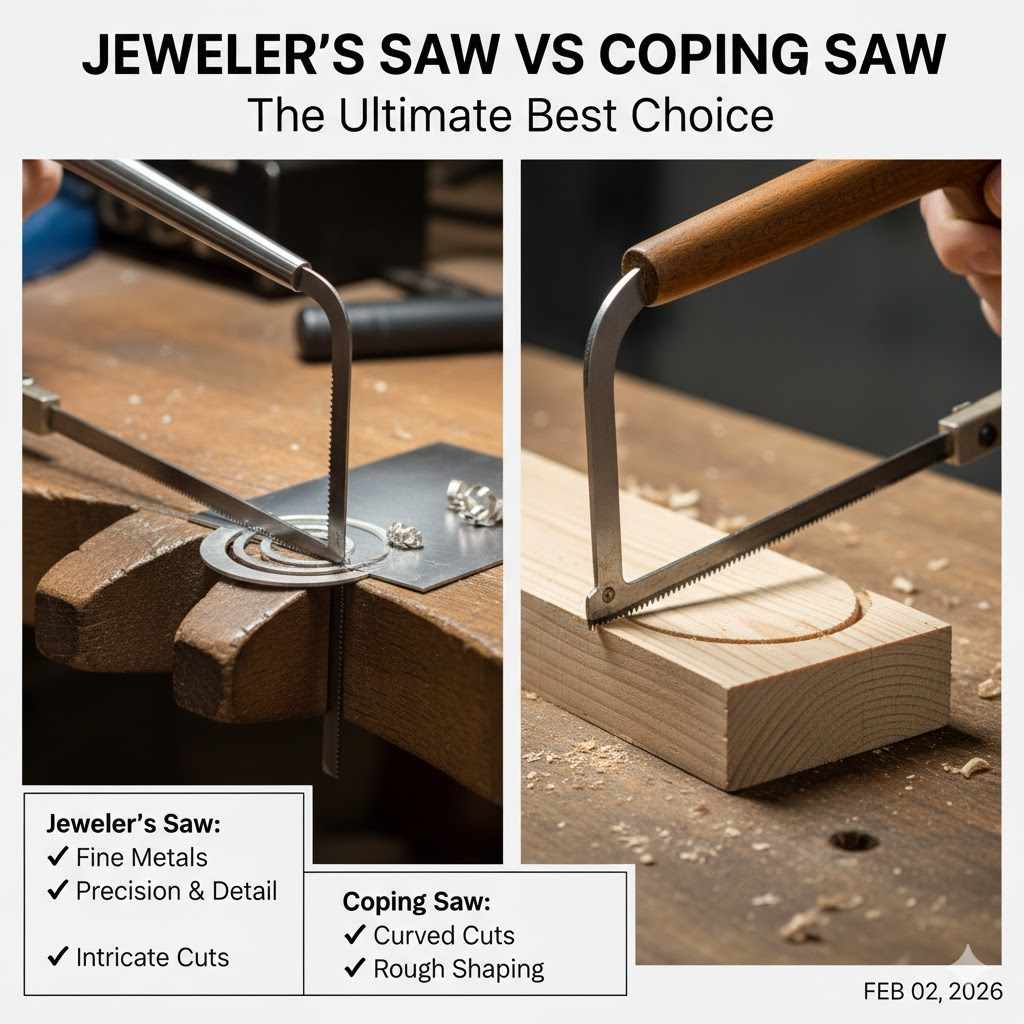

Jeweler’s Saw Vs Coping Saw: The Ultimate Best Choice

A jeweler’s saw is for extremely fine, detailed work on thin wood, metal, or plastic, offering high precision. A coping saw is for cutting curves and shapes in thicker wood, like trim and molding. For general woodworking and DIY projects, a coping saw is the more versatile and durable choice.

Hello fellow makers! It’s Md Meraj, and today we’re tackling a question that often trips up new woodworkers and DIY enthusiasts: what’s the difference between a jeweler’s saw and a coping saw? They look similar, with that classic C-shaped frame, but they are built for very different jobs. Choosing the wrong one can lead to broken blades, messy cuts, and a lot of frustration.

Don’t worry, though. Picking the right tool is much easier than it seems once you understand what each one does best. In this guide, I’ll walk you through everything you need to know. We’ll compare them side-by-side, look at their specific jobs, and help you decide which one deserves a spot in your workshop. Let’s get you cutting with confidence!

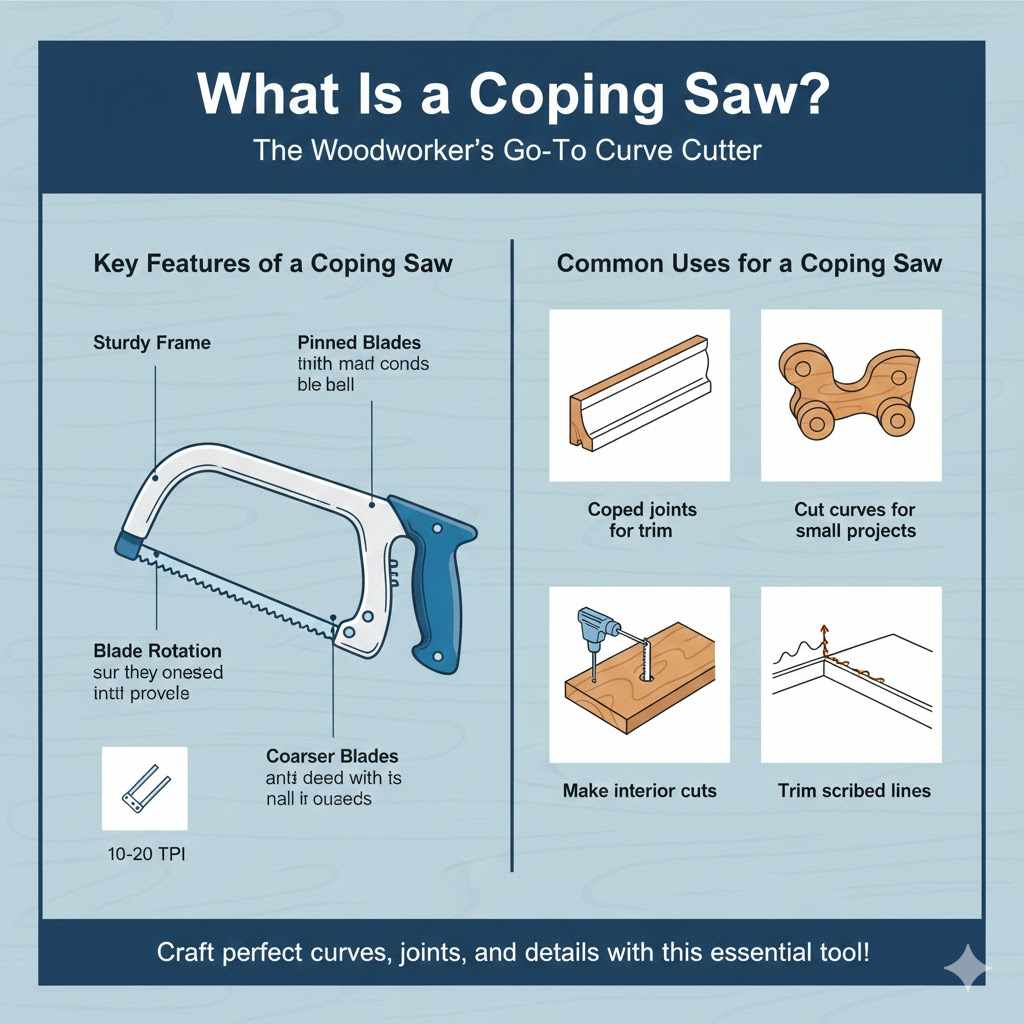

What Is a Coping Saw? The Woodworker’s Go-To Curve Cutter

Think of a coping saw as the workhorse for curved cuts in woodworking. If you’ve ever seen beautifully fitted trim in the corner of a room, a coping saw was probably used to make that joint. Its main job is to remove wood from the back of one piece of molding so it fits perfectly against the profile of another.

It’s a simple, manual handsaw with a C-shaped steel frame, a wooden or plastic handle, and a thin, removable blade. The blade is held in place by two pins and can be rotated, which is incredibly useful for navigating tight curves without having to awkwardly turn the whole frame.

Key Features of a Coping Saw

- Sturdy Frame: The frame is relatively thick and strong, designed to handle the tension needed for cutting wood up to an inch or two thick.

- Pinned Blades: Coping saw blades have small pins on each end that hook into slots on the saw frame. This makes changing blades quick and easy.

- Blade Rotation: The pins that hold the blade can be rotated, allowing you to change the cutting angle without moving the saw frame. This is a huge advantage for complex shapes.

- Coarser Blades: Compared to a jeweler’s saw, coping saw blades are thicker and have fewer teeth per inch (TPI), usually ranging from 10 to 20 TPI. This allows for faster, more aggressive cutting in wood.

Common Uses for a Coping Saw

This tool is a favorite among carpenters, trim installers, and hobbyist woodworkers. You’ll reach for it when you need to:

- Create coped joints for crown molding and baseboards.

- Cut curves for small woodworking projects, like toys or decorative brackets.

- Make interior cuts by drilling a pilot hole, detaching one end of the blade, threading it through, and reattaching it.

- Trim scribed lines on cabinets or countertops for a perfect fit against an uneven wall.

What Is a Jeweler’s Saw? The Master of Fine Detail

Now, let’s look at the jeweler’s saw. As the name suggests, it was originally created for jewelers to cut intricate shapes in precious metals. However, its incredible precision has made it a favorite among other craftspeople, including woodworkers who specialize in ultra-fine details.

A jeweler’s saw looks like a more delicate, stretched-out version of a coping saw. It has a much deeper frame (called the “throat”) and uses incredibly fine, hair-like blades. This deep throat allows you to make cuts far from the edge of your material, which is perfect for detailed fretwork or marquetry.

Key Features of a Jeweler’s Saw

- Deep Throat: The frame can be anywhere from 3 to 8 inches deep (or more!), giving you excellent reach for interior cuts.

- Pinless Blades: Jeweler’s saw blades are flat on the ends and are held in place by small clamps. This design allows for much finer blades than the pinned style of a coping saw.

- Extremely Fine Blades: These blades are hair-thin and come in a vast range of sizes, measured in a gauge system from 8 (coarsest) down to 8/0 (finest). They can have over 100 TPI, perfect for glass-smooth cuts in metal, plastic, or thin wood.

- Adjustable Frame: Many jeweler’s saws have an adjustable frame, allowing you to use blades that may have broken and are now shorter, which helps save money and reduce waste.

Common Uses for a Jeweler’s Saw

You’ll want a jeweler’s saw when precision is more important than speed. It excels at:

- Marquetry and Inlay: Cutting thin wood veneers into complex shapes to create decorative patterns.

- Fretwork: Creating intricate, lace-like patterns in thin wood, like on antique clock faces or decorative boxes.

- Model Making: Cutting tiny, precise parts for models of ships, planes, or buildings.

- Jewelry Making: Piercing and cutting shapes in sheets of silver, brass, or copper.

- Circuit Board Prototyping: Cutting custom shapes in PCB material.

Jeweler’s Saw vs Coping Saw: A Head-to-Head Comparison

Seeing them side-by-side really highlights their differences. Let’s break it down feature by feature so you can see why you can’t just substitute one for the other.

1. Frame and Throat Depth

Coping Saw: Has a shallow throat, usually around 4 to 6 inches deep. The frame is thick and rigid to withstand the pressure of woodworking. This limits how far you can cut from an edge, but it provides strength.

Jeweler’s Saw: Has a significantly deeper throat, often 5 to 8 inches or more. This is its superpower, allowing you to perform intricate cuts in the middle of a large piece of material. The frame is lighter and more springy to maintain tension on very fine blades.

2. Blades and Teeth (TPI)

This is the most critical difference. It’s like comparing a lumberjack’s axe to a surgeon’s scalpel.

Coping Saw Blades:

- Thick, robust, and pinned at the ends.

- Low TPI (Teeth Per Inch), typically 15-20 TPI.

- Designed for removing wood quickly.

- Not suitable for metal or very fine details.

Jeweler’s Saw Blades:

- Extremely thin, delicate, and pinless (clamped).

- Very high TPI, ranging from 20 up to 100+ TPI.

- Categorized by a size number (e.g., #2, #1/0, #8/0), where higher numbers are coarser and “/0” numbers are finer.

- Designed for surgical precision, leaving a smooth edge (kerf) that needs little to no sanding.

3. Intended Materials

Coping Saw: Its home turf is wood. It can handle both softwoods like pine and hardwoods like oak, typically up to an inch or so thick. It can also be used on PVC pipe or other soft plastics, but it’s not designed for metal.

Jeweler’s Saw: This is a multi-material specialist. It was born to cut non-ferrous metals like silver and brass. It also works beautifully on thin hardwoods, plywood, plastic, shell, and acrylic. Using it on thick wood will just break the blade.

For more on working with different materials, this resource from the University of Wisconsin’s wood properties guide can be incredibly helpful for understanding how different species behave.

Summary Comparison Table

Here’s a simple table to put all that information in one easy-to-read spot.

| Feature | Coping Saw | Jeweler’s Saw |

|---|---|---|

| Primary Use | General woodworking, cutting curves in trim | Ultra-fine detail work, inlay, jewelry |

| Blade Type | Thick, with pins on ends | Hair-thin, pinless (clamped) |

| Teeth Per Inch (TPI) | 10 – 20 TPI | 20 – 100+ TPI |

| Frame (Throat Depth) | Shallow (4″ – 6″) | Deep (5″ – 8″+) |

| Materials | Wood, soft plastics, PVC | Thin wood, metal, hard plastics, shell |

| Cut Quality | Good for curves, but may need sanding | Extremely clean and precise |

| Learning Curve | Easy | Moderate (blades are very fragile) |

When Should You Choose a Coping Saw?

A coping saw is the right choice for 90% of home DIY and general woodworking tasks involving curves. If you are a homeowner, hobbyist, or aspiring carpenter, this saw is a must-have.

Choose a Coping Saw for:

- Installing Trim and Molding: This is its #1 job. It’s perfect for making coped joints that look seamless.

- Simple Craft Projects: Making wooden toys, birdhouses, or simple decorative cutouts.

- General Repair Work: Cutting notches in shelving to fit around pipes or scribing a board to fit an uneven surface.

- Learning to Cut Curves: Its forgiving nature and durable blades make it the best tool for practicing curved cuts in wood.

Pros & Cons of a Coping Saw

Pros:

- Durable: The saw and its blades can handle the rigors of a typical workshop.

- Inexpensive: A good quality coping saw and replacement blades are very affordable.

- Easy to Use: Installing and tensioning the pinned blades is straightforward.

- Versatile for Woodworking: Excellent for most common woodworking curve-cutting needs.

Cons:

- Not for Fine Detail: The blades are too coarse for delicate inlay or fretwork.

- Limited by Throat Depth: You can only cut a few inches from the edge of your material.

- Rougher Finish: The cuts will have a slightly rough edge that usually requires a bit of sanding.

When Should You Choose a Jeweler’s Saw?

You’ll reach for a jeweler’s saw when your work moves from carpentry into artistry. If the tiniest detail matters and the material is thin, this is your tool.

Choose a Jeweler’s Saw for:

- Intricate Scrollwork or Fretwork: Cutting delicate, lace-like patterns in thin wood (typically 1/4″ or less).

- Marquetry and Inlay: Cutting pieces of veneer with incredible precision to fit together perfectly.

- Jewelry and Metalwork: Piercing and cutting shapes in sheets of non-ferrous metal.

- Precision Model Building: When parts are tiny and accuracy is paramount.

Pros & Cons of a Jeweler’s Saw

Pros:

- Unmatched Precision: Capable of cutting hair-thin lines and incredibly tight turns.

- Clean Cuts: Leaves a very smooth finish that needs minimal cleanup.

- Deep Reach: The deep throat allows for complex internal cuts far from any edge.

- Works on Many Materials: Your go-to tool for fine work in metal, plastic, and thin wood.

Cons:

- Extremely Fragile Blades: Beginners should expect to break a lot of blades. Buying them by the dozen is a must.

- Slower Cutting: This is a tool for patience, not speed.

- Steeper Learning Curve: Learning to properly install, tension, and use the blades without breaking them takes practice.

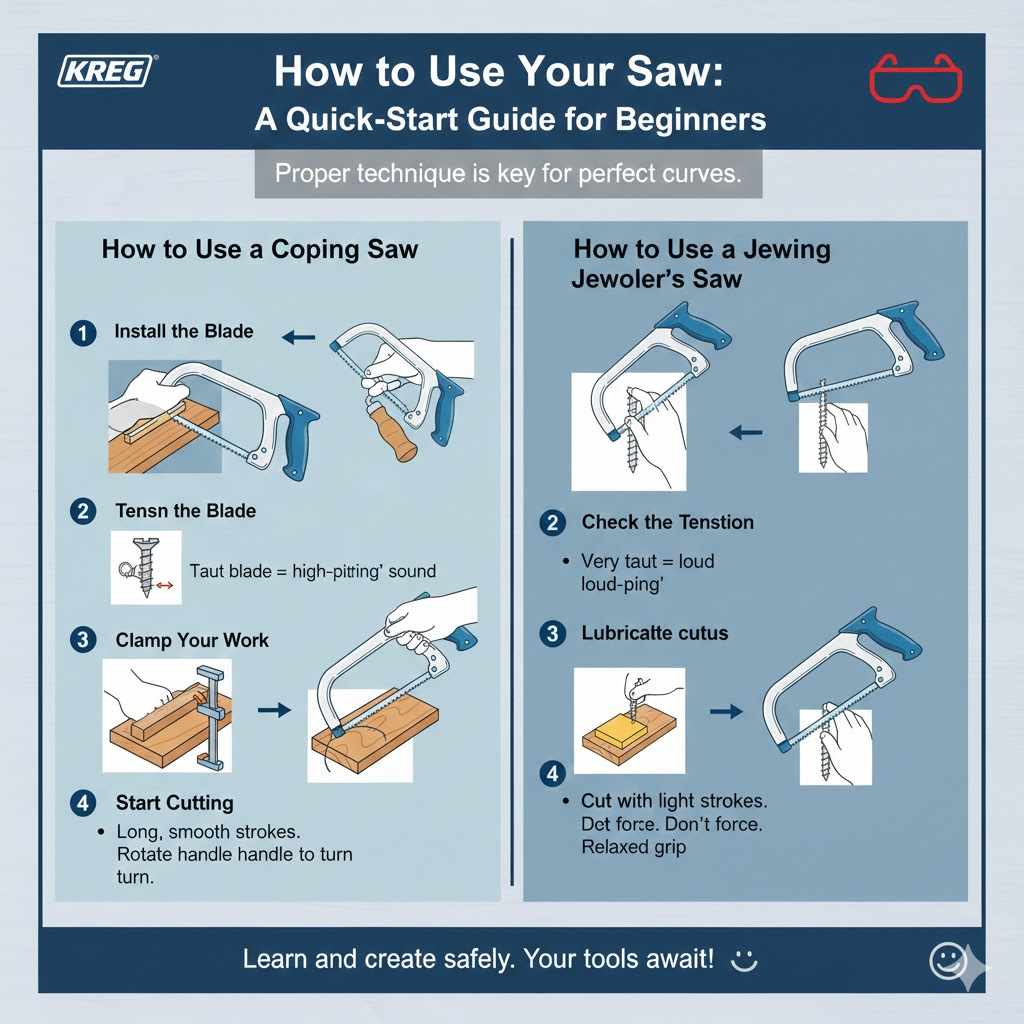

How to Use Your Saw: A Quick-Start Guide for Beginners

Whichever saw you choose, proper technique is key. Here’s a simple rundown for each.

How to Use a Coping Saw

- Install the Blade: Hook one pin into the slot farther from the handle. Squeeze the frame gently against your workbench to shorten the distance, and hook the other pin into the slot near the handle. The teeth should point towards the handle, as a coping saw cuts on the pull stroke.

- Tension the Blade: Tighten the handle by turning it clockwise. The blade should be taut and make a high-pitched “ping” sound when you pluck it. A loose blade will wander and break.

- Clamp Your Work: Always secure your workpiece to a workbench. Never try to hold it with your other hand. A V-board or bench pin can be very helpful for supporting the work.

- Start Cutting: Hold the saw vertically. Use long, smooth strokes, letting the saw do the work. Don’t force it. To turn, keep the saw moving up and down while gently rotating the handle to guide the blade around your marked line.

How to Use a Jeweler’s Saw

- Install the Blade: This is the trickiest part. Clamp one end of the blade into the jaw farthest from the handle, with the teeth pointing out and down towards the handle. Rest the handle on your bench and press down firmly on the top of the frame to flex it. While it’s flexed, clamp the other end of the blade into the jaw near the handle.

- Check the Tension: When you release the pressure, the frame’s springiness will tension the blade. Like the coping saw, it should “ping” when plucked. It must be very taut.

- Lubricate the Blade: For cutting metal, always use a lubricant like beeswax or a commercial product like Bur-Life. This reduces friction and blade breakage.

- Cut with a Gentle Touch: Hold the saw frame perfectly upright. Use short, light, and quick strokes. Think of it more like filing than sawing. Let the weight of the saw do the work. If you force it, the blade will snap instantly. Keep a relaxed grip.

Always prioritize safety. For detailed safety guidelines, especially when starting out, check resources like the OSHA guide on hand and power tools. Eye protection is non-negotiable!

Frequently Asked Questions (FAQ)

1. Can I use a coping saw for metal?

It’s not recommended. Coping saw blades are designed for wood and are too coarse for metal. They will likely catch, skip, and break. For metal, a jeweler’s saw or a hacksaw is the correct tool.

2. Can I use a jeweler’s saw for thick wood?

No. Jeweler’s saw blades are extremely fine and fragile. They are designed for thin materials, typically under 1/4 inch thick. Trying to cut thick wood will cause the blade to wander, bind, and snap immediately.

3. Why do my jeweler’s saw blades keep breaking?

This is the most common issue for beginners! The top reasons are: too much pressure (let the saw do the work), insufficient tension (the blade must be taut), twisting the blade on a turn, or not using lubricant when cutting metal.

4. Which way should the teeth on the blade face?

For both saws, the teeth should point down towards the handle. These saws are designed to cut on the pull stroke. This gives you much better control than cutting on the push stroke.

5. Is a scroll saw just a powered version of these saws?

In a way, yes! A scroll saw is a stationary power tool that uses blades very similar to a jeweler’s saw or coping saw. It automates the up-and-down cutting motion, allowing for faster and more intricate work. If you find yourself doing a lot of detailed fretwork, a scroll saw is the next logical upgrade.

6. I’m making a pine derby car. Which saw should I use?

A coping saw is the perfect tool for cutting the rough shape of a pine derby car. The block of wood is too thick for a jeweler’s saw, and the coping saw has enough strength to handle the curves and shaping you’ll need to do.

7. Can I interchange the blades between the two saws?

No, the blade mounting systems are completely different. Coping saws use pinned blades, while jeweler’s saws use clamped, pinless blades. They are not compatible in any way.

The Final Verdict: Which Saw is Right for You?

So, we’ve come to the end of our comparison. The “ultimate best choice” between a jeweler’s saw and a coping saw isn’t about which one is better overall, but about which one is better for your specific project.

For the vast majority of homeowners, DIYers, and general woodworkers, the coping saw is the clear winner. It’s robust, easy to use, and perfect for the kind of curved cuts you’ll encounter in projects like installing trim, making simple crafts, or doing home repairs. It’s an essential, affordable, and forgiving tool that belongs in every basic woodworking toolkit.

The jeweler’s saw is a specialist tool for the precision artist. If your passion lies in creating intricate inlays, delicate fretwork, detailed models, or jewelry, then a jeweler’s saw is not just a good choice—it’s the only choice. Its ability to produce surgical-grade cuts is unmatched by any other handsaw.

My advice is simple: start with a good coping saw. Learn to master it. If you find your projects getting smaller, more detailed, and demanding a level of finesse that the coping saw can’t provide, that’s your sign to welcome a jeweler’s saw into your workshop. Happy cutting!