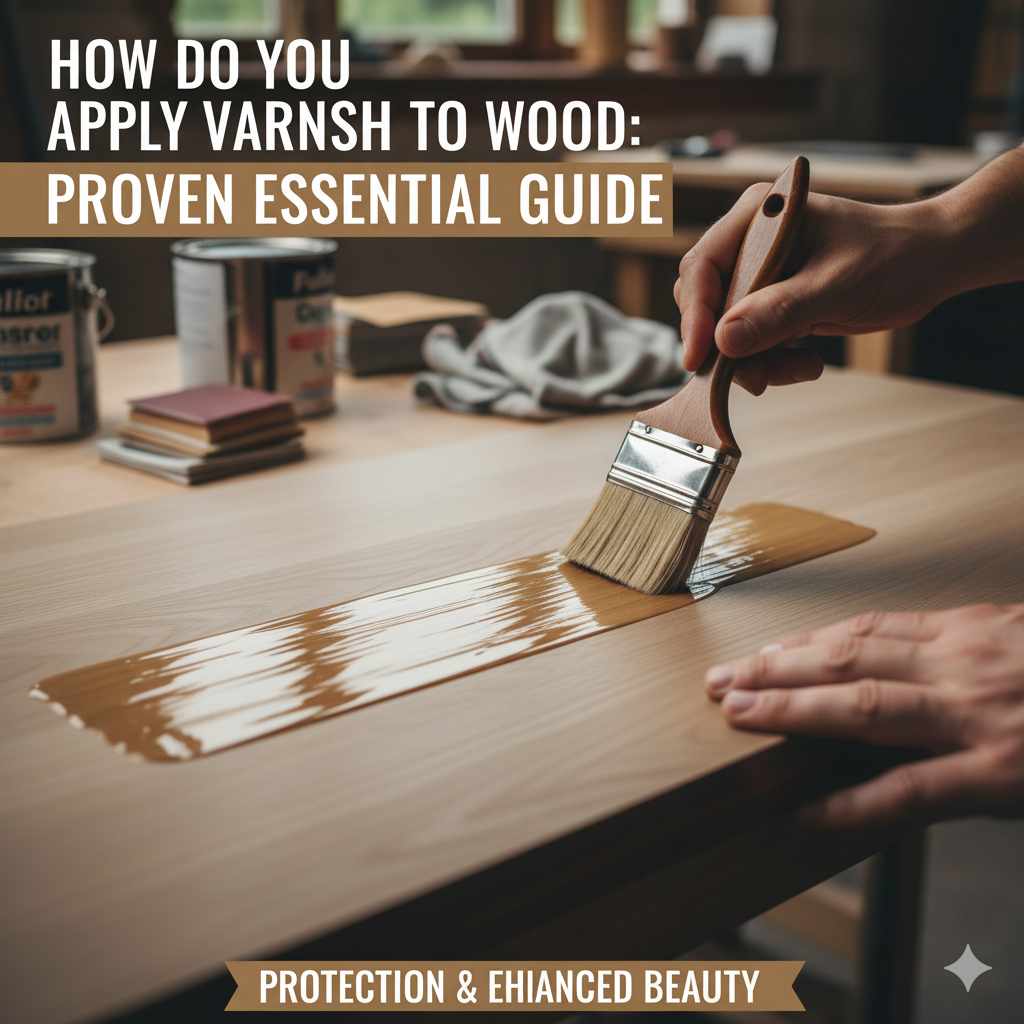

How Do You Apply Varnish to Wood: Proven Essential Guide

Applying varnish to wood is straightforward! Achieve a durable, beautiful finish by preparing your surface, choosing the right varnish, applying thin, even coats with a good brush or sprayer, and allowing proper drying time between coats. This guide breaks down each step, ensuring a professional look for your woodworking projects.

Have you ever looked at a beautiful wooden furniture piece, admired its smooth, protective sheen, and wondered how you could achieve that same look on your own projects? Applying varnish might seem daunting, especially when you’re just starting out. Many beginners worry about streaks, drips, or an uneven finish. But here’s the good news: it’s a skill that anyone can learn with a little patience and the right guidance. I’m here to walk you through every step, just like we do in the workshop, making the process clear, simple, and even enjoyable.

We’ll cover everything from prepping your wood to the final protective coat. By the end of this guide, you’ll have the confidence and know-how to varnish your projects like a pro, giving them that lasting beauty and protection they deserve. Let’s get started!

Why Varnish Your Wood? The Benefits Explained

Before we dive into the ‘how,’ let’s talk about the ‘why.’ Varnish isn’t just about making wood look pretty; it’s a crucial protective layer. Think of it as a suit of armor for your wooden creations, shielding them from everyday wear and tear.

- Protection from Moisture: Wood can absorb water, leading to swelling, warping, or rot. Varnish creates a waterproof barrier, safeguarding your pieces from spills, humidity, and even outdoor elements if you choose the right type of varnish.

- Durability and Scratch Resistance: Daily use can leave its mark in the form of scratches and scuffs. Varnish hardens the wood surface, making it significantly more resistant to damage, keeping your furniture looking newer for longer.

- Enhancing Wood’s Natural Beauty: Varnish can bring out the rich colors and intricate grain patterns of wood, giving it a depth and luster that simply isn’t there on raw wood. It can also provide different sheens, from a subtle matte to a high-gloss shine.

- Ease of Cleaning: A smooth, varnished surface is much easier to wipe clean than unfinished wood. Dust, grime, and spills can be removed with a damp cloth, making maintenance a breeze.

Choosing the Right Varnish for Your Project

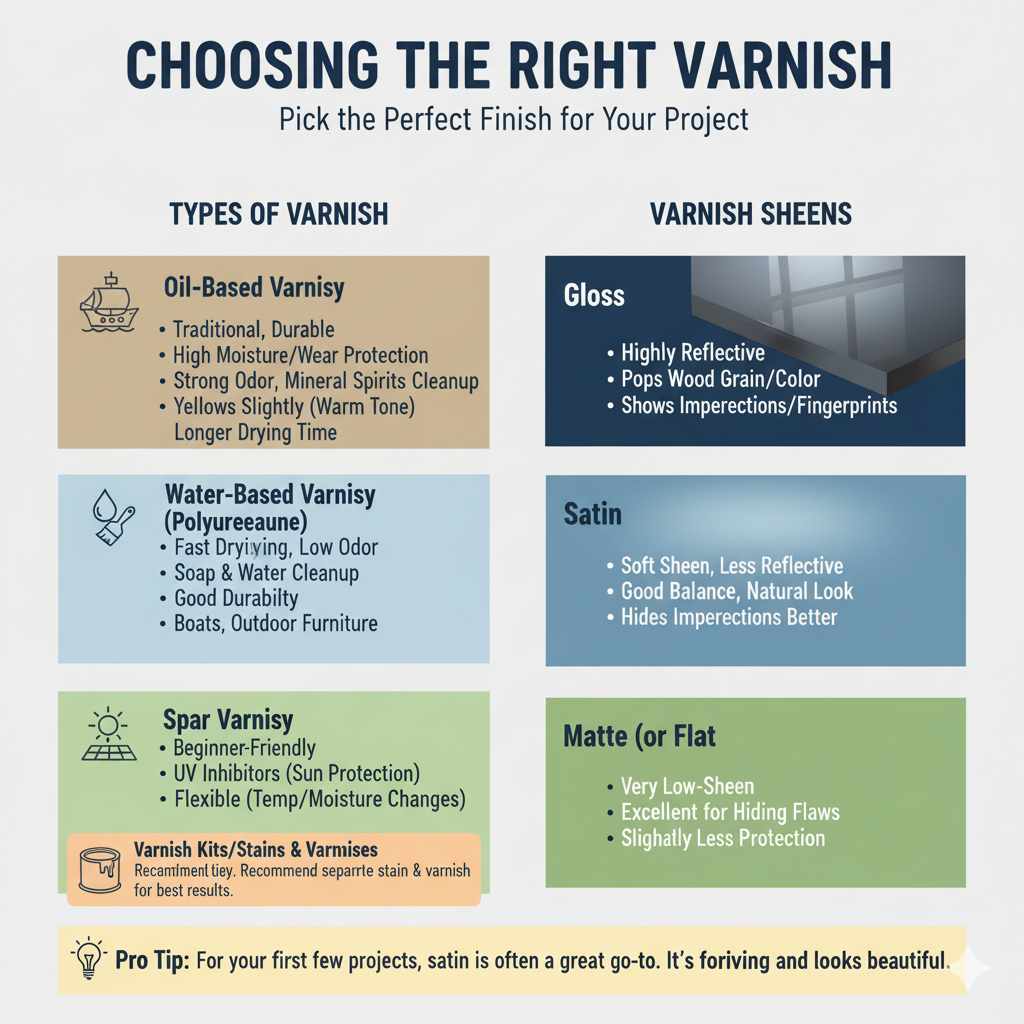

Not all varnishes are created equal! The type you choose will depend on what you’re varnishing and where it will live. Here’s a quick rundown of the most common types you’ll encounter:

Types of Varnish

- Oil-Based Varnish: These are traditional and very durable. They offer excellent protection against moisture and wear, creating a hard, flexible finish. However, they can have a strong odor, require mineral spirits for cleanup, and tend to yellow slightly over time, which can add a warm tone to certain woods. They also have longer drying times.

- Water-Based Varnish (Polyurethane): Also known as waterborne polyurethane, these are a popular choice for beginners. They dry much faster than oil-based versions, have low odor, and clean up easily with soap and water. They provide good durability and protection, though they might not be quite as tough as oil-based for very high-traffic areas. They are also less prone to yellowing.

- Spar Varnish: This is a specialized oil-based varnish designed for outdoor use. It contains extra UV inhibitors to protect the wood and finish from sun damage and is formulated to be more flexible to handle temperature and moisture changes. It’s great for outdoor furniture, boats, or even interior pieces exposed to direct sunlight.

- Varnish Kits/Stains & Varnishes: Some products combine a stain and a topcoat in one. While convenient, these often compromise on the durability of the topcoat and may require a separate clear varnish layer for maximum protection. For best results, it’s usually recommended to stain first, then apply a dedicated varnish.

Varnish Sheens: Gloss vs. Satin vs. Matte

The finish, or sheen, of your varnish dramatically affects the look of your wood. Here’s what those terms mean:

- Gloss: This creates a highly reflective, mirror-like surface. It really pops the wood grain and color but can show imperfections and fingerprints more easily.

- Satin: A popular choice, satin gives a soft sheen that’s less reflective than gloss. It offers a good balance of protection, durability, and a natural look, and it hides imperfections better.

- Matte (or Flat): This gives a very low-sheen, almost dull look. It’s excellent for hiding flaws and provides a very natural wood appearance but offers slightly less protection than gloss or satin and can sometimes look a bit “chalky.”

Pro Tip: For your first few projects, satin is often a great go-to. It’s forgiving and looks beautiful on most wood types.

Gathering Your Essential Tools and Materials

Having the right gear makes the job so much smoother. Don’t worry; you don’t need a professional workshop for this. Here’s what you’ll need:

| Item | Purpose | Beginner Tips |

|---|---|---|

| Varnish | The protective coating. Choose based on your project (see above). | Start with a water-based polyurethane in a satin finish for ease of use. |

| Sanding Blocks or Sandpaper | To prepare and smooth the wood surface. Grits typically range from 80 to 220. | Use 120-grit for initial smoothing and 220-grit for a final smooth finish before varnishing. |

| Tack Cloth or Microfiber Cloth | To remove dust after sanding. | A tack cloth is designed to pick up fine dust particles. A clean, dry microfiber cloth also works well if a tack cloth isn’t available. |

| Good Quality Bristle Brush or Foam Brush | For applying the varnish. | For water-based varnishes, synthetic bristles (like nylon or polyester) are best. For oil-based, natural bristles work well. Foam brushes offer a smooth finish but can be less durable. Aim for a brush that’s about half the width of your project surface. A 2-inch brush is often a good all-around size. |

| Stir Sticks | To stir, not shake, the varnish. | Many cans come with one, or you can use a clean piece of scrap wood. |

| Mineral Spirits or Water | For cleaning brushes (depending on varnish type). | Always check the varnish can for recommended cleanup solvents. Enthusiasts at This Old House often recommend matching your solvent to your varnish type precisely. |

| Disposable Gloves | To keep your hands clean. | Latex or nitrile gloves work well. |

| Safety Glasses | To protect your eyes from dust and varnish splatters. | Clear safety glasses are essential, especially when sanding or spraying. |

| Drop Cloth or Newspaper | To protect your workspace. | Cover a larger area than you think you’ll need! |

| Fine-Grit Sandpaper (e.g., 320 or 400-grit) | For light sanding between coats. | This is optional but highly recommended for a super-smooth finish. |

The Proven Step-by-Step Guide to Applying Varnish

Now for the exciting part! Follow these steps carefully, and you’ll be applying varnish like a seasoned pro in no time. Remember, patience is key!

Step 1: Prepare Your Workspace

Find a well-ventilated area away from dust and direct sunlight. If you’re working indoors, lay down a drop cloth or old newspapers to protect your floor. Ensure the temperature is within the range recommended on your varnish can (usually between 50°F and 80°F or 10°C and 27°C).

Step 2: Prepare the Wood Surface

This is arguably the most important step for a flawless finish. The wood must be clean, dry, and smooth.

- Clean the Wood: If your wood is already finished, ensure it’s completely clean from any grease, wax, or old finishes. For unfinished wood, wipe it down with a damp cloth to remove surface dust.

- Sand the Wood:

- Start with a medium-grit sandpaper (around 120-grit) to smooth out any rough spots or imperfections. Sand in the direction of the wood grain.

- Follow up with a finer grit (220-grit) for a silky-smooth surface. The smoother the wood, the better the varnish will adhere and look.

- For very fine finishes, you can even go to 320-grit.

- Remove All Dust: This is crucial! After sanding, use a tack cloth or a clean microfiber cloth to wipe away all the fine dust particles. You can also use a vacuum cleaner with a brush attachment. If you don’t remove all the dust, it will get trapped in the varnish, creating a bumpy finish.

Step 3: Stir the Varnish (Don’t Shake!)

Open your can of varnish. If there’s a skin on top, carefully remove it. Now, instead of vigorous shaking (which creates air bubbles), gently stir the varnish with a stir stick. This blends the ingredients without incorporating air. Scrape the sides and bottom to ensure everything is mixed thoroughly.

A common mistake is shaking the can. This introduces air bubbles that will transfer to your wood, creating tiny craters in your finish. Think of it like gently folding ingredients in a cake batter for a smooth result!

Step 4: Apply the First Coat

This is where the magic happens! Dip your brush about one-third of the way into the varnish. Tap excess varnish off the brush on the rim of the can; don’t wipe it, as this can also introduce air bubbles.

Work in long, smooth strokes, following the direction of the wood grain. Apply a thin, even coat. Avoid over-brushing; try to lay the varnish on and then make one or two light passes to even it out. Thicker coats dry unevenly and are more prone to drips.

Important: If you’re varnishing a vertical surface, start at the top and work your way down. For horizontal surfaces, stroke the length of the piece in one go.

Step 5: Allow Drying Time

This step requires patience! Check the varnish can for specific drying times. It’s usually listed as “dry to touch” and “recoat time.” The “recoat time” is what you’re looking for. For water-based varnishes, this can be as short as 2-4 hours, while oil-based can take 6-12 hours or even overnight.

Ensure the environment is dust-free during drying. Any speck of dust settling on the wet varnish will mar the finish. You can even use a clean, empty cardboard box or plastic sheeting to loosely cover the project if dust is a major concern, but ensure there’s airflow.

Step 6: Lightly Sand Between Coats (Optional but Recommended)

Once the varnish is dry to the touch and ready for the next coat, it’s time for some very light sanding. Use very fine-grit sandpaper (320-grit or higher) or a fine synthetic sanding pad. The goal here isn’t to remove the varnish but to knock down any tiny dust nibs or imperfections and to create a slightly “toothy” surface for the next coat to adhere to.

After sanding, use a tack cloth or a clean microfiber cloth to remove all dust. Again, dust is the enemy of a smooth finish!

Step 7: Apply Subsequent Coats

Repeat Steps 4, 5, and 6 for each subsequent coat. Most projects will require 2-3 coats for good protection, but furniture that receives heavy use might benefit from 4 or even more coats.

Each coat should be slightly thinner than the last. The final coat should be applied very carefully, using light strokes to achieve a beautiful, uniform sheen.

Step 8: The Final Cure

Even after the varnish is dry to the touch and recoatable, it will take several days, or even weeks, to fully harden and cure. During this time, be gentle with your project. Avoid placing heavy objects on it, dragging things across the surface, or exposing it to moisture. Refer to your varnish can for specific cure times.

Troubleshooting Common Varnish Issues

Even with the best intentions, you might run into a few hiccups. Here’s how to fix some common problems:

- Brush Marks: These happen when you overwork the varnish or use too much. If they appear while the varnish is wet, try to gently feather them out. If they dry, you’ll need to sand them down and reapply that section or the entire coat.

- Drips or Runs: These occur when too much varnish is applied, especially on vertical surfaces. You’ll typically see a thicker line of varnish pooling at the bottom edge. Gently brush them out while wet, or let them dry, sand them smooth, and reapply the area.

- Bubbles: This is usually caused by shaking the varnish or excessive brushing. Stir gently. If bubbles appear in a coat, let it dry completely, sand them out, and reapply a thin coat.

- Dust Nibs: Tiny specks of dust trapped in the finish. Lightly sand with very fine grit sandpaper (400-grit) after the varnish is fully dry, and then apply another thin coat, ensuring a dust-free environment. Using a tack cloth meticulously before each coat is the best prevention.

- Uneven Sheen: This can happen if you don’t mix the varnish well or if it dries unevenly. A light sanding with 400-grit paper and a careful reapplication of a thin coat can often even it out.

For more detailed advice on dealing with finishes, resources like Wood Magazine’s finishing troubleshooting section can be incredibly helpful.

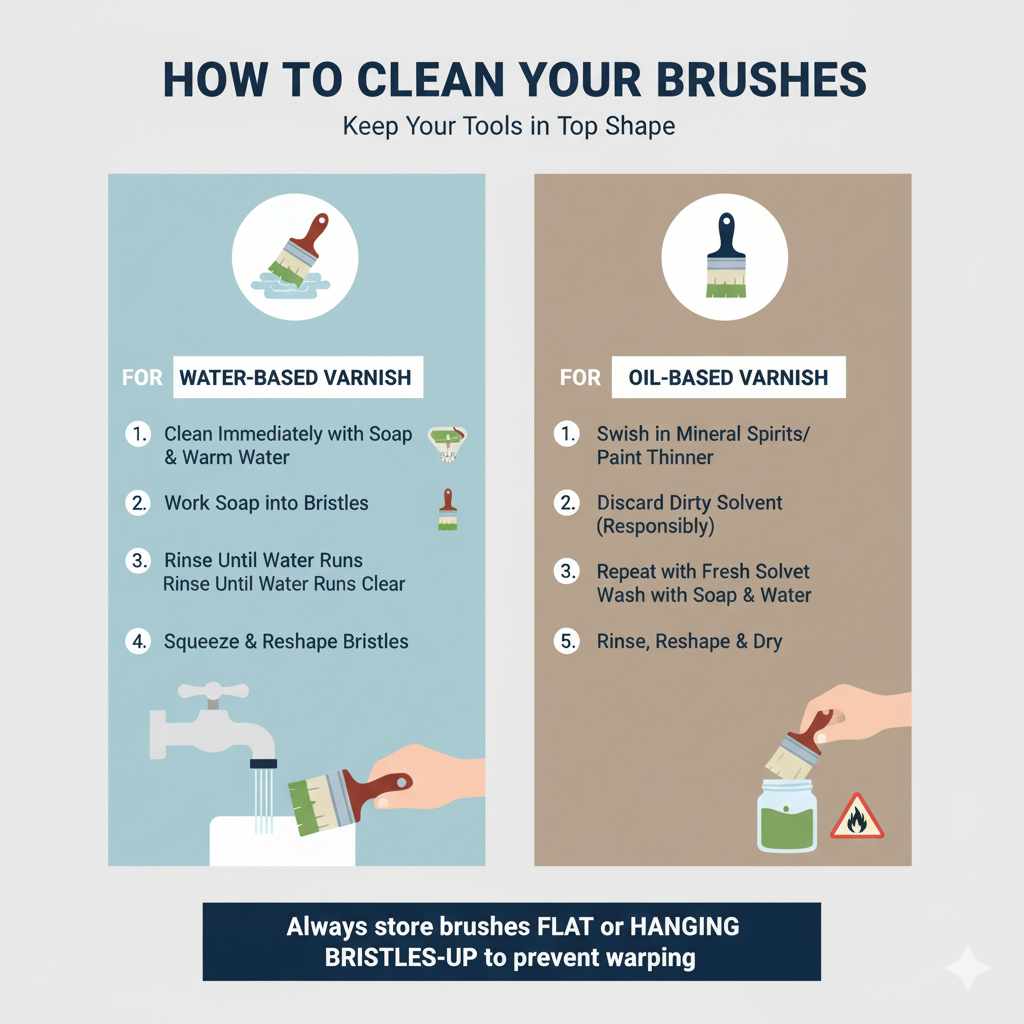

How to Clean Your Brushes

Cleaning your brushes properly is essential for their longevity and for achieving a good finish. The method depends on the type of varnish you used:

- For Water-Based Varnish: Clean your brush immediately after use with soap and warm water. Work the soap into the bristles until all the varnish is out. Rinse thoroughly until the water runs clear. Gently squeeze out excess water and reshape the bristles.

- For Oil-Based Varnish: You’ll need mineral spirits or paint thinner. Swish the brush in the solvent, working the varnish out. Discard the dirty solvent (dispose of it responsibly, as it’s flammable and hazardous waste!). Repeat with fresh solvent until no more varnish comes out. Then, wash the brush with soap and water to remove any remaining solvent residue. Rinse, reshape, and let dry.

Always store your cleaned brushes flat or hanging bristles-up to prevent warping.

Frequently Asked Questions (FAQ)

How many coats of varnish are typically needed?

For indoor furniture, 2-3 coats are usually sufficient. For high-traffic items like tabletops or cutting boards, or for outdoor pieces, 3-4 coats or more will provide better durability and protection.

What is the difference between varnish and polyurethane?

Polyurethane is a type of varnish. The term “varnish” is a broader category for protective, liquid coatings. Polyurethane specifically contains a plastic polymer called polyurethane, known for its toughness and durability. So, while all polyurethanes are varnishes, not all varnishes are polyurethanes.

How long does varnish take to dry?

Drying times vary greatly by product type and environmental conditions. Water-based varnishes typically dry to touch in 1-2 hours and are recoatable in 2-4 hours. Oil-based varnishes take longer, often 6-8 hours to touch and 12-24 hours to recoat. Full curing can take weeks.

Can I apply varnish outdoors?

Yes, but use a specific outdoor or spar varnish, which contains UV inhibitors and is more flexible to withstand weather changes. Ensure you are in a protected area away from direct sun, wind, rain, and dust.