How to Install Vinyl Hardwood Flooring: Genius Essential Guide

Installing vinyl hardwood flooring is a rewarding DIY project! This guide breaks down each step, from preparing your subfloor to locking planks in place, ensuring a beautiful, durable floor even for beginners. You’ll achieve professional results with our easy-to-follow instructions.

Hey DIY friends! Ever looked at your current floor and thought, “I wish this looked better, but I’m not a pro”? You’re not alone. Many homeowners feel intimidated by flooring projects. But what if I told you that achieving a stunning new vinyl hardwood floor might be within your reach? That’s right, with a little patience and the right guidance, you can transform your space. Vinyl hardwood flooring is a fantastic choice because it’s resilient, water-resistant, and incredibly stylish. It looks just like real wood but is much easier to care for and install, making it perfect for busy homes. This guide is crafted to walk you through installing vinyl hardwood flooring, step by step. We’ll cover everything you need to know to get started, so grab your tools, and let’s build something beautiful together!

Your Genius Essential Guide to Installing Vinyl Hardwood Flooring

As your go-to mentor for all things DIY, I’m thrilled to guide you through installing vinyl hardwood flooring. It’s a project that can dramatically upgrade your home’s look and feel without needing a construction crew. Vinyl hardwood flooring, often called Luxury Vinyl Plank (LVP) or Luxury Vinyl Tile (LVT) when it mimics wood, is incredibly DIY-friendly. Its click-lock or peel-and-stick systems make it accessible for beginners, and its durability is a huge plus for families and pets. Let’s dive into how you can achieve a professional-looking finish right in your own home.

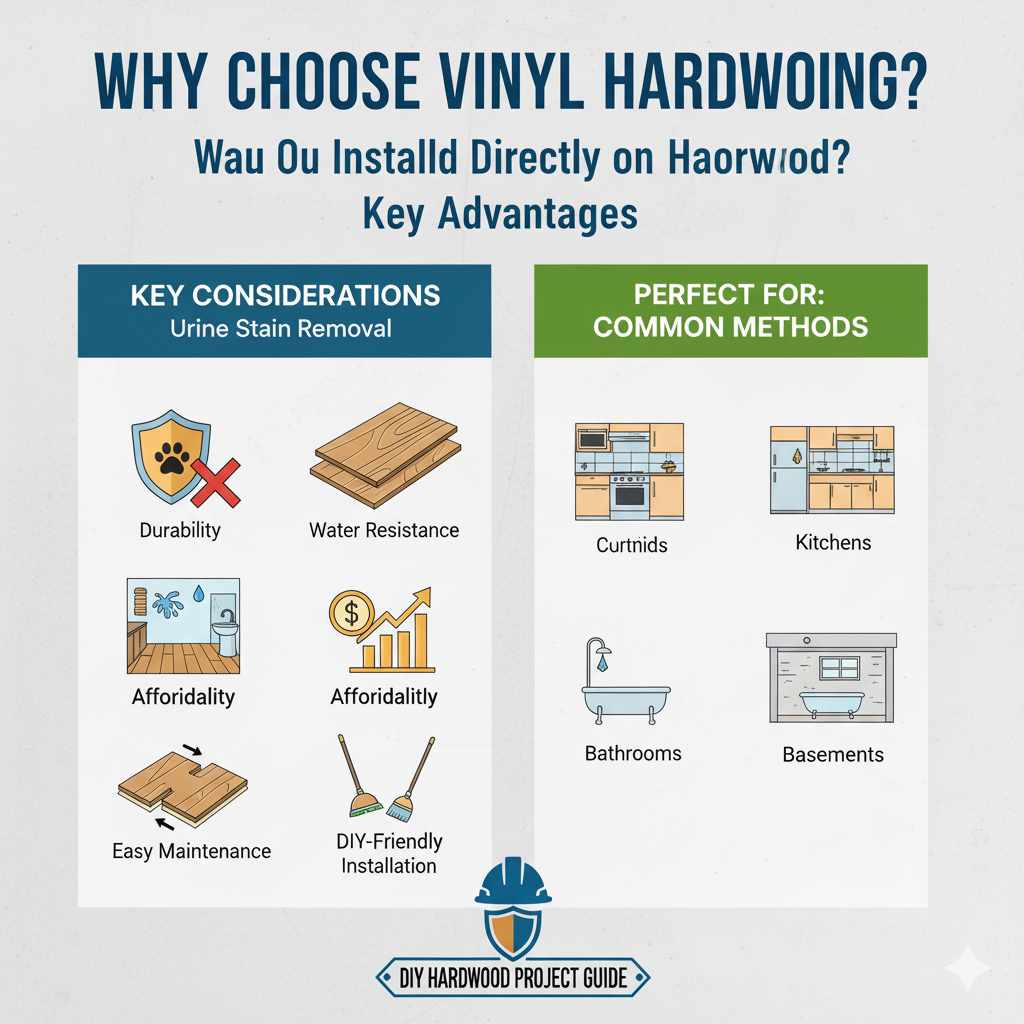

Why Choose Vinyl Hardwood Flooring?

Before we grab our tools, let’s talk about why vinyl hardwood is such a smart choice for your next flooring project. It’s the perfect blend of form and function.

Key Advantages:

- Durability: Vinyl is tough! It resists scratches, dents, and stains, making it ideal for high-traffic areas and homes with kids or pets.

- Water Resistance: Unlike traditional hardwood, vinyl can handle moisture, making it perfect for kitchens, bathrooms, and basements.

- Affordability: You get the look of real hardwood at a fraction of the cost.

- Easy Maintenance: A quick sweep or mop is usually all it takes to keep it looking great.

- DIY-Friendly Installation: Many vinyl flooring options feature click-lock systems that are designed for easy DIY installation.

Gathering Your Essential Tools and Materials

Just like any good woodworking project, preparation is key. Having the right tools and materials ready before you start will make the installation process much smoother and more enjoyable. Don’t worry if you don’t have everything; many of these can be rented or borrowed.

Tools You’ll Need:

- Tape Measure

- Utility Knife with plenty of sharp blades

- Pencil

- Safety Glasses

- Work Gloves

- Knee Pads (your knees will thank you!)

- Chalk Line or Straight Edge

- Tapping Block (often comes with the flooring kit)

- Pull Bar (also often included in flooring kits)

- Handsaw, Jigsaw, or Miter Saw (for cutting planks, especially around obstacles)

- Spacers (for expansion gaps)

- Broom or Vacuum

- Possibly a Rubber Mallet

Materials You’ll Need:

- Vinyl Hardwood Flooring Planks or Tiles

- Underlayment (if recommended by the manufacturer)

- Moisture Barrier (especially for basements or concrete subfloors)

- Quarter Round Molding and Nails (to cover expansion gaps at walls)

- Possibly new baseboards

Step 1: Prepare Your Subfloor Like a Pro

This is arguably the most critical step. A clean, level, and dry subfloor is the foundation for a beautiful and long-lasting vinyl floor. You can install vinyl over existing hard-surface flooring, but a clean, flat subfloor is key. Ensure your subfloor is clean of debris – sweep or vacuum thoroughly. Check for any loose planks or tiles if you’re working over an existing wood subfloor and secure them. For concrete subfloors, check for moisture. A simple plastic sheet test can help: lay a 3’x3’ piece of plastic sheeting on the concrete, taping down the edges. After 24 hours, check for condensation. If it’s present, you’ll need a proper moisture barrier. For any significant dips or bumps, you might need to level the subfloor with a floor leveling compound. A good rule of thumb is that the subfloor should be flat within 3/16″ over a 10-foot span. If you’re installing over concrete in a basement, a vapor barrier is highly recommended. You can learn more about subfloor preparation from resources like BuildingGreen.

Step 2: Acclimate Your Vinyl Flooring

This step is super important and often overlooked! Vinyl flooring, like wood, can expand and contract with temperature and humidity changes. You need to let the planks “get used to” the environment in the room where they’ll be installed. This prevents buckling or gaps later on. Leave the boxes of vinyl flooring flat in the room for at least 48-72 hours before you start. Make sure the room is at its normal living temperature and humidity level during this acclimation period.

Step 3: Plan Your Layout and Start

Visualize your room. Where will you start? Most people choose to start along the longest, straightest wall. You’ll want to lay your first plank with the tongue side facing the wall. However, you’ll typically need to cut off the tongue of the first row of planks that faces the wall so you have a clean edge to start. Always check the manufacturer’s specific instructions, as some may recommend a different starting point or orientation. Use a chalk line to ensure your first row is perfectly straight. Remember to account for the manufacturer’s recommended expansion gap around the perimeter of the room. This gap is usually filled with spacers and then hidden by baseboards or quarter-round molding.

Step 4: Laying the First Row

This is where the magic begins! You’ll lay your first plank (with the tongue side facing the wall, remember to cut off the tongue if needed) and then attach the next plank. Most vinyl hardwood flooring uses a click-lock system. You’ll angle the tongue of the new plank into the groove of the previous one and then gently lower it to create a secure connection. You might hear a slight click as they lock together. Use your tapping block and rubber mallet (gently!) if needed to ensure a tight seam, but don’t hit too hard, or you could damage the locking mechanism. Use spacers between the planks and the walls to maintain that crucial expansion gap. This gap allows the flooring to expand and contract naturally.

Step 5: Cutting Planks for a Perfect Fit

No room is a perfect rectangle, so you’ll inevitably need to cut planks. Measure the space where the last plank of a row needs to fit. Mark your cut line on the vinyl plank, ensuring you account for the expansion gap. For straight cuts, a utility knife and a straight edge are often sufficient. Score the top side of the plank deeply, then flip it over and score the back. You can then usually snap the plank cleanly over a table edge. For more intricate cuts, like around doorframes or pipes, a jigsaw is your best friend. Always measure twice and cut once! If you’re cutting the last plank in a row, make sure the cut piece is long enough to engage the next plank. A good tip is to start your next row with the offcut from the previous row, as long as it’s at least 6-8 inches long. This creates a staggered, natural look.

Step 6: Working Around Obstacles

Doorways, cabinets, and pipes can seem tricky, but they’re manageable with the right approach. For doorways, you’ll often need to cut the vinyl plank to fit. Sometimes, you can undercut the existing door jamb with a handsaw (place a piece of your vinyl flooring under the jamb to get the correct height for your cut) and then slide the new plank underneath for a seamless look. For pipes, you’ll need to drill holes in the plank slightly larger than the pipe diameter to allow for expansion. Then, you can cut out a small section of the plank so it can fit around the pipe, and fill the gap with caulk or a small piece of matching vinyl.

Step 7: Laying Subsequent Rows

Continue laying planks row by row, just as you did with the first. For a natural look, stagger the end joints of your planks. This means the seams where one plank ends and another begins in adjacent rows should not line up. Aim for at least a 6-inch stagger. You can achieve this by starting your second row with a cut piece of the plank you used at the end of the first row. Then, continue with full planks until you get to the end of the room. You’ll likely need to cut the last plank in the row to fit, again remembering to account for the expansion gap. These offcut pieces can often be used to start the next row, as mentioned before, as long as they are long enough.

Step 8: The Final Row and Finishing Touches

The last row can be the trickiest because you’ll need to measure and cut each plank to fit the remaining space. Remember the expansion gap! You’ll likely need to cut the length and possibly the width. Use your pull bar to gently lock the final planks into place. Once the flooring is installed, remove all your spacers. Now it’s time to hide those expansion gaps. Install quarter-round molding around the perimeter of the room, nailing it to the baseboards (not the floor itself!). This molding covers the gap and gives a clean, finished look. If your baseboards were removed, you can reattach them over the molding. If you’re using new baseboards, install them now.

Proper Disposal of Waste

As you worked, you’ll have generated some waste, especially byproducts from cutting. It’s important to dispose of this responsibly. Check with your local waste management services for guidelines on disposing of construction materials. Many flooring retailers also offer take-back programs for unused materials. Some vinyl can be recycled, so inquire about local recycling options.

Maintaining Your New Vinyl Hardwood Floor

Congratulations, you’ve installed your new floor! Now, let’s talk about keeping it looking fantastic for years to come. Regular cleaning is key. Sweep or vacuum your floors regularly to remove dirt and grit that can scratch the surface. For spills and deeper cleaning, use a damp mop and a pH-neutral cleaner specifically designed for vinyl flooring. Avoid using harsh chemicals, abrasive cleaners, or excessive amounts of water, as these can damage the finish or seep into the seams. You can find excellent tips on vinyl floor care from EPA.gov’s page on home maintenance which often touches on flooring care best practices.

Table: Vinyl Hardwood Flooring Installation Checklist

Here’s a quick checklist to keep you on track:

| Task | Completed (✓) | Notes |

|---|---|---|

| Subfloor Prepared & Cleaned | Level, dry, and free from debris. | |

| Flooring Acclimated | At least 48-72 hours in the room. | |

| Expansion Gaps Accounted For | Use spacers around the perimeter. | |

| First Row Straight & Secure | Tongue likely needs to be trimmed. | |

| Planks Staggered Correctly | Minimum 6-inch stagger recommended. | |

| All Cuts Measured Accurately | Measure twice, cut once! | |

| Obstacles Handled Properly | Door jambs, pipes, etc. | |

| Final Row Installed Securely | Use pull bar if needed. | |

| Quarter Round/Molding Installed | Covers expansion gaps. | |

| Area Cleaned Up | Dispose of waste properly. |

Frequently Asked Questions (FAQ)

Q1: Can I install vinyl hardwood flooring myself, or do I need a professional?

A1: Absolutely! Vinyl hardwood flooring, especially the click-lock varieties, is designed for DIY installation. With clear instructions like these and the right tools, beginners can achieve fantastic results. It’s a very forgiving material to work with.

Q2: What’s the difference between LVP and LVT?

A2: LVP stands for Luxury Vinyl Plank, which mimics the look of wood planks. LVT stands for Luxury Vinyl Tile, which can mimic stone, ceramic tile, or wood. For this guide, we’re focusing on the plank style that looks like hardwood, but the installation process is very similar for both.

Q3: Do I need underlayment for vinyl hardwood flooring?

A3: It depends on the product and your subfloor. Many vinyl planks have a built-in underlayment. However, your manufacturer might recommend a specific underlayment for added comfort, sound dampening, or moisture protection, especially over concrete. Always check the product’s installation guide!

Q4: How do I deal with a really uneven subfloor?

A4: For minor unevenness (less than 3/16″ over 10 feet), you might use a self-leveling compound. For significant issues, you may need to repair or replace sections of the subfloor. A truly level subfloor is crucial for LVP/LVT installation to ensure the locking mechanisms work properly and prevent potential damage.

Q5: What’s the minimum expansion gap I need?

A5: The recommended expansion gap varies by manufacturer and the size of the room. For most residential installations, it’s typically between 1/4″ and 1/2″. Always refer to the flooring manufacturer’s specific instructions for their recommended gap size.

Q6: Can I install vinyl hardwood flooring over existing tile?

A6: Generally, yes, if the existing tile is well-adhered, smooth, and level. You’ll want to ensure the grout lines are filled so they don’t telegraph through the new flooring. If the tile is loose or uneven, it’s best to remove it and address the subfloor.

Conclusion: You’ve Got This!

Installing vinyl hardwood flooring is a project that’s well within your reach. You’ve learned how to prepare your subfloor, acclimate your materials, lay the planks with precision, handle those tricky cuts, and finish with professional-looking touches. Remember, patience and careful measurement are your best tools. Don’t rush the process, and don’t be afraid to consult those manufacturer instructions – they are your best friend for your specific flooring product. The satisfaction of stepping onto a beautiful, newly installed floor that you did yourself is incredibly rewarding. You’ve built confidence and skills today, and that’s what DIY is all about. Enjoy your stunning new space!