How to Make Wooden Saw Horses: Proven Essential Build

Build a sturdy, reliable pair of wooden saw horses with this easy-to-follow guide. This essential DIY project provides a stable workspace for any cutting or building task, proving that durable, professional-quality tools are achievable for any beginner.

Working on projects around the house or in the shop often means you need a stable surface to cut wood. Without a good workbench or stable supports, your cuts can be wobbly, and safety can become a concern. Many DIYers find themselves wishing they had a dedicated, sturdy spot to rest their lumber. This is where saw horses come in. They are one of woodworking’s most versatile and essential tools. Don’t worry if you’ve never built anything like this before. We’ll break down exactly how to make wooden saw horses, step-by-step, so you can create your own reliable support system for years to come. Get ready to build something truly useful!

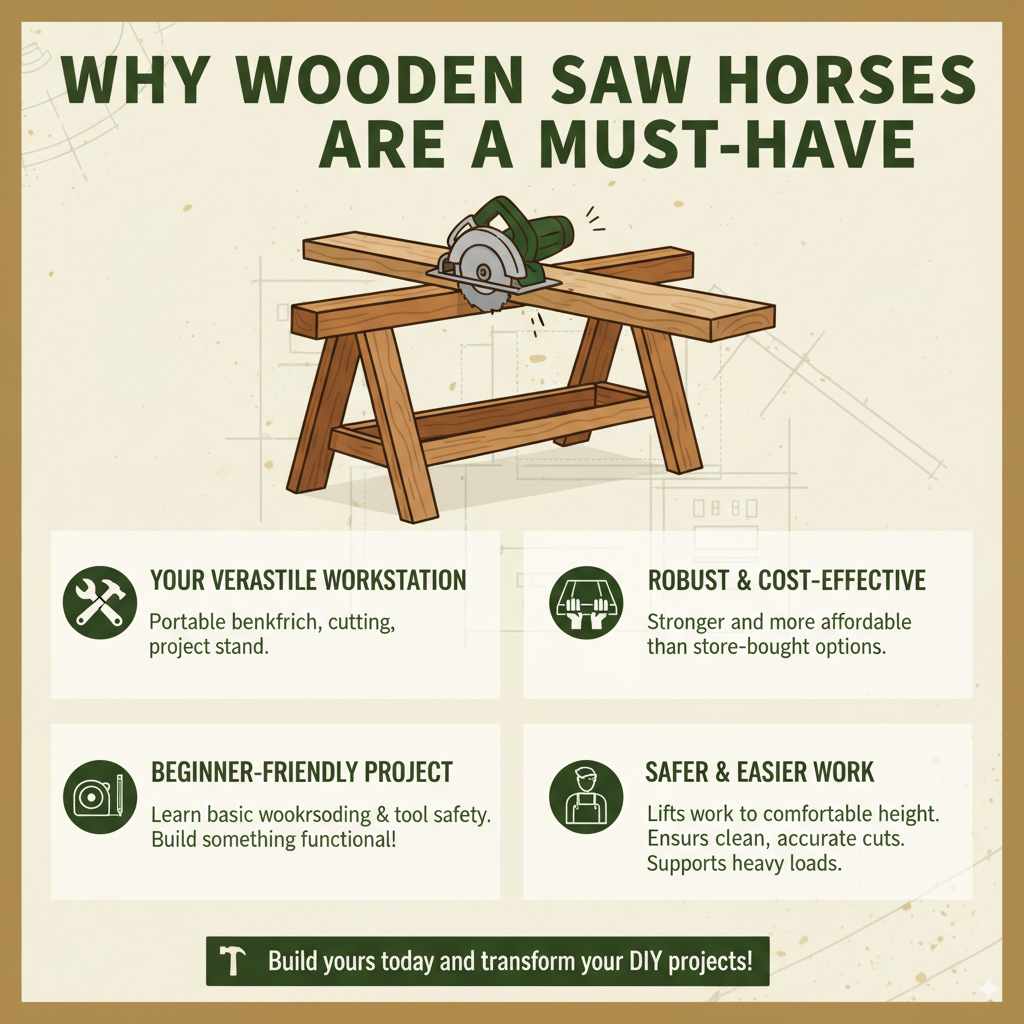

Why Wooden Saw Horses Are a Must-Have

Saw horses are the unsung heroes of the workshop and any DIY project. They’re your portable workbench, your cutting support, and your project stand, all rolled into one. For beginners, building your own wooden saw horses is a fantastic starting point. It introduces you to basic woodworking techniques, tool safety, and the satisfaction of creating something incredibly functional. Plus, homemade saw horses are often much more robust and cost-effective than their store-bought counterparts.

Imagine needing to cut a long piece of plywood or trim some lumber. Where do you put it? On the floor? That’s a recipe for awkward angles and potential injury. Saw horses lift your work to a comfortable height, allowing for clean, accurate cuts. They can support heavy loads, giving you the confidence to tackle bigger projects. Whether you’re building a deck, crafting furniture, or even just assembling some shelves, a good pair of saw horses makes the job easier, safer, and more enjoyable.

Essential Tools and Materials

Gathering your tools and materials beforehand is key to a smooth build. This project is designed to be beginner-friendly, so you likely won’t need a super specialized toolkit. We’ll focus on common items you might already have or can easily acquire.

Tools You’ll Need:

- Measuring Tape: For accurate measurements.

- Pencil: To mark your cuts.

- Safety Glasses: Always protect your eyes when working with wood and power tools. Check out the CDC’s guide on preventing eye injuries for more safety tips.

- Hearing Protection: Especially if using power saws.

- Clamps: Useful for holding pieces together while you fasten them.

- Saw: A handsaw will work, but a circular saw or miter saw will make cuts faster and more precise.

- Drill/Driver: For pre-drilling holes and driving screws.

- Square: To ensure your cuts are at 90-degree angles.

- Optional: Sandpaper: For smoothing rough edges.

Materials You’ll Need:

For a basic, sturdy saw horse, you’ll typically use dimensional lumber. Here’s a common setup:

- Legs & Top Crossmembers: 2×4 lumber (common pine or fir is fine). You’ll need a few 8-foot lengths.

- Leg Braces: A few more 8-foot lengths of 2×4.

- Fasteners: 2.5-inch or 3-inch wood screws (deck screws are a good, weather-resistant choice).

- Optional finishes: Exterior paint or wood sealer if you plan to use them outdoors frequently.

Design Considerations for Your Saw Horses

Before we start cutting, let’s think about what makes a good saw horse. We want stability, durability, and ease of use. For a beginner-friendly build, a common A-frame design is excellent. This design naturally spreads the load and provides excellent stability at various heights.

Height: The ideal height is usually around 30-36 inches. This brings your work surface to a comfortable standing height for most people, similar to a standard kitchen counter. You can adjust this based on your personal preference and the common tasks you perform.

Width & Depth: A top width of around 30-36 inches provides a good surface area to place lumber, while the leg spread (depth) should be wide enough to prevent tipping. About 18-24 inches at the base is generally sufficient.

Angle of Legs: The legs need to be angled outward. A common angle is around 10-15 degrees from vertical. This angle is crucial for stability and is often determined by the way the legs join the top. Don’t worry too much about a perfect angle measurement; we’ll guide you on how to achieve a stable result.

Step-by-Step Guide: How to Make Wooden Saw Horses

Let’s get building! We’ll aim for a classic A-frame saw horse design. This guide will cover building one saw horse; you’ll simply repeat the process for the second one.

Step 1: Cut Your Lumber

Accuracy here makes everything else easier. Measure twice, cut once!

For each saw horse, you will need:

- 2×4 Top Pieces: Two pieces, each 36 inches long.

- 2×4 Leg Pieces: Four pieces, each about 30 inches long (we’ll cut angles later).

- 2×4 Leg Brace: One piece, about 24 inches long (we’ll cut angles later).

Tip: It’s easiest to cut all your pieces for both saw horses at once.

Step 2: Mark and Cut Leg Angles

This is where the A-frame takes shape. You need to cut an angle on the top of each leg so they sit flush against the top brace.

- Take one of your 30-inch leg pieces. Lay it flat.

- Now, imagine your saw horse top. The legs will meet the sides of the top. We need to cut the top of the leg so it will angle inwards towards the center of the saw horse top.

- On one end of the leg piece, measure down about 1.5 inches (the thickness of the 2×4 top piece) from the end. Make a pencil mark.

- With your square or a protractor, draw a line from that mark to the opposite corner of the same end. This creates a 10-15 degree angle.

- Cut along this line. This is your first angled leg.

- Repeat this process for all four leg pieces, ensuring you create two “mirror image” pairs for each side of the saw horse. This means for each set of two legs that will go on one side, one will be angled to the left and the other to the right at the top.

Step 3: Cut the Leg Brace Angles

The leg brace connects the two legs on each side and adds a lot of stability. It also needs angled cuts to sit flush against the legs.

- Take your 24-inch leg brace piece.

- On each end, you need to cut an angle so it sits flat against the inside of the angled legs.

- To do this precisely, clamp two of your angled leg pieces parallel to each other, just as they would sit in the saw horse. Then, place the leg brace between them where you want it (usually about 6-8 inches from the bottom). Mark the angles needed on the brace where it meets each leg, then cut.

- A simpler method for beginners: Set your saw to a 10-15 degree bevel. Cut an angle off each end of the 24-inch piece. You might need to adjust this based on the angle of your legs. The goal is for the brace to sit flush against the inside faces of the legs.

Step 4: Assemble the Legs

Now we bring the A-frame legs together.

- Take two of your angled leg pieces. Lay them down so they form an “A” shape.

- Position the leg brace between them, ensuring the angled ends of the brace meet the inside faces of the legs.

- Pre-drill holes through the legs into the ends of the brace (two holes per joint).

- Drive screws to firmly attach the brace to the legs.

- Repeat this with the other two leg pieces and another leg brace to create the second set of legs for your saw horse.

Step 5: Attach Legs to the Top

This connects your A-frame structure to the main top of the saw horse.

- Take one of your 36-inch 2×4 top pieces.

- Position one assembled leg structure onto one end of the top piece. The angled top of the legs should sit snugly against the underside of the 2×4 top. The legs should spread outward. It’s common to have them flush with the sides of the top piece, or slightly set in.

- Pre-drill holes through the top piece down into the tops of the legs (two screws per leg).

- Drive screws to secure the legs to the top.

- Flip the saw horse over and attach the second leg structure to the other end of the top piece in the same manner.

Step 6: Add the Second Top Piece

This top piece provides a solid surface and adds significant strength.

- Place the second 36-inch 2×4 top piece on top of the first one. It should sit flush.

- Align it carefully.

- Pre-drill holes every 8-12 inches through the top piece and into the piece below.

- Drive screws to securely fasten the two top pieces together. This creates a robust, thick work surface.

There you have it! One complete saw horse. Repeat all these steps to build your second saw horse.

Optimizing Your Saw Horses for Durability

While the basic build is strong, a few extras can make your saw horses last longer and perform better, especially if they’ll be exposed to the elements or heavy use.

Reinforcing Joints

For heavy-duty use, consider adding metal L-brackets or corner braces to the leg-to-top connection points. Also, ensure your screws are driven in straight and tight. For the leg brace to leg connection, if you find it needs extra strength, you can add a screw or two from the outside of the leg into the end of the brace.

Adding a Work Surface or Shelf

Some people like to add a wider piece of plywood or MDF on top for a more continuous work surface. You can also add a lower shelf between the legs for storing tools or materials. Simply cut a piece of plywood to size and attach it with screws.

Finishing and Protection

If your saw horses will live outdoors or get splashed with water or paint, consider applying a finish. Exterior-grade paint or a good quality sealer will protect the wood from moisture and UV damage. This also makes them easier to clean!

Alternative Saw Horse Designs for Different Needs

The A-frame is fantastic, but there are other designs worth knowing about.

Folding Saw Horses

These are brilliant for saving space. They typically use a hinged leg design that allows them to collapse flat for easy storage. They can be a bit more complex to build, often requiring specific hardware for the hinges.

Heavy-Duty Saw Horses

For those who regularly work with very heavy materials like large beams or granite slabs, heavier-duty designs are available. These often use thicker lumber (like 4x4s) and have wider bases for maximum stability.

Saw Horse with Adjustable Height

Some advanced designs incorporate telescoping legs or crank mechanisms to adjust the working height. These are more complex but offer incredible versatility.

Comparison of Common Saw Horse Types

| Design Type | Pros | Cons | Best For |

|---|---|---|---|

| Basic A-Frame (Our Build) | Simple, robust, easy to build, very stable. | Not easily portable/storable if built large. | General workshop use, DIY projects, stable cutting. |

| Folding Saw Horses | Space-saving storage, portable. | More complex build, potentially less robust than fixed. | Small workshops, limited storage, mobile jobs. |

| Heavy-Duty Designs | Extremely strong, very stable under heavy loads. | Heavier, bulkier, more expensive materials. | Professional contractors, furniture making with heavy materials. |

| Adjustable Height Designs | Versatile height options. | Most complex and expensive to build. | Professionals needing variable work surfaces. |

Safety First, Always!

Woodworking is safer and more enjoyable when you prioritize safety. Here are some key points to remember:

- Wear Your Safety Glasses: This is non-negotiable. Flying sawdust or wood chips can cause serious eye injury.

- Use Hearing Protection: Power saws are loud. Protect your hearing for the long term.

- Keep Your Workspace Tidy: Clutter can lead to trips and accidents.

- Understand Your Tools: Read the manuals for your power tools and know how to use them safely. If you’re new to a tool, consider watching instructional videos or getting help from an experienced woodworker. OSHA provides excellent resources on workplace safety, including tool safety.

- Secure Your Work: Always ensure the wood you are cutting is stable and won’t shift. Your new saw horses will help immensely with this!

- Check Your Build: Before putting heavy weight on your new saw horses, give them a good shake. Ensure all screws are tight and the structure feels solid.

FAQ About Building Saw Horses

Q: What kind of wood is best for saw horses?

A: For most DIY projects, standard dimensional lumber like pine or fir 2x4s are excellent. They are affordable, readily available, and strong enough for the job. If you plan to use them outdoors a lot, opt for pressure-treated lumber or consider a good exterior finish.

Q: How tall should my saw horses be?

A: A common and comfortable height for general workshop use is between 30 and 36 inches. This typically aligns with standard workbench heights and reduces strain when working. You can adjust this based on your own height and needs.

Q: Do I need special fasteners?

A: Standard wood screws, particularly deck screws (which are corrosion-resistant), work perfectly. For a robust build, use 2.5-inch or 3-inch screws to ensure a strong connection.