaps. | Easy to use, no shrinking, good for small repairs. | Not as durable for structural repairs, may not accept stain well. |

| Wood Filler (Water-Based) | A sandable, paintable, or stainable water-based paste. Available in various colors. | Small to medium gaps, scratches, nail holes. | Easy to clean up, easy to sand, good finish options. | Can shrink slightly if applied too thick, may not be as strong as epoxy fillers. |

| Wood Filler (Solvent-Based/Epoxy) | A two-part compound that offers superior strength and durability when mixed. | Larger gaps, structural repairs, areas that require significant strength. | Very strong, durable, minimal to no shrinkage, holds screws well. | Requires mixing, can be messy, harder to sand, may have strong odors. |

| Wood Dough/Plastic | A moldable compound that hardens to a very durable state. | Larger holes, chips, or when a strong, permanent fill is needed. | Extremely durable, can be drilled and shaped, excellent for deep fills. | Can be difficult to work with, might require specialized tools for shaping. |

For most common hardwood flooring gaps between boards, a good quality water-based wood filler in a matching or natural tone is an excellent choice. It’s forgiving, easy to work with, and sands beautifully for a smooth finish. If you’re dealing with very wide or unstable gaps where structural integrity is a concern, a two-part epoxy wood filler might be considered, but always test it on an inconspicuous area first to ensure it takes stain or finish properly.

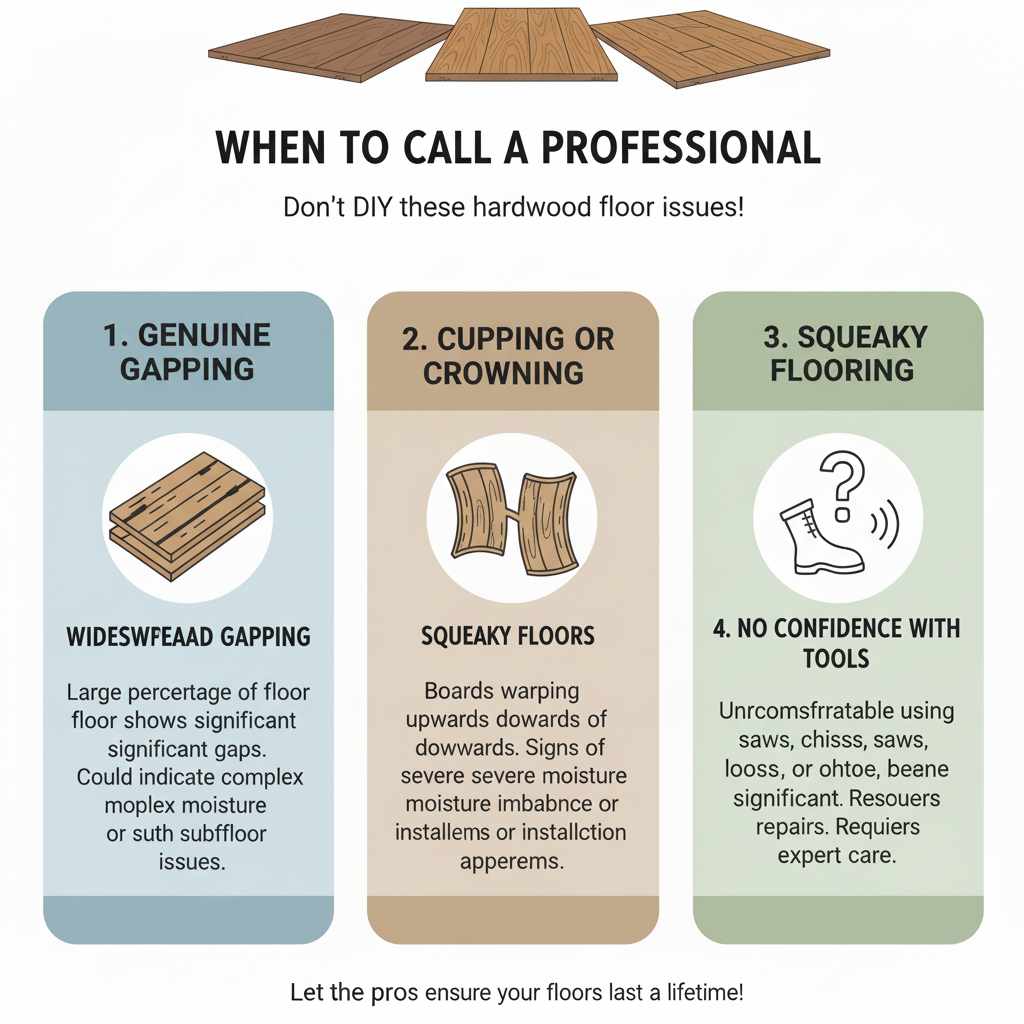

When to Call a Professional

While many gap issues can be tackled by a DIYer, there are times when it’s best to call in the pros. If you notice any of the following, it might be time to seek expert advice:

- Widespread Gapping: If a large percentage of your floor is showing significant gaps, it could indicate a larger issue with the subfloor or a more complex moisture problem that requires professional assessment.

- Cupping or Crowning: These are conditions where boards warp significantly upwards (cupping) or downwards (crowning) at the edges. They’re often signs of severe moisture imbalance or installation issues.

- Squeaky Floors: Persistent squeaks, especially widespread ones, can signal loose boards or subfloor problems that are best addressed by a flooring specialist.

- No Confidence with Tools: If you’re uncomfortable using saws, chisels, or other tools required for more involved repairs, it’s safer and often more effective to let a professional handle it.

- Valuable or Historic Floors: For antique floors or very expensive hardwood, you might want the expertise of a professional to ensure the repairs are done correctly without compromising the floor’s integrity or value.

A professional flooring installer or refinisher has specialized tools and knowledge to diagnose and fix complex issues, ensuring a long-lasting, beautiful result.

Frequently Asked Questions (FAQ)

Q1: How wide a gap can I fill with wood filler?

A: For standard wood fillers, it’s generally best to stick to gaps no wider than 1/4 inch. For wider gaps, you might need to build them up in layers, let each layer dry, or consider using wood strips or dowels for a more robust repair.

Q2: Will filling hardwood floor gaps stop them from coming back?

A: Filling gaps addresses the visible problem, but the underlying cause is the wood’s reaction to humidity. If humidity levels are not managed, gaps can reappear over time. Consistent humidity control is key to long-term prevention.