How to Use a Circular Saw As a Table Saw: Ultimate Guide

To use a circular saw as a table saw, you can create a makeshift table saw by clamping a straight edge guide to the material and using the circular saw to make the cuts. This method allows you to achieve straight and accurate cuts similar to a table saw.

Now, let’s delve into the details of how to utilize a circular saw as a table saw. Using a circular saw as a table saw can be a practical solution, especially for individuals who may not have access to a table saw but still need to make precise cuts.

By following certain steps and utilizing additional tools, you can transform your circular saw into a makeshift table saw, allowing you to accurately cut materials with ease. This guide will provide you with the necessary steps and precautions to effectively use a circular saw as a table saw.

Assessing Safety And Requirements

When using a circular saw as a table saw, it’s essential to assess the safety requirements and necessary tools for operation. From wearing proper safety gear to choosing the right circular saw model, each step is crucial to ensure a safe and effective setup. Understanding the essential safety gear, selecting a suitable circular saw model, and preparing the workspace are key components in assessing safety and requirements before utilizing a circular saw as a table saw.

Essential Safety Gear For Operation

Prior to using a circular saw as a table saw, it’s crucial to have the right safety equipment. This typically includes safety goggles, hearing protection, and a dust mask to prevent any potential injuries or exposure to sawdust. Additionally, wearing cut-resistant gloves can provide added safety when handling wood and operating the saw.

Identifying A Suitable Circular Saw Model

Choosing the appropriate circular saw model is imperative when creating a makeshift table saw. Look for a circular saw with a powerful motor, adjustable depth, and a stable base. The saw should also have precise cutting capabilities and a smooth fence adjustment mechanism to ensure accurate and secure cutting.

Preparing Your Workspace

Prior to using your circular saw as a table saw, ensure your workspace is set up correctly. This includes clearing the area of any clutter or debris that could obstruct your movement. Additionally, creating a sturdy and level work surface to support the circular saw is vital for safe and accurate operation.

Materials And Tools Needed

When considering using a circular saw as a table saw, having the right materials and tools is crucial. This modification not only requires proper safety precautions but also the correct equipment to ensure accuracy and efficiency. Let’s explore the materials and tools needed to effectively convert a circular saw into a table saw.

List Of Necessary Materials

Converting a circular saw into a table saw requires a few essential materials to ensure stability and precision. Here’s a list of the necessary materials:

- Sturdy workbench or table

- Measuring tape

- Clamps

- Ruler or straight edge

- Board for the saw platform

- Safety goggles and gloves

- Wood screws and drill

- Level

- Wood glue

Specific Tools For The Conversion

Several specific tools are required to successfully convert a circular saw into a table saw. These tools aid in the precise assembly and ensure a safe and functional setup. Here are the specific tools needed:

- Circular saw

- Adjustable square

- Table saw fence or straight edge guide

- Circular saw stand or support

- Router (if creating a dado blade slot)

- Set square

If specific tools for the conversion are not readily available, there are alternative methods to achieve a similar result. These methods might require creativity and adaptability to ensure the successful transformation of a circular saw into a table saw. Here are some alternative options:

- Improvise using a makeshift table or work surface to support the circular saw

- Utilize a straight piece of lumber as a makeshift fence

- Create a basic platform using scrap wood and clamps

Aligning And Clamping For Stability

When using a circular saw as a table saw, aligning and clamping the saw securely is essential to ensure stability and safety. Properly aligning the saw and securing it in place can prevent accidents and inaccuracies during cutting. Here, we’ll discuss the process for securing the circular saw, ensuring blade alignment, and tips for maintaining firm clamping for stability.

Process For Securing Circular Saw

Securing the circular saw onto the table requires precision to prevent any movement during operation. This process involves firmly attaching the saw to the table using clamps or screws. Here are the steps to secure the circular saw:

- Place the circular saw on the table at the desired location.

- Position the saw base parallel to the edge of the table to ensure even support.

- Use clamps or screws to firmly secure the saw to the table, ensuring a tight fit.

Ensuring Blade Alignment

Proper blade alignment is crucial to achieving accurate cuts and preventing kickback. Here’s how to ensure the blade alignment:

- Check and adjust the saw’s blade depth to align it with the table surface.

- Use a straight edge or rip fence to verify that the blade is parallel to the table’s edge.

- Make necessary adjustments to align the blade accurately before securing it in place.

Tips For Maintaining Firm Clamping

Securing the circular saw with firm clamping is vital for stability and safety. Here are some tips to maintain a firm clamping:

- Use heavy-duty clamps designed for woodworking applications to ensure a secure grip.

- Check the clamps periodically to ensure they remain tight during operation.

- Consider adding additional support, such as wooden blocks, to reinforce the clamping and minimize any potential movement.

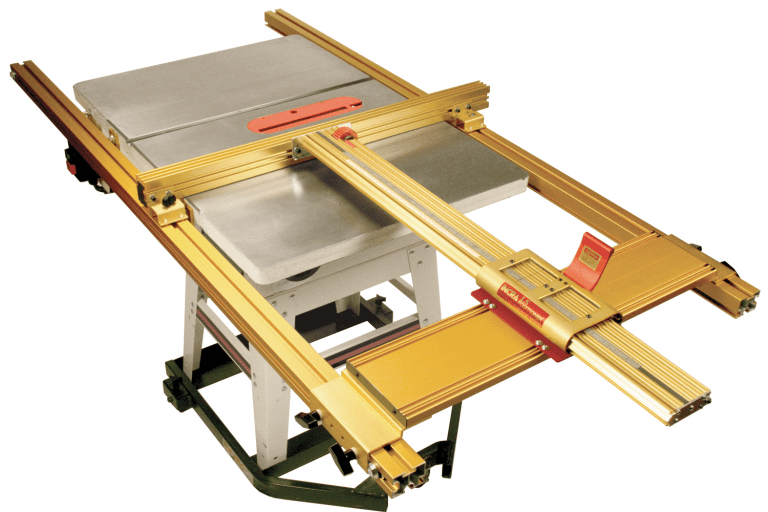

Building A Makeshift Table Saw Surface

When building a makeshift table saw surface for your circular saw, it’s crucial to ensure safety, accuracy, and stability. Creating a stable platform for your circular saw can greatly enhance its functionality, allowing you to use it as a table saw for various woodworking tasks. By following a step-by-step guide, selecting the right materials, and implementing workspace optimization techniques, you can construct a reliable and efficient table saw surface.

Step-by-step Guide For Surface Construction

Building a makeshift table saw surface involves careful planning and precise execution. The following step-by-step guide outlines the process:

- Measure the base of your circular saw to determine the size of the table surface.

- Prepare a sturdy, flat piece of plywood or medium-density fiberboard (MDF) to serve as the table surface.

- Align and secure the circular saw to the underside of the table surface using clamps or screws, ensuring that the blade is positioned accurately.

- Create a slit in the table surface to accommodate the blade, allowing it to protrude through the top surface for cutting.

- Install a rip fence to enhance cutting accuracy and safety when using the makeshift table saw surface.

Materials Best Suited For The Table Saw Surface

Choosing the right materials for the table saw surface is essential for durability and stability. The following materials are well-suited for creating a sturdy and reliable surface:

- Plywood: Provides a strong and rigid base for the table surface, offering stability for accurate cuts.

- MDF (Medium-Density Fiberboard): Known for its smooth and flat surface, MDF is an ideal choice for creating a consistent cutting platform.

- Particleboard: Offers a cost-effective option for building a table saw surface, although it may require additional reinforcement for stability.

Techniques To Optimize The Workspace

Optimizing the workspace ensures efficient and safe operation of the makeshift table saw surface. The following techniques can enhance the functionality of the workspace:

- Clean and Organize: Keep the workspace clutter-free to prevent accidents and maintain a clear working area.

- Use Adequate Lighting: Proper lighting improves visibility and accuracy when using the table saw surface.

- Secure Workpiece: Use clamps or other secure methods to hold the workpiece in place during cutting for added stability.

How To Use A Circular Saw As A Table Saw: Ultimate Guide

When it comes to woodworking, a table saw is a versatile tool that allows for precise and efficient cuts. However, not everyone has the space or budget for a dedicated table saw. Using a circular saw as a table saw can be a cost-effective and space-saving alternative. In this ultimate guide, we’ll explore the steps to effectively use a circular saw as a table saw, covering adjusting the blade depth, achieving accurate cuts, and maintaining consistency with repeated cuts.

Adjusting The Blade Depth

Before using a circular saw as a table saw, it’s essential to adjust the blade depth to ensure it cuts through the material without causing splintering or chipping. To do this, follow these steps:

- Unplug the circular saw and remove the battery if cordless.

- Use the blade depth adjustment lever or knob to set the desired depth for the material being cut.

- Securely tighten the depth adjustment to ensure the blade remains at the set depth during use.

Achieving Accurate And Precise Cuts

Consistency and precision are crucial when using a circular saw as a table saw. To achieve accurate and precise cuts, consider the following tips:

- Use a straight edge or guide to ensure straight cuts.

- Mark the cut line and align the circular saw blade with the mark before making the cut.

- Use clamps to secure the material and prevent movement during cutting.

Maintaining Consistency With Repeated Cuts

When making multiple cuts, maintaining consistency is key to achieving uniform results. To maintain consistency with repeated cuts, consider the following:

- Use a stop block or fence to ensure consistent lengths for repeated cuts.

- Take the time to set up the cutting area to minimize errors and make adjustments as needed.

- Regularly check and maintain the alignment of the circular saw blade for consistent cuts

Fine-tuning And Maintenance

Fine-tuning and maintenance are crucial aspects of using a circular saw as a table saw. Regular checks for accuracy, cleaning, and troubleshooting common issues play a pivotal role in ensuring the efficiency and longevity of your tool. Let’s delve into each of these areas to understand how to keep your circular saw functioning smoothly and effectively.

Regular Checks For Accuracy

Performing regular checks for accuracy is essential to ensure precision in your cuts. Here are the key areas to focus on:

- Alignment of the blade

- Rip fence and miter gauge calibration

- Measurement accuracy

Cleaning And Maintenance Best Practices

Maintaining cleanliness and good condition of your circular saw is vital for its optimal performance. Adopt these best practices:

- Regularly clean sawdust and debris from the saw and its components.

- Apply lubrication to the blade and moving parts to prevent friction and wear.

- Check and replace the blade when it shows signs of dullness or wear.

Troubleshooting Common Issues During Use

It’s important to be prepared to handle common issues that may arise during the use of a circular saw as a table saw. Here are some common problems and their solutions:

| Common Issue | Troubleshooting |

|---|---|

| The saw blade is producing burns on the wood. | Adjust the blade speed and feed rate. Ensure the blade is sharp and not overheating. |

| Irregular cuts or wobbling blade | Check and straighten the blade, arbor, and washers. Tighten the blade securely. |

| Poor dust collection | Check and clean dust collection ports and ensure the vacuum system is functioning correctly. |

Frequently Asked Questions For How To Use A Circular Saw As A Table Saw

How Can I Safely Use A Circular Saw As A Table Saw?

To safely use a circular saw as a table saw, ensure that the circular saw is securely mounted to a stable surface. Use a straight edge guide to make precise cuts and always wear safety goggles and appropriate clothing.

What Type Of Blade Should I Use For A Circular Saw?

For using a circular saw as a table saw, select a fine-toothed blade with the appropriate diameter and arbor size to ensure smooth and accurate cuts. The blade should be suitable for the material being cut, such as wood or plastic.

Can A Circular Saw Be Transformed Into A Table Saw?

Yes, a circular saw can be converted into a table saw by mounting it to a stable surface and using accessories like a straight edge guide and adjustable fence. This allows for precision cutting and versatility in different woodworking tasks.

Conclusion

Using a circular saw as a table saw can greatly expand your woodworking capabilities. With proper setup and caution, this versatile tool can effectively handle a variety of cuts. Remember to prioritize safety measures and refer to the manufacturer’s guidelines.

By following the tips outlined in this guide, you can confidently transform your circular saw into a functional table saw.